Professional Documents

Culture Documents

The Idea That A Machine Can Be Decomposed Into Simple Movable Elements Led Archimedes To Define The Lever

Uploaded by

Endalkachew AbateOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Idea That A Machine Can Be Decomposed Into Simple Movable Elements Led Archimedes To Define The Lever

Uploaded by

Endalkachew AbateCopyright:

Available Formats

The idea that a machine can be decomposed into simple movable elements led Archimedes to

define the lever, pulley and screw as simple machines. By the time of the Renaissance this list

increased to include the wheel and axle, wedge and inclined plane. The modern approach to

characterizing machines focusses on the components that allow movement, known as joints.

Wedge (hand axe): Perhaps the first example of a device designed to manage power is the hand

axe, also called biface and Olorgesailie. A hand axe is made by chipping stone, generally flint, to

form a bifacial edge, or wedge. A wedge is a simple machine that transforms lateral force and

movement of the tool into a transverse splitting force and movement of the workpiece. The

available power is limited by the effort of the person using the tool, but because power is the

product of force and movement, the wedge amplifies the force by reducing the movement. This

amplification, or mechanical advantage is the ratio of the input speed to output speed. For a

wedge this is given by 1/tanα, where α is the tip angle. The faces of a wedge are modeled as

straight lines to form a sliding or prismatic joint.

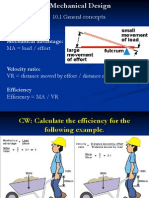

Lever: The lever is another important and simple device for managing power. This is a body that

pivots on a fulcrum. Because the velocity of a point farther from the pivot is greater than the

velocity of a point near the pivot, forces applied far from the pivot are amplified near the pivot

by the associated decrease in speed. If a is the distance from the pivot to the point where the

input force is applied and b is the distance to the point where the output force is applied, then a/b

is the mechanical advantage of the lever. The fulcrum of a lever is modeled as a hinged or

revolute joint.

Wheel: The wheel is an important early machine, such as the chariot. A wheel uses the law of

the lever to reduce the force needed to overcome friction when pulling a load. To see this notice

that the friction associated with pulling a load on the ground is approximately the same as the

friction in a simple bearing that supports the load on the axle of a wheel. However, the wheel

forms a lever that magnifies the pulling force so that it overcomes the frictional resistance in the

bearing.

Illustration of a four-bar linkage from The Kinematics of Machinery, 1876

The classification of simple machines to provide a strategy for the design of new machines was

developed by Franz Reuleaux, who collected and studied over 800 elementary machines.[46] He

recognized that the classical simple machines can be separated into the lever, pulley and wheel

and axle that are formed by a body rotating about a hinge, and the inclined plane, wedge and

screw that are similarly a block sliding on a flat surface.[47]

Simple machines are elementary examples of kinematic chains or linkages that are used to model

mechanical systems ranging from the steam engine to robot manipulators. The bearings that form

the fulcrum of a lever and that allow the wheel and axle and pulleys to rotate are examples of a

kinematic pair called a hinged joint. Similarly, the flat surface of an inclined plane and wedge are

examples of the kinematic pair called a sliding joint. The screw is usually identified as its own

kinematic pair called a helical joint.

This realization shows that it is the joints, or the connections that provide movement, that are the

primary elements of a machine. Starting with four types of joints, the rotary joint, sliding joint,

cam joint and gear joint, and related connections such as cables and belts, it is possible to

understand a machine as an assembly of solid parts that connect these joints called a mechanism .

[48]

Two levers, or cranks, are combined into a planar four-bar linkage by attaching a link that

connects the output of one crank to the input of another. Additional links can be attached to form

a six-bar linkage or in series to form a robot.[48]

You might also like

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Wedge (Hand Axe) : Perhaps The First Example of A Device Designed To Manage Power Is TheDocument2 pagesWedge (Hand Axe) : Perhaps The First Example of A Device Designed To Manage Power Is TheSamirNo ratings yet

- Archimedes Lever Pulley Screw Simple Machines Wheel and Axle Wedge Inclined Plane JointsDocument1 pageArchimedes Lever Pulley Screw Simple Machines Wheel and Axle Wedge Inclined Plane JointsSamirNo ratings yet

- Wheel and AxleDocument6 pagesWheel and AxleJon PotterNo ratings yet

- Machine (Mechanical) - Wikipedia, The Free EncyclopediaDocument10 pagesMachine (Mechanical) - Wikipedia, The Free EncyclopediabmxengineeringNo ratings yet

- Simple MachineDocument12 pagesSimple MachinemillgibsonNo ratings yet

- Wheel and AxleDocument12 pagesWheel and AxleJustin Jan DaetNo ratings yet

- Mechanism (Engineering) - Wikipedia, The Free EncyclopediaDocument5 pagesMechanism (Engineering) - Wikipedia, The Free EncyclopedianidharshanNo ratings yet

- Mechanics of Machines For Eie (1588)Document9 pagesMechanics of Machines For Eie (1588)GODFREYNo ratings yet

- Physics 10Document17 pagesPhysics 10Shaheena YasmeenNo ratings yet

- Mass College ProjectDocument68 pagesMass College ProjectGLOBAL INFO-TECH KUMBAKONAMNo ratings yet

- B Ing Kita AsuDocument48 pagesB Ing Kita AsuUnknown Music LabNo ratings yet

- SICC AGRICULTURAL ENGINEERING M3 Converted AutosavedDocument44 pagesSICC AGRICULTURAL ENGINEERING M3 Converted AutosavedShanelle FuentesNo ratings yet

- Mechanical ActuatorsDocument39 pagesMechanical ActuatorsKashif UsmanNo ratings yet

- Lesson: Levers That Lift: Quick LookDocument12 pagesLesson: Levers That Lift: Quick Lookamerican_guy10No ratings yet

- Literature Review of Motorized Lift TableDocument5 pagesLiterature Review of Motorized Lift Table'Aizat Hafiz'0% (2)

- Engineering MechanicsDocument16 pagesEngineering Mechanicsbetelhemterefe wondimagenihuNo ratings yet

- Unit 4Document36 pagesUnit 4hisuresh196No ratings yet

- PulleyDocument6 pagesPulleySanthosh PothulaNo ratings yet

- Bybliographycal Research of Analysis of MechanismsDocument9 pagesBybliographycal Research of Analysis of MechanismsJuanca SolorioNo ratings yet

- This Article Is About Devices Designed To Perform Tasks. For Other Uses, SeeDocument13 pagesThis Article Is About Devices Designed To Perform Tasks. For Other Uses, Seeonline kingdomNo ratings yet

- 10 Mechanical Design HL ExtensionDocument38 pages10 Mechanical Design HL ExtensionSyeda Fariya Nisar AliNo ratings yet

- Simple Machine Part 2Document4 pagesSimple Machine Part 2Sherilyn ApostolNo ratings yet

- Mechanical Actuation SystemsDocument14 pagesMechanical Actuation SystemsnkchandruNo ratings yet

- Simple MachinesDocument7 pagesSimple MachinesAtupan M. MaritesNo ratings yet

- Final Term Paper of DomDocument12 pagesFinal Term Paper of DomAvinash RajputNo ratings yet

- Kinds and Functions of Simple Machine: MachinesDocument8 pagesKinds and Functions of Simple Machine: MachinesAman LilaniNo ratings yet

- The 6 Simple Machines: Wedge Screw Inclined PlaneDocument27 pagesThe 6 Simple Machines: Wedge Screw Inclined Planefiey_ra100% (3)

- CamesDocument22 pagesCamesعبدالله عمرNo ratings yet

- Hand-Powered CranksDocument3 pagesHand-Powered CranksHakeemi BaseriNo ratings yet

- MechanismDocument11 pagesMechanismAravind Raj PandianNo ratings yet

- Unit 3. Simple MachinesDocument38 pagesUnit 3. Simple MachinesffergallNo ratings yet

- Experiment No. 5 Objective: Four Bar Mechanism (Fig 5.1)Document6 pagesExperiment No. 5 Objective: Four Bar Mechanism (Fig 5.1)Waqas IbrahimNo ratings yet

- Simple MachinesDocument2 pagesSimple MachinesJejeLyan AmbaNo ratings yet

- Ars (AutoRecovered) 5Document11 pagesArs (AutoRecovered) 5christinachikafaNo ratings yet

- Mechanical ActuatorsDocument19 pagesMechanical Actuatorsjasonmani90100% (1)

- Project ReportDocument5 pagesProject ReportAshley Sam100% (1)

- PulleyDocument9 pagesPulleypedropicapiedrantomeNo ratings yet

- Ijmet 09 06 029Document6 pagesIjmet 09 06 029Rohit BhaleNo ratings yet

- The Wheel and AxleDocument7 pagesThe Wheel and AxleKathryn Bianca AcanceNo ratings yet

- Term Paper As in 2 YearDocument25 pagesTerm Paper As in 2 YearRoopak GoyalNo ratings yet

- List of Material For SpringDocument8 pagesList of Material For SpringPatranNo ratings yet

- Reciprocating: Slider-Crank Mechanism, Arrangement of Mechanical PartsDocument3 pagesReciprocating: Slider-Crank Mechanism, Arrangement of Mechanical PartsHanzlah NaseerNo ratings yet

- Diferent I AlDocument10 pagesDiferent I AlJef PerezNo ratings yet

- Pulley: Previous (Pulitzer Prize) Next (Pulmonary Alveolus)Document7 pagesPulley: Previous (Pulitzer Prize) Next (Pulmonary Alveolus)Mohan ChetriNo ratings yet

- Pulley and Lever System.Document1 pagePulley and Lever System.radz111No ratings yet

- Simple Machines PDFDocument6 pagesSimple Machines PDFDainelle Angelo A. LabutonNo ratings yet

- Simple Machines Are Basic Devices That Help Accomplish Physical Tasks With Few or No Moving PartsDocument4 pagesSimple Machines Are Basic Devices That Help Accomplish Physical Tasks With Few or No Moving PartsSherilyn ApostolNo ratings yet

- Other Mechanisms: Looking For GATE Preparation Material? Join & Get Here Now!Document7 pagesOther Mechanisms: Looking For GATE Preparation Material? Join & Get Here Now!Akash SoniNo ratings yet

- Different Kinds of MechanismsDocument31 pagesDifferent Kinds of Mechanismslockenload92% (13)

- Simple MachinesDocument3 pagesSimple MachinesMarium BilleNo ratings yet

- Mechanical Actuation SystemDocument34 pagesMechanical Actuation Systemdildar123100% (2)

- Natnael Getasew, Abel Gebremedhin, Yonatan Yakob, Abel TesfayeDocument24 pagesNatnael Getasew, Abel Gebremedhin, Yonatan Yakob, Abel TesfayeYonatan YakobNo ratings yet

- Cranck ShaftDocument11 pagesCranck ShaftMochamad AsrofiNo ratings yet

- History: Hand Axe WinchesterDocument4 pagesHistory: Hand Axe WinchesterHerrieGabicaNo ratings yet

- Gears AssignmentDocument9 pagesGears AssignmentAbhishek BhardwajNo ratings yet

- Gear T.worksyop 3Document26 pagesGear T.worksyop 3Cakap AhNo ratings yet

- UNIT 1. Introduction To KOM PDFDocument40 pagesUNIT 1. Introduction To KOM PDFAravind MuddebihalNo ratings yet

- Mechanical Advantage DeviceDocument4 pagesMechanical Advantage DeviceAnkita WalkeNo ratings yet

- Human and Animal Effort Were The Original Power Sources For Early MachinesDocument2 pagesHuman and Animal Effort Were The Original Power Sources For Early MachinesEndalkachew AbateNo ratings yet

- Ethiopia (Democratic Republic of Ethiopia, Is A: ListenDocument2 pagesEthiopia (Democratic Republic of Ethiopia, Is A: ListenEndalkachew AbateNo ratings yet

- Nativity of Jesus: From Wikipedia, The Free Encyclopedia For Other Uses, SeeDocument3 pagesNativity of Jesus: From Wikipedia, The Free Encyclopedia For Other Uses, SeeEndalkachew AbateNo ratings yet

- A Mechanical System Manages Power To Accomplish A Task That Involves Forces and MovementDocument1 pageA Mechanical System Manages Power To Accomplish A Task That Involves Forces and MovementEndalkachew AbateNo ratings yet

- History: George SantayanaDocument2 pagesHistory: George SantayanaEndalkachew AbateNo ratings yet

- EritreaDocument1 pageEritreaEndalkachew AbateNo ratings yet

- SomalilandDocument1 pageSomalilandEndalkachew AbateNo ratings yet

- Date of Birth of JesusDocument2 pagesDate of Birth of JesusEndalkachew AbateNo ratings yet

- Calendar Era: 2020 in Various CalendarsDocument2 pagesCalendar Era: 2020 in Various CalendarsEndalkachew AbateNo ratings yet

- Thread EngagementDocument15 pagesThread Engagementsumeetsaini88No ratings yet

- Jesus in ChristianityDocument1 pageJesus in ChristianityEndalkachew AbateNo ratings yet

- Xuzhou Hongsengmeng Group Co., LTD.: Since 2018Document7 pagesXuzhou Hongsengmeng Group Co., LTD.: Since 2018Endalkachew AbateNo ratings yet

- Inventor-Gears - Jeffery J Jensen Wiki PDFDocument30 pagesInventor-Gears - Jeffery J Jensen Wiki PDFEndalkachew Abate100% (1)

- Screw Thread Basics PDFDocument15 pagesScrew Thread Basics PDFEndalkachew AbateNo ratings yet

- Metric Coarse Thread Data PDFDocument3 pagesMetric Coarse Thread Data PDFEndalkachew AbateNo ratings yet

- Metric Screw Dimensions ISO Fasteners PDFDocument3 pagesMetric Screw Dimensions ISO Fasteners PDFEndalkachew AbateNo ratings yet

- Transformation Features and Advancefdfb D ModelinDocument1 pageTransformation Features and Advancefdfb D ModelinEndalkachew AbateNo ratings yet

- Insert To Load To Download BooksDocument1 pageInsert To Load To Download BooksEndalkachew AbateNo ratings yet

- JGHKDocument1 pageJGHKEndalkachew AbateNo ratings yet

- Transformation Features andDocument1 pageTransformation Features andEndalkachew AbateNo ratings yet

- Transformation FuturesDocument1 pageTransformation FuturesEndalkachew AbateNo ratings yet

- Transformation Features and Advancefdfb D ModelinDocument1 pageTransformation Features and Advancefdfb D ModelinEndalkachew AbateNo ratings yet

- JGHKDocument1 pageJGHKEndalkachew AbateNo ratings yet

- Ntroduces The Readers ToDocument1 pageNtroduces The Readers ToEndalkachew AbateNo ratings yet

- Selecting Control and Balancing Valves in A Variable Flow System - ASHRAe Journal - Jun 1997Document10 pagesSelecting Control and Balancing Valves in A Variable Flow System - ASHRAe Journal - Jun 1997Vince DavidNo ratings yet

- Maquinaria de Labranza PrimariaDocument2 pagesMaquinaria de Labranza PrimariaPiero GonzalesNo ratings yet

- AK Tutorial - Building An AK Pistol - Arizona Response SystemsDocument3 pagesAK Tutorial - Building An AK Pistol - Arizona Response SystemsDale WadeNo ratings yet

- Power Tools - Montly HSE Inspection ChecklistDocument2 pagesPower Tools - Montly HSE Inspection ChecklistAbdus SamadNo ratings yet

- Goyma ImpexDocument8 pagesGoyma ImpexGOYMA IMPEXNo ratings yet

- Spare Parts Catalogue: ZF Do Brasil LtdaDocument45 pagesSpare Parts Catalogue: ZF Do Brasil LtdaWillNo ratings yet

- 8m Octagonal Pole DrawingDocument1 page8m Octagonal Pole DrawingSameer KmNo ratings yet

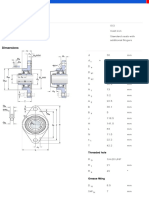

- Ball Bearing Oval Flanged units-FYTB 30 TFDocument2 pagesBall Bearing Oval Flanged units-FYTB 30 TFCosmin ManoleNo ratings yet

- Pro Series Valve: Assembly InstructionsDocument1 pagePro Series Valve: Assembly InstructionsCarlofranco Ruiz DazaNo ratings yet

- Aircon (Power Point Presentation) .PpsDocument13 pagesAircon (Power Point Presentation) .PpsRajeswaranNo ratings yet

- Gypsum BreakdownDocument6 pagesGypsum BreakdownAbigail SalazarNo ratings yet

- Service Methods Manual: Signalite and Hde Patient TransportDocument260 pagesService Methods Manual: Signalite and Hde Patient TransportJongchan Jason MoonNo ratings yet

- E-K17 Rail Clamp ZwaDocument4 pagesE-K17 Rail Clamp ZwaArif ortakcıNo ratings yet

- Fleck 3150 Downflow: Service ManualDocument40 pagesFleck 3150 Downflow: Service ManualLund2016No ratings yet

- Air Break and Air GapDocument2 pagesAir Break and Air GapZarex BorjaNo ratings yet

- General Electric Automatic Washer Service BookDocument99 pagesGeneral Electric Automatic Washer Service BookJesus Rafael Mendoza BrachoNo ratings yet

- TX Catalogue EnglishDocument12 pagesTX Catalogue EnglishDjuraTheHarpYNo ratings yet

- Manual Valvula de Alivio RciDocument3 pagesManual Valvula de Alivio RciGonzalo DominguezNo ratings yet

- Caterpillar Cat 216B3 Skid Steer Loader (Prefix JXM) Service Repair Manual (JXM00001 and Up)Document22 pagesCaterpillar Cat 216B3 Skid Steer Loader (Prefix JXM) Service Repair Manual (JXM00001 and Up)rpoy9396615No ratings yet

- Module IV-Milling MachineDocument26 pagesModule IV-Milling MachineNalluriRavindra100% (2)

- Bamboo Spoon, Fork, Knife Making ProjectsDocument23 pagesBamboo Spoon, Fork, Knife Making ProjectsLloyd Ki'sNo ratings yet

- Plumbing ToolsDocument241 pagesPlumbing ToolsAngel NuevoNo ratings yet

- Qty Description RateDocument4 pagesQty Description RateAmir HabibNo ratings yet

- Pipe Alignment Clamps BrochureDocument12 pagesPipe Alignment Clamps BrochureJevgenij NevzorovNo ratings yet

- ManufacturingTechnology II GKV PDFDocument23 pagesManufacturingTechnology II GKV PDFfdsdNo ratings yet

- Forensic Ballistics ReviewerDocument2 pagesForensic Ballistics ReviewerWilliam Bryle Pertos100% (3)

- Maintenance & Service CV Yobelindo Ok CompressDocument10 pagesMaintenance & Service CV Yobelindo Ok CompressfrediNo ratings yet

- Design & Fabrication of Hand Operated Screw Jack: Prof. Gaurav Nagdive, Dipak Sonwane, Anil Bodkhe, Omesh LilhareDocument3 pagesDesign & Fabrication of Hand Operated Screw Jack: Prof. Gaurav Nagdive, Dipak Sonwane, Anil Bodkhe, Omesh LilhareRohit ArashingodiNo ratings yet

- Cam Imp (Veena)Document16 pagesCam Imp (Veena)Sidpara DeepNo ratings yet

- MCQ in Machine Design and Shop Practice Part 8 ME Board ExamDocument12 pagesMCQ in Machine Design and Shop Practice Part 8 ME Board Examtagne simo rodrigue100% (1)