Professional Documents

Culture Documents

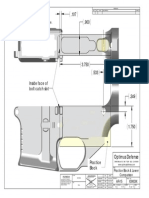

AR-15 Scratch-Built Receiver Blueprint

AR-15 Scratch-Built Receiver Blueprint

Uploaded by

Juan Pablo Leos SantanaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AR-15 Scratch-Built Receiver Blueprint

AR-15 Scratch-Built Receiver Blueprint

Uploaded by

Juan Pablo Leos SantanaCopyright:

Available Formats

Readme for Scratchbuilt AR-15 Receiver Blueprints

by elmgrove1765@yahoo.com

1. Release Dates

June 2002: scratch-built AR15 receiver project completed and test fired

October 2002: Initial release of first 7 of 11 parts blueprints:

bufferstop_rev_A.pdf - buffer retainer rod

fcwell_rev_A.pdf - fire control well bottom

magleft_rev_A.pdf - magazine well left sideplate

magright_rev_A.pdf - magazine well right sideplate

sideleft_rev_A.pdf - receiver fire control well, receiver left sideplate

sideright_rev_A.pdf - receiver fire control well, receiver right sideplate

tguard_rev_A.pdf - trigger guard

December 2002: Released two more parts blueprints:

buffer_rev_A.pdf - buffer tube part

magfront_rev_A.pdf - magazine well front

March 2003: Last two parts blueprints released (all done!):

grip_rev_A.pdf - grip part

magback_rev_A.pdf - magazine well back

Note**: "left" and "right" refer to the user's point of view when the rifle is held in the normal firing position.

2. Links

For more information or photos please see:

Webpage: http://www.geocities.com/elmgrove1765 (See link for "P6: AR15 receiver")

Photo albums: http://community.webshots.com/user/user_556

3. Decimal inch cross reference

The blueprint dimensions are in decimal inches. Listed below are some of the less common fractional inch

equivalents that were used during machining (for drill sizes, end mill diameters, etc.)

0.0890" -> use #43 (drill size)

0.1065" -> use #36 (drill size)

0.1094" -> use 7/64"

0.1360" -> use #29 (drill size)

0.1563" -> use 5/32" (radius of 5/16" diameter)

0.2031" -> use 13/64"

0.2130" -> use #3 (drill size)

4. Notes

1) Every effort has been made to ensure the plans are correct, but in the unlikely event there is an error or if

you have any suggestions, please email the author. Note that the author assumes no liability for any

adverse consequences resulting from the construction or use of this AR15 receiver. Please obey all laws.

2) If you use 1/8" plate stock for the sideplates, note that the actual thickness of the plate may have a

tolerance of +/- .005" or more. The actual thickness is not critical as long as the flats machined at the end of

the fire control well sideplates has a thickness of 0.104" (see Sheet 3 of Receiver - Left Side and

Sheet 5 of Receiver - Right Side)

3) The only holes that should be reamed to the final diameter are the trigger and hammer pin holes - the

other holes can be drilled normally. The "Colt Redraw Blueprints" by D. Snider (the most common one

available on WWW) show the hammer and trigger pin holes as .1560 +/- .0015. The blueprints and the

scratchbuilt were built using hammer/trigger pin holes of .15625" (5/32") which is a standard reamer size.

4) The "Colt Redraw Blueprints" by D. Snider show the magazine release button hole with a width (narrower

dimension) of .318". I measured several magazine release buttons, and the maximum size I found was 0.3"

wide. Since I don't have a .318" endmill, these blueprints reflect that the receiver was built using a magazine

release button width of 5/16" (.3125") - a standard end mill diameter.

5) The fire control well bottom has a thickness of 0.125" (see Fire Control Well) I got a bit lazy and used 1/8"

aluminum plate as is without machining it to the correct thickness. The thickness of the part turned out to be

0.120" - a bit off, but still acceptable since the depth of the fire control well has a tolerance of +/- .010" (as

shown in D. Snider's print)

6) Although I put a copyright on the blueprints, everyone has the right to download or distribute as many

copies as they want. I put the notice on the blueprints just to claim authorship. ;) I am not claiming any rights

to the design, so free to build it (subject to local laws, of course).

7) Have fun and be safe!

You might also like

- Ar15 A3 Style Upper Receiver BlueprintsDocument8 pagesAr15 A3 Style Upper Receiver Blueprintsjbrownrg94% (18)

- PPs Semi-Auto FCGDocument5 pagesPPs Semi-Auto FCGangelines12375% (8)

- Firearms - Blueprint - Sten MK III Sub Machine Gun Receiver BondDocument1 pageFirearms - Blueprint - Sten MK III Sub Machine Gun Receiver Bondanjan971% (14)

- Glock Full Auto PartsDocument5 pagesGlock Full Auto PartsHarley Hunter Sites82% (11)

- Ruger 10-22 Receiver BlueprintDocument2 pagesRuger 10-22 Receiver Blueprintelvergonzalez1100% (1)

- Blueprints To Build A Mark II Sten GunDocument25 pagesBlueprints To Build A Mark II Sten GunKawchhar Ahammed100% (1)

- Full Auto - TabDocument5 pagesFull Auto - Tabbkausshen67% (6)

- Selective Fire Kit For Lightning Link Using ARDocument3 pagesSelective Fire Kit For Lightning Link Using ARSpector_27567% (12)

- 2008-11!23!233015 Receiver Template 7 SimplifiedDocument1 page2008-11!23!233015 Receiver Template 7 Simplifiedpalaciosro100% (3)

- The Gun Digest Book of Firearms Assembly/Disassembly Part V - ShotgunsFrom EverandThe Gun Digest Book of Firearms Assembly/Disassembly Part V - ShotgunsRating: 5 out of 5 stars5/5 (3)

- Bolt Together AR15 Lower ReceiverDocument0 pagesBolt Together AR15 Lower ReceiverLogicIndustriesLLC100% (1)

- Glock Select Fire - SilencerTalk Review - Multiple VarietiesDocument86 pagesGlock Select Fire - SilencerTalk Review - Multiple Varietiesgsdbonjon367% (3)

- Practical Guide to the Operational Use of the PPS-43 Submachine GunFrom EverandPractical Guide to the Operational Use of the PPS-43 Submachine GunNo ratings yet

- Antique Firearms Assembly/Disassembly: The comprehensive guide to pistols, rifles & shotgunsFrom EverandAntique Firearms Assembly/Disassembly: The comprehensive guide to pistols, rifles & shotgunsRating: 4.5 out of 5 stars4.5/5 (2)

- Practical Guide to the Operational Use of the PPSh-41 Submachine GunFrom EverandPractical Guide to the Operational Use of the PPSh-41 Submachine GunRating: 5 out of 5 stars5/5 (2)

- Guide To Investing: Warren BuffettDocument8 pagesGuide To Investing: Warren BuffettAsh Max100% (1)

- User Manual: Full HD Led TVDocument12 pagesUser Manual: Full HD Led TVbytestefNo ratings yet

- AR-15 Practice BlockDocument1 pageAR-15 Practice Blockwiccanways100% (2)

- Colt AR-15 Rifle Lightning LinkDocument5 pagesColt AR-15 Rifle Lightning Linkelvergonzalez1100% (2)

- AR-15 Bolt Schematic Part 2Document1 pageAR-15 Bolt Schematic Part 2S Klars100% (2)

- The SWD Lightning LinkDocument2 pagesThe SWD Lightning LinkRay Bailey100% (3)

- UZI ReceiverDocument7 pagesUZI Receiverbrowar444100% (1)

- Sten mk2 Complete Machine Instructions PDFDocument24 pagesSten mk2 Complete Machine Instructions PDFTristan Jones100% (2)

- Bolt Together AR15 Receiver 042910Document11 pagesBolt Together AR15 Receiver 042910IM_JohnnyV100% (7)

- Lightning Link Plans (For The AR-15 Rifle)Document8 pagesLightning Link Plans (For The AR-15 Rifle)anthony100% (1)

- Grasshopper Ak-47 Jig GuncoDocument5 pagesGrasshopper Ak-47 Jig Guncoterrencebelles100% (2)

- AK Bolt Gap SetupDocument22 pagesAK Bolt Gap SetupAdam Hemsley100% (2)

- Liste Des Plan D'armes TemplateDocument23 pagesListe Des Plan D'armes Templatecorsinu100% (1)

- Gunsmithing the AR-15, Vol. 3: The Bench ManualFrom EverandGunsmithing the AR-15, Vol. 3: The Bench ManualRating: 2.5 out of 5 stars2.5/5 (4)

- Chrysler ATF MS 9602Document1 pageChrysler ATF MS 9602Anonymous oAbjbl4HNo ratings yet

- EcoSafe TF 25 BrochuresDocument4 pagesEcoSafe TF 25 BrochuresAnonymous oAbjbl4HNo ratings yet

- Optimus AR-15 Man MillDocument2 pagesOptimus AR-15 Man Millwiccanways50% (2)

- AR15 ExtractorDocument1 pageAR15 ExtractorfuriousgaulNo ratings yet

- United States "Patents PDFDocument17 pagesUnited States "Patents PDFTien Nguyen VanNo ratings yet

- Mujahadeen AR-15Document13 pagesMujahadeen AR-15Chris Leahy100% (2)

- AK-47 Souptonuts 5Document7 pagesAK-47 Souptonuts 5tshirley47100% (3)

- Revolver PatentDocument5 pagesRevolver PatentdududadamikeNo ratings yet

- Assembling Your Own Stripped AR - 1Document103 pagesAssembling Your Own Stripped AR - 1bigwhiteguy100% (1)

- АК туториалDocument63 pagesАК туториалLucas Gabriel100% (2)

- 级触发自动武器 PDFDocument15 pages级触发自动武器 PDFJin SongNo ratings yet

- Us1517483 PDFDocument10 pagesUs1517483 PDFJin SongNo ratings yet

- Print - How To Build An AK-47Document8 pagesPrint - How To Build An AK-47Lord Ellam100% (5)

- Io Inc January 2016 News Press ReleaseDocument4 pagesIo Inc January 2016 News Press Releaseapi-242710584No ratings yet

- Lightning Link Printable Template V1.0Document5 pagesLightning Link Printable Template V1.0Luis Carlos Martinez100% (1)

- AR-15 Bolt Schematic Part 3Document1 pageAR-15 Bolt Schematic Part 3S Klars100% (1)

- Practical Guide to the Operational Use of the UZI Submachine GunFrom EverandPractical Guide to the Operational Use of the UZI Submachine GunNo ratings yet

- The Gunsmith's Manual: Practical Guide to All Branches of the TradeFrom EverandThe Gunsmith's Manual: Practical Guide to All Branches of the TradeNo ratings yet

- The Gun Digest Book of the AK & SKS: A Complete Guide to Guns, Gear and AmmunitionFrom EverandThe Gun Digest Book of the AK & SKS: A Complete Guide to Guns, Gear and AmmunitionNo ratings yet

- Cartridges of the AR-15: A Complete Reference Guide to AR -15 and AR-10 AmmoFrom EverandCartridges of the AR-15: A Complete Reference Guide to AR -15 and AR-10 AmmoNo ratings yet

- Shell Gadus S1 A150 2 From Multiroad CT2Document1 pageShell Gadus S1 A150 2 From Multiroad CT2Anonymous oAbjbl4HNo ratings yet

- Operation Maintenance M1 CarbineDocument2 pagesOperation Maintenance M1 CarbineAnonymous oAbjbl4HNo ratings yet

- Shell Gadus S2 A320 From Rhodina EPLFDocument2 pagesShell Gadus S2 A320 From Rhodina EPLFAnonymous oAbjbl4HNo ratings yet

- Shell Diala S3 ZX-IG DriedDocument2 pagesShell Diala S3 ZX-IG DriedAnonymous oAbjbl4HNo ratings yet

- Shell Gadus S2 OG 85Document2 pagesShell Gadus S2 OG 85Anonymous oAbjbl4HNo ratings yet

- Shell Gadinia AL 40Document2 pagesShell Gadinia AL 40Anonymous oAbjbl4HNo ratings yet

- Shell Gadus S2 High Speed Coupling GreaseDocument3 pagesShell Gadus S2 High Speed Coupling GreaseAnonymous oAbjbl4HNo ratings yet

- Anderol 1255 PDFDocument1 pageAnderol 1255 PDFAnonymous oAbjbl4HNo ratings yet

- Shell Caprinus XS9 40 (En) TDSDocument2 pagesShell Caprinus XS9 40 (En) TDSAnonymous oAbjbl4HNo ratings yet

- Shell Diala S2 ZU-I Dried PDFDocument2 pagesShell Diala S2 ZU-I Dried PDFAnonymous oAbjbl4H100% (1)

- Shell Corena S4 R - TDSDocument3 pagesShell Corena S4 R - TDSAnonymous oAbjbl4HNo ratings yet

- Shell Gadus S1 A150 2 From Multiroad CT2Document1 pageShell Gadus S1 A150 2 From Multiroad CT2Anonymous oAbjbl4HNo ratings yet

- Shell Caprinus Xs9 Oil: High Performance, Zinc-Free Railroad Engine OilsDocument2 pagesShell Caprinus Xs9 Oil: High Performance, Zinc-Free Railroad Engine OilsAnonymous oAbjbl4HNo ratings yet

- Shell Corena S4 P 100 (En) TDS v1Document3 pagesShell Corena S4 P 100 (En) TDS v1Anonymous oAbjbl4HNo ratings yet

- Shell Corena S4 P - TDSDocument3 pagesShell Corena S4 P - TDSAnonymous oAbjbl4HNo ratings yet

- Shell Advance 4T Ultra 10W-40Document2 pagesShell Advance 4T Ultra 10W-40Anonymous oAbjbl4HNo ratings yet

- Shell Corena S3 R - TDSDocument3 pagesShell Corena S3 R - TDSAnonymous oAbjbl4HNo ratings yet

- Shell Corena S3 RJ - TDSDocument3 pagesShell Corena S3 RJ - TDSAnonymous oAbjbl4HNo ratings yet

- Shell Corena S2 R - TDSDocument3 pagesShell Corena S2 R - TDSAnonymous oAbjbl4HNo ratings yet

- Shell Diala S3 ZX-IGDocument2 pagesShell Diala S3 ZX-IGAnonymous oAbjbl4HNo ratings yet

- Shell Diala S2 ZU-I Dried PDFDocument2 pagesShell Diala S2 ZU-I Dried PDFAnonymous oAbjbl4HNo ratings yet

- Shell Cyprina 963 PDFDocument2 pagesShell Cyprina 963 PDFAnonymous oAbjbl4HNo ratings yet

- Shell Corena S2 P - TDS PDFDocument3 pagesShell Corena S2 P - TDS PDFAnonymous oAbjbl4H100% (1)

- Shell Caprinus XS9 40 (En) TDSDocument2 pagesShell Caprinus XS9 40 (En) TDSAnonymous oAbjbl4HNo ratings yet

- Technical Data Sheet: Aeroshell AscenderDocument2 pagesTechnical Data Sheet: Aeroshell AscenderAnonymous oAbjbl4HNo ratings yet

- AeroShell Turbine Oil 500 PDFDocument2 pagesAeroShell Turbine Oil 500 PDFAnonymous oAbjbl4HNo ratings yet

- Shell Argina X: Medium-Speed Trunk-Piston Diesel Engine OilDocument3 pagesShell Argina X: Medium-Speed Trunk-Piston Diesel Engine OilengrsurifNo ratings yet

- Shell Caprinus XR 40: Technical Data SheetDocument2 pagesShell Caprinus XR 40: Technical Data SheetAnonymous oAbjbl4HNo ratings yet

- L3548 4 07Document2 pagesL3548 4 07Héctor Hugo Sánchez GómezNo ratings yet

- Math 563 Lecture Notes Numerical Integrations (FUNDAMENTALS)Document12 pagesMath 563 Lecture Notes Numerical Integrations (FUNDAMENTALS)Aditi JhaNo ratings yet

- Principles of Mercantalism, How Did England Implement ThemDocument4 pagesPrinciples of Mercantalism, How Did England Implement ThemGunjan MadanNo ratings yet

- A Programmable Baseband Chain For A GSMDocument4 pagesA Programmable Baseband Chain For A GSMMENANI ZineddineNo ratings yet

- Mapeh Learners Individual Record Card Sy 2023 2024Document2 pagesMapeh Learners Individual Record Card Sy 2023 2024Karen May Urlanda100% (1)

- Congestive Heart FailureDocument37 pagesCongestive Heart FailurePierre Aseron ManuelNo ratings yet

- KDC-MP225 KDC-MP4026/G KDC-W4527/G/GY/Y KDC-W427Y: Service ManualDocument32 pagesKDC-MP225 KDC-MP4026/G KDC-W4527/G/GY/Y KDC-W427Y: Service Manualluispider74No ratings yet

- Is Ambition Positive or NegativeDocument3 pagesIs Ambition Positive or NegativeKiss KingaNo ratings yet

- APP Suggested Apprentice Body Piercer Guidelines and Curriculum 2020 Edition Version 3Document18 pagesAPP Suggested Apprentice Body Piercer Guidelines and Curriculum 2020 Edition Version 3JulioNo ratings yet

- 9100C Urm - Ge AnesthesiaDocument174 pages9100C Urm - Ge AnesthesiaJohn Joseph LuNo ratings yet

- Sustainable Development Strategies - A Resource Book (2002) PDFDocument382 pagesSustainable Development Strategies - A Resource Book (2002) PDFHamisu HussainiNo ratings yet

- Role of Government Inshaping Business EnvironmentDocument19 pagesRole of Government Inshaping Business Environmentankit161019893980100% (1)

- SouthwarkDocument76 pagesSouthwarkDavid NewbyNo ratings yet

- FINN 400 - Applied Corporate Finance-Fazal Jawad Seyyed PDFDocument7 pagesFINN 400 - Applied Corporate Finance-Fazal Jawad Seyyed PDFAhmed RazaNo ratings yet

- Techniques To Measure Grain-Size Distributions of Loamy Sediments: A Comparative Study of Ten Instruments For Wet AnalysisDocument32 pagesTechniques To Measure Grain-Size Distributions of Loamy Sediments: A Comparative Study of Ten Instruments For Wet AnalysiscmendozatNo ratings yet

- By Dr. Mahendra Parihar Associate Professor, Mpstme, Nmims MumbaiDocument26 pagesBy Dr. Mahendra Parihar Associate Professor, Mpstme, Nmims MumbaiShrey VyasNo ratings yet

- New Draft SI HRD-01Document166 pagesNew Draft SI HRD-01Toto SubagyoNo ratings yet

- Pharmacology of Renin-Angiotensin-System Blockers and COVID-19: Confusion Around ACE2Document3 pagesPharmacology of Renin-Angiotensin-System Blockers and COVID-19: Confusion Around ACE2Sharan SahotaNo ratings yet

- Thesis For MD Community MedicineDocument7 pagesThesis For MD Community Medicinedianaturnerspringfield100% (2)

- Labmgt Reviewer 1Document11 pagesLabmgt Reviewer 1Allison IliganNo ratings yet

- Ahmad Rifai, Evi Susanti: American International Journal of Business Management (AIJBM)Document18 pagesAhmad Rifai, Evi Susanti: American International Journal of Business Management (AIJBM)aijbmNo ratings yet

- Geovista: Caliper ProbesDocument1 pageGeovista: Caliper ProbesShahzad KhanNo ratings yet

- ELIOS 2 User Manual V1-Compressed - 1Document11 pagesELIOS 2 User Manual V1-Compressed - 1danielNo ratings yet

- Heat Exchanger System Piping Design For A Tube Rupture EventDocument10 pagesHeat Exchanger System Piping Design For A Tube Rupture Eventmarco8garciaNo ratings yet

- Fire ProtectionDocument7 pagesFire ProtectionRonaldNo ratings yet

- Intaglio Carving Technique On Transparent Stones by Vladimir PopovichDocument1 pageIntaglio Carving Technique On Transparent Stones by Vladimir Popovichmuhammad hamzaNo ratings yet

- Comparative Study of Madhyama-NikayaDocument622 pagesComparative Study of Madhyama-NikayaAnonymous 87cpqABhUNo ratings yet

- Hema QuizDocument6 pagesHema QuizTrisha ArizalaNo ratings yet