Professional Documents

Culture Documents

MCA PSC Checklist

MCA PSC Checklist

Uploaded by

fredy22120 ratings0% found this document useful (0 votes)

15 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views2 pagesMCA PSC Checklist

MCA PSC Checklist

Uploaded by

fredy2212Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

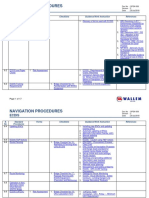

EXPANDED INSPECTION EXPANDED INSPECTION – Cont.

PORT STATE CONTROL & GI Doc No

AIDE-MEMOIRE

ALL SHIP TYPES Availability of chemical detection equipment with an appropriate Ref: Paris MOU Annex 9 & 10 / PSCCI

number of suitable gas detection tubes for the cargo carried MSF5500

STRUCTURAL CONDITION 52/2019/12 REV 3 / Dir. 2009/16/EC as

Condition of hull and deck Test of deck shower amended

Revision

WATER/WEATHERTIGHT CONDITION Test of fixed firefighting installations on deck (as required by the 6

Name of Vessel

Water/Weathertight doors product carried) June 2020

Date

Ventilators, air-pipes and casing Cabin escape sets with respiratory and eye protection if required

Hatchways by the products listed in the relevant Certificate of Fitness

ALL INSPECTIONS

EMERGENCY SYSTEMS ADDITIONAL ITEMS FOR GENERAL CARGO, Ro-Ro, CONTAINER,

Simulated black-out/start of emergency generator IN THE MASTER’S CABIN

REFRIGERATED, OFFSHORE, SPS, MODU, FPSO, OTHER CARGO

Emergency lighting WATERTIGHT / WEATHERTIGHT CONDITION Certificates/Documents (see Paris MOU Annex 10) available /

Test of bilge pumping arrangements Condition of hatch covers, if applicable not expired / translated if required

Test of closing devices / watertight doors Accesses to cargo holds / tanks Certificates/Documents valid in form and content (electronic

Test of steering gear incl. emergency steering gear Bow / Stern doors (Ro-Ro Cargo), if applicable certification validated as per PSC Circular 81)

RADIO COMMUNICATIONS CARGO OPERATIONS Documents for cargo carried according to CoF/IMDG/IMSBC

Test of reserve source of power Loading equipment Does manning conform to Minimum Safe Manning Document

Test of main installation including facilities for reception of Lashing arrangements Minimum rest period applied, hours of work/rest posted, table of

marine safety information shipboard working arrangements posted

Test of GMDSS portable VHF sets ADDITIONAL ITEMS FOR OIL TANKERS/OBO (carrying liquid cargo)

Crew certificates/valid/translated/appropriate

FIRE SAFETY Fixed deck foam system and appropriate certification

Cargo Medical examination available/valid

Test of fire detection and alarm system Control of pressure of inert gas and oxygen content thereof;

Minimum age complied with

Fire drill including a demonstration of the ability to use fireman’s Reports of structural surveys; thickness measurement reports, ISM: Crew familiar with company Safety and Environmental Policy

outfits and firefighting equipment and appliances Condition Evaluation Reports - documents are on board,

Ship’s Logbooks – Required entries / Drills / LSA inspections

Test of emergency fire pump (with 2 hoses) complete and endorsed by the flag State or RO,

Previous inspection(s) deficiencies rectified?

Test of remote emergency stopping of ventilation and associated Ballast tanks: at least one of the ballast tanks within the cargo

area to be examined from manhole access in first instance, and Sulphur content of fuel in use/in storage tanks meets MARPOL &

dampers EC requirements. FO changeover recording and compliance.

Test of remote emergency stopping of fuel pumps entered if clear grounds for further inspection established

No non-compliant fuel carried (non EGC vessels)

Test of remote operation of quick closing valves ADDITIONAL ITEMS FOR PASSENGER SHIPS, Ro-PaX and HS Pax

Fire Doors, condition, closing and latching RO-PAX & HS Pax Craft PSC INSPECTIONS

Craft Not on a Regular Service

Fixed fire extinguishing installations and associated alarms

LIVING AND WORKING CONDITIONS DOCUMENTATION (DOCUMENTED EVIDENCE OF): On Regular Service - Refer to MSF 5514 & Dir 2017/2110

The seafarers’ employment agreement Crowd Management training

The fulfilment of requirements for hours of work and rest Familiarisation training INITIAL INSPECTION

The standard of accommodation Safety training for personnel providing direct safety assistance to (MAY include function tests of equipment)

The food and catering facilities passengers in passenger spaces, and in particular to elderly and THE WALK THROUGH

The facilities on board for medical care disabled persons in an emergency NAVIGATION

The risk evaluation programmes, training and instruction, Crisis management and human behaviour training Navigational equipment

accident reporting and protective equipment WATERTIGHT / WEATHERTIGHT CONDITION : Management of charts and publications/ECDIS

LIFESAVING APPLIANCES Bow and stern doors as applicable Bridge visibility

Launching arrangements for survival and rescue craft (if Test of remote and local controls of watertight bulkhead doors / Record of tests and drills of steering gear

evidence of disuse, craft to be lowered to the water) Passage Plan

flood control doors

POLLUTION PREVENTION EMERGENCY SYSTEMS Evidence of stability management/longitudinal strength checks

Test of oil filtering equipment Crew familiarity with damage control plan RADIO NAVIGATION

CARGO OPERATIONS Radio installations

ADDITIONAL ITEMS FOR BULK CARRIERS / OBO

Lashing arrangements as applicable Radio equipment and batteries

Cargo check against the DoC for Dangerous Goods

FIRE SAFETY Record of operation and maintenance

Loading Instruments approval

Test remote and local controls for closing dampers FIRE FIGHTING APPLIANCES

Bulkheads and coamings - condition

ALARMS Fire Control Plan

Verification of operation of hold water ingress alarms

Test of public address system Firefighting system, Fire Fighters radios

Ballast Tanks – At least one tank within cargo area to be

Test of fire detection and alarm system Fire doors

examined from manhole access, and entered if clear grounds

LIFESAVING APPLIANCES Means of Escape

ESP structural surveys; thickness measurement reports,

Inert Gas System

Condition Evaluation Reports - verification that the documents

are on board, complete and endorsed by the flag State or RO Abandon ship drill (including lowering rescue and lifeboat to Management of Fire Control Plan & Instructions

water) Fire Pumps

ADDITIONAL ITEMS FOR GAS AND CHEMICAL CARRIERS OTHER Hydrants

Check that the product carried is on Certificate of Fitness Ro-Ro deck CCTV Fire Hoses

CARGO OPERATIONS Extinguishers

Water Leakage Detection System test

Cargo tank monitoring and safety devices relating to LIFESAVING APPLIANCES

Bridge closure of fire doors and WTDs

temperature, pressure and ullage Lifeboats and rescue boats, passenger tenders (Class I)

Oxygen analysing and explosimeter devices, including their Launching arrangements

calibration Liferafts / MES System (if fitted)

MORE DETAILED INSPECTION

INITIAL INSPECTION – Cont. (SHOULD include operational controls in some areas)

MORE DETAILED INSPECTION – Cont.

Personal lifesaving appliances HULL STRUCTURE ENGINE ROOM - Cont

Management of Emergency Plans and Instructions Shell Plating, Frames and End Brackets Piping – Chronic steam / oil leaks. Condition of remote / extended

Mandatory maintenance, examination, overhaul & repair Transverse bulkheads and associated structure valve operation. No. & type of temporary repairs

CARGO

records HANDLING Cargo hatchway corners, hatch covers, coamings & topside tanks

Main and auxiliary engines (temperature/pressure indicators, fuel

Cargo gear & additional equipment Double bottoms including hopper cargo spaces

& lubricating oil systems, cooling water system, exhaust gas

Cargo securing devices Fore and aft peak structure system, boilers and associated systems). Evidence of

ENGINE ROOM / STEERING GEAR Valves and electric conduits disconnected safety devices and operation of crankcase or

Main & Auxiliary engines Access doors, ladderways & railings scavenge space relief devices

Pipework Means of closure Means of communication between bridge and engine room and of

HP Fuel pipes etc as per SOLAS II-2, reg.4(2) Gaskets and tightening devices the alarms

Pumps Scuppers, inlets and discharges Emergency power source, incl. emergency generator second start

Valves Vent pipes and means of preventing ingress Enough Electrical Power if a Generator out of commission

Cleanliness of machinery spaces and bilges Supporting documents for the inspection: Survey report file, main Emergency steering.

Emergency escape routes structural plans of cargo holds and ballast tanks, and descriptive FIRE-FIGHTING SYSTEMS

Steering gear room documents referred to by IMO Res A.744 (18)

Fire doors (local and remote operation)

ELECTRICAL EQUIPMENT NAVIGATION Fire dampers and smoke dampers

Generators, Switchboards and presence of earth faults Updating of charts, publications and backup provision if required Structure fire protection, condition and any divisions compromised

Lighting Voyage Planning Quick closing valves and remote fuel stops – Verify condition and

Cables, Cable Glands, Terminations, deck/bulkhead penetrations Navigation lights and sound signals test if required.

POLLUTION PREVENTION Validity of the table/curve of residual deviation Ventilation systems – Means of Closing / Stopping

Oily-water separator, equipment and Oil Record Book Records in the compass error log Fixed fire-fighting system in ER and cargo spaces – alarm,

Garbage Arrangements and Garbage Record Book ECDIS – ENCs latest version? servicing

Fire detection and alarm system

Sewage arrangements Management of manoeuvring booklet and information IGS manual, IGS alarm, oxygen analysers, approved plan

Air pollution prevention arrangements, use of scrubbers & records Instructions on the steering changeover procedures

LIVING AND WORKING CONDITIONS Record of tests of the steering system Main and emergency fire pumps, including fire main, hydrants &

Ventilation Radar installations nozzles – operation and condition

Heating Rudder angle indicator Firefighting appliances comply with the plan

Lighting Steering gear power unit POLLUTION PREVENTION

Cabins Communication between bridge and steering gear room Oil, cargo and garbage record books

Sanitary facilities Bridge Equipment functioning (i.e. VDR, AIS, BNWAS etc) Reception facilities - properly used

Record of accommodation inspections RADIO EQUIPMENT Standard discharge connection, the oily water separator, the oil

Food/water Service documents, operators’ qualifications & Radio Logbook discharge monitoring device, 15 ppm alarm

Galleys Reserve source of energy – condition Garbage management - in accordance with the plan

Pantries EPIRB, test report, marking and hydrostatic release/battery expiry LIVING AND WORKING CONDITIONS

Messroom SART and portable VHF batteries – expiry Masters inspections recorded

EXTERNAL HULL NAVTEX - recent messages Furniture and fittings – condition

Hull EPIRB internal test DSC/DPT SART Cold and hot water - availability

Freeboard Marks LIFESAVING APPLIANCES Heating Ventilation and Air Con (HVAC)

Accommodation ladder / Gangway / Pilot Ladders Lifeboat / Rescue boat – equipment and operation Lighting Adequate – Artificial / Natural

Mooring arrangements Boats - condition and stowage Doors, floor tiles and drainage in the sanitary facilities - condition

HULL EXPOSED DECK Embarkation arrangements Food and water supplies – quantity & quality

Deck plating Life-buoys, rockets, smoke signals, radar transponders & line Food catering and storage spaces – condition, fridge

Bulwark & stays throwing appliances. temperatures, signs of vermin/pests

Guard-rails Emergency over-side lighting & illumination of the posters/signs Medicine and medical equipment and first aid boxes

Hatch coamings and drains Davits, falls, winches and brakes – close examination Personal protective equipment - availability

Hatch covers and securing arrangements Liferafts – condition, service intervals, stowage, embarkation OPERATIONAL CONTROLS – Ref PSCI 51/2018/07

Piping ladder, hydrostatic

Lifejackets, release

immersion suits, thermal protective aids, the number, EXAMPLES OF OPERATIONAL CONTROLS TO VERIFY

Vents condition and stowage EFECTIVENESS OF CREW MEMBERS COMMUNICATION &

Medical Facilities ARE AWARE OF THEIR ROLES AND RESPONSIBILITIES:

Emergency means of communication between control stations,

muster and embarkation stations Familiarity with LSA/FFA equipment / Muster list / Damage control

Escape signage, emergency illumination & over-side lights plan / fire control plan / SOPEP etc. tested through a drill

Recovery of persons from the water, plan & provision. Launching of lifeboat / rescue boat

General alarm system Navigation equipment – handling and procedures

ENGINE ROOM Handling of GMDSS and/or other communication equipment

Engine room equipment – handling and procedures

Engine room condition (plates, gratings, stairs, handrails, lighting,

Power management features - understanding

moveable parts, hot surfaces, bilges, cables properly secured,

emergency routes and escapes). Assigned specific duties related to the cargo – crew familiar with

those duties

Information given in manuals and instructions – familiarisation

You might also like

- Mooring and Anchoring Ships Vol 1Document278 pagesMooring and Anchoring Ships Vol 1fredy2212100% (4)

- Navstation User's GuideDocument398 pagesNavstation User's GuideDelsonNo ratings yet

- Fire Control PlanDocument1 pageFire Control Plandinar rosandy100% (2)

- DigiMoorX7 Software IntroductionDocument24 pagesDigiMoorX7 Software IntroductionSachin SikkaNo ratings yet

- Port State Control Quick Guide: Achieving ComplianceDocument19 pagesPort State Control Quick Guide: Achieving Compliancefredy2212100% (1)

- HW-6 Normal Type Free-Fall Life BoatDocument130 pagesHW-6 Normal Type Free-Fall Life BoatCleverson SchmidtNo ratings yet

- MN-5-034-3 Safety Checklist SOLAS PDFDocument7 pagesMN-5-034-3 Safety Checklist SOLAS PDFJose Manuel Baldor GutierrezNo ratings yet

- OIL TANKER OPERATIONS (Loading) - Conventional Tanker BasicsDocument3 pagesOIL TANKER OPERATIONS (Loading) - Conventional Tanker BasicsShoaib100% (2)

- International Navigation Limits (Inl) - WarrantiesDocument5 pagesInternational Navigation Limits (Inl) - WarrantiesKonstantinVallasteNo ratings yet

- Annual Summary of Admiralty Notices To MarinersDocument3 pagesAnnual Summary of Admiralty Notices To Marinersss_tayade100% (1)

- Nav-00 PASSAGE PLANDocument25 pagesNav-00 PASSAGE PLANIrakli BakuridzeNo ratings yet

- Colreg Week 2Document36 pagesColreg Week 2Paul Andrei Dellomas100% (3)

- Lsa Ffa Monthly ChecksDocument11 pagesLsa Ffa Monthly ChecksakashNo ratings yet

- Navigation 8 - ECDISDocument17 pagesNavigation 8 - ECDISAmit Kumar100% (1)

- Lifebuoy Line Correctly DeployedDocument2 pagesLifebuoy Line Correctly DeployedTeoStanciu100% (1)

- Abs Condition of ClassDocument16 pagesAbs Condition of ClassJon LopezNo ratings yet

- IMO Requirements On Carriage of Publications On Board ShipsDocument6 pagesIMO Requirements On Carriage of Publications On Board Shipsalevent100% (1)

- Familiarization TrainingDocument40 pagesFamiliarization TrainingAdina Anghel100% (1)

- DP FootPrint (Amended)Document5 pagesDP FootPrint (Amended)amu_more44No ratings yet

- HK Flag Req For Lsa Ffa InspectionDocument13 pagesHK Flag Req For Lsa Ffa InspectionMohit S Sodhi100% (1)

- PSC Deficiencies List - China - 6 Month TrendDocument22 pagesPSC Deficiencies List - China - 6 Month TrendOm Prakash Raj100% (3)

- Mandotory CertificatesDocument5 pagesMandotory CertificatesShimon FNo ratings yet

- Jotran Sart ManualDocument24 pagesJotran Sart Manualsathish kumar100% (3)

- 05.00.005 Passage Plan - Port ArrivalDocument2 pages05.00.005 Passage Plan - Port ArrivalPHYO MIN Thant100% (1)

- 4.3 Cargo Transfer Procedure and Operational Considerations Before Cargo OperationsDocument13 pages4.3 Cargo Transfer Procedure and Operational Considerations Before Cargo Operationsch100% (1)

- Recent Developments in Loading ComputersDocument3 pagesRecent Developments in Loading ComputersanandreevNo ratings yet

- Cheklist Fsi and GiDocument14 pagesCheklist Fsi and GiKumar AnandNo ratings yet

- Bridge-030-Master S Standing OrdersDocument14 pagesBridge-030-Master S Standing OrdersIvan Frühwirth100% (1)

- 32 - Techop Cross ConnectionsDocument34 pages32 - Techop Cross ConnectionsXa MauNo ratings yet

- Unseaworthy and Unsafe ShipDocument6 pagesUnseaworthy and Unsafe ShipcapmanirajNo ratings yet

- Annual Summary of Notices To Mariners What Is NP247Document2 pagesAnnual Summary of Notices To Mariners What Is NP247Kunal SinghNo ratings yet

- FOM10 Sec-10 Maintenance Repair and InspectionsDocument65 pagesFOM10 Sec-10 Maintenance Repair and Inspectionscnl files100% (1)

- Annex - 3 Maintenance Requirements of Life Saving AppliancesDocument5 pagesAnnex - 3 Maintenance Requirements of Life Saving AppliancesTanker Bneider100% (2)

- Activity in Dec: Specific LN Supply Operations BlntunlDocument3 pagesActivity in Dec: Specific LN Supply Operations BlntunlPetta TengeNo ratings yet

- Lecture 27Document110 pagesLecture 27Mbali Mpiyane100% (1)

- 01.02.2021 - SF 06 - Fire On Terminal and Break Away From JettyDocument4 pages01.02.2021 - SF 06 - Fire On Terminal and Break Away From JettyAlikar Arslan100% (1)

- Davit Emergency Operating SystemDocument7 pagesDavit Emergency Operating Systemndagasan2000201No ratings yet

- Ship Station Licence and The Maritime Mobile Service Identity (Mmsi) NumberDocument2 pagesShip Station Licence and The Maritime Mobile Service Identity (Mmsi) NumberSkipperNo ratings yet

- Ecdis SettingsDocument16 pagesEcdis SettingsPanagiotis MouzenidisNo ratings yet

- TMMV2UserManual Procurement PDFDocument46 pagesTMMV2UserManual Procurement PDFfreebookmanNo ratings yet

- MSC.1-Circ.1327-Guidelines For The Fitting and Use of Fall Prevention Devices (FPDS)Document6 pagesMSC.1-Circ.1327-Guidelines For The Fitting and Use of Fall Prevention Devices (FPDS)CaptShivraj ManeNo ratings yet

- Uscg Inspection ProceduresDocument148 pagesUscg Inspection Proceduresluckystrike9008100% (2)

- Cargo Switching ManualDocument53 pagesCargo Switching ManualНиколай Ника100% (1)

- 3.2.8 Temporary & Preliminary Corrections and Admiralty Information Overlay (AIO)Document2 pages3.2.8 Temporary & Preliminary Corrections and Admiralty Information Overlay (AIO)udayanNo ratings yet

- Terminal Particulars QuestionnaireDocument26 pagesTerminal Particulars Questionnairemohd1khairul1anuar100% (1)

- Wilhelmsen Ships Service Unitor Welding Safety ChecklistDocument1 pageWilhelmsen Ships Service Unitor Welding Safety ChecklistEphrem GetiyeNo ratings yet

- ANCHOR SystemDocument32 pagesANCHOR SystemenglisgoNo ratings yet

- Safety Fire Radio Other Service and MaintenanceDocument30 pagesSafety Fire Radio Other Service and MaintenanceAHMED100% (1)

- Dynamic Positioning c12Document28 pagesDynamic Positioning c12S D100% (1)

- GL CL For Onboard MaintenanceDocument18 pagesGL CL For Onboard Maintenanceacere18100% (1)

- Seagull's Guide To BWMDocument5 pagesSeagull's Guide To BWMharrdy100% (1)

- Holds and Hatch Covers - Guide ClubDocument41 pagesHolds and Hatch Covers - Guide ClubCan T. Erbay100% (1)

- 2014 04 Guidance For Accurate Draft ReadingDocument2 pages2014 04 Guidance For Accurate Draft ReadingBryant Cuison100% (1)

- 2007 Circular 10 Lifting GearDocument4 pages2007 Circular 10 Lifting Gearmask_goldNo ratings yet

- Deck AbstractDocument7 pagesDeck AbstractCan T. ErbayNo ratings yet

- Gl-Top 10 PSC Defs.Document9 pagesGl-Top 10 PSC Defs.skrtal2100% (1)

- Rescue at SeaDocument16 pagesRescue at SeacaptmadhunairNo ratings yet

- Bimco Us PSC GuideDocument20 pagesBimco Us PSC Guidemavericksailor100% (1)

- Bridge 075 Passage Plan ExampleDocument3 pagesBridge 075 Passage Plan ExampleMiha MihaelaNo ratings yet

- Standard P&a ManualDocument16 pagesStandard P&a ManualVasant Kumar VarmaNo ratings yet

- ECDISDocument20 pagesECDISFrancisco GouveiaNo ratings yet

- 007 - RCS Survey Instruction and Approval - MV FRIO CONFINDANCEDocument2 pages007 - RCS Survey Instruction and Approval - MV FRIO CONFINDANCEfernando pradoNo ratings yet

- Issue 6 Inspectors NewsletterDocument2 pagesIssue 6 Inspectors NewsletterDeepakNo ratings yet

- Liberian PreArrival ChecklisDocument6 pagesLiberian PreArrival Checklisfredy2212No ratings yet

- USCG Foreign Freight Vessel Examination BookDocument52 pagesUSCG Foreign Freight Vessel Examination Bookfredy2212No ratings yet

- PSC Checklist: On Board Maintenance Check ListDocument16 pagesPSC Checklist: On Board Maintenance Check Listfredy2212No ratings yet

- MG5222DCDocument2 pagesMG5222DCTarjaya tarjayaNo ratings yet

- Wind Loads On Post-Panamax Container ShipDocument20 pagesWind Loads On Post-Panamax Container ShipAAANo ratings yet

- Preparation Guide (Existing Ship Survey) : Class No: Imo NoDocument8 pagesPreparation Guide (Existing Ship Survey) : Class No: Imo NoHarman SandhuNo ratings yet

- AMSA579 - Application For NS VesselDocument3 pagesAMSA579 - Application For NS Vesselinmran.gNo ratings yet

- tsr09286 - SJA2 Spelljammer Skull & Crossbows (Levels 6-10)Document78 pagestsr09286 - SJA2 Spelljammer Skull & Crossbows (Levels 6-10)Faz MaldovNo ratings yet

- Eurojack Up 3923 PDFDocument3 pagesEurojack Up 3923 PDFBooraj DuraisamyNo ratings yet

- SONARDocument6 pagesSONARĐoàn ThịnhNo ratings yet

- Nanni Marine Engine N4.38Document68 pagesNanni Marine Engine N4.38Abu Abdou SiyahyaNo ratings yet

- Endurance PaperDocument2 pagesEndurance Paperapi-608442899No ratings yet

- MMD SOPs (CNS)Document28 pagesMMD SOPs (CNS)Arshad SaifanNo ratings yet

- Theme - Transport: 2nd & 3rdDocument4 pagesTheme - Transport: 2nd & 3rdAngel FajmNo ratings yet

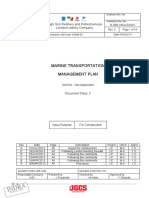

- Indra: Marine Transportation Management PlanDocument14 pagesIndra: Marine Transportation Management PlanHong Hai PhamNo ratings yet

- COSWP Prop. Amendments - Chapter 4 Emergency Drills and Procedures - 1-1-3Document3 pagesCOSWP Prop. Amendments - Chapter 4 Emergency Drills and Procedures - 1-1-3Cip GrecuNo ratings yet

- New Lamp Post PricelistDocument2 pagesNew Lamp Post Pricelistmarlon capsulaNo ratings yet

- Rahmad CVDocument1 pageRahmad CVJevrieko SatriaNo ratings yet

- Progress Barging PT. AM Dec 2022Document1 pageProgress Barging PT. AM Dec 2022wibi aryodanuNo ratings yet

- Liquid Bulk / Quantity Measurements and Other Challenges: Prepared by Jorge Pecci, Safewaters UmDocument26 pagesLiquid Bulk / Quantity Measurements and Other Challenges: Prepared by Jorge Pecci, Safewaters UmredchaozNo ratings yet

- Liquid Bulk TerminalDocument21 pagesLiquid Bulk TerminalPaola Baleta Medina100% (1)

- Rendering TestDocument7 pagesRendering TestDwiky syamcahyadi rahman100% (1)

- WWW - Associated-Shipbroking - MC: Leading Shipbroker Serving The World S Maritime and Offshore MarketsDocument8 pagesWWW - Associated-Shipbroking - MC: Leading Shipbroker Serving The World S Maritime and Offshore MarketsSahil FarazNo ratings yet

- Baltime Part 2-3Document2 pagesBaltime Part 2-3TAN AdventureNo ratings yet

- MMC 387 Mandatory Implementation of The Amendments To The 2011 ESP Code Rev. MR 2Document6 pagesMMC 387 Mandatory Implementation of The Amendments To The 2011 ESP Code Rev. MR 2Saransh MotwaniNo ratings yet

- Sea Cargo Manifest FormatDocument1 pageSea Cargo Manifest FormatFédyHamdi100% (1)

- 1 Basic Design of The ShipDocument7 pages1 Basic Design of The ShipSaid IBISSOUNo ratings yet

- Marine Insurance CasesDocument6 pagesMarine Insurance Casesnikol crisangNo ratings yet

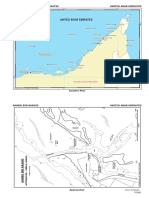

- General - United Arab Emirates United Arab EmiratesDocument21 pagesGeneral - United Arab Emirates United Arab EmiratesВаня СемчёнокNo ratings yet

- Transpo Terms 2022Document8 pagesTranspo Terms 2022garhgelhNo ratings yet

- DESH ABHIMAAN - Q88 (Ver 5)Document7 pagesDESH ABHIMAAN - Q88 (Ver 5)vimal sainiNo ratings yet