Professional Documents

Culture Documents

Installation Proporsal

Uploaded by

Giovanny SotoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Proporsal

Uploaded by

Giovanny SotoCopyright:

Available Formats

1 2 3 4 5 6 7 8 9 10

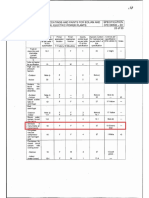

MINIMUM FREE AREA

TO BE RESERVED

Ø1200

MAINS COMPONENTS : B

1300

1 Delivery pipe : (40b)

4 5 Ensure that the discharge pipe from compressor to the air net

3335 `50

is free to expand under heat.

No external force may be exerted on the air outlet flange:

The connected pipe must be free of strain.

4 The max. total pipe length can be calculated from:

5

∆P×d×P

CABLE TRAY L= 1.85

450×Qc

L is the length of the pipe (m)

∆P is the max. Allowable pressure drop (recommended 0.6 bar)

d is the inner diameter of the pipe (mm)

P is the absolute pressure of the compressor outlet (bar)

Qc is the compressor FAD (l/s)

1a We recommend to install the receiver as close as possible to the D Booster

( less than 2.5 m )

The pulsation level at D Booster outlet on a no resonant line is less than

3% peak to peak of the average pressure.

2 Compressor room ventilation (to limit compressor room temperature)

CONVERTER The inlet grid(s) and ventilation fan should be installed in

AIR INLET such a way that any recirculation of cooling air to the C

1.5 m³/sec. compressor is avoided. The minimum temperature at the

compressor intake opening is 0°C, maximum suction air &

cooling air : 40°C (for HAT units : 50°C)

2a Required fan flow rate can be calculated from :

Qv=0.1N/∆T

Qv is the required fan flow rate (m³/s)

N is the shaft input of the ZD (ZR + D Booster) (KW)

∆T is the compressor room temperature over the outdoor

3 7 temperature (°C)

2b Ventilation air intake gratings :

The air velocity to the grid(s) has to be limited to 3m/s.

The free area(s) of the air intake opening in the wall is

calculated as follows :

S=(Qv+FAD)/v

D

S is the grid’s free area (m²)

9 Qv is the required fan flow rate (m³/s)

FAD is the air flow FAD of the ZR compressor (m³/s)

v is the allowable air velocity (=3m/s)

3 Drain pipes of ZR compressor :

Condensate collector must be open.

Drain pipes shall be always above condensate level.

Condensate collector proposal :

1

Separated ZR and MD

8 6

1300

5 drain pipes

overflow

107

950

Drain evacuation

1000 1000

4 Control cubicles with monitoring panel. E

5 Cables entries.

6 Cooling water supply : We recommend to install a filter (600 micron)

with 2 insulating valves to protect ZD at water inlet.

2b 7 Floor specification :

The unit should be installed on a level floor capable to

taking the weight of the compressor. Specific load of the

floor shall be minimum : for DX booster = 1700 daN/m²

for DN booster = 2100 daN/m²

Concrete skid of D booster is foreseen to be simply put on

the floor (no anchor at all). Floor shall be as flat & smooth

as possible : maximum default ±3mm/2m. Slope of the floor

shall not be more than 0.5cm/m.

8 Capacity of 40b air receiver represented = 3000L.

9 40b filters (submicronic and activated carbon).

F

1300

NOTE:

- For more information concerning air nets, cooling system, etc

refer to the compressor installation manual.

- For dimensions and air flow directions refer to the dimension drawing.

- Instruction for cable section, etc : see part 4.3 of instruction book.

NOTE:

INSTALLATION PROPOSAL FOR : ZD3500 VSD / ZD4100 VSD

MINIMUM FREE AREA

TO BE RESERVED

PET and HP Compressors :

2a ZD3500VSD / ZD4100VSD

AHB : "I" Installation proposal

1901 0654 58 ed.01

2970

1 07 0083 01

1460 19 UPDATED GECIA 26/07/2007 DESFORGES 01/08/2007 MACRON 01/08/2007

DN

copied, used for manufacturing or communicated to any other person or company.

Issue Modifications Drawn by Date Checked by Date Approved by Date

number G

This document is our property en shall not without our permission be altered,

Tolerances, if not indicated, according to:

ATLAS COPCO STANDARD CLASS

Name INSTALLATION DRAWING "I" CONFIGURATION Secrecy Class

Material 1102 K /

Treatment INV

Scale 1:20 Family A0 Compare Drawing owner

Drawn by GECIA Blank nr. Replaces CRP

Version Drwg Sheet 01 / 01

STATUS Blank wt. Kg Fini wt. Kg Designation

Parent 3 D model Ed . Version 3D ISSUE 1

Des checked.

COLMANT

Prod checked. Approved.

MACRON

Date

15/02/2007 1901 0654 58

You might also like

- Amerlock-2K - TDSDocument7 pagesAmerlock-2K - TDSGiovanny SotoNo ratings yet

- NRF 295 Pemex 2013 English (V 0)Document38 pagesNRF 295 Pemex 2013 English (V 0)Giovanny SotoNo ratings yet

- CFE D8500 (Air Compressor Coatings) - RALDocument16 pagesCFE D8500 (Air Compressor Coatings) - RALGiovanny SotoNo ratings yet

- Nema Ratings, Codes & Definitions Type 1Document2 pagesNema Ratings, Codes & Definitions Type 1Giovanny SotoNo ratings yet

- Nema MG 1-2016 Contents and ForewordDocument80 pagesNema MG 1-2016 Contents and Foreworddaralaketa100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 9Document36 pages9vscolegit shoppeNo ratings yet

- Anexo 1 - Generac SG625-PG563 PDFDocument6 pagesAnexo 1 - Generac SG625-PG563 PDFJuly E. Maldonado M.No ratings yet

- Saved Copy Internship 1Document1 pageSaved Copy Internship 1Mu Jta BaNo ratings yet

- DH26 Maximum Efficiency Hematology AnalyzerDocument2 pagesDH26 Maximum Efficiency Hematology AnalyzerOkura JoshuaNo ratings yet

- Tarea Vacacional PDFDocument16 pagesTarea Vacacional PDFkorina gonzalezNo ratings yet

- ARDrone Developer GuideDocument113 pagesARDrone Developer GuideIzukaitz GardonyiNo ratings yet

- CIE 121 Fluid Flow Using BEE and CEDocument2 pagesCIE 121 Fluid Flow Using BEE and CEfelixterence5No ratings yet

- BTECDocument11 pagesBTECRini SandeepNo ratings yet

- 1687836876505b6669848e0 1100623Document14 pages1687836876505b6669848e0 1100623jhon130296No ratings yet

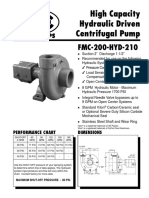

- FMC 200 Hyd 210Document2 pagesFMC 200 Hyd 210Ruben SaccoNo ratings yet

- Foss Lab Manual FinalDocument75 pagesFoss Lab Manual FinalBalraj ENo ratings yet

- Onewheel Future Motion Pint User Manual English Funshop ViennaDocument39 pagesOnewheel Future Motion Pint User Manual English Funshop Vienna1977pascoalNo ratings yet

- Experimental Phonetics 311Document7 pagesExperimental Phonetics 311Ebinabo EriakumaNo ratings yet

- Project Managemen 2 PDFDocument14 pagesProject Managemen 2 PDFMisha RanaNo ratings yet

- User Guide For Speedlink: Hearing Instrument Programming InterfaceDocument26 pagesUser Guide For Speedlink: Hearing Instrument Programming InterfaceMarcio Lobo SelvagemNo ratings yet

- Sharp CD E700 CD E77Document60 pagesSharp CD E700 CD E77Randy LeonNo ratings yet

- With Ms Excel: Advancing CareerDocument2 pagesWith Ms Excel: Advancing CareerMonjurul AhsanNo ratings yet

- EFI FLash Tool - HowToDocument15 pagesEFI FLash Tool - HowToJasonNo ratings yet

- WEG Programing Manual 10003989140 SSW900 enDocument167 pagesWEG Programing Manual 10003989140 SSW900 enAntonio Sergio Correa JuniorNo ratings yet

- SRX SFP 10ge Dac 1MDocument7 pagesSRX SFP 10ge Dac 1MAssem SamirNo ratings yet

- ZXUN USPP Load BalancingDocument69 pagesZXUN USPP Load BalancingTawhid AlamNo ratings yet

- 1 SadasDocument3 pages1 Sadas廾aאɢe ZøeNo ratings yet

- Python Regular Expressions (RegEx) Cheat SheetDocument4 pagesPython Regular Expressions (RegEx) Cheat SheetbabjeereddyNo ratings yet

- 06na NW Parts BreakdownDocument14 pages06na NW Parts BreakdownAmaurys Centeno100% (6)

- UMN EE 1301 Sample Problems and Solutions for Quiz 1Document14 pagesUMN EE 1301 Sample Problems and Solutions for Quiz 1ganxx019No ratings yet

- 8051 Atmel DatasheetDocument12 pages8051 Atmel Datasheetpranav_c22100% (3)

- Technical Specifications 500 - 11 - 0.415 Dyn11 CuAl Imp 6Document1 pageTechnical Specifications 500 - 11 - 0.415 Dyn11 CuAl Imp 6Dilesh SwitchgearNo ratings yet

- Microsoft Excel Exam Assessment Questions: Important InstructionsDocument3 pagesMicrosoft Excel Exam Assessment Questions: Important InstructionsKaartiikBenNo ratings yet

- MATH 103 - Thinking Mathematically I: Gesen @bilkent - Edu.trDocument2 pagesMATH 103 - Thinking Mathematically I: Gesen @bilkent - Edu.trVitto e Leo FerragniNo ratings yet

- Gear Ratio Application Chart 150-151Document2 pagesGear Ratio Application Chart 150-151Gustavo MosqueraNo ratings yet