Professional Documents

Culture Documents

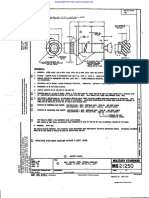

LENGTH .010 D E: Bombardier Standards Manual

Uploaded by

John CollinsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LENGTH .010 D E: Bombardier Standards Manual

Uploaded by

John CollinsCopyright:

Available Formats

Bombardier Standards Manual

CAGE CODE 3AB48

LENGTH ±.010

D

E

S (SEE NOTE 2)

100° C B F G

±1/2°

A DIA. T (SEE NOTE 2)

R .010 MAX.

H

P

Dimensions in inches. Unless otherwise stated, tolerances: Decimals: ± .010

Table 1:

A B DIA. C DIA. P G

E F H T

NOM. DIA. (ACTUAL) (THEOR.) (6) D PROTRUSION GAUGE S

+.003 +.002 RAD.

DIA. +.002 REF DIA. ±.010

-.000 -.000 ±.010

-.001 MAX. MIN. MAX. MIN. MAX. MIN. MAX. MIN. ±.0001

3/32 .094 .136 .128 .1467 .1420 .021 .003 .096 .086 .0150 .0130 .1110 .003 .029 .023

1/8 .125 .184 .176 .1944 .1897 .027 .003 .144 .134 .0153 .0133 .1580 .003 .039 .031

5/32 .156 .236 .228 .2458 .2411 .036 .003 .195 .185 .0209 .0189 .1960 .003 .049 .039

3/16 .187 .291 .283 .3013 .2966 .046 .003 .208 .198 .0240 .0220 .2441 .004 .059 .047

1/4 .250 .384 .376 .3943 .3896 .059 .003 .326 .316 .0265 .0245 .3312 .004 .078 .062

MATERIAL: Aluminium alloys 2117-T4 (AD), 5056-H32 (B), 2024-T4 (DD) and 7050-T73 (KE)

per QQ-A-430.

Titanium columbium alloy 45cb - 55Ti (U) per AMS4982.

FINISH: Aluminium rivet Chemical conversion coating per MIL-C-5541, class IA,

clear (Code S).

Anodize, per MIL-A-8625 type II, class I, clear (code A).

Titanium rivet No finish (No Code).

NOTES:

1. .001 inch shank diameter increase permissible within .100 inch of base of head.

2. All rivets must be procured with a 20° chamfer to the “S” dimension, or a radius to the “T” dimension.

3. A profile view of land area may vary from a line parallel with the shank to a curve that will fall within the limits

allowed.

4. The conical surface of the head shall be concentric with the shank of the rivet within .005 (.010 Total

Indicator Reading)

RIVET, SOLID, 100° CSK REDUCED HEAD, CLOSE

TOLERANCE, ALUMINIUM OR TITANIUM ALLOY B0205014

ISSUE: H DATE: 2008-10-23 PAGE 1 OF 4

BT0550-02 FM REV 2004-09 COMPILED BY ENGINEERING STANDARDS, BOMBARDIER INC. © 2008 BOMBARDIER INC.

Bombardier Standards Manual

CAGE CODE 3AB48

5. Head-cocking angle relative to axis of rivet ½° max.

6. Diameter “C” is to theoretical sharp corners as measured by projection.

7. For part numbers of rivet length not listed show 1/16" increment required.

8. Additional 1/32" increments may be obtained by adding -5 after the last digit in part number.

9. No code for aluminium alloy inactive for new design. Superseded by code “S”.

10. The following head identifications apply:-

.030 MAX .030 MAX .030 MAX .030 MAX .050 MAX

2117 AD 5056 B 2024 DD 7050 KE 45cb U

DIMPLED RAISED CROSS RAISED DOUBLE RAISED CIRCLE INDENTED DIAMOND

(.020 MAX HEIGHT) .010 MAX. DASH .010 MAX. .010 MAX. .010 MAX.

11. Example of part number:

2117-T4 aluminium alloy, 1/8 diameter, 3/4 long, anodized clear.

B0205014AD4-12A

ADDITIONAL LENGTH

Add -5 for additional 1/32 inch increments

FINISH

A anodize, clear per MIL-A-8625, type II, class I,

clear.

S chemical surface treatment per MIL-C-5541,

class IA, clear.

(No code) chemical surface treatment per MIL-C5541

class IA, gold. (see note 9)

(No code) no finish - titanium rivets only

LENGTH

In 1/16 of an inch.

DIAMETER

In 1/32 of an inch.

MATERIAL

AD 2117-T4

B 5056-H32

DD 2024-T4

KE 7050-T73

U Titanium columbium alloy 45cb.

BASIC PART NUMBER

B0205014 ISSUE: H DATE: 2008-10-23 PAGE 2 OF 4

BT0550-02 FM REV 2004-09 COMPILED BY ENGINEERING STANDARDS, BOMBARDIER INC. © 2008 BOMBARDIER INC.

Bombardier Standards Manual

CAGE CODE 3AB48

12. The following lengths and dash numbers apply;

DIAMETERS

LENGTHS

.094 .125 .156 .187 .250

.1875 3-3 4-3

.2500 3-4 4-4 5-4

.3125 3-5 4-5 5-5 6-5

.3750 3-6 4-6 5-6 6-6 8-6

.4375 3-7 4-7 5-7 6-7 8-7

.5000 3-8 4-8 5-8 6-8 8-8

.5625 3-9 4-9 5-9 6-9 8-9

.6250 3-10 4-10 5-10 6-10 8-10

.7500 3-12 4-12 5-12 6-12 8-12

.8750 3-14 4-14 5-14 6-14 8-14

1.0000 3-16 4-16 5-16 6-16 8-16

1.1250 4-18 5-18 6-18 8-18

1.3750 4-22 5-22 6-22 8-22

1.5000 4-24 5-24 6-24 8-24

1.7500 4-28 5-28 6-28 8-28

USAGE INFORMATION

B0205014 is a close tolerance version of NAS1097 rivet.

These rivets are primarily for use in thin sheet applications.

Flush head solid shank rivet for use in structural applications. Countersink provides a smooth surface to reduce

aerodynamic drag on external surfaces. The use of rivets in tension areas is not advisable and should be

avoided where possible.

It is good practice to specify a grip length of no more than 4 x rivet diameter.

The expansion of the shank generally limits the use of this rivet to metallic applications.

“AD” (2117) field rivets are preferred for general usage in aluminium alloy structure. Use “KE” rivets where high

strength is required . Manual installation of “KE” rivets should not be attempted where the rivet diameter

exceeds 5/32".

Use “DD” for high strength when “KE” rivets are not suitable. These rivets require in house heat treatment and

must be driven 10 to 20 minutes after removal from refrigeration.

Use “U” (titanium) rivet in noble metallic structures i.e. cres, titanium etc.

Anodized finish for maximum corrosion protection.

Chemical conversion coating provides better electrical conductivity.

B0205014 ISSUE: H DATE: 2008-10-23 PAGE 3 OF 4

BT0550-02 FM REV 2004-09 COMPILED BY ENGINEERING STANDARDS, BOMBARDIER INC. © 2008 BOMBARDIER INC.

Bombardier Standards Manual

CAGE CODE 3AB48

PROCUREMENT INFORMATION:

Procurement specification MIL-R-5674.

APPROVED MANUFACTURERS:

BOMBARDIER PART ALLFAST AEROSPACE RIVET A.H.G

NUMBER (CAGE CODE 53551) (CAGE CODE 64728) (CAGE CODE F0095)

B0205014( )( )-( )( ) B0205014( )( )-( )( )

B0205014 ISSUE: H DATE: 2008-10-23 PAGE 4 OF 4

BT0550-02 FM REV 2004-09 COMPILED BY ENGINEERING STANDARDS, BOMBARDIER INC. © 2008 BOMBARDIER INC.

You might also like

- On The Determination of Stress Intensity Factors For Some Common Structural ProblemsDocument19 pagesOn The Determination of Stress Intensity Factors For Some Common Structural Problemsalireza100% (1)

- Aerospace Material SpecificationDocument8 pagesAerospace Material SpecificationAlberto De La CruzNo ratings yet

- The Flight Shop Catalog Rev 7Document77 pagesThe Flight Shop Catalog Rev 7Tan Chinwei100% (1)

- Music. Classicism TeoryDocument9 pagesMusic. Classicism Teorymanolowar13No ratings yet

- Metallic Static Strength Training - Ed. FDocument270 pagesMetallic Static Strength Training - Ed. FCamelia MunteanuNo ratings yet

- Buckling of Flat Isotropic Plates Under Uniaxial and Biaxial LoadingDocument21 pagesBuckling of Flat Isotropic Plates Under Uniaxial and Biaxial LoadingfaqirNo ratings yet

- Rib Boom Drilling A380Document28 pagesRib Boom Drilling A380gygjhkjnl100% (1)

- Inspection and Repair of Aircraft Integral Tanks AND Fuel CellsDocument222 pagesInspection and Repair of Aircraft Integral Tanks AND Fuel CellsgnanasekarNo ratings yet

- Fuel System NotesDocument43 pagesFuel System NotesKumaraShanNo ratings yet

- Hybrid Structure Solution For The A400M Wing Attachment FramesDocument38 pagesHybrid Structure Solution For The A400M Wing Attachment FramesszymusgNo ratings yet

- Demage Tolerant Design PDFDocument818 pagesDemage Tolerant Design PDFJoão Júnior LopêsNo ratings yet

- 6535 Inter-Rivet BucklingDocument6 pages6535 Inter-Rivet Bucklingkmr128351No ratings yet

- Section 13 NacelleDocument5 pagesSection 13 NacellealexNo ratings yet

- Aluminum Alloy Development For The Airbus 380Document7 pagesAluminum Alloy Development For The Airbus 380BlueOneGaussNo ratings yet

- Allsafe Aerospace 25-3-14Document68 pagesAllsafe Aerospace 25-3-14Sergey FedorinovNo ratings yet

- STUD ADHESIVE BONDED M10x50mm PDFDocument61 pagesSTUD ADHESIVE BONDED M10x50mm PDFEd2sverissimoNo ratings yet

- Bruhn - and - Supplement PDFDocument1,115 pagesBruhn - and - Supplement PDFMihai PopNo ratings yet

- Parts of The House and FurnitureDocument6 pagesParts of The House and FurnitureLaura Jimena SanabriaNo ratings yet

- Mmpds 2015 2007aeromat Presentation PDFDocument29 pagesMmpds 2015 2007aeromat Presentation PDFl365l365100% (1)

- Aerospace Seat TracksDocument7 pagesAerospace Seat TracksSergey FedorinovNo ratings yet

- TYE Insert Cross Reference ListDocument11 pagesTYE Insert Cross Reference ListJesse KrebsNo ratings yet

- Large Scale Composites TestingDocument38 pagesLarge Scale Composites Testingmavis16No ratings yet

- Failure Analysis of Fibre Reinforced Composite Laminates: 1. Use of The Program 1.1 1.1.1 General NotesDocument47 pagesFailure Analysis of Fibre Reinforced Composite Laminates: 1. Use of The Program 1.1 1.1.1 General Notesjunjie yiNo ratings yet

- LISI AEROSPACE - PULL-STEM™ and PULL-IN™ PinsDocument6 pagesLISI AEROSPACE - PULL-STEM™ and PULL-IN™ PinsLeandro González De CeccoNo ratings yet

- Thesis Ilhan - 10122010 - Final VersionDocument180 pagesThesis Ilhan - 10122010 - Final VersionRamesha Aswathanarayanappa100% (2)

- Aerospace Fastener Applications Part1 R2010Document31 pagesAerospace Fastener Applications Part1 R2010MarkNo ratings yet

- AGARD-AG-37 - Advanced Aero Engine TestingDocument312 pagesAGARD-AG-37 - Advanced Aero Engine TestingQuý VũNo ratings yet

- Sor 25 PDFDocument16 pagesSor 25 PDFIan KellyNo ratings yet

- HJHJHJDocument38 pagesHJHJHJEslam NagyNo ratings yet

- Atr 72Document5 pagesAtr 72birjuNo ratings yet

- EASA Presentation Antennas GeneralDocument11 pagesEASA Presentation Antennas Generalayhun100% (1)

- MMPDS 11 PreviewDocument24 pagesMMPDS 11 Previewmfregeau3654No ratings yet

- Final Fix Retrofit - Splice Angle Installation: Exit MenuDocument23 pagesFinal Fix Retrofit - Splice Angle Installation: Exit MenugygjhkjnlNo ratings yet

- Airbus DTA AntennaDocument37 pagesAirbus DTA AntennaTabatha BarnesNo ratings yet

- Panel Fastener Cross Refer AnceDocument5 pagesPanel Fastener Cross Refer AnceblackhawkNo ratings yet

- Ancra Aircraft-Catalog403Document28 pagesAncra Aircraft-Catalog403Robert FlorezNo ratings yet

- HCSR Chapter 8 - BucklingDocument62 pagesHCSR Chapter 8 - Bucklingjitenisha1010No ratings yet

- Boxes Part V7Document70 pagesBoxes Part V7davidNo ratings yet

- Non Linear Analysis 2019 290719Document32 pagesNon Linear Analysis 2019 290719Stefano MilaniNo ratings yet

- Challenges Metallic FuselageDocument12 pagesChallenges Metallic FuselageAntonio ValenteNo ratings yet

- Nasm21250 (MS21250, Nas624 .. Nas644)Document4 pagesNasm21250 (MS21250, Nas624 .. Nas644)Bogdan RusuNo ratings yet

- Avions Marcel Dassault: Maintenance ManualDocument4 pagesAvions Marcel Dassault: Maintenance ManualSergio VázquezNo ratings yet

- BAMS 551-007 - A Structural Foaming AdhesivesDocument17 pagesBAMS 551-007 - A Structural Foaming AdhesivesJohn Collins100% (1)

- Airbus A320 Structural Repair Manual Perfect PointDocument1 pageAirbus A320 Structural Repair Manual Perfect PointAli KashiNo ratings yet

- TOX Powerpackage-line-Q 10Q 201404 enDocument4 pagesTOX Powerpackage-line-Q 10Q 201404 enPurece EugenNo ratings yet

- FEMDocument49 pagesFEMnag728100% (1)

- Armacoil Catalog HelicoilDocument28 pagesArmacoil Catalog Helicoilmishnator666No ratings yet

- Thesis Ilhan - 10122010 - Final Version PDFDocument180 pagesThesis Ilhan - 10122010 - Final Version PDFSanchir NyamNo ratings yet

- Implementation CATIA V5Document38 pagesImplementation CATIA V5Himawari KanaNo ratings yet

- Gif2008 Workshop Composites HellardDocument26 pagesGif2008 Workshop Composites HellardAlejandroPoloLlanaNo ratings yet

- PTB Magazine BookletDocument24 pagesPTB Magazine BooklettcalithNo ratings yet

- CADCDocument60 pagesCADCCamelia MunteanuNo ratings yet

- Calculation of Wing LoadsDocument55 pagesCalculation of Wing LoadsJony Oliver Lazo RamosNo ratings yet

- Fighter Aircrafts PDFDocument2 pagesFighter Aircrafts PDFJesseNo ratings yet

- G (SEE NOTE 6.3) L: Dscpg&ispecomments@dla - MilDocument4 pagesG (SEE NOTE 6.3) L: Dscpg&ispecomments@dla - MilJesus HedzNo ratings yet

- Spreadsheets To BS 8110: Internal ColumnDocument9 pagesSpreadsheets To BS 8110: Internal ColumnKhac Hoang PhamNo ratings yet

- ORIFICESDocument6 pagesORIFICESbasiri jayadeepNo ratings yet

- NIC Components NFI SeriesDocument5 pagesNIC Components NFI SeriesNICCompNo ratings yet

- Spreadsheets To BS 8110: Internal ColumnDocument10 pagesSpreadsheets To BS 8110: Internal ColumnMohammad Twaha JaumbocusNo ratings yet

- MS20001 - Hinge StandardDocument5 pagesMS20001 - Hinge StandardSooraj V VNo ratings yet

- Foundry CastingDocument4 pagesFoundry Casting奥世迈拓No ratings yet

- Cutting ToolsDocument8 pagesCutting ToolsmoghanmogaNo ratings yet

- Plasma Ion NitridingDocument2 pagesPlasma Ion Nitridingyadu kumar singhNo ratings yet

- The New PEriodic Table SongDocument2 pagesThe New PEriodic Table Songpedro.sposito.uberaba.mgNo ratings yet

- Influence of Austempering and Quenching and Partitioning (Q&P) Heat Treatment On The Mechanical Properties and Wear Behavior of Aisi 9255 SteelDocument142 pagesInfluence of Austempering and Quenching and Partitioning (Q&P) Heat Treatment On The Mechanical Properties and Wear Behavior of Aisi 9255 SteeljhonNo ratings yet

- Lecture 08 Phase Diagram Type III GroupDocument20 pagesLecture 08 Phase Diagram Type III GroupAhmad NawazNo ratings yet

- Tugas 10 - Chapter 15Document6 pagesTugas 10 - Chapter 15hana haddadNo ratings yet

- Workshop TechnologyDocument101 pagesWorkshop TechnologyIbtsaam ElahiNo ratings yet

- Autoliv Material Specification: Flat Hot Rolled Steel For Safety Products - E116088Document4 pagesAutoliv Material Specification: Flat Hot Rolled Steel For Safety Products - E116088krishnamartial8269No ratings yet

- Tankage History Sheet: Project: Petronas Rapid Project - Refinery Tank FarmDocument54 pagesTankage History Sheet: Project: Petronas Rapid Project - Refinery Tank FarmjalNo ratings yet

- Jayaam Galvanizers Private Limited: InspectionDocument2 pagesJayaam Galvanizers Private Limited: InspectionYazhisai SelviNo ratings yet

- SAG Mill Liner DesignDocument37 pagesSAG Mill Liner DesignRodrigo GarcíaNo ratings yet

- Pitting CorrosionDocument2 pagesPitting CorrosionMohamedNo ratings yet

- Jgeosci.255 HenryDocument22 pagesJgeosci.255 HenryJack MilitemusNo ratings yet

- Astm A153Document5 pagesAstm A153rachedNo ratings yet

- NCSD 09catalog 0409Document28 pagesNCSD 09catalog 0409Cindy100% (2)

- Climatronic Self DiagnosticsDocument12 pagesClimatronic Self DiagnosticsAnonymous jcvsaT9No ratings yet

- Is.15961.2012 (AZ150) PDFDocument12 pagesIs.15961.2012 (AZ150) PDFChoudhary Archit SangwanNo ratings yet

- Optimization of Spheroidized Annealing Process Parameters On AISI 10B21 Steel Wire Using Taguchi ApproachDocument4 pagesOptimization of Spheroidized Annealing Process Parameters On AISI 10B21 Steel Wire Using Taguchi ApproachTanzil ZaidiNo ratings yet

- Vidhi Acharya, D.K.Basa, and G.V.S.MurthyDocument8 pagesVidhi Acharya, D.K.Basa, and G.V.S.MurthyVigneswaranNo ratings yet

- Structure Diagram STST WeldmetalDocument1 pageStructure Diagram STST WeldmetalwenigmaNo ratings yet

- Steelplant Refractories Containing Alphabond Hydratable Alumina BindersDocument31 pagesSteelplant Refractories Containing Alphabond Hydratable Alumina BinderssonalisabirNo ratings yet

- Repeated Weld Repair and Its Influence On Welded Carbon SteelDocument9 pagesRepeated Weld Repair and Its Influence On Welded Carbon SteelRabah BrikaNo ratings yet

- Sheet Metal OperationDocument17 pagesSheet Metal Operationsekar_scribd60% (5)

- 05 Askeland ChapDocument10 pages05 Askeland ChapWeihanZhang100% (1)

- Rail Specification S & CorrosionDocument94 pagesRail Specification S & CorrosionGowthami Priya HanumuthuNo ratings yet

- Chapter2 - 2nd LectureDocument22 pagesChapter2 - 2nd LectureKAMALJEET SINGHNo ratings yet

- Casting: Workshop Practice ME-105Document20 pagesCasting: Workshop Practice ME-105Mazahir habib100% (1)

- Oreas 402Document2 pagesOreas 402flysch_ukNo ratings yet

- ESM GR MG GranulesDocument3 pagesESM GR MG GranulesjucyapleNo ratings yet