Professional Documents

Culture Documents

Military COTS 270V Filter: Input Attenuator Module

Uploaded by

anandOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Military COTS 270V Filter: Input Attenuator Module

Uploaded by

anandCopyright:

Available Formats

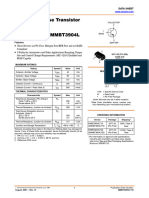

Military COTS 270VIN Filter

M-FIAM3

Example Model Number M-FIAM3M21

Actual size:

2.28 x 2.2 x 0.5in

[57,9 x 55,9 x 12,7mm]

Input Attenuator Module

Features & Benefits Absolute Maximum Rating

• EMI filtering: MIL-STD-461E [b] Parameter Rating Unit Notes

375 VDC Continuous

• Transient protection: MIL-STD-704E/F +IN to –IN

400 VDC 100ms

• Environments: MIL-STD-810,

Mounting torque 5 [0.57] in.lbs [N.m] 6 each, #4-40 or M3

MIL‑STD-202

500 [260] °F [°C] <5sec; wave solder

• Environmental stress screening Pin Soldering temperature

750 [390] °F [°C] <7sec; hand solder

• Low-profile mounting options

• Output current up to 3A

• Mini-sized package

Thermal Resistance and Capacity

• Inrush current limiting Parameter Min Typ Max Unit

Baseplate to sink

flat, greased surface 0.16 °C/Watt

Product Highlights with thermal pad (P/N 20264) 0.1 °C/Watt

The M-FIAM3 is a DC front-end module that Baseplate to ambient

provides EMI filtering and transient protection. Free convection 7.9 °C/Watt

The M-FIAM3 enables designers using 1000LFM 2.2 °C/Watt

Vicor Maxi, Mini, Micro Series 300V DC‑DC

converters to meet conducted emission/

conducted susceptibility per MIL‑STD-461E; MTBF per MIL-HDBK-217F (M-FIAM3M21)

and input transients per MIL‑STD-704E/F.

The M-FIAM3 accepts an input voltage Temperature Environment MTBF Unit

of 180 – 375VDC and delivers output

current up to 3A. 25°C Ground Benign: G.B. 13,291 1,000Hrs

50°C Naval Sheltered: N.S. 2,392 1,000Hrs

M-FIAM3 is housed in an industry‑standard

“half-brick” module measuring 65°C Airborne Inhabited Cargo: A.I.C. 1,874 1,000Hrs

2.28 x 2.2 x 0.5in and depending upon model

selected, may be mounted onboard or inboard

for height‑critical applications. Part Numbering

Compatible Products M-FIAM3 M 2 1

• Maxi, Mini, Micro Series 300V Input Product Grade Temperatures (°C) Pin Style Baseplate

Product

Grade Operating Storage 1 = Short Pin 1 = Slotted

DC-DC converters H = –40 to +100 – 55 to +125 2 = Long Pin 2 = Threaded

M = –55 to +100 – 65 to +125 S = Short ModuMate [a] 3 = Thru hole

N = Long ModuMate [a]

F = Short RoHS

G = Long RoHS

K = Extra Long RoHS [c]

[a] Compatible with SurfMate and InMate socketing system

[b] EMI performance is subject to a wide variety of external influences such as PCB construction,

circuit layout etc. External components in addition to those listed herein may be required in specific

instances to gain full compliance to the standards specified at various line and load conditions.

[c] Not intended for socket or Surfmate mounting

Note: Product images may not highlight current product markings.

M-FIAM3 Rev 3.2

Page 1 of 6 06/2019

M-FIAM3M21

Specifications

Typical at TBP = 25°C, nominal line and 75% load, unless otherwise specified.

Input Specifications

Parameter Min Typ Max Unit Notes

Input voltage 180 270 375 VDC Continuous

Inrush limiting 0.018 A/µF

Transient immunity Exceeds limits of MIL-STD-704E/F

Output Specifications

Parameter Min Typ Max Unit Notes

Output current 3 A

Efficiency 96 98 %

Internal voltage drop 3.0 5.0 V @ 3A, 100°C baseplate

External capacitance See Figure 5 on page 4.

10 22 µF 400V

Control Pin Specifications

Parameter Min Typ Max Unit Notes

ON/OFF control

Enable (ON) 0.0 1.0 VDC Referenced to –VOUT

Disable (OFF) 3.5 5.0 VDC 100kΩ internal pull-up resistor

Safety Specifications

Parameter Min Typ Max Unit Notes

1,500 VRMS Input/Output to Base

Dielectric withstand

2,121 VDC Input/Output to Base

EMI

Standard Test Procedure Notes

MIL-STD-461E

Conducted emissions: CE101, CE102

Conducted susceptibility: CS101, CS114, CS115, CS116

EMI performance is subject to a wide variety of external influences such as PCB construction, circuit layout etc. As such, external components in addition to

those listed herein may be required in specific instances to gain full compliance to the standards specified.

M-FIAM3 Rev 3.2

Page 2 of 6 06/2019

M-FIAM3M21

Specifications (Cont.)

Typical at TBP = 25°C, nominal line and 75% load, unless otherwise specified.

General Specifications

Parameter Min Typ Max Unit Notes

Weight

3.3 [94] Ounces [grams]

Warranty 2 Years

Environmental Qualification

Altitude

MIL-STD-810F, Method 500.4, Procedure I & II, 40,000ft. and 70,000ft. Operational.

Explosive Atmosphere

MIL-STD-810F, Method 511.4, Procedure I, Operational.

Vibration

MIL-STD-810F, Method 514.5, Procedure I, Category 14, Sine and Random vibration per Table 514.5C for Helicopter AH-6J Main Rotor with overall level of

5.6Grms for 4 hours per axis. MIL-STD-810F, Method 514.5C, General Minimum Integrity Curve per Figure 514.5C-17 with overall level of 7.7Grms for 1

hour per axis.

Shock

MIL-STD-810F, Method 516.5, Procedure I, Functional Shock, 40g. MIL-S-901D, Lightweight Hammer Shock, 3 impacts/axis, 1,3,5 ft.

MIL-STD-202F, Method 213B, 60g, 9ms half sine. MIL-STD-202F, Method 213B, 75g, 11ms Saw Tooth Shock.

Acceleration

MIL-STD-810F, Method 513.5, Procedure II, table 513.5-II, Operational, 2-7g, 6 directions.

Humidity

MIL-STD-810F, Method 507.4.

Solder Test

MIL-STD-202G, Method 208H, 8 hour aging.

Environmental Stress Screening

Parameter H-Grade M-Grade

Operating temperature –40 to +100°C –55 to +100°C

Storage temperature –55 to +125°C –65 to +125°C

12 cycles 12 cycles

Temperature cycling*

–65 to +100°C –65 to +100°C

Ambient test @ 25°C Yes Yes

Power cycling burn-in 12 hours, 29 cycles 24 hours, 58 cycles

Functional and parametric ATE tests –40 and +100°C –55 and +100°C

Hi-Pot test Yes Yes

Visual inspection Yes Yes

Test data vicorpower.com vicorpower.com

*Temperature cycled with power off, 17°C per minute rate of change.

Storage

Vicor products, when not installed in customer units, should be stored in ESD safe packaging in accordance with ANSI/ESD S20.20,

“Protection of Electrical and Electronic Parts, Assemblies and Equipment” and should be maintained in a temperature controlled factory/

warehouse environment not exposed to outside elements controlled between the temperature ranges of 15°C and 38°C. Humidity shall not

be condensing, no minimum humidity when stored in an ESD compliant package.

M-FIAM3 Rev 3.2

Page 3 of 6 06/2019

M-FIAM3M21

Output

Input

Figure 1 — Conducted noise; M-FIAM3 and V300A48C500BG Figure 2 — Transient immunity; M-FIAM3 output response to an

DC-DC converter operating at 270VDC input at 450W input transient

M-FIAM3 Diff. & Comm. Mode Insertion Loss

10.000

0.000

-10.000

IL [dB] -20.000

-30.000

-40.000

-50.000

-60.000

-70.000

0.01 0.1 1 10

Frequency [MHz] Diff. Mode IL

Comm. Mode IL

Figure 3 — Inrush limiting; inrush current with 22µF external Figure 4 — Insertion loss curve

capacitance, (C1 in Figure 5)

Note: The M-FIAM3 is shown in the on state. To disable,

open the connection between ON/OFF and –OUT.

4700pF

Y2 type 0.01µF

+IN +OUT +OUT

+IN

+S

F1 MOV P/N

NC NC PC Maxi, Mini, Micro

M-FIAM3 0.3µF

Input 30076 NC C1 300 Vdc Input SC

EMI

GND

ON

OFF

PR DC-DC Converter –S

–IN –OUT –IN –OUT

4700pF 0.01µF

Y2 type

Component Suggestions

Recommended Fuse: (F1) 3A Max., Bussmann ABC style

Capacitance: (C1)10µF(min), 22µF(max)

Figure 5 — Basic connection diagram with transient, surge protection and recommended reverse-polarity protection

M-FIAM3 Rev 3.2

Page 4 of 6 06/2019

M-FIAM3M21

Mechanical Drawings

0.50 ±0.02

Module Pins 12,7 ±0,5

No. Function Label

1 +IN + 2.20 kl{hpsGX 0.01

55,9 YGaGX

No 0.23 1.76

2 NC 5,8

(REF)

44,7

Connection

(9X) PLATED style 2 & 3 0.12* 0.20** 0.49 2.000 0.10

THROUGH HOLE DIA

baseplates only 12,4 2,5

3 Ground EMI/GND 0.300 ±0.015

7,62 ±0,38 (4X)***

3,1 5,1 50,80

0.10

X 45˚

4 –IN – 2,5

CHAMFER

2 3 4

5 –OUT – 0.300 ±0.015

1 2 3 4 0.35 (2X)

8,8 0.65 FULL R (6X)

7,62 ±0,38

6 ON/OFF ON/OFF

(ALL MARKINGS

THIS SURFACE)

16,5

1.900 Pin CL 2.28 1.30

ALUMINUM

48,26 57,9 33,0

No BASEPLATE 0.130

7 NC (6X)

Connection 9 8 7 6 5

3,30

8 7 6 5

No Use a 4-40 Screw (6X)

8 NC

Connection 0.150 DIA,(2X)

3,81 0.43 0.06

Torque to:

5 in-lbs

R (3X) 2.20

0.400 10,9 1,5 0.57 N-m

9 +OUT + FULL R (6X)

10,16

0.080 DIA,(7X)

2,03

55,9

L 0.54 (REF.)

0.700 * 0.700 (9X) Pin Style 1&S

Slotted 13,7

17,78 17,78 (Short Pin)

1.000 * 1.000

* DENOTES TOL= ±0.003 0.13 0.62

25,40 (6X) 25,40 (9X) Pin Style 2&N

±0,08 3,3 15,7

1.400 * 1.400 (Long Pin)

35,56 35,56

0.71

Threaded

SLOTTED BASEPLATE

18,0

(9X) Pin Style K

ns (Extra Long Pin)

4-40 UNC-2B (6X)

* Style 1 baseplate only

** Style 2 & 3 baseplates NOTES:

1. MATERIAL:

Thru Hole

2. DIMENSIONS AND VALUES IN BRACKETS ARE METRIC *** Reserved for Vicor accessories

BASE: 6000 SERIES ALUMINUM

3. MANUFACTURING CONTROL IS IN PLACE TO#30 Drill Thru

ENSURE THAT (6X)

THE SPACING Not for mounting COVER: LCP, ALUMINUM 3003 H14

BETWEEN THE MODULES LABEL SURFACE TO THE PRINTED CIRCUIT BOARD

(0.1285) CL Pin center line PINS: RoHS PINS GOLD PLATE 30 MICRO INCH MIN; NON-RoHS

OF THE APPLICATION RANGES FROM DIRECT CONTACT (ZERO), TO THE

MAXIMUM GAP AS CALCULATED FROM THE TOLERANCE STACK-UP PINS: TIN/LEAD 90/10 BRIGHT

AND IS NOT SUBJECT NEGATIVE TOLERANCE ACCUMULATION 2. DIMENSIONS AND VALUES IN BRACKETS ARE METRIC

3. MANUFACTURING CONTROL IS IN PLACE TO ENSURE THAT THE SPACING

BETWEEN THE MODULES LABEL SURFACE TO THE PRINTED CIRCUIT BOARD

Figure 6 — Mechanical diagram OF THE APPLICATION RANGES FROM DIRECT CONTACT (ZERO), TO THE

MAXIMUM GAP AS CALCULATED FROM THE TOLERANCE STACK-UP

AND IS NOT SUBJECT NEGATIVE TOLERANCE ACCUMULATION

INBOARD ONBOARD

INBOARD ONBOARD SOCKET SOCKET

SOLDER SOLDER MOUNT SURFACE MOUNT

MOUNT MOUNT

SOCKET SURFACE MOUNT

SHORT PIN STYLE LONG PIN STYLE

0.183 ±0.003

0.062 ±0.010 0.094 ±0.003 0.094 ±0.003 N/A

PCB THICKNESS (7X) 4,65 ±0,08

1,57 ±0,25 2,39 ±0,08 2,39 ±0,08

PLATED 0.266 ±0.003 N/A

THROUGH HOLE 0.164 ±0.003 0.164 ±0.003

1.790** (2X) 6,76 ±0,08

DIA 4,16 ±0,08 4,16 ±0,08 ALL MARKINGS

0.06 45,47 THIS SURFACE

R (4X) 0.158

1,5

4,01

1 2 3 4

1.900* 1.575**

48.26

48,26 40,00

ALUMINUM

BASEPLATE

9 8 7 6 5 PINS STYLES

SOLDER:TIN / LEAD PLATED

MODUMATE: GOLD PLATED COPPER

RoHS: GOLD PLATED COPPER

0.400* 0.46 0.56

10,16 0 43

0.45

0.45 0.53

11,7 14,2

0.700* 11,5 13,5

17,78 SOCKETS SOCKET HEADERS

0.080" DIA. PINS (7X) (SURFACE MOUNT)

1.000* P/N 13632 (100 pcs.) KIT INCLUDES

25,40 * DENOTES TOL =

±0.003 0.150" DIA. PINS (2X) INPUT & OUTPUT

0.195 1.400* ±0,08 P/N 13633 (100 pcs.) P/N 16021

4,95 35,56 ** PCB WINDOW P/N 16019 (9 pc. Kit)

Figure 7 — PCB mounting specifications

M-FIAM3 Rev 3.2

Page 5 of 6 06/2019

M-FIAM3M21

Vicor’s comprehensive line of power solutions includes high density AC-DC and DC-DC modules and

accessory components, fully configurable AC-DC and DC-DC power supplies, and complete custom

power systems.

Information furnished by Vicor is believed to be accurate and reliable. However, no responsibility is assumed by Vicor for its use. Vicor

makes no representations or warranties with respect to the accuracy or completeness of the contents of this publication. Vicor reserves

the right to make changes to any products, specifications, and product descriptions at any time without notice. Information published by

Vicor has been checked and is believed to be accurate at the time it was printed; however, Vicor assumes no responsibility for inaccuracies.

Testing and other quality controls are used to the extent Vicor deems necessary to support Vicor’s product warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

Specifications are subject to change without notice.

Visit http://www.vicorpower.com/mil-cots_dc-dc/mil-cots_m-fiam_filter_input_attenuator_module for the latest product information.

Vicor’s Standard Terms and Conditions and Product Warranty

All sales are subject to Vicor’s Standard Terms and Conditions of Sale, and Product Warranty which are available on Vicor’s webpage

(http://www.vicorpower.com/termsconditionswarranty) or upon request.

Life Support Policy

VICOR’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS WITHOUT THE

EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL COUNSEL OF VICOR CORPORATION. As used

herein, life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected to

result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness. Per Vicor Terms

and Conditions of Sale, the user of Vicor products and components in life support applications assumes all risks of such use and indemnifies

Vicor against all liability and damages.

Intellectual Property Notice

Vicor and its subsidiaries own Intellectual Property (including issued U.S. and Foreign Patents and pending patent applications) relating to the

products described in this data sheet. No license, whether express, implied, or arising by estoppel or otherwise, to any intellectual property

rights is granted by this document. Interested parties should contact Vicor’s Intellectual Property Department.

Contact Us: http://www.vicorpower.com/contact-us

Vicor Corporation

25 Frontage Road

Andover, MA, USA 01810

Tel: 800-735-6200

Fax: 978-475-6715

www.vicorpower.com

email

Customer Service: custserv@vicorpower.com

Technical Support: apps@vicorpower.com

©2019 Vicor Corporation. All rights reserved. The Vicor name is a registered trademark of Vicor Corporation.

All other trademarks, product names, logos and brands are property of their respective owners.

M-FIAM3 Rev 3.2

Page 6 of 6 06/2019

You might also like

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- PBT GF30 - Vampter 3026 V0 DFDocument1 pagePBT GF30 - Vampter 3026 V0 DFarmandoNo ratings yet

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- (N) TMCGEH3S 3x120sqmm Orange TPU JacketDocument3 pages(N) TMCGEH3S 3x120sqmm Orange TPU JacketAbl Jara MamaniNo ratings yet

- Low Pressure Transmitter in Short and Compact Design: DescriptionDocument4 pagesLow Pressure Transmitter in Short and Compact Design: DescriptionJordi AltayóNo ratings yet

- Surge Protector and Filter Specifications: Technical DataDocument16 pagesSurge Protector and Filter Specifications: Technical DataJuan Esteban Benjumea BenjumeaNo ratings yet

- I2R T2DC 500S TT - Datasheets - USDocument3 pagesI2R T2DC 500S TT - Datasheets - USabdulkawi alasharyNo ratings yet

- Cable Group ListingDocument6 pagesCable Group ListingEzhar Savero RomanNo ratings yet

- 20xx-SPECTRUM-SMP Between Series AdaptersDocument4 pages20xx-SPECTRUM-SMP Between Series Adaptersketab_doostNo ratings yet

- 364 23768 0 BLF278Document23 pages364 23768 0 BLF278MelLda UdjuNo ratings yet

- Compact SubstationDocument6 pagesCompact SubstationHafiza Sulaiman100% (1)

- Central Semiconductor Corp. Cmdsh-3trDocument5 pagesCentral Semiconductor Corp. Cmdsh-3trFaulhaber AdrianNo ratings yet

- Littelfuse SIDACtor DO 214 Datasheet PDFDocument5 pagesLittelfuse SIDACtor DO 214 Datasheet PDFdvalinaNo ratings yet

- Data Sheet lh351c Rev.13.0aDocument27 pagesData Sheet lh351c Rev.13.0aArda ErenNo ratings yet

- DatasheetDocument2 pagesDatasheetSebastian ChaileNo ratings yet

- EPCOS Switching Spark Gap, 230V Breakdown Voltage, 300A, 25Hz Max. Switching Frequency, 2000000Document4 pagesEPCOS Switching Spark Gap, 230V Breakdown Voltage, 300A, 25Hz Max. Switching Frequency, 2000000Mansoor AsifNo ratings yet

- RT Duroid 5870 5880 Data Sheet PDFDocument2 pagesRT Duroid 5870 5880 Data Sheet PDFNom MonNo ratings yet

- Specification For HV Transformer (Hyundai Heavy Industries CO., LTD.)Document32 pagesSpecification For HV Transformer (Hyundai Heavy Industries CO., LTD.)Oleksandr RakshaNo ratings yet

- Separable Connectors: Asymmetrical T-Type Connectors 630A 1250A Umax 36kVDocument3 pagesSeparable Connectors: Asymmetrical T-Type Connectors 630A 1250A Umax 36kVLizbeth Lizbeth AmesquitaNo ratings yet

- Daikin Ceiling Concealed TM FDBM 0515 CDocument111 pagesDaikin Ceiling Concealed TM FDBM 0515 CWing Hong SamNo ratings yet

- ATS400Document1 pageATS400Noel RamosNo ratings yet

- Ats400e 092406Document1 pageAts400e 092406Javier SilvaNo ratings yet

- MICRORAMDocument8 pagesMICRORAMalexanderNo ratings yet

- KR Air Cooled Screw R134a 50Hz 60Hz HPDocument110 pagesKR Air Cooled Screw R134a 50Hz 60Hz HPMaxmore KarumamupiyoNo ratings yet

- 6 Miniature Circuit Breaker (MCB)Document5 pages6 Miniature Circuit Breaker (MCB)Srini VasanNo ratings yet

- Miniature Circuit Breaker (MCB) PDFDocument5 pagesMiniature Circuit Breaker (MCB) PDFThomas CarpenterNo ratings yet

- Rain Sheds Rightangle Boots Straight BootsDocument2 pagesRain Sheds Rightangle Boots Straight BootsEhab Abd-allaNo ratings yet

- Circuit BreakersDocument60 pagesCircuit Breakerslian tineoNo ratings yet

- Vampamid 6 0024 V0Document1 pageVampamid 6 0024 V0Plasticos CusenNo ratings yet

- Crouse Hinds MTL Zonebarrier Telecom Catalog PageDocument2 pagesCrouse Hinds MTL Zonebarrier Telecom Catalog PageSaraiNo ratings yet

- Subminiature Fuse, 8.5 MM, Time-Lag T, 250 VAC, 63 VDCDocument5 pagesSubminiature Fuse, 8.5 MM, Time-Lag T, 250 VAC, 63 VDCMohammed Qaid AlathwaryNo ratings yet

- Littelfuse SIDACtor PxxxxS4xLRP Datasheet pdf-1623197Document5 pagesLittelfuse SIDACtor PxxxxS4xLRP Datasheet pdf-1623197chawkigenieNo ratings yet

- B170/B - B1100/B: 1.0A High Voltage Schottky Barrier RectifierDocument6 pagesB170/B - B1100/B: 1.0A High Voltage Schottky Barrier RectifierRandi Eka PutraNo ratings yet

- MMBT3904LT1DB - General Purpose TransistorDocument9 pagesMMBT3904LT1DB - General Purpose Transistorpratul.goyalNo ratings yet

- Multimetals Presentation On Annealing and PicklingDocument31 pagesMultimetals Presentation On Annealing and Picklingvishesh_vijayNo ratings yet

- Ab Cable GTPDocument17 pagesAb Cable GTPNaresh Ch MahapatraNo ratings yet

- Vishay Siliconix: Product SummaryDocument5 pagesVishay Siliconix: Product SummarySantiago SerranoNo ratings yet

- D-4 Design of Module Mounting Structure & Civil Works: Technical SpecificationsDocument4 pagesD-4 Design of Module Mounting Structure & Civil Works: Technical SpecificationsAshish VajirNo ratings yet

- JS4BD-KB Series: Technical SpecificationsDocument12 pagesJS4BD-KB Series: Technical SpecificationsKokoNo ratings yet

- 783 y AdaptorDocument1 page783 y AdaptorDavide GuerreiroNo ratings yet

- SMAJ5.0 (C) A - SMAJ170 (C) A: 400W Surface Mount Transient Voltage Suppressor FeaturesDocument4 pagesSMAJ5.0 (C) A - SMAJ170 (C) A: 400W Surface Mount Transient Voltage Suppressor Featuresedi purwantoNo ratings yet

- HTR India - Products - Wire Wound Resistors - Silicone Coated Resistors - HIP (English)Document3 pagesHTR India - Products - Wire Wound Resistors - Silicone Coated Resistors - HIP (English)crplzNo ratings yet

- Icme - Technical Quotatti̇onDocument5 pagesIcme - Technical Quotatti̇onSHIBANY01No ratings yet

- SMBJ 1Document8 pagesSMBJ 1Omar MelchorNo ratings yet

- Features: Unregulated ConvertersDocument7 pagesFeatures: Unregulated ConvertersBinuNo ratings yet

- J0231 LV TR - FINAL变压器2Document21 pagesJ0231 LV TR - FINAL变压器2SerhiiNo ratings yet

- 1LE1503-1DB21-7AB4-Z B02+D22+L22+Y82 Datasheet enDocument2 pages1LE1503-1DB21-7AB4-Z B02+D22+L22+Y82 Datasheet enMostafaElrakhawyNo ratings yet

- Cat MecalbiDocument27 pagesCat MecalbiAhmed BenmimounNo ratings yet

- Silicon 5 Watt Zener Diodes: 1N5333B Thru 1N5388BDocument5 pagesSilicon 5 Watt Zener Diodes: 1N5333B Thru 1N5388Bameer_jaburNo ratings yet

- RT Duroid 5870 5880 Data SheetDocument2 pagesRT Duroid 5870 5880 Data SheetAnonymous zBSE9MNo ratings yet

- 1LE1503-2AA43-4AA4 Datasheet enDocument1 page1LE1503-2AA43-4AA4 Datasheet enAndrei LupuNo ratings yet

- cMT-G03 Datasheet ENG PDFDocument2 pagescMT-G03 Datasheet ENG PDFAshutosh Vivek ParabNo ratings yet

- We en Web in Ar Sic Mosfet 1638931895460Document29 pagesWe en Web in Ar Sic Mosfet 1638931895460Алексей ЯмаNo ratings yet

- Diode TVS Codes SMAJ5.0CA-SMAJ200CADocument6 pagesDiode TVS Codes SMAJ5.0CA-SMAJ200CAAntónio AzevedoNo ratings yet

- 5SY Siemens Miniature CircuitDocument5 pages5SY Siemens Miniature Circuitm.hatemNo ratings yet

- Fuse T250ma 250 MST - 250Document4 pagesFuse T250ma 250 MST - 250JULIO DOMINGUEZNo ratings yet

- Dmn66D0Ldw Product Summary Features and Benefits: Dual N-Channel Enhancement Mode MosfetDocument6 pagesDmn66D0Ldw Product Summary Features and Benefits: Dual N-Channel Enhancement Mode Mosfetzigmund zigmundNo ratings yet

- Float Operated Level TransmttersDocument29 pagesFloat Operated Level TransmttersBatsha PonnusamyNo ratings yet

- HT Cable Termination Kit 14.3.22Document8 pagesHT Cable Termination Kit 14.3.22JIGSNo ratings yet

- IM-TD Series: D1/C1/C2/C3 Data/Signal Lines Protection - SPD With Overcurrent ProtectionDocument2 pagesIM-TD Series: D1/C1/C2/C3 Data/Signal Lines Protection - SPD With Overcurrent ProtectionAnonymous Cpe6vcNo ratings yet

- Bcci ScandalDocument6 pagesBcci ScandalNausaf AhmedNo ratings yet

- Chinese Paper Cutting Work SheetDocument4 pagesChinese Paper Cutting Work Sheet黃梓No ratings yet

- Ilocos Norte Youth Development Office Accomplishment Report 2Document17 pagesIlocos Norte Youth Development Office Accomplishment Report 2Solsona Natl HS MaanantengNo ratings yet

- Aditya Birla GroupDocument21 pagesAditya Birla GroupNarendra ThummarNo ratings yet

- EdisDocument227 pagesEdisThong Chan100% (1)

- Computer Class 3 ThirdDocument1 pageComputer Class 3 ThirdbeakraamNo ratings yet

- Vemu Institute of Technology: Department of Computer Science & EngineeringDocument79 pagesVemu Institute of Technology: Department of Computer Science & EngineeringSiva SankarNo ratings yet

- Case Study Single Sign On Solution Implementation Software Luxoft For Ping IdentityDocument5 pagesCase Study Single Sign On Solution Implementation Software Luxoft For Ping IdentityluxoftNo ratings yet

- A Medium-Rise Residential Building: A B C E D F G HDocument3 pagesA Medium-Rise Residential Building: A B C E D F G HBabyjhaneTanItmanNo ratings yet

- Kapinga Kamwalye Conservancy ReleaseDocument5 pagesKapinga Kamwalye Conservancy ReleaseRob ParkerNo ratings yet

- Grade 9 Science Biology 1 DLPDocument13 pagesGrade 9 Science Biology 1 DLPManongdo AllanNo ratings yet

- Project Document EiDocument66 pagesProject Document EiPrathap ReddyNo ratings yet

- Business-Communication Solved MCQs (Set-3)Document8 pagesBusiness-Communication Solved MCQs (Set-3)Pavan Sai Krishna KottiNo ratings yet

- What Is Universe?Document19 pagesWhat Is Universe?Ruben M. VerdidaNo ratings yet

- Report FinalDocument48 pagesReport FinalSantosh ChaudharyNo ratings yet

- DMIT - Midbrain - DMIT SoftwareDocument16 pagesDMIT - Midbrain - DMIT SoftwarevinNo ratings yet

- Trade MarkDocument2 pagesTrade MarkRohit ThoratNo ratings yet

- Haier in India Building Presence in A Mass Market Beyond ChinaDocument14 pagesHaier in India Building Presence in A Mass Market Beyond ChinaGaurav Sharma100% (1)

- BS 7974 2019Document68 pagesBS 7974 2019bcyt00No ratings yet

- Dreaded Attack - Voyages Community Map Rules v1Document2 pagesDreaded Attack - Voyages Community Map Rules v1jNo ratings yet

- Dec JanDocument6 pagesDec Janmadhujayan100% (1)

- Maritta Koch-Weser, Scott Guggenheim - Social Development in The World Bank - Essays in Honor of Michael M. Cernea-Springer (2021)Document374 pagesMaritta Koch-Weser, Scott Guggenheim - Social Development in The World Bank - Essays in Honor of Michael M. Cernea-Springer (2021)IacobNo ratings yet

- Measuring Temperature - Platinum Resistance ThermometersDocument3 pagesMeasuring Temperature - Platinum Resistance Thermometersdark*nightNo ratings yet

- Lesson Plan For Implementing NETSDocument5 pagesLesson Plan For Implementing NETSLisa PizzutoNo ratings yet

- BSBITU314 Assessment Workbook FIllableDocument51 pagesBSBITU314 Assessment Workbook FIllableAryan SinglaNo ratings yet

- Bba VDocument2 pagesBba VkunalbrabbitNo ratings yet

- National Football League FRC 2000 Sol SRGBDocument33 pagesNational Football League FRC 2000 Sol SRGBMick StukesNo ratings yet

- 2 To 20 Years - Girls Stature-For-Age and Weight-For-Age PercentilesDocument1 page2 To 20 Years - Girls Stature-For-Age and Weight-For-Age PercentilesRajalakshmi Vengadasamy0% (1)

- Gaming Ports MikrotikDocument6 pagesGaming Ports MikrotikRay OhmsNo ratings yet

- Angle Grinder Gws 7 100 06013880f0Document128 pagesAngle Grinder Gws 7 100 06013880f0Kartik ParmeshwaranNo ratings yet