Professional Documents

Culture Documents

Raysafe Pro-Fluoro 150: User Manual

Uploaded by

Nidhal Ben Khalifa0 ratings0% found this document useful (0 votes)

79 views5 pagesOriginal Title

1921059_raysafe_pro-fluoro_150_user_manual_2.1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

79 views5 pagesRaysafe Pro-Fluoro 150: User Manual

Uploaded by

Nidhal Ben KhalifaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

USER MANUAL

RaySafe Pro-Fluoro 150

© 2020.08 Unfors RaySafe 1921059-2.1

ABOUT THE RAYSAFE PRO-FLUORO 150

The phantom is made of PMMA (polymethyl methacrylate) and copper, with details of different

materials. The phantom complies with DIN 6868-150, DIN 6868-4 and IEC 61223-3-1.

The phantom is supplied with:

- Cone for perpendicularity testing

- Pro-RF Al 25 – 25mm aluminium filter, patient body equivalent

- Pro-RF Cu 1 – additional 1mm copper filter for test at and above 100kV

- Pro-RF Rack – holder for mounting the phantom on a chest wall

- Pro-RF Stand – a stand for mounting filter above the phantom

1. Dynamic copper step wedge.

2. Spatial resolution test pattern.

3. Detail contrast objects.

4. Detail contrast objects on copper step wedge.

5. Collimation lines for alignment of light and X-ray field.

© 2020.08 Unfors RaySafe 1921059-2.1

TECHNICAL SPECIFICATION

The phantom is made of a 17 mm thick PMMA (Polymethyl methacrylate) plate and a 1.5 mm

thick copper plate. The phantom complies with DIN 6868 150, DIN 6868-4 and IEC 61223-3-1.

1. Dynamic copper step wedge, consisting 17 steps made of different Cu thickness: 0.00,

0.18, 0.36, 0.54, 0.74, 0.95, 1.16, 1.38, 1.50, 1.73, 1.96, 2.21, 2.45, 2.70, 2.96, 3.22, 3.48

mm. The PMMA is thinned out at the site of the copper step wedge: 4 mm PMMA in

step 1–8, and 12 mm at step 10–17.

2. Spatial resolution test pattern with 3 periods for each resolution: 0.6, 0.7, 0.8, 0.9, 1.0,

1.2, 1.4, 1.6, 1.8, 2.0, 2.2, 2.5, 2.8, 3.1, 3.4, 3.7, 4.0, 4.3, 4.6, 5.0 LP/mm. The pattern is

made of 100 μm thick.

3. Eight circular detail contrast objects, Ø 10 mm, in the homogeneous field. The objects

are air cavities in the PMMA: 0.4, 0.6, 0.8, 1.2, 1.7, 2.4, 3.4, 4.0 mm deep.

At 75kV and with additional 25mm Al objects produce following contrasts: 0.9 %, 1.3 %

1.8 %, 2.8 %, 4.0 %, 5.6 %, 8.0 %, 9.4 %.

4. 17 circular detail contrast objects on copper step wedge, Ø 4 mm, air cavities with a

depth of 2.5 mm in PMMA on every step of the copper step wedge.

5. Collimation lines for alignment of light and x-ray field. Dimensions: 26×26; 18×24; 16×16

cm. Circular diameter dimensions: 26, 22, 19, 16 cm.

TEST PROCEDURE

This is an example. Be sure to comply with your local regulations.

1. Position the phantom on the table.

Use FTD of about 1m. The center

and main axis should align with the

light marker of the apparatus.

2. Narrow the light field (which

should represent the X-ray field) to

the chosen markings on the

phantom.

3. Check that the machine has AEC

turned on.

4. Use an additional 25 mm aluminium filter (patient equivalent) for the test for the tube

voltage to reach the desired range (for example 75 ± 7 kV according to DIN 6868-150).

Mount the Al 25 filter in rails on the collimator.

For test above 100kV use additional 1mm Cu filter.

© 2020.08 Unfors RaySafe 1921059-2.1

Some x-ray systems don’t have the possibility to add the 25 mm Al filter in a slot close to

the collimation, for example when the tube is positioned underneath the table. Use the

Pro-RF Stand for positioning the filter and the phantom properly in these cases.

5. Make the exposure and read the results from the image.

© 2020.08 Unfors RaySafe 1921059-2.1

1. Dynamic range: Number of Cu

steps visible (max 17)

2. Spatial resolution: Number of

line pairs per millimeter (max 5.0

LP/mm)

3. Contrast resolution: Visibility

of detail contrast objects (max 8)

4. Contrast resolution: Visibility

of detail contrast objects on

copper step wedge (max 17)

5. Collimator light field and beam

alignment: Check the alignment

using the grid and circles (ok or

not)

6. Beam perpendicularity: Check

the perpendicularity with the

cone (ok or not)

7. Homogeneity: Artefacts in the

image (yes/no)

OTHER SETUPS

The phantom and holder can be used for mounting on chest wall.

© 2020.08 Unfors RaySafe 1921059-2.1

You might also like

- Reinforcement Plan Pedestal Plan: Saudi Arabian Oil CompanyDocument1 pageReinforcement Plan Pedestal Plan: Saudi Arabian Oil CompanyDomie Neil Bucag SalasNo ratings yet

- BreathControl PDFDocument11 pagesBreathControl PDFClaudio Andrés Mendez CerdaNo ratings yet

- Rochet: Short Course For Papua New Guinea Non-Formal SectorDocument22 pagesRochet: Short Course For Papua New Guinea Non-Formal SectorKim So-HyunNo ratings yet

- Zero Carbon Building StandardsDocument32 pagesZero Carbon Building Standardsjoslinmtg100% (1)

- Instruction Manual For Testing The Acr CT PhantomDocument16 pagesInstruction Manual For Testing The Acr CT PhantomMuchti IndriyatiNo ratings yet

- IGEM-UP-1C Draft For Comment - 2nd Consultation (IGEM-TSP-10-122)Document54 pagesIGEM-UP-1C Draft For Comment - 2nd Consultation (IGEM-TSP-10-122)eastway98100% (2)

- Introduction To Microstrip AntennasDocument180 pagesIntroduction To Microstrip AntennasMegha Nagaraj100% (1)

- Rms Auto Ut Corrosion Mapping PDFDocument6 pagesRms Auto Ut Corrosion Mapping PDFSangeeth Kavil PNo ratings yet

- Evo Ma10: Scanning Electron MicroscopeDocument14 pagesEvo Ma10: Scanning Electron MicroscopeVidas Makarevicius100% (1)

- Lab6-Tubular Flow ReactorDocument11 pagesLab6-Tubular Flow ReactorNurtasha Atikah100% (1)

- Measurement of Focal Spots of Industrial X-Ray Tubes by Pinhole ImagingDocument7 pagesMeasurement of Focal Spots of Industrial X-Ray Tubes by Pinhole ImagingERNESTO ENRIQUE FERNANDEZ BAPTISTANo ratings yet

- Smart AntennasDocument40 pagesSmart AntennasMeeraNo ratings yet

- Transitions from Digital Communications to Quantum Communications: Concepts and ProspectsFrom EverandTransitions from Digital Communications to Quantum Communications: Concepts and ProspectsNo ratings yet

- User Manual Pro-Fluo en v.1Document10 pagesUser Manual Pro-Fluo en v.1Muhammad Ihsan0% (1)

- TFM - Karl DeustchDocument8 pagesTFM - Karl DeustchJean Andrés SantacolomaNo ratings yet

- Single Photon Emission Positron Tomography 2Document25 pagesSingle Photon Emission Positron Tomography 2Andrew GrantNo ratings yet

- Problem 1: Fabry-Perot Displacement Sensor: EE 231, Lasers Spring 2007 Problem Set 2 Due 5PM 25 AprilDocument2 pagesProblem 1: Fabry-Perot Displacement Sensor: EE 231, Lasers Spring 2007 Problem Set 2 Due 5PM 25 AprilHusam Abduldaem MohammedNo ratings yet

- Mocoeur SF2A 05Document4 pagesMocoeur SF2A 05SantonierNo ratings yet

- Tutorial Sonnet eDocument26 pagesTutorial Sonnet eSomnath DasNo ratings yet

- Imaging Carbon NanotubesDocument13 pagesImaging Carbon NanotubesSaransh RajNo ratings yet

- 3 Fault Classification PDFDocument8 pages3 Fault Classification PDFAnonymous bUubLDNo ratings yet

- 1735Document15 pages1735mrta mrtaNo ratings yet

- Single-Sided Contacting of Out-of-Plane Polarized Piezo Films For Fluid Membrane LensesDocument4 pagesSingle-Sided Contacting of Out-of-Plane Polarized Piezo Films For Fluid Membrane LensesLesly RuizNo ratings yet

- 2-2 Preumont PresentationDocument33 pages2-2 Preumont PresentationYusuf TurgutNo ratings yet

- Scintillation Camera Quality ControlDocument53 pagesScintillation Camera Quality Controlknno87No ratings yet

- Optical Vortex Phase Plate Application NotesDocument5 pagesOptical Vortex Phase Plate Application NotesDu RoyNo ratings yet

- FLUORO 4 User ManualDocument8 pagesFLUORO 4 User ManualFalya GiyassalNo ratings yet

- High Resolution Phased Array Imaging Using The Total Focusing Method (Kierspel Et Al - 2017)Document8 pagesHigh Resolution Phased Array Imaging Using The Total Focusing Method (Kierspel Et Al - 2017)pjhollowNo ratings yet

- .Fraunhofer - Diffraction.at - The.slit.Document6 pages.Fraunhofer - Diffraction.at - The.slit.NCHE BORISNo ratings yet

- Overview of Semiconductor Photon DetectorsDocument8 pagesOverview of Semiconductor Photon DetectorsIsaí Raya FaríasNo ratings yet

- RTS/OTS810 Series Total StationDocument2 pagesRTS/OTS810 Series Total StationMonehoi ZechalyNo ratings yet

- E986-04 (Reapproved 2017)Document3 pagesE986-04 (Reapproved 2017)Miguel BazalduaNo ratings yet

- FE Modeling of Surfaces With Realistic 3D Roughness: Roughness Effects in Optics of Plasmonic NanoantennasDocument4 pagesFE Modeling of Surfaces With Realistic 3D Roughness: Roughness Effects in Optics of Plasmonic NanoantennasJorge CabreraNo ratings yet

- Bio-Medical RF Simulations With CST MICROWAVE STUDIODocument35 pagesBio-Medical RF Simulations With CST MICROWAVE STUDIOMontadaalahraralyamanion Yemeni0% (1)

- UT-L2-specific THICKNESS - AnsDocument4 pagesUT-L2-specific THICKNESS - Ansnasrul haziqNo ratings yet

- Considerations ForDocument9 pagesConsiderations Forkiyong namNo ratings yet

- HYPERION Optical Sensing Instrument - Si255: Description Key FeaturesDocument2 pagesHYPERION Optical Sensing Instrument - Si255: Description Key FeaturesYi-jen ChanNo ratings yet

- Cawangan Keselamatan Sinaran Bahagian Perkhidmatan KejuruteraanDocument8 pagesCawangan Keselamatan Sinaran Bahagian Perkhidmatan KejuruteraansaifulNo ratings yet

- E 986 - 04 (2010)Document3 pagesE 986 - 04 (2010)ruben carcamoNo ratings yet

- FEM Acoustic Analysis - NDT Angle Beam ExampleDocument28 pagesFEM Acoustic Analysis - NDT Angle Beam ExampleN DNo ratings yet

- Specification Mechelle 7500 Integrated With The DiCAM-PRO ICCD ...Document4 pagesSpecification Mechelle 7500 Integrated With The DiCAM-PRO ICCD ...Saranya VsNo ratings yet

- Introduction To Phased Array Ultrasonic Technology Applications 216-220Document5 pagesIntroduction To Phased Array Ultrasonic Technology Applications 216-220Kevin HuangNo ratings yet

- NDT - Auto RT 5Document12 pagesNDT - Auto RT 5paimpillyNo ratings yet

- Instrumentation For Surface Resistivity Measurement - Aimil LTD Is Trusted Suppliers in IndiaDocument4 pagesInstrumentation For Surface Resistivity Measurement - Aimil LTD Is Trusted Suppliers in IndiaAimilNo ratings yet

- AFm PDFDocument8 pagesAFm PDFsirgh1105No ratings yet

- Results For Laser InterferometryDocument3 pagesResults For Laser InterferometrychetsNo ratings yet

- Introduction To Microstrip AntennasDocument175 pagesIntroduction To Microstrip AntennasDhivya Dhanalakshmi ECENo ratings yet

- Quiz - Solution - Design A SingDocument9 pagesQuiz - Solution - Design A SingPaulNo ratings yet

- Traceable Roughness of ProductsDocument7 pagesTraceable Roughness of ProductsSaraswantoNo ratings yet

- Front-Vs Back-Illuminated CCD Cameras For Photometric Surveys: A Noise Budget AnalysisDocument4 pagesFront-Vs Back-Illuminated CCD Cameras For Photometric Surveys: A Noise Budget Analysisvideo76No ratings yet

- AFM - ManualDocument18 pagesAFM - ManualHong Nguyen 눈 꽃No ratings yet

- Super 16Document4 pagesSuper 16Jonas FrykbergNo ratings yet

- 2014 IBRACON-mNotizDocument50 pages2014 IBRACON-mNotizJulio LopesNo ratings yet

- Terratek CPTUS Test Standards EnglishDocument12 pagesTerratek CPTUS Test Standards EnglishJohn STCNo ratings yet

- SRF HRF SSR DanjouxDocument12 pagesSRF HRF SSR Danjouxalexander100% (1)

- EM Pro Simulation: Geometr y Port/Feed Simulatio N Setting Post-Processin GDocument9 pagesEM Pro Simulation: Geometr y Port/Feed Simulatio N Setting Post-Processin GHa Tran KhiemNo ratings yet

- Introduction To Microstrip AntennasDocument179 pagesIntroduction To Microstrip Antennasmanjula vadulapuramNo ratings yet

- Afm NotDocument11 pagesAfm Notidilaynur38No ratings yet

- N2510 - Ftu PDFDocument1 pageN2510 - Ftu PDFRodrigovitch100% (1)

- 2021 ELF 10000 - Flyer 1Document1 page2021 ELF 10000 - Flyer 1Zhang zhenshengNo ratings yet

- Telescope Optics: 6.1 Requirements and GuidelinesDocument62 pagesTelescope Optics: 6.1 Requirements and GuidelinesRupesh KumarNo ratings yet

- Quantitative Determination of Radio-Opacity Equivalence of Digital and Film X-Ray SystemsDocument7 pagesQuantitative Determination of Radio-Opacity Equivalence of Digital and Film X-Ray SystemsdtkerimNo ratings yet

- Uv / Vis Spectrophotometer: Emclab Instruments GMBHDocument20 pagesUv / Vis Spectrophotometer: Emclab Instruments GMBHAude Steaven Mackaya BoloNo ratings yet

- Digital Ultrasonic Flaw DetectorDocument4 pagesDigital Ultrasonic Flaw DetectorNarcizo Eliseo Luna PerezNo ratings yet

- Radio Frequency Identification and Sensors: From RFID to Chipless RFIDFrom EverandRadio Frequency Identification and Sensors: From RFID to Chipless RFIDNo ratings yet

- From Microstructure Investigations to Multiscale Modeling: Bridging the GapFrom EverandFrom Microstructure Investigations to Multiscale Modeling: Bridging the GapDelphine BrancherieNo ratings yet

- Daily Report Installation of J312 G2: Tenerflow International SaDocument19 pagesDaily Report Installation of J312 G2: Tenerflow International SaNidhal Ben KhalifaNo ratings yet

- Air Starter T121B TDI Report SN2.05Document4 pagesAir Starter T121B TDI Report SN2.05Nidhal Ben KhalifaNo ratings yet

- Condition Monitoring of Rotating Machinery Through Vibration AnalysisDocument5 pagesCondition Monitoring of Rotating Machinery Through Vibration AnalysisNidhal Ben KhalifaNo ratings yet

- Vibration Based Condition Monitoring of Rotating MDocument18 pagesVibration Based Condition Monitoring of Rotating MNidhal Ben KhalifaNo ratings yet

- What Is Preventative Maintenance and Why Is It Important?: Prevent Costly DowntimeDocument3 pagesWhat Is Preventative Maintenance and Why Is It Important?: Prevent Costly DowntimeNidhal Ben KhalifaNo ratings yet

- Development and Implementation of Preventive-Maintenance Practices in Nigerian IndustriesDocument19 pagesDevelopment and Implementation of Preventive-Maintenance Practices in Nigerian IndustriesNidhal Ben KhalifaNo ratings yet

- HVAC Validation 1649296351Document15 pagesHVAC Validation 1649296351jeyapragash RamadassNo ratings yet

- Flexi Multiradio 10 Base Station Transmission DescriptionDocument27 pagesFlexi Multiradio 10 Base Station Transmission DescriptionMohamedNasser Gad El MawlaNo ratings yet

- Biodiversiti UnescoDocument9 pagesBiodiversiti UnescoYullyFahmiNo ratings yet

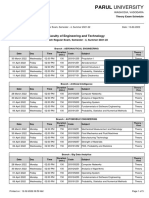

- Parul University: Faculty of Engineering and TechnologyDocument5 pagesParul University: Faculty of Engineering and TechnologySudhanshu SinghNo ratings yet

- Youtalk Grammar Ii: Class 30.7Document5 pagesYoutalk Grammar Ii: Class 30.7ToTo hostoyseNo ratings yet

- Nursing Care Plan: Clustered Cues Nursing Diagnosis Rationale Outcome Criteria Nursing Interventions Rationale EvaluationDocument2 pagesNursing Care Plan: Clustered Cues Nursing Diagnosis Rationale Outcome Criteria Nursing Interventions Rationale EvaluationCLEMENT, EUGENE CHADNo ratings yet

- Ee 8Document8 pagesEe 8RushilNo ratings yet

- Krohne mfc300 Manual PDFDocument180 pagesKrohne mfc300 Manual PDFJorge GilNo ratings yet

- AtlasPoCu CCC 20190805Document33 pagesAtlasPoCu CCC 20190805David GoteraNo ratings yet

- Dee Mandala InfoMemoDocument27 pagesDee Mandala InfoMemoSheetalkumarNo ratings yet

- Supplemental Type Certificate: N UmberDocument2 pagesSupplemental Type Certificate: N UmberJuan C BalderasNo ratings yet

- Study On Solar Irrigation System in BangladeshDocument61 pagesStudy On Solar Irrigation System in Bangladeshavocadocolor100% (2)

- Active & PASSIVE VOICE GRADE 8Document5 pagesActive & PASSIVE VOICE GRADE 8fathima sarahNo ratings yet

- I. Objectives: Write The LC Code For EachDocument3 pagesI. Objectives: Write The LC Code For EachNica Joy AlcantaraNo ratings yet

- Philips HTS3510 PDFDocument66 pagesPhilips HTS3510 PDFJesusNo ratings yet

- Manual PelucheraDocument7 pagesManual Pelucheralvplus0% (1)

- Layer 3 48-Port 10G SFP+ + 2-Port 40G QSFP+ + 4-Port 100G QSFP28 Managed SwitchDocument10 pagesLayer 3 48-Port 10G SFP+ + 2-Port 40G QSFP+ + 4-Port 100G QSFP28 Managed Switchbader eddine khezamiNo ratings yet

- HUAWEI CUN U29-Bitel Phone Upgrade Guide - V1.1 - 20161128Document10 pagesHUAWEI CUN U29-Bitel Phone Upgrade Guide - V1.1 - 20161128Danny J GonzalezNo ratings yet

- Sithkop005 AnswersDocument46 pagesSithkop005 AnswersSid SharmaNo ratings yet

- Dine Catalogue Eng 20 21Document318 pagesDine Catalogue Eng 20 21l4k9xxxNo ratings yet

- Automated Sand Gravity Sand Filter SystemDocument58 pagesAutomated Sand Gravity Sand Filter SystemMichaelNo ratings yet

- High-Precision Chilled Mirror HygrometerDocument4 pagesHigh-Precision Chilled Mirror HygrometerAldrin HernandezNo ratings yet