Professional Documents

Culture Documents

Gas Fuel Suitability: GFS-89527: Caterpillar Confidential Green

Uploaded by

moh12109Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gas Fuel Suitability: GFS-89527: Caterpillar Confidential Green

Uploaded by

moh12109Copyright:

Available Formats

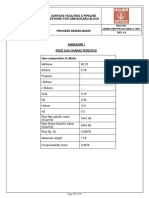

Gas Fuel Suitability: GFS-89527

Composition

Component % Mole % Weight

Hydrogen(H2) 3.21 0.36

Methane(CH4) 85.17 75.91

Ethane(C2H6) 7.38 12.33

Propane(C3H8) 2.16 5.29

I-Butane(C4H10) 0.52 1.68

N-Butane(C4H10) 0.58 1.87

I-Pentane(C5H12) 0.22 0.88

N-Pentane(C5H12) 0.12 0.48

N-Hexane(C6H14) 0.06 0.29

Nitrogen(N2) 0.58 0.90

Calculated Results

LHV BTU/lb (Vap.): 21101 LHV BTU/SCF (Vap.): 1001

Wobbe Index (LHV): 1270 Corrected Wobbe Index (LHV): 1270

Molecular Wt: 17.999 Specific Gravity (Vap.): 0.6214

Min Fuel Supply Temp (NGL) (°F / °C) @Max SEP: 64.6 / 18.11 Min Fuel Supply Temp (H2O) (°F / °C) @Max SEP:

NEC/CSA Gas Group: D IEC Gas Group: IIA

Adiabatic Flame Temperature (°F / °C): 4099.00 / 2259.44 MESG (Maximum Experimental Safe Gap): 1.05256

Total energetics (%): 4.71 Inert Gas (%): 0.58

Gas Constant R (ft-lbf/lbm-R): 85.9

FlameSpeed (cm/sec): 128.0 AutoIgnition (ms): 96.1

ISO Full Load NOx (ppm, estimate) : 173

ISO CO2 Emissions Factor (HHV)(lb/MMBtu / kgCO2/mmBTU): 118.18 / 53.61

Warnings

ES9-98 Compliance

Strict compliance with Solar specification ES 9-98 regarding air, water, fuel filtration and handling is required. Contamination allowed to enter the engine

impacts performance, accelerates degradation, and puts the unit at risk. Reference PIL 162 for fuel handling guidelines.

Fuel Superheat Requirements

The minimum fuel supply temperature (MFST) must be the largest value of the following:

• 50°F above NGL dew point

• 20°F above H2O dew point

• 130°F for Titan 250 SoLoNOx (see ES9-98)

• -20°F for a standard Solar package

• For geographic regions at risk for elemental sulfur, heating to 130°F, or at minimum provisioning for such heating, is strongly recommended.

See ES9-98 and PIL246 for guidance.

If fuel heating is not required based on this GFS run, it is highly recommended to provision space and capacity for future installation of a fuel gas heater

should issues arise.

If the surrounding temperature is less than the minimum supply temperature, the customer must pre-heat the supply line to ensure liquids do not form

in the gas, particularly when the line is not flowing. A liquid trap with a drain is required at the skid inlet. Lines should be pitched away from the skid.

The skid inlet piping must be heated by one or more of the following methods:

• Heat tracing and/or insulating supply lines (CF 42306)

• Recirculating or venting hot gas in the supply line prior to starting (CF 43304)

• Locate flowing hot gas supply line next to Solar skid

Caterpillar Confidential Green

• Heat entire area

Minimum Fuel Superheat Temperature Curves

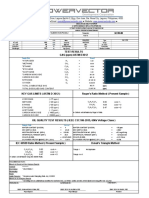

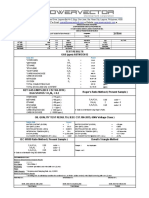

Engine Maximum Skid Edge Pressure (PSIG) NGL H2O

CENTAUR 40 500 64.6 °F

Caterpillar Confidential Green

You might also like

- En List of Cars For CAN-BUS 1406Document10 pagesEn List of Cars For CAN-BUS 1406moh12109No ratings yet

- Flares CalculationsDocument14 pagesFlares CalculationsAnonymous oVRvsdWzfBNo ratings yet

- Ductile Cast IronDocument23 pagesDuctile Cast IronManicharanNo ratings yet

- JOS - Proposal, R3 - DU-12 Flare System With KOD and LS (In Process) PDFDocument12 pagesJOS - Proposal, R3 - DU-12 Flare System With KOD and LS (In Process) PDFJabel Oil Services Technical DPTNo ratings yet

- Solution To Problems On Design of Machine Elements 4th Edition - Virgil M Faires, Roy M Wingren (Problem Book)Document962 pagesSolution To Problems On Design of Machine Elements 4th Edition - Virgil M Faires, Roy M Wingren (Problem Book)Ahmed Zawad Shovon89% (66)

- BS&B Process System Inc Fired Heater Input SheetDocument52 pagesBS&B Process System Inc Fired Heater Input SheetAnonymous bHh1L1No ratings yet

- 3 Heat CalcDocument7 pages3 Heat CalcNITINNo ratings yet

- 19 +ECU+Power+Source+CircuitDocument5 pages19 +ECU+Power+Source+Circuitmoh12109100% (1)

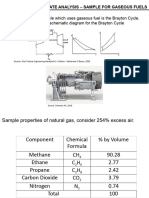

- Natural Gas AnalysisDocument9 pagesNatural Gas AnalysisCharles AshmanNo ratings yet

- Heat CalcDocument7 pagesHeat CalcasdfghjkNo ratings yet

- Compound Forming Extractants, Solvating Solvents and Inert Solvents: Iupac Chemical Data SeriesFrom EverandCompound Forming Extractants, Solvating Solvents and Inert Solvents: Iupac Chemical Data SeriesNo ratings yet

- Heat DutyDocument7 pagesHeat Dutyingegnere1234No ratings yet

- 8g Materials and Their PropertiesDocument30 pages8g Materials and Their PropertiesTheo Thomas100% (1)

- Basra Light - Summary Crude Oil Assay ReportDocument3 pagesBasra Light - Summary Crude Oil Assay ReportAhmed Mohamed KhalilNo ratings yet

- Combustion Engineering: Technical Development Program For Process Performance EngineersDocument36 pagesCombustion Engineering: Technical Development Program For Process Performance Engineersvikubhardwaj9224100% (1)

- Heatcalc: A Natural Gas Heat of Combustion CalculatorDocument7 pagesHeatcalc: A Natural Gas Heat of Combustion CalculatorMuzzamilNo ratings yet

- Department of Chemical Engineering: Analysis & Comparison of Cheaper Binder For Coal FinesDocument26 pagesDepartment of Chemical Engineering: Analysis & Comparison of Cheaper Binder For Coal FinesVijaya GosuNo ratings yet

- North West Shelf Condensate Feb 2012Document3 pagesNorth West Shelf Condensate Feb 2012hbatesNo ratings yet

- Gasoline: US Gallon 115,000 Btu 121 MJ 32 MJ/liter (LHV) - HHV 125,000 Btu/gallon 132 MJ/gallon 35 MJ/literDocument12 pagesGasoline: US Gallon 115,000 Btu 121 MJ 32 MJ/liter (LHV) - HHV 125,000 Btu/gallon 132 MJ/gallon 35 MJ/literHarryBouterNo ratings yet

- Tabel Termo Moran PDFDocument47 pagesTabel Termo Moran PDFlaode syahrinNo ratings yet

- Padmasree - Methane NoDocument1 pagePadmasree - Methane NoShankar RajaNo ratings yet

- Fuel Composition: WKI Calculation Hydrocarbons Non-HydrocarbonsDocument1 pageFuel Composition: WKI Calculation Hydrocarbons Non-HydrocarbonsDiego MillanNo ratings yet

- Procedure For Calculating Fuel Gas Saturated Lower Heating Value (SLHV)Document3 pagesProcedure For Calculating Fuel Gas Saturated Lower Heating Value (SLHV)Muhammad AsadNo ratings yet

- Comb & ThermochemistryDocument5 pagesComb & ThermochemistryVigneshWaranNo ratings yet

- JUM RF Technical DocumentDocument2 pagesJUM RF Technical DocumentMaxime HullmanNo ratings yet

- Flare Gas Monitoring 1575295586Document8 pagesFlare Gas Monitoring 1575295586Musab MohammedNo ratings yet

- Predicted Engine Performance: Customer ModelDocument1 pagePredicted Engine Performance: Customer ModelCong Trinh NGuyenNo ratings yet

- Gas - Density - Gas Molecular Weight - Table PDFDocument2 pagesGas - Density - Gas Molecular Weight - Table PDFD K SNo ratings yet

- Crude Summary Report: Reference: Cupiagua17 Tipo II Crude: Cupiagua Tipo IIDocument2 pagesCrude Summary Report: Reference: Cupiagua17 Tipo II Crude: Cupiagua Tipo IIDiana Alejandra GodoyNo ratings yet

- NGL Fractionation - Full PaperDocument5 pagesNGL Fractionation - Full PaperArash EsmaeiliNo ratings yet

- Combustion CalculationDocument2 pagesCombustion CalculationSteve WanNo ratings yet

- CNG JournalDocument11 pagesCNG JournalVaibhavNo ratings yet

- Lee2014 Ie500110v Si 001Document3 pagesLee2014 Ie500110v Si 001Bidesh M KirtaniaNo ratings yet

- Hda Process: Flash Separator ReactorDocument2 pagesHda Process: Flash Separator ReactorElma RodriguesNo ratings yet

- 32 TR 14Document1 page32 TR 14John Aaron ComiaNo ratings yet

- Surface Facilities & Pipeline Network For CBM Bokaro BlockDocument1 pageSurface Facilities & Pipeline Network For CBM Bokaro BlockEr Mangesh MohiteNo ratings yet

- 32 TR 12Document1 page32 TR 12John Aaron ComiaNo ratings yet

- 32 TR 11Document1 page32 TR 11John Aaron ComiaNo ratings yet

- Fuel System Design Data SheetDocument13 pagesFuel System Design Data Sheetmuhi salehNo ratings yet

- 32 TR 10Document1 page32 TR 10John Aaron ComiaNo ratings yet

- Performance Data-1 PDFDocument4 pagesPerformance Data-1 PDFlubangjarumNo ratings yet

- Gas Formula Molecular weight - ρDocument5 pagesGas Formula Molecular weight - ρChristian RossoNo ratings yet

- Crude Summary Report: Crude: OSEBERG 2016 04 Reference: OSEBERG201604Document3 pagesCrude Summary Report: Crude: OSEBERG 2016 04 Reference: OSEBERG201604Jorge Rodriguez HerreraNo ratings yet

- Adiab FL Temp v2Document8 pagesAdiab FL Temp v2Fares JawadNo ratings yet

- Trace Impurity Analysis of Hydrogen Fuel in Fuel Cell Vehicle-Related Fields. Application Note (Shimadzu)Document2 pagesTrace Impurity Analysis of Hydrogen Fuel in Fuel Cell Vehicle-Related Fields. Application Note (Shimadzu)Maikel Perez NavarroNo ratings yet

- Pengantar Teknik Kimia - Oil Refining 2018Document39 pagesPengantar Teknik Kimia - Oil Refining 2018Annisah MardiyyahNo ratings yet

- 32 TR 13Document1 page32 TR 13John Aaron ComiaNo ratings yet

- 32 TR 09Document1 page32 TR 09John Aaron ComiaNo ratings yet

- ComgasDocument6 pagesComgasPhilip Anthony MasilangNo ratings yet

- Combustion Analysis of Natural GasDocument1 pageCombustion Analysis of Natural GasMuzzamilNo ratings yet

- Steam Tables A1 - A6Document12 pagesSteam Tables A1 - A6Muhammad Hashim KhanNo ratings yet

- Specific Heat Ideal Gases: F (20 C) and 14.7 Psia (1 Atm) )Document4 pagesSpecific Heat Ideal Gases: F (20 C) and 14.7 Psia (1 Atm) )Pete BasNo ratings yet

- Index To Tables in SI UnitsDocument54 pagesIndex To Tables in SI UnitsNac DE CristoNo ratings yet

- Tabel Sifat AirDocument11 pagesTabel Sifat AirChristian WilmarNo ratings yet

- Meridian - Cat Bead - SpecificationDocument3 pagesMeridian - Cat Bead - SpecificationMarthin PurbaNo ratings yet

- Common Fuel PropertiesDocument1 pageCommon Fuel Propertiesanam abbasNo ratings yet

- Cossack - Summary Crude Oil Assay Report: Source of Sample Light Hydrocarbon Analysis Assay Summary / TBP DataDocument55 pagesCossack - Summary Crude Oil Assay Report: Source of Sample Light Hydrocarbon Analysis Assay Summary / TBP DataDaniel LautaroNo ratings yet

- Crudo 1 Abgami NigeriaDocument2 pagesCrudo 1 Abgami NigeriaFlorencia GonzalezNo ratings yet

- 32 TR 01Document1 page32 TR 01John Aaron ComiaNo ratings yet

- V94.2 Beggenum Experience & Improve Concept For Syngas Application PDFDocument24 pagesV94.2 Beggenum Experience & Improve Concept For Syngas Application PDFEliyanto E BudiartoNo ratings yet

- 32 TR 05Document1 page32 TR 05John Aaron ComiaNo ratings yet

- Tablas para Examen-1Document15 pagesTablas para Examen-1Daniel MartinezNo ratings yet

- Atomic or Molecular Weights and Critical Properties of Selected Elements and CompoundsDocument21 pagesAtomic or Molecular Weights and Critical Properties of Selected Elements and CompoundsRicardo Adán Barajas SalazarNo ratings yet

- Properties TableDocument36 pagesProperties TableMPRajNo ratings yet

- Pipeline Case 2 HydraulicDocument23 pagesPipeline Case 2 Hydraulicbimo wahyuNo ratings yet

- Report For Apiay Blend OficialDocument1 pageReport For Apiay Blend OficialweinigunNo ratings yet

- Instruction and Maintenance Manual Electronic Lung Ventilator Model 190Document12 pagesInstruction and Maintenance Manual Electronic Lung Ventilator Model 190moh12109No ratings yet

- UserGuides TNM-U-E-0081 SRP9130 Plus Brief GuideDocument2 pagesUserGuides TNM-U-E-0081 SRP9130 Plus Brief Guidemoh12109No ratings yet

- Service Bulletin: Subject: Installation Procedures For Interconnect ShaftDocument12 pagesService Bulletin: Subject: Installation Procedures For Interconnect Shaftmoh12109No ratings yet

- 1106D-E70TA PerkinsDocument2 pages1106D-E70TA PerkinsRuben Espinoza CruzNo ratings yet

- Land Cruiser Prado 150 Series: Year Model Features Winches Part NoDocument2 pagesLand Cruiser Prado 150 Series: Year Model Features Winches Part Nomoh12109No ratings yet

- VND600SP-E: Double Channel High-Side DriverDocument27 pagesVND600SP-E: Double Channel High-Side Drivermoh12109No ratings yet

- Tech Tips: Troubleshooting J1939 Connector Digital Multimeter Terex Models Using J1939 ConnectorsDocument5 pagesTech Tips: Troubleshooting J1939 Connector Digital Multimeter Terex Models Using J1939 ConnectorsJhair Michele Andree Díaz AranaNo ratings yet

- DF Series 150 and 250 Electron Control System Ser. Man. Pn-Yz103052 PDFDocument29 pagesDF Series 150 and 250 Electron Control System Ser. Man. Pn-Yz103052 PDFjosehemeNo ratings yet

- 107 Inste PDFDocument2 pages107 Inste PDFfernandoNo ratings yet

- Smart Obdii Interface AdapterDocument6 pagesSmart Obdii Interface AdapteriglaiNo ratings yet

- 4JX1 Section 6C Fuel System Workshop Manual PDFDocument22 pages4JX1 Section 6C Fuel System Workshop Manual PDFUriel Gustavo OrcelletNo ratings yet

- SP3222E SP3232E SipexDocument20 pagesSP3222E SP3232E SipexZaegor100% (1)

- General Purpose Transistor: Semiconductor 2N2907ASDocument5 pagesGeneral Purpose Transistor: Semiconductor 2N2907ASmoh12109No ratings yet

- Baby PDFDocument2 pagesBaby PDFmoh12109No ratings yet

- Smart Obdii Interface AdapterDocument6 pagesSmart Obdii Interface AdapteriglaiNo ratings yet

- General Purpose Transistor: Semiconductor 2N2907ASDocument5 pagesGeneral Purpose Transistor: Semiconductor 2N2907ASmoh12109No ratings yet

- Service Bulletin: Continental Aircraft EngineDocument3 pagesService Bulletin: Continental Aircraft Enginemoh12109No ratings yet

- WCLIB Standard17 Grading RulesDocument17 pagesWCLIB Standard17 Grading Rulesblake441No ratings yet

- SFRC - Stålfiberbeton I Danske Bygværker - Peter MjoernellDocument21 pagesSFRC - Stålfiberbeton I Danske Bygværker - Peter MjoernellCleiton GomesNo ratings yet

- Ipc2022-87288 - Don't Crack Up - Composite Repair of SSWCDocument5 pagesIpc2022-87288 - Don't Crack Up - Composite Repair of SSWCOswaldo MontenegroNo ratings yet

- NPTEL - Electrical Properties in NanomaterialsDocument26 pagesNPTEL - Electrical Properties in NanomaterialsShubham VermaNo ratings yet

- 0575 Verbs Answer Key 597469020157837078Document12 pages0575 Verbs Answer Key 597469020157837078reenaNo ratings yet

- Piping Spec C ClassDocument1 pagePiping Spec C Classnestor ferrel floresNo ratings yet

- Activation: FIG. 5.5. Flowsheet For The Manufacture of Fuller's EarthDocument3 pagesActivation: FIG. 5.5. Flowsheet For The Manufacture of Fuller's EarthBrianNo ratings yet

- 1,1,1,2 - Tetrafluoroethane. (R134a) : Material Safety Data Sheet (MSDS)Document3 pages1,1,1,2 - Tetrafluoroethane. (R134a) : Material Safety Data Sheet (MSDS)Syed FirozNo ratings yet

- Techniques To Separate and Identify Contaminants in Recycled PlasticsDocument6 pagesTechniques To Separate and Identify Contaminants in Recycled Plasticssameh100% (1)

- Evaluation of The Role of Sulfidation in Deposition of Gold, Screamer Section of The Betze-Post Carlin-Type Deposit, NevadaDocument21 pagesEvaluation of The Role of Sulfidation in Deposition of Gold, Screamer Section of The Betze-Post Carlin-Type Deposit, NevadaHEBERT JHON RAFAEL AGUILARNo ratings yet

- Bentonite, Kaolin, and Selected Clay Minerals: Environmental Health Criteria 231Document196 pagesBentonite, Kaolin, and Selected Clay Minerals: Environmental Health Criteria 231Atif AhmedNo ratings yet

- TuflineLinedBallValve 332148 2-07Document12 pagesTuflineLinedBallValve 332148 2-07Marcio NegraoNo ratings yet

- Jianbang Coating Company ProfileDocument8 pagesJianbang Coating Company ProfileJaya IrawanNo ratings yet

- Solution 1:: Acids, Bases and SaltsDocument9 pagesSolution 1:: Acids, Bases and SaltsgraceNo ratings yet

- Characterization of MaterialsDocument1 pageCharacterization of MaterialsSalem GarrabNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2014/0100293 A1Document17 pagesPatent Application Publication (10) Pub. No.: US 2014/0100293 A1JutonoNo ratings yet

- Vitalograph Alpha Service ManualDocument23 pagesVitalograph Alpha Service ManualaliNo ratings yet

- Complexation and Protein Binding-Unit IvDocument31 pagesComplexation and Protein Binding-Unit IvSiddhant BanwatNo ratings yet

- Safety Data Sheet: Nitrogen, Compressed GasDocument6 pagesSafety Data Sheet: Nitrogen, Compressed Gasabe_seinNo ratings yet

- Effect of Silica Fume Ash On Bond Strength and Compressive Strength of ConcreteDocument9 pagesEffect of Silica Fume Ash On Bond Strength and Compressive Strength of Concretesunleon31No ratings yet

- Intermolecular ForcesDocument23 pagesIntermolecular ForcesRonel LisingNo ratings yet

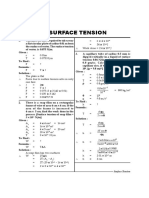

- SurfacetensDocument5 pagesSurfacetensomNo ratings yet

- Laundry Soap PDFDocument4 pagesLaundry Soap PDFAjay Prajapati100% (1)

- 3 Intro CoreDocument13 pages3 Intro CoreMuntazir DarNo ratings yet

- Sae Technical Paper Series: Gerhard FischerDocument10 pagesSae Technical Paper Series: Gerhard FischerHakim Sakib100% (1)

- Skarn Part.1Document69 pagesSkarn Part.1berna quispe cariNo ratings yet