Professional Documents

Culture Documents

Alteration of Paint-Peeling of Coil Spring Coil Spring Load Deflection Diagrams

Alteration of Paint-Peeling of Coil Spring Coil Spring Load Deflection Diagrams

Uploaded by

khairulyuslizarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alteration of Paint-Peeling of Coil Spring Coil Spring Load Deflection Diagrams

Alteration of Paint-Peeling of Coil Spring Coil Spring Load Deflection Diagrams

Uploaded by

khairulyuslizarCopyright:

Available Formats

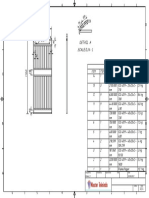

ALTERATION OF PAINT-PEELING OF COIL SPRING COIL SPRING LOAD DEFLECTION DIAGRAMS

-GUIDE-

We stock all our coil spring products after painting for the purpose of identification and rustproofing. However, in an attempt to satisfy IFor high deflection type

customers who are troubled by coating coming off, we have started providing alteration of paint-peeling of coil springs. F11~42 F10.5~43 F10.5~50 F10.5~52 F14.5~37

SWY L20 SWU L15 SWR L15 SWS L20 SWN L20

~

~

~

Ultra Super high Medium Low

300 300 High deflection 400 300 300

high deflection deflection deflection deflection

Operation frequency One million times 300,000 times Operation frequency One million times 300,000 times Operation frequency One million times 300,000 times Operation frequency One million times 300,000 times Operation frequency One million times 300,000 times

Deflection rate 65% 70% Deflection rate 60% 65% Deflection rate 50% 55% Deflection rate 40% 45% Deflection rate 30% 35%

KOperation frequency one million times KOperation frequency 300,000 times

Load(N) Load(N)

Load 200 Load 200

(kgf) (kgf)

Regular painted product Paint peeled product SWS

150 1470 150 1470

SWS

Guide for alteration of paint-peeling

SWN

Alteration of paint-peeling applies shot peeling to the painted coil springs to peel off its painting, then grease is applied for rust prevention. SWR

100 SWN 980 100 980

SWR

After the total processing, the paint for identification is completely peeled off, and the bare spring material is exposed.

SWU SWU

50 490 50 490

SWY SWY

<Painting peeling process: outline>

Painted coil

Paint peeling Applying antirust F10.5F12.5 F14.5 F17 F21 F26 F31 F37 F43 F46 F50 F10.5F12.5 F14.5 F17 F21 F26 F31 F37 F43 F46 F50

springs Tempering Delivery SWY F11 F12.5 F16.5 F20.5 F24.5 F30 F42 SWS F52 SWY F11 F12.5 F16.5 F20.5 F24.5 F30 F42 SWS F52

by shot peening agent

(finish product) CLoad{kgf}= Load NM0.101972 CLoad{kgf}= Load NM0.101972

IHigh load type

F6~30 F6~70 F6~70 F6~70 F6~70

Applicable springs SWF SWL SWM SWH

SWC L15 SWUF L10 SWUL L10 SWUM L15 SWUH L15

~

Coil springs: applicable for SWY , SWU , SWR , SWS , SWN , SWC , SWF , SWL , SWM , SWH , SWB Extra minimal load 200 Minimal load 350 Light load 350 Medium load 350 Heavy load 350

(D=11~42)

(D=10.5~43)

(D=10.5~50)

(D=10.5~37)

(D=14.5~37)

(D=6~30) (D=6~70)(D=6~70)(D=6~70)(D=6~70)(D=6~70)

Coil spring SWG,SWZ(for press mold)not applicable. Operation frequency One mil ion times 500,000 times 300,000 times Operation frequency One mil ion times 500,000 times 300,000 times Operation frequency One mil ion times 500,000 times 300,000 times Operation frequency One mil ion times 500,000 times 300,000 times Operation frequency One mil ion times 500,000 times 300,000 times

Deflection rate 50% 55% 60% Deflection rate 40% 45% 50% Deflection rate 32% 36% 40% Deflection rate 25.5% 28.8% 32% Deflection rate 19.2% 21.6% 24%

Note on handling KOperation frequency one million times

Although antirust agent is applied to the paint-peeled springs, silicon chrome steel oil temper line(SWOSC-V)painted on the coil springs is F6~70 F10~50

Load

extremely vulnerable to rust. Please be careful in handling them. (kgf) Load(N)

SWB L15

SWG L25

~

Extra heavy load 350 Hyper heavy load 150 1500 14700

Since rusted springs could cause early breakage, we recommend customers to reduce the deflection rate of paint-peeled springs compared to the SWB

regular painted products and replace them periodically depending on the usage environment. Early use after purchasing is also recommended.

Operation frequency One mil ion times 500,000 times 300,000 times Operation frequency One mil ion times 500,000 times 300,000 times

SWG SWHCSWUF

Deflection rate 16% 18% 20% Deflection rate 16% 18% 20% 1000 9800

Compared to regular painted springs, there may be some dispersions in terms of load and length, etc. depending on the lot.

SWMCSWUL

Since paint-peeled products are difficult to identify even from line thickness or the number of turns, please manage them carefully.

500 SWLCSWUM 4900

SWFCSWUL

When you order alteration of paint-peeling, please put NT before part number on the ordering sheet. SWC

Order F6 F8 F10F12F14F16F18F20F22 F25F27 F30 F35 F40 F50 F60 F70 FD

N T - S W U 2 6 - 8 0 CLoad{kgf}= Load NM0.101972

KOperation frequency 500,000 times KOperation frequency 300,000 times

Load Load(N)Load Load(N)

(kgf) (kgf) SWB

Paint peeling Regular part number SWB

1500 14700 1500 14700

SWG SWHCSWUF

SWG SWHCSWUF

1000 9800 1000 9800

SWMCSWUL

SWMCSWUL

SWLCSWUM

SWLCSWUM

500 4900 500 4900

SWFCSWUL

SWFCSWUL

SWC SWC

F6 F8 F10F12F14F16F18F20F22 F25F27 F30 F35 F40 F50 F60 F70 FD F6 F8 F10F12F14F16F18F20F22 F25F27 F30 F35 F40 F50 F60 F70 FD

C {kgf}

Load = Load NM0.101972 CLoad{kgf}= Load NM0.101972

You might also like

- Amapola PartituraDocument13 pagesAmapola PartituraAmedeo GiulianiNo ratings yet

- Shamsi Rashid MissionDocument1 pageShamsi Rashid MissionRana MazharNo ratings yet

- Hegenhaus - Old & New Folksongs (Horn, Piano)Document5 pagesHegenhaus - Old & New Folksongs (Horn, Piano)Pierre F.No ratings yet

- Kuffner - Op87 Doce-DuosDocument9 pagesKuffner - Op87 Doce-Duosluimiranda48No ratings yet

- Dokumen - Tips Motor Protection RelayspdfDocument23 pagesDokumen - Tips Motor Protection RelayspdfJuan GarcíaNo ratings yet

- So Different: From The Album "So Different" by Kinky Foxx (1983) Ã 112Document7 pagesSo Different: From The Album "So Different" by Kinky Foxx (1983) Ã 112valery.bassNo ratings yet

- Holiday Favorites ImpresiónDocument22 pagesHoliday Favorites ImpresiónImpresionespabloarango Pablo0% (1)

- SVT3 Pro - CopieDocument63 pagesSVT3 Pro - CopieBernard Joseph CalteauNo ratings yet

- Giant Map TM 2023Document1 pageGiant Map TM 2023evih646No ratings yet

- VP 2025JV0P10005 V 111 101 D15 009 V03 (Crude Distillation Column Nozzle Detail (714) EQPT. No. V)Document1 pageVP 2025JV0P10005 V 111 101 D15 009 V03 (Crude Distillation Column Nozzle Detail (714) EQPT. No. V)Vasilica BArbarasaNo ratings yet

- PR - D02110 Vie PC01 STN DWG KC FRP 02110Document1 pagePR - D02110 Vie PC01 STN DWG KC FRP 02110Ashish BhartiNo ratings yet

- The Effect of Prison Crowding On Inmate BehaviorDocument119 pagesThe Effect of Prison Crowding On Inmate BehaviorFelipe JuremaNo ratings yet

- .... ::P S::JVT::L F - I.. L - ,-R-I - 1::::P::: : :J : .... :J:) - # t.LI LL-I+-2 - F+ - ( - L..:: - ::1-:i: - 1-. .-2 - IDocument1 page.... ::P S::JVT::L F - I.. L - ,-R-I - 1::::P::: : :J : .... :J:) - # t.LI LL-I+-2 - F+ - ( - L..:: - ::1-:i: - 1-. .-2 - IMohammed H SaeedNo ratings yet

- Our Town October 30, 1947Document6 pagesOur Town October 30, 1947narberthcivicNo ratings yet

- Peel MapDocument1 pagePeel MapTom AmaralNo ratings yet

- Loveland Ski Resort Trail MapDocument1 pageLoveland Ski Resort Trail MapGglupps Gglupps GgluppsyNo ratings yet

- Dep1G: Detalle EDocument1 pageDep1G: Detalle EPedro Jose CorderoNo ratings yet

- Fender Mustang ShematicDocument12 pagesFender Mustang Shematicyebaim100% (4)

- HP Pdp124pDocument1 pageHP Pdp124pefremofe100% (2)

- Fire Sprinkler 1-ModelDocument1 pageFire Sprinkler 1-ModelVishnu PrajapatiNo ratings yet

- Mustang Iv: SMPS + AMP Schematic Diagram 1/3Document12 pagesMustang Iv: SMPS + AMP Schematic Diagram 1/3Valentin NichiforNo ratings yet

- 1953 1 EngDocument30 pages1953 1 EngTateNo ratings yet

- JESUS CRISTO MUDOU MEU VIVER - 1st Alto SaxDocument2 pagesJESUS CRISTO MUDOU MEU VIVER - 1st Alto SaxJose Carlos VieiraNo ratings yet

- KkcitymapDocument1 pageKkcitymapAbu Bakar Hj PunimanNo ratings yet

- TopogDocument3 pagesTopogSally MichaelNo ratings yet

- S19091 Sal Bawi Sob FD e Ele 01 B1 03 0103 01Document1 pageS19091 Sal Bawi Sob FD e Ele 01 B1 03 0103 01Ibrahim AlqunoonNo ratings yet

- Francistown AerodromeDocument1 pageFrancistown Aerodromelegae ramajaNo ratings yet

- JMPGuitars 18 Watt Tremolo TMB Reverb PCB v1.40 LayoutDocument1 pageJMPGuitars 18 Watt Tremolo TMB Reverb PCB v1.40 LayoutRenan Franzon GoettenNo ratings yet

- FFF FFFFFFFFFFFFFFFFFFFFFFFF FFFFF FF FF FF F FFF FFDocument11 pagesFFF FFFFFFFFFFFFFFFFFFFFFFFF FFFFF FF FF FF F FFF FFYESHASWININo ratings yet

- Proyecto Departamentos Mejorado2Document1 pageProyecto Departamentos Mejorado2WilliamYucraNo ratings yet

- Rsag7 820 4900Document10 pagesRsag7 820 4900Isabel GarciaNo ratings yet

- Maisonettes - Type M & M1 Plans Section & ElevationsDocument1 pageMaisonettes - Type M & M1 Plans Section & ElevationsmaxNo ratings yet

- 2023-08-12 - OPTION 1 - Banquet Hall - ds18 template-DOORS AND WINDOWSDocument1 page2023-08-12 - OPTION 1 - Banquet Hall - ds18 template-DOORS AND WINDOWSds18.albertcastroNo ratings yet

- Vicinity MapDocument1 pageVicinity MapJazzine PetutschnigNo ratings yet

- Chung Chi TOEFL PrimaryDocument2 pagesChung Chi TOEFL PrimaryTrần Thị Khánh LinhNo ratings yet

- Produced by An Autodesk Educational Product: TL: 1/25 TL: 1/25Document1 pageProduced by An Autodesk Educational Product: TL: 1/25 TL: 1/25Sang TrầnNo ratings yet

- EE12Document1 pageEE12Mamad SoheNo ratings yet

- The CamperVan and Motorhome BookDocument74 pagesThe CamperVan and Motorhome Bookdevil fixitNo ratings yet

- PHG - 2800-003 - Et-03 ChoDocument1 pagePHG - 2800-003 - Et-03 ChoComercializadora S&ENo ratings yet

- Trumerei by Robert Schumann Clarinet and PianoDocument2 pagesTrumerei by Robert Schumann Clarinet and PianoAndrea LaiNo ratings yet

- Jesus Cristo Mudou Meu Viver - 3rd TromboneDocument2 pagesJesus Cristo Mudou Meu Viver - 3rd TromboneJose Carlos VieiraNo ratings yet

- PR - D02109 Vie PC01 STN DWG KC FRP 02109Document1 pagePR - D02109 Vie PC01 STN DWG KC FRP 02109Ashish BhartiNo ratings yet

- VP 2025JV0P10005 V 111 101 D15 006 V03 (Crude Distillation Column Nozzle Detail (414) EQPT. No. V)Document1 pageVP 2025JV0P10005 V 111 101 D15 006 V03 (Crude Distillation Column Nozzle Detail (414) EQPT. No. V)Vasilica BArbarasaNo ratings yet

- Coast Artillery Journal - Oct 1937Document84 pagesCoast Artillery Journal - Oct 1937CAP History Library100% (1)

- BottomDocument1 pageBottomRiza VirsadaNo ratings yet

- Electrical Circuit Manitou MT1440Document3 pagesElectrical Circuit Manitou MT1440khanh khanh100% (3)

- gradienteHTM299 eDocument1 pagegradienteHTM299 ebrazilbestNo ratings yet

- Produced by An Autodesk Student Version: Ground Floor PlanDocument1 pageProduced by An Autodesk Student Version: Ground Floor PlanTwinkle MaharajwalaNo ratings yet

- Legend:: Department Name:Rural Development DepartmentDocument1 pageLegend:: Department Name:Rural Development DepartmentLambodar NaikNo ratings yet

- GDEW1248T3Document1 pageGDEW1248T3Nguyen Vu Hoang ThachNo ratings yet

- COMPONENT LOCATION - XT1965 - Top PDFDocument1 pageCOMPONENT LOCATION - XT1965 - Top PDFNando ParraNo ratings yet

- POLYTRON BT5 - U-Slim - PS52UV232G - PS52UM70 - HBEE-010A - HBT-01-05 - HBT-05-001 - 7N65 STV9325 MD2009 D313 JF0501-19587 LA44402 PDFDocument4 pagesPOLYTRON BT5 - U-Slim - PS52UV232G - PS52UM70 - HBEE-010A - HBT-01-05 - HBT-05-001 - 7N65 STV9325 MD2009 D313 JF0501-19587 LA44402 PDFAndika100% (6)

- DWG Hvac Pump StationDocument8 pagesDWG Hvac Pump StationRamy MahmoudNo ratings yet

- (Applicable in Only Beam Fin Plate) : Tack Weld TYP Stud Weld TYPDocument1 page(Applicable in Only Beam Fin Plate) : Tack Weld TYP Stud Weld TYPKhelen ThoudamNo ratings yet

- Paper 1 Article Science News 1Document4 pagesPaper 1 Article Science News 1api-624084180No ratings yet

- RiedingConcertoOp24 265Document30 pagesRiedingConcertoOp24 265Jaume Pons SampolNo ratings yet

- PIO - San - Rafael 5 - 9Document1 pagePIO - San - Rafael 5 - 9KOLD News 13No ratings yet

- GRAMMAR AVYAYAM 10th CBSEDocument6 pagesGRAMMAR AVYAYAM 10th CBSEPravin NairNo ratings yet

- Differentiated Reading for Comprehension, Grade 2From EverandDifferentiated Reading for Comprehension, Grade 2Rating: 4 out of 5 stars4/5 (1)

- O Mq+Bho Fibm) - :+5:Bmfbn: +05 X - U/X - Ii:O Mqabho OfibmDocument3 pagesO Mq+Bho Fibm) - :+5:Bmfbn: +05 X - U/X - Ii:O Mqabho OfibmkhairulyuslizarNo ratings yet

- Description: S - 011 S - 078 S - 062 S - 047Document1 pageDescription: S - 011 S - 078 S - 062 S - 047khairulyuslizarNo ratings yet

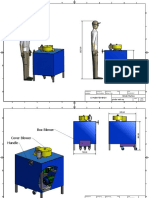

- PT. Inspirasi Kreasi OH Dryer Jaguar Dan KIT 3000HDocument1 pagePT. Inspirasi Kreasi OH Dryer Jaguar Dan KIT 3000HkhairulyuslizarNo ratings yet

- CNC Setting Tool: Computer Numerical Control ProductsDocument182 pagesCNC Setting Tool: Computer Numerical Control ProductskhairulyuslizarNo ratings yet

- Pagar Rumah 1Document1 pagePagar Rumah 1khairulyuslizarNo ratings yet

- Item Ke2Document1 pageItem Ke2khairulyuslizarNo ratings yet

- Grinder With MipDocument3 pagesGrinder With MipkhairulyuslizarNo ratings yet

- System Oil CleaningDocument3 pagesSystem Oil CleaningkhairulyuslizarNo ratings yet

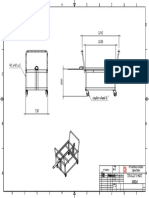

- Paint Mat'l: Trolly Part MKMDocument1 pagePaint Mat'l: Trolly Part MKMkhairulyuslizarNo ratings yet

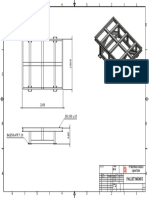

- Pallet MKM Ii: PT - Inspirasi Kreasi SejahteraDocument1 pagePallet MKM Ii: PT - Inspirasi Kreasi SejahterakhairulyuslizarNo ratings yet

- Jib Crane 3 DetailDocument3 pagesJib Crane 3 DetailkhairulyuslizarNo ratings yet

- Mixer 100 KG1Document2 pagesMixer 100 KG1khairulyuslizarNo ratings yet

- Ducting 400 Sus 304 18: Room Powder Room Powder 1 / 2Document2 pagesDucting 400 Sus 304 18: Room Powder Room Powder 1 / 2khairulyuslizarNo ratings yet

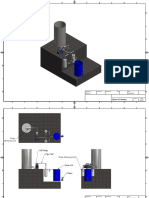

- Jig Drill ps120Document5 pagesJig Drill ps120khairulyuslizarNo ratings yet

- Oven BurnerDocument1 pageOven BurnerkhairulyuslizarNo ratings yet

- Pallete D80Document1 pagePallete D80khairulyuslizarNo ratings yet

- Palette Hino DistroDocument1 pagePalette Hino DistrokhairulyuslizarNo ratings yet

- Meja & PlateDocument3 pagesMeja & PlatekhairulyuslizarNo ratings yet

- Jig Drill Ps 100Document4 pagesJig Drill Ps 100khairulyuslizarNo ratings yet

- Pallete D80Document1 pagePallete D80khairulyuslizarNo ratings yet

- Pallet TrollyDocument1 pagePallet TrollykhairulyuslizarNo ratings yet

- Bahl and Bahl Organic Chemistry Chapter 11 To 15Document121 pagesBahl and Bahl Organic Chemistry Chapter 11 To 15Boago DrBiz DihutsoNo ratings yet

- CO Corrosion Rate Calculation Model: Norsok StandardDocument20 pagesCO Corrosion Rate Calculation Model: Norsok Standardnorman1968No ratings yet

- I J CRT 21101841Document14 pagesI J CRT 21101841Christina Christina ChristinaNo ratings yet

- EXPERIMENT NO.1B Polo, David Jonathan S.Document2 pagesEXPERIMENT NO.1B Polo, David Jonathan S.Jonathan PoloNo ratings yet

- Lista de Minerales 2015 PDFDocument200 pagesLista de Minerales 2015 PDFMaykohol Enrique Escalante MoralesNo ratings yet

- Engineering Physics 2022 AKTUDocument2 pagesEngineering Physics 2022 AKTUrajuvermame258No ratings yet

- Case Study of Converter Performance Evaluation On Sulfuric Acid ProductionDocument5 pagesCase Study of Converter Performance Evaluation On Sulfuric Acid Productionhafidz maNo ratings yet

- 3.4365 Alznmgcu1.5/Alzn5,5Mgcu en Aw-7075: Chemical Composition: (In %)Document1 page3.4365 Alznmgcu1.5/Alzn5,5Mgcu en Aw-7075: Chemical Composition: (In %)Samuel AbiNo ratings yet

- D 543 - 95 - Rdu0my05nqDocument7 pagesD 543 - 95 - Rdu0my05nqLuis RebolledoNo ratings yet

- Calculations Sag Tension LineDocument5 pagesCalculations Sag Tension LineANANDNo ratings yet

- Fundamentals of Green ChemistryDocument120 pagesFundamentals of Green ChemistryIndah BatamNo ratings yet

- 04 Electrochemistry - MCQs Paper 2Document68 pages04 Electrochemistry - MCQs Paper 2anwarulhaqNo ratings yet

- Chemical Bonding and Molecular Structure - DPPsDocument12 pagesChemical Bonding and Molecular Structure - DPPsRaxit PathakNo ratings yet

- Technical Submittal CicozincrichDocument22 pagesTechnical Submittal CicozincrichmunirNo ratings yet

- Chapter 6 - StoichiometryDocument54 pagesChapter 6 - Stoichiometrythur.libraNo ratings yet

- INOVOL F3600 Polyether Polyol TDSDocument1 pageINOVOL F3600 Polyether Polyol TDSvikashNo ratings yet

- Seybold Erin CV Dec2022Document8 pagesSeybold Erin CV Dec2022api-372907504No ratings yet

- The Role of PH in Food ScienceDocument9 pagesThe Role of PH in Food Sciencepushpinder paulNo ratings yet

- Ss 2 Chemistry Week 4 - 10Document40 pagesSs 2 Chemistry Week 4 - 10palmer okiemuteNo ratings yet

- Co Trimoxazole TabletDocument2 pagesCo Trimoxazole TabletYessi LopezNo ratings yet

- Ion Exchange Separation and Purification of AntibioticsDocument3 pagesIon Exchange Separation and Purification of AntibioticsAnonymous k41BMGYDLNo ratings yet

- Stability of Biochem in WB and SerumDocument10 pagesStability of Biochem in WB and SerumDwitaRiadiniNo ratings yet

- LP Metals, Nonmetals, MetalloidsDocument4 pagesLP Metals, Nonmetals, MetalloidsEverly Joy JingcoNo ratings yet

- Specifying Slide Gate ValveDocument4 pagesSpecifying Slide Gate ValvesahirprojectsNo ratings yet

- Gasket - 6500AC Data SheetDocument2 pagesGasket - 6500AC Data SheetAndrey AndrukhovichNo ratings yet

- Chem Lab - Magnisium Ribbon - Synthesize An Ionic CompoundDocument3 pagesChem Lab - Magnisium Ribbon - Synthesize An Ionic CompoundKevin WeathersNo ratings yet

- Ibuprofeno Suspensión USP 32Document4 pagesIbuprofeno Suspensión USP 32jorgeNo ratings yet

- IMDG1998Document587 pagesIMDG1998craciunmarcelgeorgeNo ratings yet

- TDS Sodium Hydrosulphide (NaHS)Document1 pageTDS Sodium Hydrosulphide (NaHS)Marthinus BoxyNo ratings yet

- The Osmotic Significance of Heteroside 1995Document9 pagesThe Osmotic Significance of Heteroside 1995Alex osorioNo ratings yet