Professional Documents

Culture Documents

Process Mil. Spec. Thickness Comments Chrome Qqc-320B

Process Mil. Spec. Thickness Comments Chrome Qqc-320B

Uploaded by

bitconcepts9781Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Mil. Spec. Thickness Comments Chrome Qqc-320B

Process Mil. Spec. Thickness Comments Chrome Qqc-320B

Uploaded by

bitconcepts9781Copyright:

Available Formats

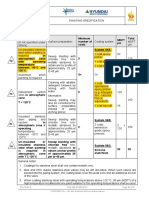

MILITARY PLATING SPECIFICATIONS

PROCESS MIL. SPEC. THICKNESS COMMENTS

CHROME QQC-320b

Excellent hardness(Rc 68-74) Type 1………… ………………… Bright

Wear resistance, and erosion Type 11………. . ……………….. Satin

Resistance.. Has low coefficient Class 1………… .00001-.00002” .. Decorative plating. (usually over

Of friction, and is resistant to copper and nickel undercoats.)

Heat. In addition to above Class 2………… as specified on Engineering plating.

Properties, can be rendered on drawing.

Pourous for lubrication purposes.

Post bake at 375 deg +/- 25 deg Class 2a……….. ………………… Plated to specified dimensions or

F for 3 hrs or as specified. Processed to specified

Dimensions after plating.

Shot peening and post baking Class 2b………. ………………… Parts below Rockwell C40 and

Not required. And subject to static loads or

Designed for limited life under

Dynamic loads.

Shot peen per MIL-S-13165 Class 2c………. ………………… Parts below Rockwell C40 and

Designed for unlimited life under

Dynamic loads.

Post bake at 375 deg +/- 25 deg Class 2d………. ………………… Parts have hardness of Rockwell

F for 3 hrs. C40 or above and subject to static

Loads or designed for limited life

Under dynamic loads

Shot peen before plating. Class 2e……… ……………….. Parts have hardness of Rockwell

Post bake at 375 deg +/- 25 deg C40 or above and are designed

F for 3 hrs. for unlimited life under dynamic

Loads.

ELECTROLESS NICKEL Mil-C-26074B

Similar to stainless steel in color. Class 1………. Unless otherwise As coated

Plates uniformly in recesses and Class 2………. Specified……… Steel, copper, nickel, and cobalt

Cavities (does not build up on base alloys. Heat treated after

Edges. Plating.

Corrosion resistance is good for Class 3……… ……………….. Aluminum alloys other than

Coatings over .001” thickness. Alloy 7075. Heat treated after plarting.

Electroless nickel is used extens- Grade A…….. .001”…………. Minimum thickness. For iron and

Ively in salvage of mis-machined aluminum based alloys.

Parts. Also, for inside dimensions Grade B…….. .0005”……….. Minimum thickness. For copper,

And irregular shapes (where assy nickel, and cobalt based alloys.

Tolerances need uniformity pro-

Vided by “electroless” process.)

NICKEL QQ-N-290A

Class 1 plating is used to pro- Class 1……….. ……………….. Corrosion protective plating.

Tect iron, copper, or zinc Steel, Zinc & Copper and

Alloys against corrosive attack. Zinc alloys. Copper alloys

Used as undercoat for chromium

Or precious metals; or for décor- Grade A……… .0016”………… SD, and M …………….

Ative. Grade B……… .0012”………… SD, and M SB, and M

Forms of nickel deposition: Grade C……… .0010”………… M SB,SD, and M

SB-Single layer coating. Fully Grade D…….. .0008”………… SB, SD & M1 SD & M

Bright finish: SD-single layer in Grade E……… .0006”………… SB, SD, & M1 SB, SD, & M1

A dull or semi bright finish. Grade F……… .0004”………… SB, SD, & M1 SB, SD, & M1

(Contains less than .005 % sulfer) Grade G……… .0002”………… ……………… SB, SD, & M1

M-Multi-layer coating. See spec.

Class 2 Plating. Resistance and Note: 1; SD or M may be sub-

Abrasion resistance: for build up Class 2………. ..……………… stituted for SB in mild or mod-

Of worn or undersized parts: pro- Nickel plated to erate service condition.

Tection against corrosive spec thickness. Engineering Plating

Chemical environments. Type of nickel process should be

Called out. For salvage and great

Hardness & corrosion required.

CADMIUM QQ-P-416-F

Bright silvery white. Supple- Type 1……….. ……………….. No supplementary treatment.

Mentary treatments for Type 11

Can be golden, iridescent, amber Type11………. ……………….. Supplementary chromte treatment

Black, olive drab. Corrosion re-

Sistance is very good especially Type 111……. ………………. Supplementary phosphate tretmnt

With Type 11 finish. Type11

Shall show no surface corrosion Class 1………. .0005” min…... Type 11 best for corrosion resist.

Products after 96 hrs (20%) salt

Spray exposure. Parts with hard- Class 2………. .0003” min…... Type 111 is used as paint base .

Ness greater than Rc-40 shall be Excellent for plating Stainless

Stress relieved before cleaning Class 3………. .0002” min….. steels that are to be used in con-

And plating. Parts subject to junction with aluminum to pre-

Flexure (springs, etc) over Rc-40 vent galvanic corrosion.

Hardness shall be given a 375 deg

+/- 25 deg F post bake.

GOLD MIL-C-45204b

Yellow to orange color depend- Amendment 2 unless otherwise

Ing on proprietary process used. specified

Will range from matte to bright Type 1…….. …………………. 99.7% gold min.

Finish depending on basis metal. Type 11…… …………………. 99.0% gold min.

Good corrosion resistance, and Type 111….. …………………. 99.9% gold min.

Has high tarnish resistance. Pro- Class 00…… .00002”…………. Grade A 90 Knoop max.

Vides a low contact resistance, Class 0……. .00003”…………. Grade B 91-129 Knoop

And a great coductor. Has ex- Class 1…….. .00005”…………. Grade C 130-200 Knoop

Cellent solderability. Class 2……. .00010”………… Grade D 201 Knoop and over

Class 3……. .00020”…………

Class 4……. .00030”………… Type 1 (grades A, B, or C)

Class 5……. .00050”………… Type 11 (grades A, B or C)

Class 6……. .00150”………… Type111 (grade A only)

SILVER QQ-S-365a

White matte to very bright in ap- .0005” min. unless Increasing use in both decorative

Pearance. Good corrosion resis- otherwise specified. and engineering fields including

Tance, depending on base metal. Electrical and electronic fields.

Will tarnish easily. Hardness var- Type 1…… …………………… Matte.

Ies from about 90 Brinell to about Type 11….. …………………… Semi-bright

135 Brinell depending on process Type 111… …………………… Bright

and plating conditions. Solderabil- Grade A….. …………………… Chromate post treatment to increase

ity is excellent, but decreases with tarnish resistance.

age. Best electrical conductor. Has Grade B…… …………………… No chromate treatment.

excellent lubricity and smear char-

acteristics for anti-galling uses on

static seals, bushings, etc.

SULFAMATE NICKEL MIL-P-27418

The plating conforming to this Unless otherwise The nickel plating shall have a

Specification is intended to facil- specified: columnar crystalline structure

Itate the formation of a seal be- 0.0020” before annealing.

Tween two metalic surfaces. Plat- +/- 0.0003” on all

Ing hardness: Not to excees 150 surfaces that can be

Knoop hardness (500 gm. Load) touched by .0625”

After annealing (or 300 Knoop dia. Ball.

Befor annealing)

LUBRICANT, SOLID MIL-L-46010D

FILM

Used to prevent galling and seiz- For sliding motion applications

Ure of metals. Lubricant covered Unless otherwise such as plain and spherical bear-

By this specification is intended specified. ings, flap tracks, hinges, threads,

For use on aluminum, copper, Type 1…………… 0.0002 – 0.0005” cam surfaces, etc. Do not use on

Steel and stainless steel titanium, (302 deg F cure) materials adversely affected by

And chromium and nickel surfaces. exposure to temperatures of 300

Useful where conventional lubric- deg F for 1 hr. – on bearings con-

Ants are difficult to apply or retain Type 11…………. taining rolling elements – or where

Or where other lubricants may be (400 deg F cure) there is potential contact with

Easily contaminated. Cured lubric- liquid oxygen. Pretreatment of

Ant film is highly resistant to con- metals such as anodizing, passiv-

Ventional fluid lubricants,. ation, phosphating, etc. required

Prior to the solid film process.

You might also like

- Plating and MetPLATING & METAL FINISHING SPECIFICATIONS ISO 9001:2008, Nadcap, ITAR, Federal Fire Arms Licenseal Finishing SPECDocument1 pagePlating and MetPLATING & METAL FINISHING SPECIFICATIONS ISO 9001:2008, Nadcap, ITAR, Federal Fire Arms Licenseal Finishing SPECStas Zabarsky50% (2)

- Brochure - Rev 15 PDFDocument9 pagesBrochure - Rev 15 PDFCicero Gomes de SouzaNo ratings yet

- EN10346:2015Document2 pagesEN10346:2015Adriano Onairda0% (1)

- Stainless Steel AOD Operation and Slag Optimisation PDFDocument41 pagesStainless Steel AOD Operation and Slag Optimisation PDFPrakash MishraNo ratings yet

- TALAT Lecture 3501: Alloys and PropertiesDocument8 pagesTALAT Lecture 3501: Alloys and PropertiesCORE MaterialsNo ratings yet

- Zinc CoatingsDocument16 pagesZinc CoatingsShojikuriakoseT100% (2)

- Accumulators Inc Entire CatalogDocument61 pagesAccumulators Inc Entire Catalogoswaldo58No ratings yet

- Xylan CoatingDocument3 pagesXylan Coatingsidhesh870% (1)

- Military Plating Spec-1Document11 pagesMilitary Plating Spec-1Durbha RaviNo ratings yet

- Manac Hot Dip GalvanizationDocument13 pagesManac Hot Dip Galvanizationeyya 007No ratings yet

- Cold Rolled Steels - AK SteelDocument8 pagesCold Rolled Steels - AK SteelRuben HernandezNo ratings yet

- CRCA Technical Notes - 2018Document11 pagesCRCA Technical Notes - 2018Sajib Chandra RoyNo ratings yet

- Basic Sheet and Coil Training Edit VersionDocument35 pagesBasic Sheet and Coil Training Edit VersioncuongdcNo ratings yet

- Brass: Characteristics and Applications of Olin Alloy C194Document4 pagesBrass: Characteristics and Applications of Olin Alloy C194AugustedNo ratings yet

- Standard Milling Grade DescriptionsDocument3 pagesStandard Milling Grade DescriptionssisosamNo ratings yet

- Engineering Considerations For Anodizing AluminumDocument1 pageEngineering Considerations For Anodizing AluminumTanzil ZaidiNo ratings yet

- Stellram Milling Grades Chart InchDocument4 pagesStellram Milling Grades Chart InchTri LilalilulaNo ratings yet

- MT30001 Materials Engineering (30001)Document38 pagesMT30001 Materials Engineering (30001)Rajesh MundaryNo ratings yet

- Non-Ferrous Alloys: Dr. Indika de Silva Senior Lecturer Dept. of Materials Science & Engineering University of MoratuwaDocument68 pagesNon-Ferrous Alloys: Dr. Indika de Silva Senior Lecturer Dept. of Materials Science & Engineering University of MoratuwaChandima K Priyamal100% (1)

- Plates PDFDocument10 pagesPlates PDFkarthiksaadhanaNo ratings yet

- 1) Relative Characteristics of Die Casting AlloysDocument10 pages1) Relative Characteristics of Die Casting AlloysLokesh BaviskarNo ratings yet

- Atkore-Unistrut 00002 13 77 79 100 127 CATDocument5 pagesAtkore-Unistrut 00002 13 77 79 100 127 CATjeffuangNo ratings yet

- Astm A 424 - 00 - QtqynaDocument2 pagesAstm A 424 - 00 - QtqynaEjat ISNo ratings yet

- Detaclad Zirconium Clad For Chemical Process EquipmentDocument2 pagesDetaclad Zirconium Clad For Chemical Process EquipmentharshadNo ratings yet

- Resource Guide: Section 4: Ni-ResistDocument8 pagesResource Guide: Section 4: Ni-ResistMiguel Angel EscalanteNo ratings yet

- High Quality Products For Welding and CladdingDocument25 pagesHigh Quality Products For Welding and Claddingsanketpavi21100% (1)

- Aluminizedt1201802 PDFDocument6 pagesAluminizedt1201802 PDFsachedalNo ratings yet

- Latest Shipbuilding MaterialsDocument9 pagesLatest Shipbuilding MaterialsAnonymous e3ceN15No ratings yet

- Voest Alpine-WireDocument2 pagesVoest Alpine-WireAnonymous wUv02fNo ratings yet

- Metallurgy Project Done By: Mohammed Al-Jaloudi Abdallah Al-Majali Qusai Al-Kharabsheh Mohammed Al-Ananza Mahmood Al-KhateebDocument6 pagesMetallurgy Project Done By: Mohammed Al-Jaloudi Abdallah Al-Majali Qusai Al-Kharabsheh Mohammed Al-Ananza Mahmood Al-KhateebAbdallah M Al-MajaliNo ratings yet

- Rimer On Inc Lating: White PaperDocument4 pagesRimer On Inc Lating: White PaperAndrea Perdomo FlorezNo ratings yet

- 4.0 Steel Structures Subjected To FireDocument4 pages4.0 Steel Structures Subjected To FireShakil AkhterNo ratings yet

- Asme Section Ii A-2 Sa-736 Sa-736mDocument6 pagesAsme Section Ii A-2 Sa-736 Sa-736mdavid perezNo ratings yet

- Basic Aircraft MaterialDocument14 pagesBasic Aircraft Materialanandadinatha77No ratings yet

- 06022G Sample BuyNow PDFDocument9 pages06022G Sample BuyNow PDFnuman_mobinNo ratings yet

- C 61400Document2 pagesC 61400ghetto_bmx_boyNo ratings yet

- Alumina Carbide Grades: CVD Coated Grades SteelDocument3 pagesAlumina Carbide Grades: CVD Coated Grades SteelVasoya ManojNo ratings yet

- HHI Coat SystemDocument1 pageHHI Coat SystemAiman AhmadNo ratings yet

- Unit - V Advanced Materials & Applications: 5.0 CeramicsDocument6 pagesUnit - V Advanced Materials & Applications: 5.0 Ceramicsjoel jNo ratings yet

- 1MG.002 FINAL Advanced Materials - Sintered Technical CeramicsDocument10 pages1MG.002 FINAL Advanced Materials - Sintered Technical CeramicsugurNo ratings yet

- Copper PlatingDocument8 pagesCopper PlatingHoong Chee Chung100% (1)

- Profile Catalogue - 2019Document174 pagesProfile Catalogue - 2019construction udlNo ratings yet

- PD1005 / PD1010: DLC-Coated Inserts For Non-Ferrous MetalsDocument8 pagesPD1005 / PD1010: DLC-Coated Inserts For Non-Ferrous Metalsxmen norNo ratings yet

- AM Hot Rolled Product Range For Construction 201503Document43 pagesAM Hot Rolled Product Range For Construction 201503duduqueNo ratings yet

- Advanced Ceramic Materials For Composite Armor Protection Systems General LiteratureDocument4 pagesAdvanced Ceramic Materials For Composite Armor Protection Systems General Literatureibrahim100% (1)

- ZINCALUME® G300 Steel With Activate™ Technology: Structural - S Metallic Coated - MCDocument3 pagesZINCALUME® G300 Steel With Activate™ Technology: Structural - S Metallic Coated - MCEwo50 NewNo ratings yet

- Hot Dip Galvannealed: SteelDocument6 pagesHot Dip Galvannealed: Steeldaha333No ratings yet

- Nickel in HardmetalsDocument9 pagesNickel in Hardmetalsandrea assanelliNo ratings yet

- TKS10002 CHDocument7 pagesTKS10002 CHFlavio BadaroNo ratings yet

- 23. Welding of Steel 02Document53 pages23. Welding of Steel 02Sir KoeNo ratings yet

- Preparation of Zinc (Hot-Dip Galvanized) Coated Iron and Steel Product and Hardware Surfaces For PaintingDocument5 pagesPreparation of Zinc (Hot-Dip Galvanized) Coated Iron and Steel Product and Hardware Surfaces For Paintingalaudeen2014No ratings yet

- 11-Kyocera Catalog Ca3 en 20170125Document8 pages11-Kyocera Catalog Ca3 en 20170125Mayur HandeNo ratings yet

- Zirconium Alloys Rev1 1Document19 pagesZirconium Alloys Rev1 1Christian AganoNo ratings yet

- Class Apart: Enter The World of Zinc and Copper Composite PanelsDocument9 pagesClass Apart: Enter The World of Zinc and Copper Composite PanelsKrishna8765No ratings yet

- Supertec Galvanized Steel SpecsDocument6 pagesSupertec Galvanized Steel Specszineil BlackwoodNo ratings yet

- Section 2Document62 pagesSection 2oscar perez perez nietoNo ratings yet

- Engineering Metallurgy: DATE:1/11/2017Document25 pagesEngineering Metallurgy: DATE:1/11/2017ManicharanNo ratings yet

- Grade For Solid End MillDocument1 pageGrade For Solid End MillthippakNo ratings yet

- Zink Coating 12944Document2 pagesZink Coating 12944JpolyPolyNo ratings yet

- Dickoron Duo EnglDocument2 pagesDickoron Duo EnglDusan MaksimovicNo ratings yet

- Nes 833-34 PDFDocument2 pagesNes 833-34 PDFBHARGAVNo ratings yet

- E-2020 Knitter-Catalogue KPL Für DownloadDocument252 pagesE-2020 Knitter-Catalogue KPL Für DownloadАлексей ШаповаловNo ratings yet

- Chemical Compatibility Reference Chart: AcetalDocument13 pagesChemical Compatibility Reference Chart: AcetalSreesanth SaruvilNo ratings yet

- Ty7223 FMDocument9 pagesTy7223 FMAhmad ShiplyNo ratings yet

- MKM6144 Advanced Material: Faculty of Mechanical Engineering Universiti Malaysia PahangDocument159 pagesMKM6144 Advanced Material: Faculty of Mechanical Engineering Universiti Malaysia PahangHazim HamdanNo ratings yet

- Lee Spring Catalog 2014Document316 pagesLee Spring Catalog 2014Joseph WangNo ratings yet

- Identifying Archaeological Metal PDFDocument4 pagesIdentifying Archaeological Metal PDFadonisghlNo ratings yet

- Material Specifications: Zinc Plating 1. ScopeDocument12 pagesMaterial Specifications: Zinc Plating 1. ScopeHaroldo Hubner NetoNo ratings yet

- Wang 2017Document28 pagesWang 2017Agil SetyawanNo ratings yet

- Circuits & Resistors: Conductors & InsulatorsDocument10 pagesCircuits & Resistors: Conductors & InsulatorsH Aries OñaNo ratings yet

- PCB Design Techniques To Reduce EMIDocument21 pagesPCB Design Techniques To Reduce EMIelfrichNo ratings yet

- Laton AtotechDocument6 pagesLaton AtotechKaRenthLuNaNo ratings yet

- Islamic Copper Based Metalwork From TheDocument5 pagesIslamic Copper Based Metalwork From TheSavas MaraşlıNo ratings yet

- Corrosion Action and Passivation Mechanism of Magnesium Alloy in Fluoride SolutionDocument5 pagesCorrosion Action and Passivation Mechanism of Magnesium Alloy in Fluoride SolutiondaihailongNo ratings yet

- NEDOX - "Synergistic" Surface Enhancement CoatingsDocument5 pagesNEDOX - "Synergistic" Surface Enhancement CoatingsXto PeregrinNo ratings yet

- Calotest BrochureDocument14 pagesCalotest BrochureELROHIR CULNAMONo ratings yet

- Service Manual - Sandpiper s15Document24 pagesService Manual - Sandpiper s15tineohNo ratings yet

- ALSTOM Standard DTRF 150611 F1 en For Railway Surface Protection CatalogueDocument85 pagesALSTOM Standard DTRF 150611 F1 en For Railway Surface Protection CatalogueamicjhcjyNo ratings yet

- Week 10-11 ModuleDocument44 pagesWeek 10-11 ModuleYuri MahilumNo ratings yet

- Misumi s5m Pulley p1117Document1 pageMisumi s5m Pulley p1117tigor carakaNo ratings yet

- Electroless Nickel IntroductionDocument56 pagesElectroless Nickel Introductionabhishek_giteNo ratings yet

- Metallurgical Examinations in Criminal CasesDocument30 pagesMetallurgical Examinations in Criminal CasesMonkey DragonNo ratings yet

- Artisan Plating Gold Plating - Artisan PlatingDocument7 pagesArtisan Plating Gold Plating - Artisan PlatingbirgulNo ratings yet

- Building Technology 1Document45 pagesBuilding Technology 1Danica Ragasa IlardeNo ratings yet

- Zinc Flake Vs Zinc-Nickel ComparisonDocument7 pagesZinc Flake Vs Zinc-Nickel ComparisonSon NguyenNo ratings yet

- TDK Neodymium Iron Boron MagnetsDocument30 pagesTDK Neodymium Iron Boron MagnetsDamiano ZitoNo ratings yet

- Aws C2Document8 pagesAws C2dehamanezNo ratings yet

- Surface Coating Methods For Metal SurfacesDocument10 pagesSurface Coating Methods For Metal SurfacesShristi Singh100% (1)