Professional Documents

Culture Documents

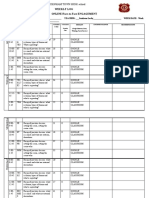

Grade 11 FURNITURE TECHNOLOGY - Machine Operations

Uploaded by

Guyan Gordon0 ratings0% found this document useful (0 votes)

10 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views3 pagesGrade 11 FURNITURE TECHNOLOGY - Machine Operations

Uploaded by

Guyan GordonCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

FURNITURE TECHNOLOGY – MACHINE OPERATIONS

MACHINES USES OF A CIRCULAR SAW

CIRCULAR SAW ripping rebating

cross-cutting dadoing

PARTS OF A CIRCULAR SAW mitring

RIPPING ON THE CIRCULAR SAW

Checking table Checking blade Aligning mitre guage

alignment angle with saw table

Position the mitre gauge Remove the table With the miter gauge

at the front of the saw insert, then butt a out of slot, use a

blade. Hold or clamp a combination square combination square to

perfectly squared wood against the saw blade confifirm that the head

block against the miter between two teeth.The is sqare with egde of

gauge and butt the end blade of the square the gauge bar.

of the block against a should fit flush against

saw blade tooth. the saw blade.

Slide the mitre gauge

and the block together

Measure the distance to the edge of a tooth nearest to the fence

toward the back of the

table while rotating the Clamp the rip fence to the table at the desired distance from the blade

blade by hand. Adjust the blade for a 90-degree cut. The blade should protrude ¼ inch

(6mm) above the stock.

Stand to one side of the path of the stock being ripped. If the stock binds

between the blade and the fence, it may be thrown back toward the

SAFETY RULES

operator.

Wear eye protection around machine tools. Turn the saw on and feed the stock against the fence and into the blade.

Keep all guards and protective devices in place. CAUTION: To rip narrow stock, a push stick should be used to feed the stock.

Do not operate defective machines. Aligning mitre guage Removing the old Installing the new

Disconnect the electrical power before changing blades or cutters or with saw blade blade blade

performing maintenance. Butt a framing square Wedge a piece of Slide the blade on the CROSS-CUTTING ON THE CIRCULAR SAW

against the mitre gauge scrap wood under a arbor with its teeth

Do not position hands where they will be in the path of cutters and blades.

and the saw blade blade tooth to prevent pointing in the direction

Do not wear loose clothing or jewellery. between two teeth. the blade from turning of blade rotation

Stand clear of the path of the stock when ripping lumber. Use the wrench Insert the washer and

Adjust saw blades only as deep as necessary. supplied with the saw start tightening by hand

Use machine tools only after you have had instruction on their use. to loosen the arbor nut with a rag and use a

Finish loosen the nut wrench supplied with

by hand and carefully the saw

lift blade off the arbor Do not use a piece of

wood as a wedge as

this could result in over-

tightening

Measure and mark off the length of the stock with a square. BAND SAW OPERATION THAT CAN BE PERFORMED ON A BAND SAW:

Adjust the height of the saw blade 1.5 to 3 mm above the thickness

PARTS OF A BAND SAW The diameter of the wheels or pulleys

of the stock.

Adjust the upper blade to just clear the stock

Push the fence out of the way and position the stock on the table

holding it firmly against the mitre gauge Check to see that the blade guides are properly adjusted.

Mark a line across the stock where it is to be sawed. Check to see if the table is properly adjusted.

Turn the saw on. Turn the saw on

Hold the stock firmly against the mitre gauge and line up the mark Place the work piece on the table and feed the stock into the blade

with the blade. with one hand each side of the table.

Push the mitre gauge and stock across the table. CAUTION: Never position your hands so that they will hit the blade if

you slip.

Remove the stock from the table before returning the mitre gauge to

the starting position. Plan the cut to require as little backing up as possible. It often helps

to make a series of relief cuts to allow the blade to turn sharply.

WOOD LATHE

PARTS OF A WOOD LATHE

Ripping Freehand cutting

Crosscutting Bevel cut

Irregular cuts Chamfer

Cutting circles

SAFETY RULES TURNING CHISEL OR LATHE TOOLS Beads &Vee Cut use the parting chisel to mark out lines for beads and

vees , then use skew to cut beads into shape

Do not wear loose fitting clothing or jewellery which could get caught A round nose hollow chisel. Used for rounding or

in the revolving stock. roughing the stock.

The tail stock should be checked to ensure that the stock is tight. Gouge JOINTER

Position the tool rest so that it suits the cutting action of the wood A double ground flat chisel with the end ground at

turning tool. an angle. Used for smoothing stocks and cutting PARTS OF A JOINTER

Ensure that the motor speed is the correct one for the size of stock Skew shoulders.

being turned. Flat ground to a point. It is used to make

Goggles or face shields must be used to protect the operator from concaves shapes

flying chips. Spear

Avoid resting unused tools on the lathe as they might cause injury or Flat with point rounded. It is used to cut out coves

become damaged when they fall. and hollows. It is one of the most used tools in

face plate turning

The wood lathe is one of the oldest types of woodworking machines. It is

Round nose

capable of producing finished jobs.

Double ground chisel, used for cutting-off or

There are two types of turning done on the wood lathe: making parts to required diameters

Parting

Spindle turning (when the stock is mounted between the head and

tail stock)

Faceplate Turning (stock is mounted onto the head stock only) ITEMS WHICH MAY BE PRODUCED ON THE LATHE

SIZE, TYPES & SPEED Rolling pins Fruit bowls

Table legs Cups

There are two factors that determined the size of a wood lathe: Lamp stems Tool handles

The swing of its face plate

The length of the longest stock (wood) that can be held between its STEPS WHEN SPINDLE TURNING

centres

Square up stock Square and mark diagonal lines at both ends of the stock

The speed of a wood lathe ranges from 350-3600 r.p.m(the larger the stock, the used a tenon saw to cut into mark about 8 mm

the lesser the revolution)

Mounting Stock Carefully position the stock between the live and dead

PARTS AND USES centre. Lock the tail stock and tighten the hand wheel

Testing Test grip by spinning with the hand and make necessary

Head This consists of the driving mechanism which includes the live adjustment to prevent binding at the dead centre.

stock centre and the spindle or spur.

Oiling place 2-3 drops of oil on the tail stock

Tail This consist of the dead centre and the locking adjustments

Roughing use the gouge to rough up the stock USES OF A JOINTER

stock

Bed This supports the body or frame. It holes both the head and tail Smoothing use the skew to smooth the stock

edge planing bevelling

stock assembles as well as the tool rest. Making Coves use the round nose chisel to make coves as well as

rebating tapering

Tool rest This is an adjustable bar used to rest turning tools on. concave shapes on the stock

chamfering face planing

Making Parts use the parting chisel to make parts on the stock

Mortise Blocks use the parting chisel when making mortise blocks

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- How To Be A Collaborative LeaderDocument3 pagesHow To Be A Collaborative LeaderGuyan GordonNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Collaborating Through Shared DecisionDocument7 pagesCollaborating Through Shared DecisionGuyan GordonNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Electrical Level 1 Cl. 2 InstructorDocument3 pagesElectrical Level 1 Cl. 2 InstructorGuyan GordonNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Collaborative LeadershipDocument9 pagesCollaborative LeadershipGuyan GordonNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Design Thinking in EducationDocument11 pagesDesign Thinking in EducationGuyan GordonNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Electrical Level 1 Cl. 1. June 2022 - InstructorDocument6 pagesElectrical Level 1 Cl. 1. June 2022 - InstructorGuyan GordonNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- HGSE-Doctoral-Viewbook 2022Document24 pagesHGSE-Doctoral-Viewbook 2022Guyan GordonNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- RE-G7 T2 U2.4 Short Version Visual Arts Classwork Local and International Artist Sheet Offline 004Document4 pagesRE-G7 T2 U2.4 Short Version Visual Arts Classwork Local and International Artist Sheet Offline 004Guyan GordonNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Safety in Industrial EnvironmentDocument3 pagesSafety in Industrial EnvironmentGuyan GordonNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Hazards - IndustrialDocument5 pagesHazards - IndustrialGuyan GordonNo ratings yet

- University of Technology, Jamaica: Faculty of Education and Liberal StudiesDocument3 pagesUniversity of Technology, Jamaica: Faculty of Education and Liberal StudiesGuyan GordonNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Electrical Installation Level 2 Cl. 1 (June 2022) - InstructorDocument4 pagesElectrical Installation Level 2 Cl. 1 (June 2022) - InstructorGuyan GordonNo ratings yet

- 7 Electrical Technolgy - Electron TheoryDocument4 pages7 Electrical Technolgy - Electron TheoryGuyan GordonNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- G7EOUTU2T2-2021 2nd Edition IIDocument4 pagesG7EOUTU2T2-2021 2nd Edition IIGuyan GordonNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- First Aid Lesson-IndustrialDocument4 pagesFirst Aid Lesson-IndustrialGuyan GordonNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Summary - LTL - Module 3Document8 pagesSummary - LTL - Module 3Guyan GordonNo ratings yet

- Module 1: Social and Emotional LearningDocument8 pagesModule 1: Social and Emotional LearningGuyan GordonNo ratings yet

- Promoting The 4Cs in Online EngagementDocument19 pagesPromoting The 4Cs in Online EngagementGuyan GordonNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- R5 Munro College Final Inspection ReportDocument43 pagesR5 Munro College Final Inspection ReportGuyan GordonNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Module 2: Communication Skills in The ClassroomDocument6 pagesModule 2: Communication Skills in The ClassroomGuyan GordonNo ratings yet

- Grade 8 Materials - Classification of MaterialDocument4 pagesGrade 8 Materials - Classification of MaterialGuyan GordonNo ratings yet

- Sense of Belonging and Social and Emotional Learning: Shifting The Current School ClimateDocument3 pagesSense of Belonging and Social and Emotional Learning: Shifting The Current School ClimateGuyan GordonNo ratings yet

- Olivia Models-1Document18 pagesOlivia Models-1Guyan GordonNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Weekly Log ONLINE/Face-to-Face ENGAGEMENTDocument2 pagesWeekly Log ONLINE/Face-to-Face ENGAGEMENTGuyan GordonNo ratings yet

- Lecky-Online Weekly Log 4 UpdateDocument3 pagesLecky-Online Weekly Log 4 UpdateGuyan GordonNo ratings yet

- Edwards-Online Weekly Log Updated 2Document3 pagesEdwards-Online Weekly Log Updated 2Guyan GordonNo ratings yet

- Answer A ( (Questions Below: Subject: Drama Date October 28, 2020 Grade: 7Document3 pagesAnswer A ( (Questions Below: Subject: Drama Date October 28, 2020 Grade: 7Guyan GordonNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Denham Town High Minutes Nov 26Document2 pagesDenham Town High Minutes Nov 26Guyan GordonNo ratings yet

- Denham Town High School-Log ReportsDocument2 pagesDenham Town High School-Log ReportsGuyan GordonNo ratings yet

- TJ Art Studios Drop in Open Studio and Independent Study SessionsDocument2 pagesTJ Art Studios Drop in Open Studio and Independent Study SessionsJess SauerNo ratings yet

- 2015 Annual Report Complete enDocument236 pages2015 Annual Report Complete enNgọc Trâm ĐặngNo ratings yet

- Wedding Dress (1916)Document2 pagesWedding Dress (1916)chapmanmuseum50% (2)

- Earth Therapy EbookDocument20 pagesEarth Therapy Ebookjonylony100% (1)

- Scarlett's Mystery - The Royal SecretDocument15 pagesScarlett's Mystery - The Royal SecretHemantPandayNo ratings yet

- Hammer Mill Job Hazard Assessment PDFDocument2 pagesHammer Mill Job Hazard Assessment PDFIfa FafaNo ratings yet

- EF3e Preint Progresstest 1 6a Answer SheetDocument2 pagesEF3e Preint Progresstest 1 6a Answer SheetEva Barrales50% (2)

- Five Rivers Auctions Firearms Specialty Auctions January 2013 CatalogDocument120 pagesFive Rivers Auctions Firearms Specialty Auctions January 2013 Catalogewood1999No ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- (Natres) Gold of Our AncestorsDocument4 pages(Natres) Gold of Our AncestorsStephanie GriarNo ratings yet

- Guitar Making Guide - Jon SevyDocument170 pagesGuitar Making Guide - Jon Sevyaboutsoundcraft100% (5)

- The Head Hunters of BorneoDocument439 pagesThe Head Hunters of Borneoh8jfjzc72cNo ratings yet

- Magebot Loot ListDocument6 pagesMagebot Loot ListLucas Fujimoto33% (3)

- SaundaryalahariDocument24 pagesSaundaryalaharikatchalldakrudNo ratings yet

- Week 26 "When They Opened The Jewelry Box, They Could Not Believe What Was in It."Document1 pageWeek 26 "When They Opened The Jewelry Box, They Could Not Believe What Was in It."Momin KhanNo ratings yet

- Who Is The Strong-Armed Monkey Who Chur PDFDocument26 pagesWho Is The Strong-Armed Monkey Who Chur PDFSovannrath VarNo ratings yet

- Manual PS-100 Limpiador UltrasonicoDocument6 pagesManual PS-100 Limpiador UltrasonicoAlexis Barnabás CollinsNo ratings yet

- Bark Cloth Beater of Arku CaveDocument5 pagesBark Cloth Beater of Arku CaveMark Anthony FauneNo ratings yet

- 10 Major Types of Natural Resources Found in PakistanDocument13 pages10 Major Types of Natural Resources Found in PakistanAbdul MajidNo ratings yet

- Dancer of Shamahka - Armen OhanianDocument280 pagesDancer of Shamahka - Armen OhanianManukSurenNo ratings yet

- SNP (A4) PDFDocument141 pagesSNP (A4) PDFestefi chanNo ratings yet

- CLORES, Ma. Ariane Aedy B. 2/4/2021 2G-PH Art - App: Applying Visual ElementsDocument2 pagesCLORES, Ma. Ariane Aedy B. 2/4/2021 2G-PH Art - App: Applying Visual ElementsAriNo ratings yet

- UD 4 Minerals and Rocks 1º ESODocument16 pagesUD 4 Minerals and Rocks 1º ESOS AP100% (1)

- Quantitative Aptitude: Permutation & Combination-2Document4 pagesQuantitative Aptitude: Permutation & Combination-2sj singhNo ratings yet

- Asamyukta Hasta or Single Hand GestureDocument34 pagesAsamyukta Hasta or Single Hand GestureJay SuriaraoNo ratings yet

- Script TAG Heuer Carrera Chronos SportDocument2 pagesScript TAG Heuer Carrera Chronos SportDevil GodNo ratings yet

- The Necklace Student WorksheetDocument5 pagesThe Necklace Student Worksheetflynnk100% (8)

- Cebu Technological University: Daanbantayan Campus Agujo, Daanbatayan, Cebu Page 1 of 8 Pages Page 1 of 8 PagesDocument14 pagesCebu Technological University: Daanbantayan Campus Agujo, Daanbatayan, Cebu Page 1 of 8 Pages Page 1 of 8 PagesJohn DilaoNo ratings yet

- The Drinker of Eyes, Bendorp Sonnet: Poems by Arthur CravanDocument2 pagesThe Drinker of Eyes, Bendorp Sonnet: Poems by Arthur CravanIonut BanceuNo ratings yet

- Decision Support System For A Jewellery ManufacturerDocument9 pagesDecision Support System For A Jewellery Manufacturerpriyaagarwal26No ratings yet

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiFrom Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiRating: 5 out of 5 stars5/5 (2)

- House Rules: How to Decorate for Every Home, Style, and BudgetFrom EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNo ratings yet

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiFrom EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiRating: 4 out of 5 stars4/5 (3)

- Bulletproof Seduction: How to Be the Man That Women Really WantFrom EverandBulletproof Seduction: How to Be the Man That Women Really WantRating: 4.5 out of 5 stars4.5/5 (170)

- Edward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsFrom EverandEdward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsNo ratings yet

- Crochet Impkins: Over a million possible combinations! Yes, really!From EverandCrochet Impkins: Over a million possible combinations! Yes, really!Rating: 4.5 out of 5 stars4.5/5 (10)

- Modern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeFrom EverandModern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeRating: 5 out of 5 stars5/5 (1)