Professional Documents

Culture Documents

Alcoholic Strength in Wine: Application Note

Uploaded by

Alfonso Pachón MarroquínOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alcoholic Strength in Wine: Application Note

Uploaded by

Alfonso Pachón MarroquínCopyright:

Available Formats

APPLICATION NOTE

F&F-K-008-2013/A2

Alcoholic Strength in Wine

Reference: OIV Method - MA - AS312 - 01A - Alcoholic strength by volume

Tested with VELP Scientifica UDK 149 Automatic Kjeldahl Distillation Unit (Code F30200140)

Copyright © 2013 VELP Scientifica. All rights reserved.

No part of this publication may be reproduced or transmitted in any form or for any purpose without the express permission of VELP.

VELP Scientifica, Italy Tel: +39 039 628 811 Fax: +39 039 628 8120 www.velp.com

ALCOHOLIC STRENGTH IN WINE

Introduction

Wine is one of the most ancient alcoholic beverage: its consumption is widespread around the world and it is a p art of

customs and tradition of many people. It is produced solely by fermentation (total or partial) of the fruit of the vine,

grapes (either pressed or not), or must, and it is dependent on the complex biochemical transformations caused by

microorganisms (e.g. Saccharomyces cerevisiae) and influenced by technical and environmental factors.

The ethylic alcohol, produced during the fermentation, determines the alcoholic strength and it can be measured by

volume as “the number of liters of ethanol contained in 100 liters of wine, both volumes being measured at temperature

of 20°C. It is expressed by the symbol %vol”.

Alcoholic Determination in Wine

Steam distillation is a method to determine the alcoholic strength in wine, made previously alkaline by a suspension of

calcium hydroxide: the distillate obtained is an ethanol – water mixture and, using a measurement of density by a

pycnometer and expressing the results through the official tables, the alcoholic strength can be calculated.

Sample

Italian Red Wine Alcoholic strength by volume (labeled value): 11.5 % vol

Sample Preparation

To remove the carbon dioxide, stir gently the sample (1000 ml in a 2000 ml flask) with a VELP magnetic stirrer.

Chemicals and Equipment

- Suspension of calcium hydroxide 2 M: 120 grams of CaO in 1 liter of water at 60-70 °C

- Alcoholic strength kit (code A00000285) composed by:

-Tweezer for closing the NaOH tube

-Kjeldahl balloon 500 ml for the distillation of sample (Code A00000082)

- Pycnometer (volume 100 ml or 50 ml)

- 200 ml volumetric flasks with stopper

- Analytical balance

- Cooled Incubator (VELP Scientifica FOC Series i.e. code F10400320)

Procedure

Measure out 200 ml of the wine using a graduated flask and thermostat it at 20 °C. Let the sample adjust to temperature,

this will take about 15 minutes. Bring down the volume of the sample exactly 200 ml by taking away excess sample by a

small pipette. Transfer the wine to the 500 ml test tube. In order to collect all the mixture residues, rinse the volumetric

flask four times with successive 5 ml washings of water and add 10 ml of distilled water as receiving solution in the same

volumetric flask. Then, pour 10 ml of the suspension of calcium hydroxide to the test tube. The colour of the wine must

change from red to deep grey. For very acid wines, it’s suggested to add some drops of phenolphthalein in the test tube,

until the color of the indicator changes. Place the volumetric flask in a beaker filled with cold water and ice , next to the

UDK149. Insert the distillate outlet tube (it must be put in contact with the receiving solution) and fix it well using

parafilm.

Distillation

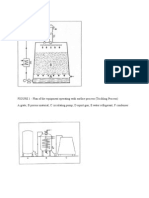

Condition the UDK 149 unit by performing a Wash down and distill the samples setting the method below:

H2 O (dilution water): 0 ml NaOH (32%): 0 ml H3BO3 (4% with indicators): 0 ml

Steam Power: 80% Distillation Time: 6.30 minutes *

* In UDK 149 settings, set a distillation time to obtain a maximum of 200 ml of distillate. After the distillation, position the

receiving flask in the thermostat for about 15 min. and finally bring up to volume (200 ml) using distilled water at 20 °C .

Copyright © 2017 VELP Scientifica. All rights reserved.

No part of this publication may be reproduced or transmitted in any form or for any purpose without the express permission of VELP.

VELP Scientifica, Italy Tel: +39 039 628 811 Fax: +39 039 628 8120 www.velp.com

ALCOHOLIC STRENGTH IN WINE

Density of the Distillate

Measure the density of the distillate through a pycnometer:

1. Weigh the empty pycnometer, clean and dry, with all parts in place (Mpyc in g)

2. Weigh the pycnometer filled with the distillate at 20 °C (M dist in g)

3. Calculate the density of the distillate at 20 °C (D dist 20°C ) following the formula:

Ddist 20°C = (Mdist - Mpyc ) / (Vpyc x 1000)

3

Vpyc (m ) is the volume of the empty pycnometer and is calculated as follows:

Vpyc =(Mpyc, H2O - Mpyc ) / (ρH2O,20°C x 1000)

Where:

Mpyc , H2O = pycnometer weight filled with water at 20 °C (g) ρH2O,20°C = density of the water at 20 °C (0.99823 g/ml)

4. Use the density table to express the results (OIV method - MA - AS312 - 01A)

5. Among measurements rinse the pycnometer with the next alcoholic solution.

6. During the entire procedure take care to avoid fat from fingertips, temperature changes when holding the pycnometer

and air bubbles in it.

Typical Results on Red Wine

Sample quantity (ml) Alcohol strength (% vol) **

200 11.48

200 11.65

200 11.49

200 11.48

200 11.58

Average ± SD% 11.54 ± 0.08

RSD% * 0.7

* RSD% = (Standard Deviation x 100) / Average

** For results conversion, official standard tables (OIV method - MA - AS312 - 01A) have been used.

For the verification of the distillation apparatus, the OIV Method - MA - AS312 - 01A specifies that, distilling an ethanol

water mixture with an alcoholic strength of 10% vol. five times in succession, the loss of alcohol must be smaller than

0,02% vol. during each distillation.

The UDK 149 satisfies completely the OIV Method - MA - AS312 - 01A.

Conclusion

The obtained results are reliable and reproducible in accordance with the expected values, with a low relative standard

deviation (RSD < 1%), that means high repeatability of the results.

Benefits of UDK 149 are:

High level of precision and reproducibility

High productivity

Worldwide official method

Reliable and easy method

Time saving

Affordable equipment cost

Moderate running costs

Copyright © 2017 VELP Scientifica. All rights reserved.

No part of this publication may be reproduced or transmitted in any form or for any purpose without the express permission of VELP.

VELP Scientifica, Italy Tel: +39 039 628 811 Fax: +39 039 628 8120 www.velp.com

You might also like

- The Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresFrom EverandThe Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresRating: 5 out of 5 stars5/5 (1)

- Alcoholic Strenght in Spirit Drinks 2 200899 218449Document3 pagesAlcoholic Strenght in Spirit Drinks 2 200899 218449jabulaniyotho79No ratings yet

- Analysis of Alcoholic BeveragesDocument56 pagesAnalysis of Alcoholic BeveragesWhoZz DizNo ratings yet

- The Chemistry of Dairy Products - A Chemical Analysis of Milk, Cream and ButterFrom EverandThe Chemistry of Dairy Products - A Chemical Analysis of Milk, Cream and ButterNo ratings yet

- %alcohol Distillation Procedure PDFDocument5 pages%alcohol Distillation Procedure PDFazwelljohnsonNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- NTD - Manual of Methods of Analysis of Foods - ALCOHOLIC BEVERAGES - FSSAI India 2015Document56 pagesNTD - Manual of Methods of Analysis of Foods - ALCOHOLIC BEVERAGES - FSSAI India 2015dmshahidch0% (1)

- Determination of Alcohol Content in Alcoholic BeveragesDocument7 pagesDetermination of Alcohol Content in Alcoholic BeveragesKaye Danielle HilomenNo ratings yet

- Determination of Water and Ethanol in CosmeticsDocument1 pageDetermination of Water and Ethanol in CosmeticsjajoriaNo ratings yet

- Dicromato 2 PDFDocument3 pagesDicromato 2 PDFGloria NumpaqueNo ratings yet

- Casein Determination in Milk Kjeldahl Method 206311Document3 pagesCasein Determination in Milk Kjeldahl Method 206311Malik XufyanNo ratings yet

- Artículo CHISA 2012Document10 pagesArtículo CHISA 2012Julian De la CruzNo ratings yet

- A V A B I: Pplication ApodestDocument9 pagesA V A B I: Pplication Apodestvateloki7No ratings yet

- Determination of Volatile Acids - IFU AnalysesDocument3 pagesDetermination of Volatile Acids - IFU AnalysesMarcelle Fernandes da SilvaNo ratings yet

- TKN - VELP Application NoteDocument4 pagesTKN - VELP Application NoteAshraf MohamedNo ratings yet

- 1 s2.0 S187770581202797X MainDocument10 pages1 s2.0 S187770581202797X MainRSalehNo ratings yet

- VELP Application Note Water-Sludge E-K-001-2015 1Document3 pagesVELP Application Note Water-Sludge E-K-001-2015 1Nur Rizky InayahNo ratings yet

- Alcohol Content by DistillationDocument5 pagesAlcohol Content by DistillationAna María Vallejo TorresNo ratings yet

- Oiv Ma As312 01aDocument33 pagesOiv Ma As312 01aMuhammed Ali SainNo ratings yet

- Ethanol From MolassesDocument6 pagesEthanol From MolassesSparrowGospleGilbertNo ratings yet

- 2006 - Beer Dealcoholization by Reverse OsmosisDocument3 pages2006 - Beer Dealcoholization by Reverse OsmosisKris NguyễnNo ratings yet

- Catalogi Ulka BombasDocument16 pagesCatalogi Ulka BombasPedrito Guillen SanzNo ratings yet

- AoacDocument11 pagesAoacIshwar ChandraNo ratings yet

- Application Note No. 065/2011: Total SO in WineDocument14 pagesApplication Note No. 065/2011: Total SO in WineLina Budi RahayuNo ratings yet

- Project PPT 1Document22 pagesProject PPT 1Swarnalatha Katta0% (1)

- Industrial Training 1Document32 pagesIndustrial Training 1KumarShiveshNo ratings yet

- Isopropyl Alcohol: The Process Flow Diagram IpaDocument40 pagesIsopropyl Alcohol: The Process Flow Diagram IpaGraciaVelitarioNo ratings yet

- Wine Experiment AbstractDocument12 pagesWine Experiment AbstractOnat YılmazNo ratings yet

- Ethyl AlcoholDocument5 pagesEthyl AlcoholTamil kumaranNo ratings yet

- Ethanol Concentration Analysis P&DDocument3 pagesEthanol Concentration Analysis P&DLeonardo WalcottNo ratings yet

- AN5391 Determination of TKN in Water by Using KT8000 SeriesDocument7 pagesAN5391 Determination of TKN in Water by Using KT8000 SeriesJaysonAbenirCabahugNo ratings yet

- Polyvinyl AlcoholDocument3 pagesPolyvinyl Alcoholhossam salahNo ratings yet

- Project Report Draft On "Isopropyl Alcohol" BY: Jariwala Divyangkumar Rajeshkumar Exam No-701022 Roll No:-821Document22 pagesProject Report Draft On "Isopropyl Alcohol" BY: Jariwala Divyangkumar Rajeshkumar Exam No-701022 Roll No:-821Arpit PatelNo ratings yet

- 2007 07 10 Methods Method 351 1 PDFDocument7 pages2007 07 10 Methods Method 351 1 PDFlinhpic99No ratings yet

- Experiment 5 Chemistry of WineDocument5 pagesExperiment 5 Chemistry of WineJahnavi BlairNo ratings yet

- WineDocument10 pagesWineVarakumar SadineniNo ratings yet

- SNI 8068-2015 Sodium TriPoliPosfar Mutu PanganDocument4 pagesSNI 8068-2015 Sodium TriPoliPosfar Mutu Panganmoriz52No ratings yet

- Eco Encore Solo Encore Technical ManualDocument121 pagesEco Encore Solo Encore Technical Manualammar1995zxjoNo ratings yet

- COI-T.20-Doc.-No-34-Rev.-1-2017 (Acidity MOA)Document4 pagesCOI-T.20-Doc.-No-34-Rev.-1-2017 (Acidity MOA)KhalidNo ratings yet

- Ethylene Glycol Heat-Transfer FluidDocument4 pagesEthylene Glycol Heat-Transfer FluiderreagaaNo ratings yet

- Detailed Analysis of WineDocument2 pagesDetailed Analysis of Winegustavo haroNo ratings yet

- Filtration of Grape Juice SedimentsDocument6 pagesFiltration of Grape Juice SedimentsJames AlvesNo ratings yet

- Fermentación AlcohólicaDocument9 pagesFermentación AlcohólicaMary GonzálezNo ratings yet

- Determination of Alcohol Content in Wines and Fermented MashesDocument2 pagesDetermination of Alcohol Content in Wines and Fermented MashesMike FidelisNo ratings yet

- Fractional Distillation of VodkaDocument3 pagesFractional Distillation of VodkaNic MacapinlacNo ratings yet

- Production GraficasDocument112 pagesProduction GraficasMiguel v.m.No ratings yet

- Presentation AccomDocument22 pagesPresentation Accomyero kumaNo ratings yet

- Otet Din VinDocument8 pagesOtet Din Vinpixel5dNo ratings yet

- Concentracion de Fusel Oil en La DestilacionDocument5 pagesConcentracion de Fusel Oil en La DestilacionKarenLissNo ratings yet

- Vanillin GCMSDocument7 pagesVanillin GCMSYap Poh SiewNo ratings yet

- Distillation 123Document12 pagesDistillation 123Mukesh TiwariNo ratings yet

- Production of Ethanol From Cheap Substrates: FermentationDocument41 pagesProduction of Ethanol From Cheap Substrates: FermentationSrinivas RallapalliNo ratings yet

- Determination of Volatile Acidity of Wine: Experiment No. 5Document10 pagesDetermination of Volatile Acidity of Wine: Experiment No. 5Vladimir LagradaNo ratings yet

- WineED EngDocument2 pagesWineED EngederjfelixNo ratings yet

- Evonik Eudragit L 100 and Eudragit S 100 Specification Sheet PDFDocument7 pagesEvonik Eudragit L 100 and Eudragit S 100 Specification Sheet PDFpict0% (1)

- 9 - 4 Original, Real and Apparent Extract and Original Gravity of Beer - ONLY FOR TEACHING USEDocument5 pages9 - 4 Original, Real and Apparent Extract and Original Gravity of Beer - ONLY FOR TEACHING USEdianaNo ratings yet

- Eo Po Block Co PolymersDocument29 pagesEo Po Block Co PolymersUtpalNo ratings yet

- Mass Transfer Lab ManualDocument53 pagesMass Transfer Lab Manualshaliq28No ratings yet

- VELP Scientific Brosur PDFDocument16 pagesVELP Scientific Brosur PDFIzzuddin NashirNo ratings yet

- VELP ECO Series Leaflet PDFDocument2 pagesVELP ECO Series Leaflet PDFalfan prayoghaNo ratings yet

- Mettler Toledo Application No. M574: Content of Sulphate in Mineral WaterDocument5 pagesMettler Toledo Application No. M574: Content of Sulphate in Mineral WaterAlfonso Pachón MarroquínNo ratings yet

- VELP Food&Feed - 052019Document24 pagesVELP Food&Feed - 052019Alfonso Pachón MarroquínNo ratings yet

- Re40d - Re50Document116 pagesRe40d - Re50Alfonso Pachón Marroquín100% (1)

- Re40d - Re50Document116 pagesRe40d - Re50Alfonso Pachón Marroquín100% (1)

- WaterrDocument4 pagesWaterrnickywulannNo ratings yet

- Determination of Ethanol in WineDocument6 pagesDetermination of Ethanol in WineAlfonso Pachón MarroquínNo ratings yet

- Task 2 - InglesDocument9 pagesTask 2 - InglesSandra AyalaNo ratings yet

- Inventario ActualDocument8 pagesInventario ActualJuan L. De Loera ZavalaNo ratings yet

- Roast and ToastDocument3 pagesRoast and ToastJanjan DumaualNo ratings yet

- Brandy 1225791473117485 9 PDFDocument14 pagesBrandy 1225791473117485 9 PDFSYEDA SALMA SULTANANo ratings yet

- Wine - Water Interface DetectionDocument2 pagesWine - Water Interface Detectionping dengNo ratings yet

- 11101988Document188 pages11101988Durga Prasad AnaganiNo ratings yet

- Project Report On Fruit Juice of Mango, Orange, Sweet Lime, Lime, Pineapple Plant (1200 Ltr. Per Hour Capacity) in Tin CansDocument8 pagesProject Report On Fruit Juice of Mango, Orange, Sweet Lime, Lime, Pineapple Plant (1200 Ltr. Per Hour Capacity) in Tin CansEIRI Board of Consultants and Publishers100% (1)

- Salami Coglioni Di MuloDocument2 pagesSalami Coglioni Di MuloNikoNo ratings yet

- Vodka: Processing Raw MaterialsDocument2 pagesVodka: Processing Raw MaterialsVerena Gweneth RobinsonNo ratings yet

- Mercury Mercruiser Marine Engine 26 GM 4 Cylinder 181 Cid 3 0l Service ManualDocument22 pagesMercury Mercruiser Marine Engine 26 GM 4 Cylinder 181 Cid 3 0l Service Manualstephanielopez010487wdt100% (115)

- 1862 TheLandLawofVictoria PDFDocument38 pages1862 TheLandLawofVictoria PDFizana saffana ilmaNo ratings yet

- Wine and Food PairingsDocument6 pagesWine and Food Pairingsapplejak100% (2)

- Biber-Short Stories On ReconciliationDocument253 pagesBiber-Short Stories On ReconciliationBojana998877No ratings yet

- OM 411 Business Process Management ASSIGDocument4 pagesOM 411 Business Process Management ASSIGleeNo ratings yet

- Project Report On Country Liquor Bottling PlantDocument7 pagesProject Report On Country Liquor Bottling PlantEIRI Board of Consultants and Publishers100% (2)

- Harry's Country Club Whiskey MenuDocument1 pageHarry's Country Club Whiskey Menusupport_local_flavorNo ratings yet

- Laboratory Work: Ifugao'S Products Fu-FudDocument6 pagesLaboratory Work: Ifugao'S Products Fu-Fudabba may dennisNo ratings yet

- Script Bewitched 132Document24 pagesScript Bewitched 132Gabriele FabbriNo ratings yet

- Bar Price ListDocument1 pageBar Price ListAruna GoudNo ratings yet

- Gingerbeer Alcohol DrinkDocument5 pagesGingerbeer Alcohol DrinkCameliaNo ratings yet

- Kopia Waldo's Guide™ To DND - Chapter 7 - TavernsDocument49 pagesKopia Waldo's Guide™ To DND - Chapter 7 - TavernsEkhem EkhemNo ratings yet

- FSM 315 Module 1Document5 pagesFSM 315 Module 1Benjamin TaduranNo ratings yet

- Skull's Rainbow Room MenuDocument4 pagesSkull's Rainbow Room MenuFOX 17 NewsNo ratings yet

- Brass Monkey Menu and Cocktails PDFDocument2 pagesBrass Monkey Menu and Cocktails PDFDaniel GerzinaNo ratings yet

- Cook S Illustrated-2018!11!01Document36 pagesCook S Illustrated-2018!11!01rambo3064100% (2)

- Beer Industry in VietnamDocument67 pagesBeer Industry in VietnamPhan proskillzNo ratings yet

- FearLess Cheat Engine - Anno 1404 Venice Memory Values ListDocument20 pagesFearLess Cheat Engine - Anno 1404 Venice Memory Values ListYsf SimsekNo ratings yet

- Clash at Kobold Cauldron 1 3Document3 pagesClash at Kobold Cauldron 1 3o mestre payakanNo ratings yet

- Lyaness Food Drink Menu PDFDocument15 pagesLyaness Food Drink Menu PDFAlok RaiNo ratings yet

- Moldova My LoveDocument15 pagesMoldova My LoveCristian100% (1)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeFrom EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeRating: 5 out of 5 stars5/5 (4)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsFrom EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsRating: 4 out of 5 stars4/5 (146)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableFrom EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableRating: 3.5 out of 5 stars3.5/5 (22)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeFrom EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeRating: 4 out of 5 stars4/5 (1)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeFrom EverandChemistry for Breakfast: The Amazing Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (90)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincFrom EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincRating: 3.5 out of 5 stars3.5/5 (137)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactFrom EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactRating: 5 out of 5 stars5/5 (5)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolFrom EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNo ratings yet

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideFrom EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideNo ratings yet

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsFrom EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsRating: 5 out of 5 stars5/5 (3)

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Transformer: The Deep Chemistry of Life and DeathFrom EverandTransformer: The Deep Chemistry of Life and DeathRating: 4.5 out of 5 stars4.5/5 (13)

- Bioplastics: A Home Inventors HandbookFrom EverandBioplastics: A Home Inventors HandbookRating: 4 out of 5 stars4/5 (2)

- Chemistry: a QuickStudy Laminated Reference GuideFrom EverandChemistry: a QuickStudy Laminated Reference GuideRating: 5 out of 5 stars5/5 (1)

- Formulating, Packaging, and Marketing of Natural Cosmetic ProductsFrom EverandFormulating, Packaging, and Marketing of Natural Cosmetic ProductsNo ratings yet

- A Perfect Red: Empire, Espionage, and the Quest for the Color of DesireFrom EverandA Perfect Red: Empire, Espionage, and the Quest for the Color of DesireRating: 4 out of 5 stars4/5 (129)

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookNo ratings yet

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeFrom EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeRating: 5 out of 5 stars5/5 (1)

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilFrom EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilRating: 5 out of 5 stars5/5 (1)