Professional Documents

Culture Documents

18.5 MLD

Uploaded by

Mohit Chauhan0 ratings0% found this document useful (0 votes)

92 views26 pagesTender draft document for 18.5 MLD CETP

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTender draft document for 18.5 MLD CETP

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

92 views26 pages18.5 MLD

Uploaded by

Mohit ChauhanTender draft document for 18.5 MLD CETP

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 26

‘Water & Wastewater Treatment

AUsTR Experts in Textile ZLD Projects

PROJECT PROPOSAL FOR

ALKALINE EFFLUENT TREATMENT PLANT

(ETP)

SUBMITTED TO

M/S JODHPUR COMMON EFFLUENT TREATEMENT PLANT,

JODHPUR, RAJASTHAN.

CAPACITY: 18.5 ML PER DAY

L FOR ALKALINE EFFLUENT.

BY

Ref: ACBTPL/JCETP/ETP/QTN-5/2018 Date: 21.01.2019

"AUSTRO CHEMICALS AND BIO-TECHNOLOGIES PVT LTD.

SF No.158/1B, SSM Dyeing Premises

Murugampalayam, Iduvampalayam Post, Tirupur ~ 641687.

Mobile No: +91 98430 33140,

AuSTRO Pm: wddawstrowatrtshcon,sles@astrowaterishsom,

Confidential

VAL AUSTRO CHEMICALS & BIOTECHNOLOGIES PVT LTD 23-01-2019

IWARAN TRUST —

ABREVIATIONS AND.

& Water & Wastewat

RO Experts in Tex

i(OTATIONS

1. TDS : Total Dissolved Solids

2. TSS : Total Suspended solids

3, COD ‘hemical Oxygen demand

4, BOD : Biological Oxygen demand

5. TH : Total Hardness

6. CRP : Colour Removal Poly

7. PAC : Poly Aluminum Chloride

8. Poly : Poly Electrolyte

9. Mei : Milligram per Liter

10.F.B Free Board

IL. RCC Reinforced Cement Concrete

12. HP Horse Power

Xe 13. LPH Liter Per Hour

14, Cuam/hr. : Metric Cube per Hour

15. EPDM : Ethylene Propylene Diene Monomer

16. VFD. : Variable Frequency Drive

17. Mwe_ + Mean water Column

18. Dia : Diameter

19. W : Working,

20.8 + Standby

21.MOC : Material of Construction

22. BIF Valve : Butterfly Valve

(23.MS : Mild Steel

24. SS : Stainless Steel

25, FRP Fibre reinforced polymer

26.DO ved Oxygen

27. Temp ‘Temperature

Xv 28, Eqt + Equivalent

29. HOS : Height on Straight

DUFUR PRADUSHAN NIWARAN TRUST

Grea \ a

Confdetiat

V0

AUSTRO CHEMICALS & BIOTECHNOLOGIES PVT LTD

23-01-2019

a Water & Wastewater Treatment

Experts in Textile ZLD Projects

v0

Motor Detail

GAS CHLORINATION SYSTEM:

Description

Specification

1 Lot

Pedestal Mounted Evaporator type

injector system 1 Set

Diffuser Scrub — One side 1No

‘Makeup water line with valves and fittings and att

instruments

Motive water lines with valves, fittings and fio

Instruments,

Booster pump with necessary BSP connected

aa 1 Set

Pressure relief valves, Hoods, Rails, Distribution

7 1 Lot

kit, control valves.

Chlorine solution line with fittings and Fat

accessories

Chlorine leakage detector with display unit and

2Nos

Single Sensor.

Air Breathing apparatus with safety mask 1No

Emergency repair Kit type B for 900 Kgs a

Cylinder.

‘Yoke and cylinder holding accessories,

supporting rollers for3 cylinders, Clamping for Lot

chlorine line and other water flow lines.

Pressure gauges and Copper tubes for Chlorine Te

inlet lines and delivery lines to Chlorine injector.

(CHEMICAL PREPERATION AGITATORS:

Deseription Specification

Quantity 2Nos

Application CRP & Poly

MOC of Agitators Cast Iron

Speed Ratio 25:1

‘Mechanism ‘Worm Reduction Right Angled shaft

Drive Model D337

Confidential

AUSTRO CHEMICALS & BIOTECHNOLOGIES PVT LTD

11 KW @ 415 V, 50 Hz

NIWARAN

23-01-2019

BUS

Be Coe

& Wastewater Treatment

Experts in Textile ZLD Projects

Centrifugal Type, Horizontal

Type

Make Johnson/Eat

Model CN Series Pump

Power Rating 90.00 KW @ 415 V, 50 Hz

BSP Connection Suction 200 mm, Delivery 160 mm

BSP End Flanged End

MOC of Motor Housing Cast Iron

MOC of Rotating Shaft 17% Chrome Steel

Mechanical Seal Stainless Steel/ Ceramic

Impeller Cast Iron

Maximum capacity 1000 Cum/he

Maximum Head 30 Mtr

\ Maximum Liquid te

“Temperature

Maximum Operating Pressure 16 Bar (800 KPa)

Maximum Speed 2900 rpm

+ Suitable for a wide span of duties * Large hydraulic

field of application + High interchangeability in spare

parts between diferent sizes, thus limiting spare parts

stock levels « Suitable for various liquids, thanks to the

aan oe large number of standard and non-standard. material

Dee options + Simple maintenance thanks to the use of

standard components and the Back-Pull-Out principle

applied + Flexible choice in bearings and shaft seal

modules + The entire pump family features only four

bearing bracket groups

“The Combi Norm is a part of the Combi System, a

( amily of different pump types having a high

interchangeabilty in parts. The Combi Norm, designed

as to EN 733 (DIN 24255), offers a great variety in

Se materials, shaft seals and bearing systems. Its modular

design offers a high interchangeability between the

variants, Hence, a Combi Norm is available to handle

most pump duties.

‘VED Control Danfoss/Schneider Equivalent

Confidential

ODHPUR

AUSTRO CHEMICALS & BIOTECHNOLOGIES PVT LTD

NV NIWARAN TRUST

ieee

Tnstee | Teste

23-01-2019

t0sTRO

& Water & Wastewater Treatment

Experts in Textile ZLD Projects

MOC of Stier Stainless steel 304

BSP Connection of Joining

Ey 40Nb

Leaf Angle 120 Deg between two spans

Make Astro

DOSING PUMP AT DISCHARGE POT

Description Specification

Quantity 1No

Flow rate 1800 Liters/Hour @ 4 Kg Pressure.

Type Centrifugal/Plunger

Moc pp

Air Inet (Female): woe

bs Fluid InlevOutlet Hybrid wae

Max. operating pressure psi 7

oe 100 Psi-7 kg

Suspended solids max. di ain

inanmy

‘Maximum dry suction lift

15 (4

aa 46)

eee annua Ee 037-0.55 KW

Pump

ELECTRICAL PANEL BOARD:

Description Specification

Quantity No

Type P54

MOC of Enclosure MS with Powder Coated

Relays & Controls. LATICES

Control Drives L&TICRS

Panel Make Austro

PIPELINE FITTINGS:

Description Specification

Quantity Lot

MOC of Pipe Line and Too! Ms/cvpvc

Bits

Confidenial

v0 AUSTRO CHEMICALS & BIOTECHNOLOGIES PVT LTD 23-01-2019

DDHPUR PRADUSYAN NIWARAN TRUST

aS sm Ul

in, Trustee | Ezeeutve Trust

a7 eS

sUSTRO

ot Freel

Water & Wastewater Treatment ) E

Experts in Textile ZLD Projects "ya ne

1, INTRODUCTION:

‘We Mis. Austro Chemicals and Bio-Technologies Pvt Ltd, Tirupur supplied more than 300

‘Treatment plants in Tamil Nadu, Kamataka, Kerala, Andra Pradesh, Ethiopia and Indonesia

including design, engineering, erection and commissioning. More than 100 projects were consulted

in India, Japan, Indonesia, Ethiopia and Sri Lanka. We are pro

Plants for all type of industries. We have appreciated as good Environmental Consultant and one of

‘our ZLD Plant awarded continuously 2"! Best plant in Kerala, Also Certified the best A grade ETP

Plant in Indonesia.

ing Zero Liquor Discharge (ZLD)

This report has been prepared for the complete treatment systems inclusive of effluent

characteristics, volume generated and different treatment sections.

2. EFFLUENT CHARACTERISTICS:

tharacteristies of Alkaline effluent — 18.5 MLD:

‘The characteristics of the effluent stream will be:

S.No Parameter Value Unit

1 Colour Dark -

2 Total dissolved solids 6000 ppm

3 pH 8,00-10.00 eS

4 cop 1000-1200 ppm

5 BOD 300-400 ppm

6 Total suspended solids 200-300 ppm

7 Total Hardness as CaCO3 100 - 150 ppm

8 Temperature 50 Deg C

9 Total Iron as Fe <1 ppm

ODHPUR >) 1

UE" AN NIWARAN TRUST

ara _ wee eS .

vanagn, Trust | E

2 ve Trusts | Teeasorer Trost

Confidential

v.10 AUSTRO CHEMICALS & BIOTECHNOLOGIES PVT LTD 23-01-2019

d Water & Wastewater Treatment

1csTRO Experts in Textile ZLD Projects

Cable entry ‘cable glands, 3 x MI6 and 2 * M12 max.

Ambient temperature range (the

accuracy specified is adhered to -10 to +50°C

within this range)

Operating temperature range 15 to #65 °C

; surface mountable housing: approx. 900 g for

eet panel mounting: approx. 480 g

Directly switchable to pH, ORP or NH3 (ammonia)

concentration » Automatic temperature compensation

+ Large LC graphics display with background

lighting + Choice of display mode: large numbers, bar

graph or trend display * Solder-free connection

system + Calibration options according to measured

variable: 142-3-point calibration + Calibration

logbook + Impedance measurement can be activated

for pH measurement + Symmetrical and asymmetrical

7 pn connection of pH sensors + pH-ISFET sensors can be

connected thanks to the sensor supply integrated in

the output + 1P67 protection (in surface mountable

housing) P65. protection (for panel mounting) +

Language changeover: German, English, French;

further languages can be loaded through the setup

program + Using the setup program: usertriendly

Programming, plant documentation, additional

languages can be loaded

GLYCERENE FILLED PRESSURE GUAGES:

Deseription Specification

Make Baumer/KI

‘MIT3-MITS: from -1..-t 0 to 0..-+ 1000 bar Seale for

Ranges vacuum and compound (pressure and vacuum). See

standard graduations overleaf

steady: 75% of full-scale value short time: 100% of

full-scale value

Accuracy Class 2,5%

according to NF EN 60529 1P54 (0 63): MIT3 IP65

@ 100): Mrs

Sensing element Cupreous metal Bourdon tube.

Brass. 14 mm hexagonal (@ 63 mm). 21 mm

hexagonal (@ 100 mm).

“10... 70°C,

Working pressure

Degree of protection

Connection

Confidential

Temperature process flui

VO AUSTRO CHEMICALS & BIOTECHNOLOGIES PVT LTD 23-01-2019

0 IR PRADUS YAN NIWARAN TRUST

SSS ie {os

Trustee | Executive Trste | Treasurer Taste

aUsTRO

& Water & Wastewater tr.

Experts in Textile ZLD Projects

temperature

‘Admissible process pressure

010450°C.

‘Max. 5 bar

v0

Dimensions 025 mm x 146 mm

Weight

Sensor including 10 mcable 827g

Sensor including 30 mcable 1984 g

Sensor shaft and membrane c8P Opriopatty stainless stel 316L or titanium

=Moc

Cable bushing Polyamide

Membrane Silicone

pH, TEMPERATURE, ORP SENSOR WITH DISPLAY UNIT:

Description Specification

Quantity 1No

Make JUMO ~ German

Model ‘quis 500

a ‘Transmitter/Controlle for pH, ORP, NH3 (ammonia)

ee concentration and temperature

Limit comparators, limit controller, pulse width

Controller type controller, pulse frequency controller, modulating

controller, continuous controller

Controller action P/PI/PD/PID

Sampling time 500 msee

Current signal 0/8 1020 mA.

Voltage signal 010 10

PH 1 to-+15 pH

orp -1500 to +1500 mV

NHS (ammonia) 0109999 ppm

Accuracy <03%

‘Temperature eror 02 %!10K

“Temperature Pt100/1000 oa

(automatic detection) Sed

AC 110 to 240 V, -15/410 9, 48 to 63 Hz. AC/DC 20

aie to 30 V, 48 to 63 Hz DC 12 to 24 V, #15 %

wee eee (permissible only for connection to SELV/PELV

circuits)

Power consumption approx. 1d VA

Moc ABS

Confidential

AUSTRO CHEMICALS & BIOTECHNOLOGIES PVT LTD

JODHPUR PRAGUE “AN NIWARAN TRIS

Sra Wh wad

agin, Trustee |

23-01-2019

&

Water & Wastewater Treatment

Experts in Textile ZLD Projects

MOC of water Flow line

‘MOC of Pumping Line

‘MOC of pipe Fittings

Flow Control Valves

INSTRUMEN’ IN AND

Kitz Make

PVC 6 Kg

PvCokg

PVC 10Kg

Kitz make with Aluminium Body

OL SYSTEM:

OPTICAL DISSOLVED OXYGEN SENSOR:

Description

Quantity

Accuracy

Response time

Luminophore operating life

(BO Disk)

‘Temperature compensation

‘Air pressure compensation

Salinity compensation

‘Max. sampling rate for

measured values

Signal interface

Voltage supply

Current consumption

Connection

Electromagnetic compatibility

‘Admissible storage temperature

Specification

1No

JUMO~German

ecoline O-DO

Optical Sensor for Dissolved Oxygen

Optical measurement according to the pri

Juminescence quenching

iple of

Dissolved oxygen Temperature

0.00 to 20.00 mg/l 0.00 to 20.00 ppm 0 to 200 %

SAT

0.01

+40.1 mg/l 40.1 ppm #1 % SAT

190<60s

‘Approx. 2 years depending on the sampling rate of

the display unit and the process conditions

Via integrated NTC, in the range from 0 to +40 °C.

‘500 to 1100 hPa (entered on display unit / controller)

0 to 60 g/kg (entered on display unit / controller)

Hz

S485 interface with Modbus RTU protocol

DC51012V

4.4 mA (at | measurement/s)

4-conductor shielded cable, open conductor ends

with ferrules

According to EN 61326-1

-10 to +60°C

Confidential

AUSTRO CHEMICALS & BIOTECHNOLOGIES PVT LTD

23-01-2019

AUSTRO

& Water & Wastewater Treatment

Experts in Textile ZLD Projects

‘Temperature error

10°C (18°F) rising or falling. Percentage of span.

ca uaine 1.4301 (AISI 304) St. St. sheet. Bezel ring crimped

‘on case (MIT)

Window Unbreakable polycarbonate (MIT).

ae Aluminium alloy, blak figures and graduations on

white background

Pointer ‘Aluminium alloy, balanced, black painted

Movement Brass.

Rugged, glycerin filled pressure gauges, especially

designed for hydraulic systems, pumps, compressors,

diesel engines, agricultural equipment, public works,

Description machine tools... Excellent resistance to vibrations

and corrosive ambient conditions. Can be used on all

gas and liquid systems compatible with cupreous

metals of the sensing element and connection,

9. BATTERY LIMITS:

Description Specification

Equalization & OR Sump Main Limited to 5 meters from Both

Header. and OR sump tank to Blower Room,

. Limited to 5 Meters from Aeration tank

Aeration tank Main Header aes

Ga Cie ian ees Limited to 6 Meters from Chlorine tonner

ena to main header

‘Make up water line for Limited to 6 meters from Inlet of Booster pump.

chlorination

Chlorine solution line to Limited to 15 meters from main header

injector to injector nozzle

Motive waterline Limited to 6 meters from outlet of Booster pump

: : Client scope fiom 6 meters of Booster pump outlet

Chlorinated waterline pepe napa

Filter Feed pump Line ted to 5 Meters from pump delivery.

‘Tertiary clarifier flow ine and ae

pumping line

Other water flow line and F

Sa Client scope as required.

Crdes Grou Hoes an alee Client scope as required.

control valves in existing setup.

Confidential

AUSTRO CHEMICALS & BIOTECHNOLOGIES PVT LTD 23-01-2019

JODHPUR >RADUS IAN NIWARAN TRUS oe!

oe —

Sata ee I

ag, Trustee | Exscutia Trustee! T

& Water & Wastewater Treatment aaa rf S c

Experts in Textile ZLD Projects | gait —

TECHNICAL OFFER

COPYRIGHT POLICY:

: ‘This Proposal is presented on the basis that it will be treated as confidential by the

recipient. The recipient will ensure that it is only seen by those of its senior managers who need

{to see it. This proposal shall not be used in whole or in material part without Austro water

technologies Agreement. This proposal is a copyright work of Austro water technologies and

may not be reproduced in whole or in part in any form or any media without the prior written

consent of Austro water technologies. The client is recommended to discuss with Austro water

technologies for any points made in the proposal related to the client's company, products or

business all information, advise and forecasts of redemptions given by Austro water

technologies are estimates and expressions of opinions only and they are given in good

the client makes use of such information, advice and forecasts at its own risk of Austro water

technologies recommends that all proposals are reviewed by the clients specialist legal advisers

before implementation. However, Austro water technologies can arrange for legal clearance to

‘be obtained for the proposal following written instruction from the client.

Confidential

co AUSTRO CHEMICALS & BIQTECHNOLOGIES PVT LTD 23-01-2019

OpiPUR PRADUEYAN NIWARAN TRIST soni

ee sR,

on

Sn wl

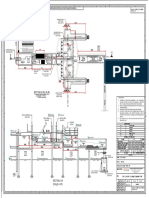

Flow Diagram of Treatment Scheme.

5. Effluent Treatment Plant — Process Description.

L 6. Treated Effluent Qualities.

7. Scope of Supply.

8. Specification of Electro-Mechanical Equipments.

9. Battery Limits

" JODHPUR PRADUSAN MIWARAN TRUST oe

San ary yee” pea

Wiaaagin, Trustee | Exoeutive

see | Freasorer Trastee

Confidential

v.10 AUSTRO CHEMICALS & BIOTECHNOLOGIES PVTLTD 23-01-2019

Water & Wastewater Treatment

Lacs7ko Experts in Textile ZLD Projects

iz = # age

3. TREATMENT SCHEME:

1. Solids and Flubs removal system by Manual Bar Screen, (Existing)

2. Oil & Grease control By Oil & Grease Trap. (Existing)

3. Homogeneous mixing equalization process. (Existing)

4, Equalization grid and Diffuser. (Proposed)

5. Activated Sludge Process. Biological aeration system. (Proposed)

6. Gas Chlorination system. (Proposed)

7. Tertiary Clarifier System — Primary Clarifier Converted into tertiary. (Existing)

8. Suspended Solid Filtration process sand & Carbon filtration. (Existing)

ODHPUR PRADUSYAN NIWARAN TRUST ye a .

Confidential

v.10 AUSTRO CHEMICALS & BIOTECHNOLOGIES PVT LTD 23-01-2019

& Water & Wastewater Treatment

Experts in Textile ZLD Projects

4, FLOW DIAGRAM OF TREATMENT SCHEME:

ALKALINE EFFLUENT: 18.5 MLD

SOLID GRID CHAMBER (Existing)

Y

MECHANICAL BARSCREEN (Existing)

’

EQUALIZATION TANK+— COARSE BUBBLE DRAIN WATER TO ALKALINE

DIFFUSION EQUALIZATION TANK

¥<— pH Neutralization

BIOLOGICAL AERATION SYSTEM «—

SLUDGE SUMP

SECONDARY CLARIFIER SYSTEM —— |

(Existing) Clz Gas by DEWATERING SYSTEM——

+ Evaporation | Exsing

GAS CHLORINATION SYSTEM (Proposed)

SOLID SLUDGE TO STORAGE

¥

OXYGEN REDUCTION SUMP +— COARSE,

(Existing) | BUBBLE DIFFUSION

¥

MIXING CHANNEL CUM — Poly

FLASH MIXER MECHANISM.

(Existing)

TERTIARY CLARIFIER SYSTEM

|4—Acid Dosing System

¥

‘TREATED WATER TANK (Existing)

|, SMBS Dosing System

Y

SAND & ACTIVATED CARBON FILTER ———————_ BACK WASH WATER TO

(Existing) ALKALINE EQ- TANK

¥

FILTRATE WATER TO DISCHARGE

Sra et

Me eS:

Confidential

VuL0 AUSTRO CHEMICALS & BIOTECHNOLOGIES PVT LTD 23-01-2019

& Water & Wastewater Treatment

sUSTRO Experts in Textile ZLD Projects

Sees

ES ENT TREATMENT PLANT — PROCESS DESC! 01

‘The effluent generated from Textile are collected in an Equalization tank through a Grid

Chamber (Existing) & Bar Screen (Existing) for removal of fibrous materials & solid

particles, Equalization tank is equipped with Coarse bubble diffusion system (Proposed) for

homogeneous mixing and temperature reduction.

‘The temperature of the effluent should be <38 Deg. C.

After Homogeneous mixing the effluent will pumped into biological aeration tank after PH

neutralization (6.5-7.0) for the purpose of growth & survival of microorganisms.

‘Aeration is done using energy efficient diffused Aeration System (Biological Treatment),

| _ which results in compact layouts and reduces the power consumption. Air from the blower

(Proposed) is diffused through the Diffuser grid (Proposed). It consists of porous

membranes of 12” dia disc type diffusers (Proposed) made of EPDM material, The diffusers

are of non-buoyant type, which during shutdown condition contracts to prevent any back-

flow.

‘The diffuser is designed to ensure uniform permeability and to produce a flow of fine air

bubbles and provides

igh contact area and more contact time due to slow rise of the bubbles

which makes the system very efficient in terms of oxygen transfer efficiency thus low

installed HP for the blower drive and hence low operational cost.

‘After a residence in the aeration tank the measure of water and activated sludge flows to a

secondary clarifier (Existing) where the biomass is allowed to settle. The settled biomass in

the clarifier is re-circulated back to the aeration tank to maintain the mixed liquor suspended

solids (MLSS) upto the level of 2000- 3000 mg/l suitable for the activated sludge process.

The excess waste sludge is sent to sludge Thickener for dewatering through screw

press/decanter. Upon drying, the sludge is used as manure for plants. The COD & BOD

reduction in the activated sludge process has been recorded up to 80-85%.

‘© The over flow clear water from the clarifier is collected in Oxygen reduction sump, online

from secondary clarifier, a gas chlorination injector (Proposed) is equipped with booster

‘pump (Proposed) for circulating the clarified water with gas chlorine to reduce the colour

value and reduction in volatile COD and BOD up to its maximum level. Oxygen Reduction

sump is equipped with partial coarse bubble diffusion (Proposed) system to reduce the

‘excess chlorine and toxies present in the clarified water.

Confidential

v.10 AUSTRO CHEMICALS & BIOTECHNOLOGIES PVT LTD 23-01-2019

DUPUR PRABUS

a

Water & Wastewater Treatment

scsTRO Experts in Textile ZLD Projects

Aller a residence in Oxygen reduction sump, t

for tertiary treatment and addition of anionic poly in mixing channel to flocculate the

effluent is flocculated in flash mixer and settled in tertiary clarifier. which is a circular type

‘tank with a hopper shape bottom for sludge drain off. A low speed racked arm will scrap the

settled sludge to center of the clarifier and when the valve is opened all accumulated sludge

will get drained. Settled matter in the clarifier is sent to sludge tank and Screw

press/Decanter for dewatering.

‘© The overflow treated water from the clarifier is collected in another tank and passed through

Pressure sand filter and activated carbon filer to control suspended solids below 100

Micron and to get final discharge quality.

6, TREATED EFFLUENT QUALITIES

Effluent after sand & Carbon Media Filtration system will have the following parameters:

S.No Parameter ‘Value Unit

1 pH 6.5-7.5 _ °

| 2 Suspended Solids <5 Mell ee

| 3 CoD <150 mea “GE ta

4 BOD <30 Mg/l o

3 Colour Nil Pt. Co

7 Other Heavy metals

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- PO For Knowledge Lens Data Logger Flow Meter BeawarDocument2 pagesPO For Knowledge Lens Data Logger Flow Meter BeawarMohit ChauhanNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Commercial Offer For 8.5 MLD Upgrade 19.09.2023Document4 pagesCommercial Offer For 8.5 MLD Upgrade 19.09.2023Mohit ChauhanNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 6MLD General Plant Layout Jhalawar For DEWATSDocument1 page6MLD General Plant Layout Jhalawar For DEWATSMohit ChauhanNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- BOQ For SPS Augmentation Fabrication WorksDocument1 pageBOQ For SPS Augmentation Fabrication WorksMohit ChauhanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 3 MLD PTU PUNJAB-ModelDocument1 page3 MLD PTU PUNJAB-ModelMohit ChauhanNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)