Professional Documents

Culture Documents

Vapour Recovery From Storage Tanks

Uploaded by

Jatin Rambo0 ratings0% found this document useful (0 votes)

207 views3 pagesOriginal Title

Vapour Recovery from Storage Tanks

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

207 views3 pagesVapour Recovery From Storage Tanks

Uploaded by

Jatin RamboCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Vapour Recovery from Storage Tanks

Dr. Vikas Mahto

Professor

Department of Petroleum Engineering

IIT(ISM), Dhanbad-826004

The hydrocarbon losses in storage tanks are identified as follows:

Working losses

(a) Filling

(b) Emptying

Other losses

(a) Breathing

(b) Standing

(c) Boiling

Filling losses occur when vapors are expelled from a tank as it is filled, no matter how the

vapors are produced. This loss occurs when the pressure inside the tank exceeds the relief-valve

pressure. For API tanks, the relief pressure is low and, therefore, filling losses can be relatively

high.

Emptying losses are experienced by the vapors that are expelled from a tank after the liquid is

removed from it. Because vaporization lags behind the expansion of the vapor space during

withdrawal, the partial pressure of a hydrocarbon vapor drops. Enough air enters during the

withdrawal to maintain the total pressure at the barometric value. However, when vaporization

into the new air reaches equilibrium, the increase in the vapor volume will cause some vapor

expansion.

Breathing losses occur when vapors are expelled from a tank under one of the following

conditions:

1. The thermal expansion of the existing vapors

2. An expansion caused by barometric pressure changes

3. An increase in the amount of vapors from added vaporization in the absence of a liquid level

change

Breathing losses take place in most types of tanks and occurs when the tank’s limits of pressure

or volume changes are exceeded.

The fixed-roof API type tanks used to store stock tank oil are designed for only for a few inches

of water pressure or vacuum and suffer relatively large breathing losses.

Standing losses are losses of vapor which result from causes other than breathing or a change in

liquid level in tanks. Sources of standing losses are vapor escape from hatches or other openings

and from glands, valves, and fittings.

Boiling losses occur when liquid boils in a tank and vapors are expelled. In other words, the

vapor pressure of the liquid exceeds the surrounding pressure.

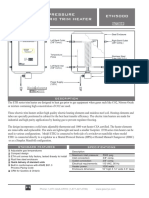

Vapour Recovery Unit

A vapor recovery unit (VRU) is a specialized compression package designed specifically to

capture low pressure, wet gas streams from oil and condensate storage tanks

Figure 1 illustrates a VRU installed on a single crude oil storage tank (multiple tank installations

are also common). Hydrocarbon vapors are drawn out of the storage (stock) tank under low-

pressure, typically between four ounces and two psi, and are first piped to a separator (suction

scrubber) to collect any liquids that condense out. The liquids are usually recycled back to the

storage tank. From the separator, the vapors flow through a compressor that provides the low-

pressure suction for the VRU system.(To prevent the creation of a vacuum in the top of a tank

when oil is withdrawn and the oil level drops, VRUs are equipped with a control pilot to shut

down the compressor and permit the back flow of vapors into the tank.) The vapors are then

metered and removed from the VRU system for pipeline sale or onsite fuel supply.

Figure 1: Vapour Recovery Unit

You might also like

- Ejector Vapour Recovery UnitDocument4 pagesEjector Vapour Recovery UnitMuhammad ImranNo ratings yet

- Evidya Oisd144Document60 pagesEvidya Oisd144shahezad yemenNo ratings yet

- Sheet 01 of 03 D03 1327804 A3 059-PD-B-044127 N/A 4JSG000001P6437Document3 pagesSheet 01 of 03 D03 1327804 A3 059-PD-B-044127 N/A 4JSG000001P6437abdulkidwai2009No ratings yet

- 4 Fire & Gas Detection System: Type of Detector LocationDocument3 pages4 Fire & Gas Detection System: Type of Detector LocationBikas SahaNo ratings yet

- JP CO2, FM-200 & Fire Alarm SystemDocument9 pagesJP CO2, FM-200 & Fire Alarm SystemL KISHORE REDDYNo ratings yet

- BBS-10-W8-DS-006 - C - Glycol Charcoal Filter DS PDFDocument1 pageBBS-10-W8-DS-006 - C - Glycol Charcoal Filter DS PDFAdianto RahmanNo ratings yet

- Heating and Cooling Generation and Distribution Systems: Central Vs Decentralized SystemsDocument15 pagesHeating and Cooling Generation and Distribution Systems: Central Vs Decentralized SystemsRakesh RanjanNo ratings yet

- On-Off Valve DatasheetDocument80 pagesOn-Off Valve Datasheetssmith2007No ratings yet

- AFS, KanpurDocument5 pagesAFS, Kanpurdipmoip2210No ratings yet

- OSP054-PR-REP-14606-Rev.7 - WASCO Firefighting System Hydraulic Calculation ReportDocument131 pagesOSP054-PR-REP-14606-Rev.7 - WASCO Firefighting System Hydraulic Calculation ReportEslam Shibl100% (1)

- Cqs Epr Ts Gen PHL 001 Rev 3.0Document25 pagesCqs Epr Ts Gen PHL 001 Rev 3.0Atty AttyNo ratings yet

- Hook Ups PDFDocument8 pagesHook Ups PDFAnonymous d7Jde8No ratings yet

- GM479-R0731-000-PR-RP-0003 - 2-Esd PhilosophyDocument19 pagesGM479-R0731-000-PR-RP-0003 - 2-Esd PhilosophySuper 7No ratings yet

- PVRVDocument4 pagesPVRVbkkbrazil100% (1)

- Desmoke System p.155-173Document19 pagesDesmoke System p.155-173Just RysdanNo ratings yet

- 7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksDocument2 pages7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksJatin Vadhera VCSPNo ratings yet

- Instructions: Landing Loss EmissionsDocument15 pagesInstructions: Landing Loss Emissionssunildubey02No ratings yet

- Operative Instruction - Shut Down 16 June 2016Document8 pagesOperative Instruction - Shut Down 16 June 2016Lokmane YellouNo ratings yet

- ANNEXURE For HVW SPRAY SYSTEM - StandardDocument1 pageANNEXURE For HVW SPRAY SYSTEM - StandardVaibhav SawantNo ratings yet

- Pump Station Sample PagesDocument5 pagesPump Station Sample PagesHedi Ben MohamedNo ratings yet

- 2 - Water System - 44-64 PDFDocument21 pages2 - Water System - 44-64 PDFAniesh MahajanNo ratings yet

- Aviation Refuelling Equipment CatalogueDocument180 pagesAviation Refuelling Equipment Catalogueviktor_gligorovNo ratings yet

- 6-66 KV SF6 BKR R3 May12Document26 pages6-66 KV SF6 BKR R3 May12PB MehtaNo ratings yet

- IG 55 CalculationDocument11 pagesIG 55 CalculationNoridhamNo ratings yet

- MMB LPG Engineering ProposalDocument52 pagesMMB LPG Engineering ProposalKamalakar SastryNo ratings yet

- Project Standard Specification: Potable-Water Storage Tanks 15450 - Page 1/12Document12 pagesProject Standard Specification: Potable-Water Storage Tanks 15450 - Page 1/12adel rihanaNo ratings yet

- QR 1008 Fire Pump JockeyDocument1 pageQR 1008 Fire Pump JockeyLéandre Ettekri NdriNo ratings yet

- Pressure Releaving StationDocument11 pagesPressure Releaving StationSreejesh Sundaresan100% (1)

- OMV E&P Philosophy: TitleDocument29 pagesOMV E&P Philosophy: TitleamdatiNo ratings yet

- Functional Design Specifications: CX-140507-FDS-001 0 24-Sep-2014 Ref #: Rev #: DateDocument44 pagesFunctional Design Specifications: CX-140507-FDS-001 0 24-Sep-2014 Ref #: Rev #: Datewqs_19No ratings yet

- Annex1 Hydraulic Calculation of The Sewer NetworkDocument17 pagesAnnex1 Hydraulic Calculation of The Sewer NetworkmuthunayakeNo ratings yet

- Uipl FPS Boq T1Document11 pagesUipl FPS Boq T1Sashikumar NarayanakurupNo ratings yet

- Project Name: Standpipe & Hose System of Norban Comtex LTD Area Reference: Most UnfavourableDocument4 pagesProject Name: Standpipe & Hose System of Norban Comtex LTD Area Reference: Most UnfavourablerashalNo ratings yet

- Cryogenic Refrigeration Cycle For Re-Liquefaction of LNG Boil-Off GasDocument74 pagesCryogenic Refrigeration Cycle For Re-Liquefaction of LNG Boil-Off Gasعبد الحق قنيشNo ratings yet

- Dr. Asit Patra-Dmi - CraDocument53 pagesDr. Asit Patra-Dmi - CraWRGWSRNo ratings yet

- N2 Regulator and Gauges DatasheetDocument4 pagesN2 Regulator and Gauges DatasheetpavanNo ratings yet

- Ipmg B SF DSH 1005 03Document5 pagesIpmg B SF DSH 1005 03sgh1355No ratings yet

- Vendor Data Book For Helideck Fixed Foam System (ABS Approved)Document53 pagesVendor Data Book For Helideck Fixed Foam System (ABS Approved)VAN VIET NGONo ratings yet

- Civil Document List: No Document Number Document Title Status DataDocument12 pagesCivil Document List: No Document Number Document Title Status DataMuhammad ZaidNo ratings yet

- DBR of Luminous HosurDocument81 pagesDBR of Luminous HosurrajaNo ratings yet

- 04 Hamworthy - Stein ThorsagerDocument38 pages04 Hamworthy - Stein ThorsagerRoozbeh PNo ratings yet

- QIPP-MPN012-J00-0101 Rev0 Instrument Hook Up DrawingDocument20 pagesQIPP-MPN012-J00-0101 Rev0 Instrument Hook Up DrawingWidhi ImranovichNo ratings yet

- ENGINEERING DESIGN GUIDELINES Instrumentation Selection Sizing Rev4.3webDocument20 pagesENGINEERING DESIGN GUIDELINES Instrumentation Selection Sizing Rev4.3webantonioherediaNo ratings yet

- 66 Specific Training Offerings - by Krest Vbprakashcvmar20Document19 pages66 Specific Training Offerings - by Krest Vbprakashcvmar20Raja GaramNo ratings yet

- PH Analyser Manual PH-13-SDocument22 pagesPH Analyser Manual PH-13-SSunil Chouhan100% (1)

- Condensate Storage Tank (Bang-T-050A/B)Document3 pagesCondensate Storage Tank (Bang-T-050A/B)john smithNo ratings yet

- Positioner SpecsDocument1 pagePositioner Specsbiswasdipankar05No ratings yet

- Foam Calculation Sample From ForumDocument2 pagesFoam Calculation Sample From Forumika524No ratings yet

- Most Economical Tank Height Diameter RatioDocument3 pagesMost Economical Tank Height Diameter RatioWei RongNo ratings yet

- Trim Heater PDFDocument2 pagesTrim Heater PDFsaadashfaq100% (1)

- FW Pump Suction & Discharge Cal PDFDocument2 pagesFW Pump Suction & Discharge Cal PDFkisan singh100% (1)

- IPS-MBD21907-In-506 - Datasheet of Pressure Transmitter - ADocument7 pagesIPS-MBD21907-In-506 - Datasheet of Pressure Transmitter - ANikhil KarkeraNo ratings yet

- Comments Resolution Sheet Against Comments Given by Bureau Veritas - GEC ReplyDocument2 pagesComments Resolution Sheet Against Comments Given by Bureau Veritas - GEC ReplybecpavanNo ratings yet

- 01 - Utility Consumption PDFDocument6 pages01 - Utility Consumption PDFVinod Varadan SNo ratings yet

- Datasheet Floating Roof Tanks Spill Prevention Level Switch SXRLTX A Series1 EnglishDocument4 pagesDatasheet Floating Roof Tanks Spill Prevention Level Switch SXRLTX A Series1 EnglishDylan RamasamyNo ratings yet

- Data Sheet For Cable Glands and LugsDocument8 pagesData Sheet For Cable Glands and LugsBasabRajNo ratings yet

- Sensepoint XCD TechMan MAN0873 Iss8 0913 EMEAIDocument84 pagesSensepoint XCD TechMan MAN0873 Iss8 0913 EMEAImusajcNo ratings yet

- Solenoid Valve - Which Insulation ClassDocument2 pagesSolenoid Valve - Which Insulation ClassMohd Firdaus100% (2)

- HANSA Operations Manual V3Document43 pagesHANSA Operations Manual V3HANSA blogNo ratings yet

- Arab Oil Naturalgas - Com Crude Oil Storage TanksDocument3 pagesArab Oil Naturalgas - Com Crude Oil Storage TanksWael_Barakat_31790% (1)

- Horizontal and Vertical Heater TreatersDocument4 pagesHorizontal and Vertical Heater TreatersJatin RamboNo ratings yet

- Basic Concepts and Example Problems On Hydraulic FracturingDocument4 pagesBasic Concepts and Example Problems On Hydraulic FracturingJatin RamboNo ratings yet

- Hazardous Area ClassificationDocument3 pagesHazardous Area ClassificationJatin RamboNo ratings yet

- Acid FracturingDocument7 pagesAcid FracturingJatin RamboNo ratings yet

- Gathering and Collection of Oil and Gas DDocument5 pagesGathering and Collection of Oil and Gas DJatin Rambo100% (1)

- Crude Oil Storage TanksDocument7 pagesCrude Oil Storage TanksJatin RamboNo ratings yet

- Hydraulic Fracturing Design Procedure Using PKN ModelDocument3 pagesHydraulic Fracturing Design Procedure Using PKN ModelJatin RamboNo ratings yet

- Concept of Cash Flow AnalysisDocument4 pagesConcept of Cash Flow AnalysisJatin RamboNo ratings yet

- Three Phase SeparatorsDocument6 pagesThree Phase SeparatorsJatin RamboNo ratings yet

- Connections and Operations of Tank BatteriesDocument4 pagesConnections and Operations of Tank BatteriesJatin RamboNo ratings yet

- Operation and Maintenance Considerations For Oil and Gas SeparatorsDocument2 pagesOperation and Maintenance Considerations For Oil and Gas SeparatorsJatin RamboNo ratings yet

- Types of Samples and Sampling ProcedureDocument3 pagesTypes of Samples and Sampling ProcedureJatin RamboNo ratings yet

- Stiffening Rings For Fixed Roof and Floating Roof TanksDocument4 pagesStiffening Rings For Fixed Roof and Floating Roof TanksJatin RamboNo ratings yet

- Sizing of Two Phase Vertical SeparatorDocument3 pagesSizing of Two Phase Vertical SeparatorJatin RamboNo ratings yet

- Tank GaugingDocument10 pagesTank GaugingJatin RamboNo ratings yet

- Turbine Flow MeterDocument3 pagesTurbine Flow MeterJatin RamboNo ratings yet

- Classification of Petroleum Liquids and Recommended Storage TanksDocument1 pageClassification of Petroleum Liquids and Recommended Storage TanksJatin RamboNo ratings yet

- Analysis of Surface Gathering SystemsDocument7 pagesAnalysis of Surface Gathering SystemsJatin RamboNo ratings yet

- 1 Legendre EquationDocument3 pages1 Legendre EquationJatin RamboNo ratings yet

- Determination of Thickness of Shell Courses For Storage Tanks Using One Foot MethodDocument5 pagesDetermination of Thickness of Shell Courses For Storage Tanks Using One Foot MethodJatin Rambo100% (1)

- Ultrasonic Flow MetersDocument4 pagesUltrasonic Flow MetersJatin RamboNo ratings yet

- Crude Oil Dehydration and DesaltingDocument4 pagesCrude Oil Dehydration and DesaltingJatin Rambo100% (1)

- Answers Membrane DeflectionDocument1 pageAnswers Membrane DeflectionJatin RamboNo ratings yet

- Solutions of ResDocument1 pageSolutions of ResJatin RamboNo ratings yet

- Numeical Solution On Equation of State of Highwr OrderDocument3 pagesNumeical Solution On Equation of State of Highwr OrderJatin RamboNo ratings yet

- Reservoir Fluid Thermodynamics Assignment On Numerical For BHFP and SBHPDocument3 pagesReservoir Fluid Thermodynamics Assignment On Numerical For BHFP and SBHPJatin RamboNo ratings yet

- Methods of Applied Mathematics-II: M L+M L M L M M L M M LDocument2 pagesMethods of Applied Mathematics-II: M L+M L M L M M L M M LJatin RamboNo ratings yet

- 1 Legendre EquationDocument3 pages1 Legendre EquationJatin RamboNo ratings yet

- Assignment On Advanced Reservoir Function and AnalysisDocument4 pagesAssignment On Advanced Reservoir Function and AnalysisJatin RamboNo ratings yet

- Offshore - Introduction LayoutDocument131 pagesOffshore - Introduction LayoutgeorgiadisgNo ratings yet

- 04 Vertical Roller MillsDocument12 pages04 Vertical Roller MillsaktaserdincNo ratings yet

- SPE-173598-MS A Simplified Approach To Sizing 2 and 3 Phase Separators PDFDocument21 pagesSPE-173598-MS A Simplified Approach To Sizing 2 and 3 Phase Separators PDFRicardo VargasNo ratings yet

- 80441454en Compresor NirvDocument47 pages80441454en Compresor NirvHector CastellanosNo ratings yet

- Sampling & Analysis in Oil and Gas IndustryDocument12 pagesSampling & Analysis in Oil and Gas IndustryNizar AliNo ratings yet

- MbalDocument69 pagesMbalAnthony GallardoNo ratings yet

- Classification of Reservoirs-Tarek - Ahmed - Equation - of - State - PVT - AnalysisDocument14 pagesClassification of Reservoirs-Tarek - Ahmed - Equation - of - State - PVT - AnalysisDEISA YANIANY DUSSAN RAMIREZNo ratings yet

- Process Optimisation in Sunower Oil Extraction by Supercritical CO2Document12 pagesProcess Optimisation in Sunower Oil Extraction by Supercritical CO2Davide Di ZioNo ratings yet

- Gas Liquid Separators Quantifying Separation Performance Part 1 PDFDocument11 pagesGas Liquid Separators Quantifying Separation Performance Part 1 PDFEduardo BenalcazarNo ratings yet

- Well Test Procedures ManualDocument103 pagesWell Test Procedures ManualDonaldNo ratings yet

- 10 - Filter ElementsDocument6 pages10 - Filter ElementsAalap DerasaryNo ratings yet

- Oil Separator Working PrincipleDocument2 pagesOil Separator Working PrincipleRajapandian Balan100% (1)

- Oily Water SeperatorDocument18 pagesOily Water SeperatorNiksa Kusijanovic100% (1)

- ULTISEP Element Specification Sheet - GCA5536K10VDocument2 pagesULTISEP Element Specification Sheet - GCA5536K10Vaditya sigitNo ratings yet

- Facet Bilge Water Separator CPS B MKIII & EBM14xDocument105 pagesFacet Bilge Water Separator CPS B MKIII & EBM14xLe Hoang75% (4)

- BalClor BWMS Trouble ShootingDocument41 pagesBalClor BWMS Trouble ShootingIgor Doroshchuk67% (6)

- Westfalia Separator MSD 90-01-076Document68 pagesWestfalia Separator MSD 90-01-076YounessAnas33% (3)

- Chapter 9Document41 pagesChapter 9Mahrouz MadoNo ratings yet

- Dynamic Simulator Predicts Gas Lift Well InstabilityDocument2 pagesDynamic Simulator Predicts Gas Lift Well InstabilityStélio SalatielNo ratings yet

- Manual Alfa LavalDocument95 pagesManual Alfa Lavalstopless_dalian685100% (8)

- Prodem Chapter 7 Gas Dehydration: Presented By: Rr. Sri Hastiyatisatiyah Ecp/Pro April 13th, 2015Document64 pagesProdem Chapter 7 Gas Dehydration: Presented By: Rr. Sri Hastiyatisatiyah Ecp/Pro April 13th, 2015andi dipayadnya100% (1)

- 3 - SVM Process Flow Chart HACCPDocument3 pages3 - SVM Process Flow Chart HACCPc.ramNo ratings yet

- OLGA Sample CasesDocument134 pagesOLGA Sample CasesRoberto Caceres0% (1)

- 2.separator ManualDocument198 pages2.separator Manualidigiti100% (1)

- Halliburton Surface Well Testing BrochureDocument9 pagesHalliburton Surface Well Testing BrochureValee kienNo ratings yet

- Jurutera June2012Document34 pagesJurutera June2012Ariffin NgahNo ratings yet

- PVT Experiments: Separator Test: by Admin 13 October 2017Document2 pagesPVT Experiments: Separator Test: by Admin 13 October 2017saeed0% (1)

- Piping Geometry - Grasp Line LayoutDocument7 pagesPiping Geometry - Grasp Line LayoutdzungNo ratings yet

- Petronas Technical Standards: Pts Publications and Standard SpecificationsDocument38 pagesPetronas Technical Standards: Pts Publications and Standard SpecificationsadamNo ratings yet