Professional Documents

Culture Documents

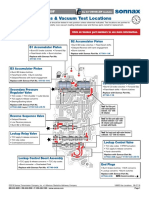

Fact Sheet: Gearbox AT2412F

Uploaded by

Mohammad Saleh AbbasiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fact Sheet: Gearbox AT2412F

Uploaded by

Mohammad Saleh AbbasiCopyright:

Available Formats

Volvo Trucks.

Driving Progress

FACT SHEET

Gearbox AT2412F

I-Shift AT2412F is a 12-speed electronically FEATURES AND BENEFITS

controlled splitter and range-change transmission

designed for automated gearchanging, with the • A fully automated gearchanging system allows high comfort

possibility of manual shifts. It is dimensioned for and fuel-efficient driving.

2400 Nm of torque. • The program package adapts the gearchanges to the prevail-

ing transport conditions.

I-Shift is characterised by a fast gearchanging system featuring • Possibility of manual gearchanging and locking of the current

minimum interruption in torque delivery during gearchanging. gear promotes high driving flexibility.

Because the gearbox has such a large ratio span, it has capacity • Low weight with base unit, range-change housing and clutch

for both high starting traction and high average speeds. I-Shift has housing made of aluminium.

advanced software with well-adapted gearchange strategies. I-Shift • I-Shift is suitable for transport applications in all segments,

AT2412F has improved counter shaft brake performance, which including special applications such as refuse trucks and

means it delivers even faster up shifting than previous models. refrigerator trucks.

I-Shift AT2412F is approved for gross combination weights of

Ratios

up to 44 tonnes. This makes it suitable for long-haul operations,

construction applications and regional and urban transportation

duties.

An oil cooler and power take-off can be fitted to the transmis-

sion. With the selectable oil cooler programme, it is possible to

adjust cooling to suit the current driving mode and road conditions.

I-Shift AT2412F has long intervals between oil changes, which

promotes low operating costs and less environmental impact. With

special oil, filter and oil changes take place after a maximum of

450,000 km or every third year.

1 2 3 4 5 6 7 8 9 10 11 12 R1 R2 R3 R4

Forward gears Reverse gears

2016-06-20 ENG Version 01 1 (3)

FACT SHEET

Gearbox AT2412F

Electronic control and ergonomic consideration Three base ratios, splitter, range and reverse gears

All gear change selection takes place with the lever to the right The base unit contains three base ratios, an integrated splitter

behind the steering wheel. By moving the lever towards the driver, it gear and reverse gears. In the range housing, there is a range gear

is possible to select automatic or manual gearchanges. In Manual of planetary type. The splitter and range gears are synchronised,

mode, the driver changes up and down by moving the lever up or while the base unit has no mechanical synchromesh. Speed syn-

down respectively. With the outer rotating ring, it is possible to lock chronisation takes place electronically with the help of the engine

first gear or to reverse. With the inner rotating ring, it is possible and transmission control units, after which the gear is changed.

to choose between neutral and drive.

Strong and dependable components

All the shafts, bearings and gears are sturdily dimensioned for high

operating reliability and long service life. All the gears are made of

special steel that has been case-hardened to provide considerable

strength. Helical gears in both the base unit and range-change

section mean that more gear surface is in mesh at any given time,

promoting quiet operation and high reliability.

A flange-mounted CVU (Clutch Valve Unit) and integrated CCA

(Concentric Clutch Actuator) including position sensor replace

the externally mounted clutch cylinder.

Fast gearchanging system with short torque

interruption

I-Shift is a very flexible gearchanging system. In Auto mode, gears

change automatically even with the cruise control engaged.

In sensitive driving conditions, the driver can switch to the

Manual mode that locks the current gear. In M, the driver changes

gear manually using a button integrated into the gear lever. Since

clutch operation is regulated by the gearchanging system, there The clutch valve unit on the transmission’s right side is integrated into the gearch-

is no clutch pedal. anging system.

Driving program for optimum efficiency SPECIFICATION

In Automatic mode, the driver can choose between the “Perfor-

Type designation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .AT2412F

mance” and “Economy” programmes via a switch on the dash- Max incoming torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2400 Nm

board. Gears are changed via a button on the gear selector. This Max gross combination weight . . . . . . . . . . . . . . . . . . . . . . . . . .44 tonnes

function offers different gearchange strategies depending on the Weight without oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .278 kg

road conditions. Economy mode provides good fuel economy. The Type . . . . . . . . . . . . . . . . . . Automatic splitter/range-change transmission

Number of forward gears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

“Performance” mode provides more aggressive gearchanging, and

Number of reverse gears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

is used when extra engine power is needed. Gear selector positions:

With a program package that is selected to suit the specific R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Reverse

transport application, it is possible to tailor the transmission’s prop- N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Neutral

erties and functions via the software. The programs are designed A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Automatic

D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Drive

to provide the best gearchanging strategy for each situation, with

M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Manual

an added bonus in the form of fast gearchanges. Driving programs:

E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Economy

P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Performance program

B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Braking program (option)

Oil-change volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . approx. 16 l

incl. oil cooler with normal capacity . . . . . . . . . . . . . . . . . . . . .approx. 16 l

incl. oil cooler with high capacity . . . . . . . . . . . . . . . . . . . . . . .approx. 17 l

Shown on the display:

1. Gear shift position. 2. Choosen gear.

2016-06-20 ENG Version 01 2 (3)

FACT SHEET

Gearbox AT2412F

Kick-down function for maximum acceleration

The kick-down function selects a gear for maximum acceleration.

When the kickdown switch on the accelerator pedal is engaged,

the system changes the gearshift strategy to maximise vehicle

acceleration. When suitable (e.g. depending on engine speed),

this leads to a downshift.

Sales variant: TKDM-ECO.

2016-06-20 ENG Version 01 3 (3)

You might also like

- AT2612E Eng 02 1685346Document2 pagesAT2612E Eng 02 1685346frank mutaleNo ratings yet

- SPO2812 Eng 03 306420309Document3 pagesSPO2812 Eng 03 306420309Shane LinNo ratings yet

- AT2512C Eng 01 953804Document2 pagesAT2512C Eng 01 953804Victor Hugo Benitez PaezNo ratings yet

- Volvo Trucks I-Shift AT2412F 12-Speed Automatic TransmissionDocument3 pagesVolvo Trucks I-Shift AT2412F 12-Speed Automatic TransmissionMohammad Saleh AbbasiNo ratings yet

- AT2412 Eng 02 324355777Document3 pagesAT2412 Eng 02 324355777bandanyimba738No ratings yet

- Transmission AT2812 - Swe - 01 - 331482018Document5 pagesTransmission AT2812 - Swe - 01 - 331482018lushnuNo ratings yet

- AT2812 Eng 01 331482018Document5 pagesAT2812 Eng 01 331482018AbelNo ratings yet

- Volvo Trucks' PT2606 6-Speed Automatic Transmission: Smooth Power for Demanding ApplicationsDocument2 pagesVolvo Trucks' PT2606 6-Speed Automatic Transmission: Smooth Power for Demanding ApplicationsShane LinNo ratings yet

- Manual 09G 09M InglesDocument66 pagesManual 09G 09M InglesOmar Xicotencatl100% (7)

- AT2612 Eng 02 324367762Document5 pagesAT2612 Eng 02 324367762Crystian PerezNo ratings yet

- Audi 01J Multitronic CVTDocument99 pagesAudi 01J Multitronic CVTenes_br95% (20)

- ATO2612 Eng 02 324367767Document5 pagesATO2612 Eng 02 324367767Satria TrianaNo ratings yet

- ATO2612F Eng 01 306008981Document4 pagesATO2612F Eng 01 306008981husan shahNo ratings yet

- Gearbox AT2612F - FACT SHEET AT2612FDocument4 pagesGearbox AT2612F - FACT SHEET AT2612FlushnuNo ratings yet

- Pipelayer: Engine Weights Lift CapacityDocument16 pagesPipelayer: Engine Weights Lift CapacityEVCYNo ratings yet

- CAT D6N Track-Type Tractor Aehq6684Document20 pagesCAT D6N Track-Type Tractor Aehq6684dsdbluegrassNo ratings yet

- Caterpillar 990H BrochureDocument20 pagesCaterpillar 990H BrochureEugene MalinowskiNo ratings yet

- Motoniveladora Cat 140M Motor C9 PDFDocument28 pagesMotoniveladora Cat 140M Motor C9 PDFdanilo100% (3)

- Multitronic 01JDocument100 pagesMultitronic 01JAlex DosofteiNo ratings yet

- SPO2812_Eng_04_331467037Document3 pagesSPO2812_Eng_04_331467037محمد رضاییNo ratings yet

- Volkswagen Service Training The 8 Speed Automatic Gearbox 0c8Document5 pagesVolkswagen Service Training The 8 Speed Automatic Gearbox 0c8kenneth100% (39)

- 8-Speed Automatic Gearbox 0C8Document51 pages8-Speed Automatic Gearbox 0C8António Fernandes100% (1)

- Manual Gearbox 0CF: Design and FunctionDocument24 pagesManual Gearbox 0CF: Design and FunctiontestNo ratings yet

- Cce WL B Series 821b 921b Brochure 06-09-2009Document28 pagesCce WL B Series 821b 921b Brochure 06-09-2009Renato Evangelista100% (1)

- Bucket Volume 4.2 M - 9.0 M Bucket Capacity 8,000 KG Operating Weight 24,600 KG Peak Net Power 320 HPDocument10 pagesBucket Volume 4.2 M - 9.0 M Bucket Capacity 8,000 KG Operating Weight 24,600 KG Peak Net Power 320 HPFuad JahićNo ratings yet

- D D D Direct S S S Shift G G G Gearbox 02E: Self-Study Programme 308Document64 pagesD D D Direct S S S Shift G G G Gearbox 02E: Self-Study Programme 308Jonathan Joel100% (1)

- SSP 507 Amarok 8 Speed Automatic Gearbox VW PDFDocument36 pagesSSP 507 Amarok 8 Speed Automatic Gearbox VW PDFFarid Mch0% (1)

- SSP 320 6 Speed Manual Gearbox 0A5Document36 pagesSSP 320 6 Speed Manual Gearbox 0A5Trương HàoNo ratings yet

- DSGDocument66 pagesDSGTM12550% (2)

- Caterpillar Motor GradersDocument32 pagesCaterpillar Motor GradersAshraf m aliNo ratings yet

- Autodidactico 309Document72 pagesAutodidactico 309Sergiu GitzuNo ratings yet

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (8)

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 2.5 out of 5 stars2.5/5 (2)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualNo ratings yet

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- VW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)No ratings yet

- Speed Changers, Drives & Gears World Summary: Market Values & Financials by CountryFrom EverandSpeed Changers, Drives & Gears World Summary: Market Values & Financials by CountryNo ratings yet

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- Variable Speed Pumping: A Guide to Successful ApplicationsFrom EverandVariable Speed Pumping: A Guide to Successful ApplicationsRating: 3 out of 5 stars3/5 (2)

- AC Electric Motors Control: Advanced Design Techniques and ApplicationsFrom EverandAC Electric Motors Control: Advanced Design Techniques and ApplicationsFouad GiriNo ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionFrom EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionRating: 4 out of 5 stars4/5 (1)

- Honda K-Series Engine Swaps: Upgrade to More Horsepower & Advanced TechnologyFrom EverandHonda K-Series Engine Swaps: Upgrade to More Horsepower & Advanced TechnologyRating: 3 out of 5 stars3/5 (4)

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- LS Gen IV Engines 2005 - Present: How to Build Max PerformanceFrom EverandLS Gen IV Engines 2005 - Present: How to Build Max PerformanceRating: 5 out of 5 stars5/5 (2)

- Chevelle Performance Projects: 1964-1972From EverandChevelle Performance Projects: 1964-1972Rating: 4.5 out of 5 stars4.5/5 (2)

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- GS1559 HD-LINX™ II Multi-Rate Deserializer With Loop-Through Cable DriverDocument74 pagesGS1559 HD-LINX™ II Multi-Rate Deserializer With Loop-Through Cable DriverMohammad Saleh AbbasiNo ratings yet

- Diesel Injection Systems BoschDocument25 pagesDiesel Injection Systems BoschMohammad Saleh AbbasiNo ratings yet

- Approved Online Courses for the Second Quarter of 1400Document26 pagesApproved Online Courses for the Second Quarter of 1400Mohammad Saleh AbbasiNo ratings yet

- Patch Cords and Test Leads: Model# Length Model# LengthDocument1 pagePatch Cords and Test Leads: Model# Length Model# LengthMohammad Saleh AbbasiNo ratings yet

- Doreh 3-4Document13 pagesDoreh 3-4Mohammad Saleh AbbasiNo ratings yet

- 74HC9114 74HCT9114: 1 General DescriptionDocument13 pages74HC9114 74HCT9114: 1 General DescriptionMohammad Saleh AbbasiNo ratings yet

- Specifications: PartsDocument1 pageSpecifications: PartsMohammad Saleh AbbasiNo ratings yet

- Vocom Wireless GGDocument9 pagesVocom Wireless GGHamilton MirandaNo ratings yet

- ASAT0014-P014C AS Product DetailsDocument3 pagesASAT0014-P014C AS Product DetailsMohammad Saleh AbbasiNo ratings yet

- South Delegated Report - 15.08.11 - Planning Sub B CtteDocument36 pagesSouth Delegated Report - 15.08.11 - Planning Sub B CtteMohammad Saleh AbbasiNo ratings yet

- ASAT0014-P014C AS Product DetailsDocument3 pagesASAT0014-P014C AS Product DetailsMohammad Saleh AbbasiNo ratings yet

- Irf 7341 PBFDocument7 pagesIrf 7341 PBFMohammad Saleh AbbasiNo ratings yet

- Renault Trucks Impact 4.16 (04.2016) MultilingualDocument1 pageRenault Trucks Impact 4.16 (04.2016) MultilingualMohammad Saleh AbbasiNo ratings yet

- Transport Management MCQ Question BankDocument7 pagesTransport Management MCQ Question BankDEBABRATA BANERJEE71% (17)

- DT Swiss Tire Pressure / Tire Dimension: Tire Width Rim Inner Width Max. Tire PressureDocument1 pageDT Swiss Tire Pressure / Tire Dimension: Tire Width Rim Inner Width Max. Tire PressureDennis SinnedNo ratings yet

- New Almaz Rs KyyXXYGfXZDocument2 pagesNew Almaz Rs KyyXXYGfXZapriewanjudinNo ratings yet

- Pedestrian Stacker PSH 200SdtfvDocument2 pagesPedestrian Stacker PSH 200SdtfvXb ZNo ratings yet

- Module 4 HighwayDocument4 pagesModule 4 HighwayKris To PherNo ratings yet

- BMW I3Document17 pagesBMW I3roberto100% (2)

- Order Part Stok BengkelDocument6 pagesOrder Part Stok BengkelAPP BENGKELNo ratings yet

- U660E VacTestGuideDocument4 pagesU660E VacTestGuidebyungchul kim100% (2)

- 2021 Ford F550 BBAS 29.09.2020Document138 pages2021 Ford F550 BBAS 29.09.2020Borneo BudiNo ratings yet

- Subject: Traffic Management and Accident InvestigationDocument2 pagesSubject: Traffic Management and Accident InvestigationJuross SumayloNo ratings yet

- Embrague CitroenDocument9 pagesEmbrague CitroenJoseNo ratings yet

- TEM March 2012 Voith Emtrac AnkaraDocument20 pagesTEM March 2012 Voith Emtrac Ankaracosty_transNo ratings yet

- Circuit diagram functions guide car repairsDocument281 pagesCircuit diagram functions guide car repairscolina.ivan100% (1)

- Maxon GP 22 BDocument1 pageMaxon GP 22 BElectromateNo ratings yet

- Traditional Markets in Gandhi BazaarDocument8 pagesTraditional Markets in Gandhi BazaarsameerasirajNo ratings yet

- BMC - Escalator, ElevatorDocument23 pagesBMC - Escalator, ElevatorJisniNo ratings yet

- Magnolia Multi-Use Trail, Construction Plans - Phase 1Document43 pagesMagnolia Multi-Use Trail, Construction Plans - Phase 1Amanda Claire CurcioNo ratings yet

- Green Vehicle Guide 2015Document87 pagesGreen Vehicle Guide 2015sandersonravin1No ratings yet

- DTC C1256 ToyotaDocument2 pagesDTC C1256 ToyotaFelipe CINo ratings yet

- Road News 23Document52 pagesRoad News 23damian00005No ratings yet

- 1.1 Function of Different Parts of Diesel EngineDocument1 page1.1 Function of Different Parts of Diesel EngineIvan Timothy Rosales Calica75% (8)

- AKD3286 - MGB Driver's HandbookDocument33 pagesAKD3286 - MGB Driver's HandbookCanCruiserNo ratings yet

- ChassisDocument3 pagesChassisRoberto MarianoNo ratings yet

- BMW G650 XChallengeDocument134 pagesBMW G650 XChallengeDanaeNo ratings yet

- Plate Wear and Starting Gear On GR801 and GR/GRS900 (Series 3 and 4)Document2 pagesPlate Wear and Starting Gear On GR801 and GR/GRS900 (Series 3 and 4)joaojitoNo ratings yet

- f10 Line Departure CodingDocument3 pagesf10 Line Departure Codingivo shterevNo ratings yet

- 3 0 SBH (IPte) Fortuner Price ListDocument1 page3 0 SBH (IPte) Fortuner Price ListlordcasioNo ratings yet

- Caltrans Bridge Rails and BarriersDocument48 pagesCaltrans Bridge Rails and BarriersMarko ŠimićNo ratings yet

- Rail and Urban Transit Infrastructure SolutionsDocument19 pagesRail and Urban Transit Infrastructure SolutionsvijkingNo ratings yet

- Catalog For Small Electric LocomotivesDocument28 pagesCatalog For Small Electric LocomotivesCesar Ruben Zúñiga AguilarNo ratings yet