Professional Documents

Culture Documents

Pressing Machine Audit Points - v3

Uploaded by

Pampanagouda Yadav0 ratings0% found this document useful (0 votes)

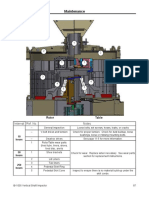

73 views1 pageThe safety audit observed several issues with two pressing machines. For the 400 Ton machine's rotor assembly, maintenance issues included play in a connecting rail block, oil leaks from various components, unsecured safety chains and cables, and loose or damaged components. For the 250 Ton machine's stator core assembly, observations noted abnormal noise during extended operation, dents and damage to the base plate, and an unsecured panel board key. The audit identified maintenance responsibilities for addressing 11 issues on the 400 Ton machine and 3 issues on the 250 Ton machine.

Original Description:

Pressing machine audit

Original Title

3. Pressing Machine Audit Points_v3

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe safety audit observed several issues with two pressing machines. For the 400 Ton machine's rotor assembly, maintenance issues included play in a connecting rail block, oil leaks from various components, unsecured safety chains and cables, and loose or damaged components. For the 250 Ton machine's stator core assembly, observations noted abnormal noise during extended operation, dents and damage to the base plate, and an unsecured panel board key. The audit identified maintenance responsibilities for addressing 11 issues on the 400 Ton machine and 3 issues on the 250 Ton machine.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

73 views1 pagePressing Machine Audit Points - v3

Uploaded by

Pampanagouda YadavThe safety audit observed several issues with two pressing machines. For the 400 Ton machine's rotor assembly, maintenance issues included play in a connecting rail block, oil leaks from various components, unsecured safety chains and cables, and loose or damaged components. For the 250 Ton machine's stator core assembly, observations noted abnormal noise during extended operation, dents and damage to the base plate, and an unsecured panel board key. The audit identified maintenance responsibilities for addressing 11 issues on the 400 Ton machine and 3 issues on the 250 Ton machine.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 1

Safety Audit Observations - Press machines safety

SL # Observations Location Issue Responsible

400 Ton Pressing machine- Rotor assembly

Connecting rail block found more

1 Rotor assembly play when compared to other 3 Maintenance

blocks

Trolley movement- no

2 Rotor assembly abnormality found during trolley Maintenance

movement

3 Rotor assembly Oil leakage / oil like observed Maintenance

below over head block

Safety chain provided not

4 Rotor assembly removed, no Hook to fix the Maintenance

chain

Ceramic cloth wrapped on

5 Rotor assembly hydraulic hoses not removed Maintenance

after use.

Oil leakage in pipe roughting to

6 Rotor assembly Maintenance

overhead cylinder

7 Rotor assembly Oil leakage in power pack Maintenance

Cable found out side the cable

8 Rotor assembly tray and found loose , chance of Maintenance

stuck during trolley movement.

9 Rotor assembly Operating buttons working found Maintenance

ok

10 Rotor assembly Oil leakage below the power Maintenance

pack and accumulated in tray

11 Rotor assembly Oil leakage found near housing Maintenance

250 Ton Pressing Machine - Stator

assembly

1 Stator core assembly Abnormal noise when core is Maintenance

pressed for longer time.

2 Stator core assembly Base plate found dents and Maintenance

damages

3 Stator core assembly Panel board key found hanged by Maintenance

using wire.

You might also like

- EPA2010ElectricalModels M2106 M2112 108SD 114SDDocument43 pagesEPA2010ElectricalModels M2106 M2112 108SD 114SDEdwin Motta Piamba91% (11)

- Meritor Preventive Maintenance ManualDocument239 pagesMeritor Preventive Maintenance ManualChristopher Ponce Yanac100% (1)

- Engine Exhaust BrakeDocument12 pagesEngine Exhaust BrakeTamer MoustafaNo ratings yet

- Single-Reduction Differential Carriers: Single Rear Drive Axles, Rear-Rear Tandem Drive Axles and Front Drive Steer AxlesDocument94 pagesSingle-Reduction Differential Carriers: Single Rear Drive Axles, Rear-Rear Tandem Drive Axles and Front Drive Steer AxlesTavyLocNo ratings yet

- Stihl 021 023 025 Workshop Manual PDFDocument52 pagesStihl 021 023 025 Workshop Manual PDFTony Wells100% (2)

- Mock 03 001 PDFDocument30 pagesMock 03 001 PDFmasud khanNo ratings yet

- LF90LS Operations and Service Manual PDFDocument154 pagesLF90LS Operations and Service Manual PDFDavid Fino Y. Seguro100% (1)

- HIRA For Solar Roof Top Work at ExcavationDocument2 pagesHIRA For Solar Roof Top Work at ExcavationPampanagouda Yadav100% (8)

- Tadano gr700n ManualDocument200 pagesTadano gr700n ManualAndrey80% (5)

- Tyrone Gear Pump DiagnosisDocument20 pagesTyrone Gear Pump DiagnosisMohamad SaremyNo ratings yet

- SMT Crane Maintenance ManualDocument84 pagesSMT Crane Maintenance ManualArun Tiwari100% (1)

- System NGRDocument268 pagesSystem NGRaji.isrambo100% (1)

- Machine Profiles: D9R Track-Type TractorsDocument8 pagesMachine Profiles: D9R Track-Type TractorsJavier Pagan TorresNo ratings yet

- En Maintenance and Repair Module 1 PDFDocument55 pagesEn Maintenance and Repair Module 1 PDFvaisakhNo ratings yet

- Diesel Generator Service Manual: OPEN TYPE: DHY6000LE / DHY6000LE-3 Soundproof Type: Dhy6000Se / Dhy6000Se-3Document57 pagesDiesel Generator Service Manual: OPEN TYPE: DHY6000LE / DHY6000LE-3 Soundproof Type: Dhy6000Se / Dhy6000Se-3Nestor LopezNo ratings yet

- Behaviour Based Safety (BBS)Document54 pagesBehaviour Based Safety (BBS)Pampanagouda YadavNo ratings yet

- Vespa Service Manual 08-04-2021Document322 pagesVespa Service Manual 08-04-2021Julio Borrero100% (1)

- Ducati Case: The Making of A Grand Prix MotorcycleDocument3 pagesDucati Case: The Making of A Grand Prix Motorcyclehagar sudhaNo ratings yet

- Safety For Children OrdinanceDocument3 pagesSafety For Children OrdinanceChristmyrian BalabaNo ratings yet

- 5 Transmission-N900 Series JMCDocument36 pages5 Transmission-N900 Series JMCRusonegroNo ratings yet

- Offshore PlatformsDocument55 pagesOffshore PlatformsFoyez Ahmad100% (2)

- Societe Chinoise LTD: Irrevocable Corporate Purchase OrderDocument4 pagesSociete Chinoise LTD: Irrevocable Corporate Purchase OrderPatrick NoelNo ratings yet

- Behaviour-Based Safety in Organizations: Saving Life Before The Accident, 2/eDocument2 pagesBehaviour-Based Safety in Organizations: Saving Life Before The Accident, 2/ePampanagouda YadavNo ratings yet

- Traffic Engineering-Lecture 1Document10 pagesTraffic Engineering-Lecture 1Ahmad Salih100% (1)

- Designing Airport Passenger Buildings For The 21stDocument28 pagesDesigning Airport Passenger Buildings For The 21stWanNo ratings yet

- Maintenance: Rotor Interval Ref. No. NotesDocument11 pagesMaintenance: Rotor Interval Ref. No. NotesEduardo AcostaNo ratings yet

- Abs Guide For Passenger Comfort On ShipsDocument106 pagesAbs Guide For Passenger Comfort On ShipsMahdiNo ratings yet

- Compressor Inspection Report PLQDocument15 pagesCompressor Inspection Report PLQkhairul muzamil khairuddinNo ratings yet

- EON New ManualDocument38 pagesEON New ManualS S ThakurNo ratings yet

- Mooring Deck Guidelines UpdateDocument20 pagesMooring Deck Guidelines UpdateAlchemist_JVCNo ratings yet

- 01.01.2021 - Mob DrillDocument5 pages01.01.2021 - Mob DrillAlikar ArslanNo ratings yet

- KSB Pump Movi ManualDocument12 pagesKSB Pump Movi ManualVenkat Dora100% (4)

- Tomahawk 404M 4040 404XLM 4040XL 505M 5050 505XLM 5050XL Instruction Book PDFDocument20 pagesTomahawk 404M 4040 404XLM 4040XL 505M 5050 505XLM 5050XL Instruction Book PDFДима ЧернеевNo ratings yet

- Giant MPH-3 Disc Brake System Model Year 2002: Owners ManualDocument24 pagesGiant MPH-3 Disc Brake System Model Year 2002: Owners Manuallock.offNo ratings yet

- Giant MPH-3 Disc Brake System Model Year 2002: Owners ManualDocument24 pagesGiant MPH-3 Disc Brake System Model Year 2002: Owners Manuallock.offNo ratings yet

- 3.1training - Manual - TBN Steam Path (Rotor)Document16 pages3.1training - Manual - TBN Steam Path (Rotor)Tung Nguyen100% (1)

- RT-137 - A1 Onboard Repair Kits and Order NumbersDocument6 pagesRT-137 - A1 Onboard Repair Kits and Order Numbers郑开元No ratings yet

- Orbitrol Repairing 2Document14 pagesOrbitrol Repairing 2Islam ShoukryNo ratings yet

- RWRG0001 - Auxiliary Drive Gear Bearing Failure: Roadranger Warranty Repair Guideline RWRG0001Document1 pageRWRG0001 - Auxiliary Drive Gear Bearing Failure: Roadranger Warranty Repair Guideline RWRG0001Bart JohnNo ratings yet

- RWRG0003 - Auxiliary Drive Gear Bearing Failure: Roadranger Warranty Repair Guideline RWRG0003Document1 pageRWRG0003 - Auxiliary Drive Gear Bearing Failure: Roadranger Warranty Repair Guideline RWRG0003Bart JohnNo ratings yet

- 3-CA4250P25K2T1E5A80-DY640-engine AccessoriesDocument24 pages3-CA4250P25K2T1E5A80-DY640-engine AccessoriesJesus gomez corvalanNo ratings yet

- 0 Operating Manual - PKOM1Document11 pages0 Operating Manual - PKOM1Yormary TorresNo ratings yet

- Canter Shop ManualDocument75 pagesCanter Shop ManualchadyNo ratings yet

- Manual 600 NEWDocument5 pagesManual 600 NEWabhayuietNo ratings yet

- Section 4 - Cam Followers/Tappets - Group 04Document9 pagesSection 4 - Cam Followers/Tappets - Group 04Miodrag HuberNo ratings yet

- Maintenance Manual Moster185 Eng 022Document138 pagesMaintenance Manual Moster185 Eng 022ecadashvili.guramiNo ratings yet

- PV776-20 006112 PDFDocument6 pagesPV776-20 006112 PDFJhosepNo ratings yet

- FP - A.1 - Consequential Damage and Inspection Techniques From Lack of Lubrication, Steam Turbine CaseDocument14 pagesFP - A.1 - Consequential Damage and Inspection Techniques From Lack of Lubrication, Steam Turbine Casemhdsoleh100% (1)

- Summary of AC Motor Induction ProceduresDocument1 pageSummary of AC Motor Induction ProceduresMunazar HussainNo ratings yet

- RK4 Rotor Kit Datasheet - 141592Document5 pagesRK4 Rotor Kit Datasheet - 141592Lincoln Luiz CorrêaNo ratings yet

- P 105 Mechanical Seal Failure (29-04-2021)Document5 pagesP 105 Mechanical Seal Failure (29-04-2021)Zaman SuhailNo ratings yet

- Roller Chain MaintenanceDocument8 pagesRoller Chain MaintenanceRodrigo SenedezeNo ratings yet

- Yamaha YZFR6X Service Manual 2008 (235-434)Document200 pagesYamaha YZFR6X Service Manual 2008 (235-434)Harold CruzNo ratings yet

- Disc Rotor (6 Bolt Type) : General Safety InformationDocument1 pageDisc Rotor (6 Bolt Type) : General Safety InformationRuben BareiroNo ratings yet

- 8-CA3250P25K15L3T1E5A80-DW014H-power Drive ShaftDocument10 pages8-CA3250P25K15L3T1E5A80-DW014H-power Drive ShaftJesus gomez corvalanNo ratings yet

- Elecon Eon Installation Maintenance ManualDocument38 pagesElecon Eon Installation Maintenance Manualbudibuzen23No ratings yet

- CJC Crusher Brochure PDFDocument12 pagesCJC Crusher Brochure PDFjohn xezeNo ratings yet

- Teagle Tomahawk Common Backplate 404 404m 4040 505 505m 5050 Issue 1111Document44 pagesTeagle Tomahawk Common Backplate 404 404m 4040 505 505m 5050 Issue 1111regivaldojrNo ratings yet

- Is-V3155b Agcdr-0071-EnDocument15 pagesIs-V3155b Agcdr-0071-EnPrakash WarrierNo ratings yet

- Coal Mill ASF Ver 2.0Document10 pagesCoal Mill ASF Ver 2.0Udhayakumar VenkataramanNo ratings yet

- RWRG0004 - Clutch Housing Gasket Leak: Pre-Authorized Warranty Repair Guideline RWRG0004Document2 pagesRWRG0004 - Clutch Housing Gasket Leak: Pre-Authorized Warranty Repair Guideline RWRG0004Bart JohnNo ratings yet

- Technical Bulletin: Wärtsilä Low-Speed EnginesDocument5 pagesTechnical Bulletin: Wärtsilä Low-Speed EnginesKr ManuNo ratings yet

- Core Acceptance Criteria GeneratorDocument5 pagesCore Acceptance Criteria Generatorgonzalo ahumadaNo ratings yet

- Problems (11.02.22)Document4 pagesProblems (11.02.22)Md. Shafikul Islam Production (Ref)No ratings yet

- Front Drive Halfshafts - : Item SpecificationDocument19 pagesFront Drive Halfshafts - : Item SpecificationJim LiebNo ratings yet

- Reliable Axle ManualDocument32 pagesReliable Axle ManualjitmarineNo ratings yet

- Eon Series: Installation, Operation & Maintenance ManualDocument38 pagesEon Series: Installation, Operation & Maintenance ManualA SuhardimanNo ratings yet

- Brake SystemDocument8 pagesBrake SystemDomingo BravoNo ratings yet

- Victa Lawnmower Assembly and Owner's Manual: Assembly - Operating K6 Final - QXD 8/12/04 1:33 PM Page 1Document28 pagesVicta Lawnmower Assembly and Owner's Manual: Assembly - Operating K6 Final - QXD 8/12/04 1:33 PM Page 1johnNo ratings yet

- 3541RL 3541RL: Service Manual Service ManualDocument18 pages3541RL 3541RL: Service Manual Service Manualyousef ALadwanNo ratings yet

- Online Version - Not For Reprint: Downloaded From Manuals Search EngineDocument13 pagesOnline Version - Not For Reprint: Downloaded From Manuals Search EngineManuel SterlingNo ratings yet

- ChecklistDocument4 pagesChecklistEyob HaylemariamNo ratings yet

- 38 EmbragueDocument52 pages38 EmbragueCarlos CandelaNo ratings yet

- Weir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedureDocument10 pagesWeir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedurePutra JawaNo ratings yet

- Rover V8 DIS Kit Instructions 1.4Document25 pagesRover V8 DIS Kit Instructions 1.4enquiries7922No ratings yet

- 2d W Cs&ws 1-2-Feb-20 Delhi spbdg313269Document5 pages2d W Cs&ws 1-2-Feb-20 Delhi spbdg313269Pampanagouda YadavNo ratings yet

- d3cd9f3f0daebb903d60011200191934Document1 paged3cd9f3f0daebb903d60011200191934Pampanagouda YadavNo ratings yet

- Guide To Proven Warehouse Solutions e BookDocument29 pagesGuide To Proven Warehouse Solutions e BookPampanagouda YadavNo ratings yet

- Final Revised 2016 Workplace Driving Safety Toolkit Funded by ODPSDocument32 pagesFinal Revised 2016 Workplace Driving Safety Toolkit Funded by ODPSPampanagouda YadavNo ratings yet

- Behaviour-Based Safety in Organizations: Saving Life Before The AccidentDocument1 pageBehaviour-Based Safety in Organizations: Saving Life Before The AccidentPampanagouda YadavNo ratings yet

- BEMP EEE ManufacturingDocument283 pagesBEMP EEE ManufacturingPampanagouda YadavNo ratings yet

- ಪರೀಷ್ಕೃತ ಸುತ್ತೋಲೆ-ಮ್ಯುಕೋರ್ ಮೈಕೋಸಿಸ್ ಸೋಂಕಿನ ಚಿಕ... ರ ಪರೀಷ್ಕೃತ ಶಿಫಾರಸ್ಸುಗಳನ್ನು ಅನುಸರಿಸುವ ಬಗ್ಗೆDocument21 pagesಪರೀಷ್ಕೃತ ಸುತ್ತೋಲೆ-ಮ್ಯುಕೋರ್ ಮೈಕೋಸಿಸ್ ಸೋಂಕಿನ ಚಿಕ... ರ ಪರೀಷ್ಕೃತ ಶಿಫಾರಸ್ಸುಗಳನ್ನು ಅನುಸರಿಸುವ ಬಗ್ಗೆPampanagouda YadavNo ratings yet

- Special Issue April May 50Document4 pagesSpecial Issue April May 50Pampanagouda YadavNo ratings yet

- Process:Inspection: Qaqc - Mechanical HAZARD (Source, Situation) and RISK IDENTIFICATIONDocument4 pagesProcess:Inspection: Qaqc - Mechanical HAZARD (Source, Situation) and RISK IDENTIFICATIONPampanagouda YadavNo ratings yet

- Machine Safety GuidelinesDocument21 pagesMachine Safety GuidelinesPampanagouda YadavNo ratings yet

- Receipt: No: PRCHE/114905 Date: 06-Jun-2021 Payment Mode: PGDocument2 pagesReceipt: No: PRCHE/114905 Date: 06-Jun-2021 Payment Mode: PGPampanagouda YadavNo ratings yet

- IMAT MEIL 21 SINGATALUR DRIP IRRIGATION PKG-01 Q2 2019-20 - ReportDocument78 pagesIMAT MEIL 21 SINGATALUR DRIP IRRIGATION PKG-01 Q2 2019-20 - ReportPampanagouda YadavNo ratings yet

- Entry-Exit Looper Rolls Cleaning 16.03.2019Document1 pageEntry-Exit Looper Rolls Cleaning 16.03.2019Pampanagouda YadavNo ratings yet

- Self Declaration - Covid 19 Pre Screening: SL No Check Points AnswerDocument1 pageSelf Declaration - Covid 19 Pre Screening: SL No Check Points AnswerPampanagouda YadavNo ratings yet

- Your Charges in Detail - 6366824087: Monthly RentalsDocument1 pageYour Charges in Detail - 6366824087: Monthly RentalsPampanagouda YadavNo ratings yet

- July 5, 2014Document16 pagesJuly 5, 2014Thief River Falls Times & Northern WatchNo ratings yet

- Model: T1400 Diesel GensetDocument5 pagesModel: T1400 Diesel Gensetengnajeeb75No ratings yet

- Distance WarningDocument2 pagesDistance Warningtarakram2809No ratings yet

- FSBR b737 Rev 19 DraftDocument75 pagesFSBR b737 Rev 19 DraftKhushboo VermaNo ratings yet

- Pay Attention To The Way The Verb Handle Collocates With Different Nouns and How It Changes Its MeaningDocument23 pagesPay Attention To The Way The Verb Handle Collocates With Different Nouns and How It Changes Its MeaningаделинаNo ratings yet

- Attic Stairs: at Last A Sturdy, Well Made Folding Attic Stair That Is Easy To Install and Easy To Use..Document5 pagesAttic Stairs: at Last A Sturdy, Well Made Folding Attic Stair That Is Easy To Install and Easy To Use..Angel Venus GuerreroNo ratings yet

- Bontrager Tire PressuresDocument3 pagesBontrager Tire PressuresJosefa ReyesNo ratings yet

- 60 - Summary of Items Discussed in APSEC Discussion Forum On 4 November 2016Document16 pages60 - Summary of Items Discussed in APSEC Discussion Forum On 4 November 2016kayau APCNo ratings yet

- Cane FurnitureDocument10 pagesCane FurnitureYaseen KhanNo ratings yet

- JN1350 - Fab Progress S Curve Structures 200217Document12 pagesJN1350 - Fab Progress S Curve Structures 200217Rendra Maha Putra JfNo ratings yet

- Tenet CarparkingDocument6 pagesTenet CarparkingSenghy MaoNo ratings yet

- SG03 CPM AmoDocument42 pagesSG03 CPM AmoAnandaMandalNo ratings yet

- Yi-Lai Berhad - COMPANY PROFILE - ProjectDocument4 pagesYi-Lai Berhad - COMPANY PROFILE - ProjectTerry ChongNo ratings yet

- Purchasing & Asset ManagementDocument31 pagesPurchasing & Asset Managementabdihil mukhlisNo ratings yet

- RenaultDocument75 pagesRenaultcostinel iordachescuNo ratings yet

- Mareng Vocabulary: Unit 3 - Loading The Ms MarinaDocument3 pagesMareng Vocabulary: Unit 3 - Loading The Ms MarinaSimon MendezNo ratings yet

- WSSRC: A Short History of Speed Sailing TimingDocument11 pagesWSSRC: A Short History of Speed Sailing TimingTim ZimmermannNo ratings yet