Professional Documents

Culture Documents

Screw Conveyor & Rotary Feeder

Uploaded by

Ervin0 ratings0% found this document useful (0 votes)

96 views22 pagesscrew conveyor & rotary feeder

Original Title

screw conveyor & rotary feeder

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentscrew conveyor & rotary feeder

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

96 views22 pagesScrew Conveyor & Rotary Feeder

Uploaded by

Ervinscrew conveyor & rotary feeder

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 22

aoe

Ic, (Hey#=) DEPT.

Phe, Pa

i!

CEE

Le

OINT LESSON

7

PT. SEMEN NUSANTARA (MC DSPT)

Core Plonning Pr

DQ Serey Con fereb-

L Cato hifany Pipenya

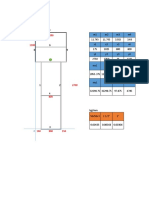

SCrew

LEZI

| Lins 6000 x Coy) D) 7 Tho

als :

facraae fs \

= @ Sime j

ze = tite, 2. i

[Ss Smee AD @ i Pia |

I |

wy (Bd) rad : i

| Ep (Feo) co’ © Tit! Tonaure Motor Ga-kayl

' N ¢ Keeupatan (Pm)

cE pt > Ze >-PiPa Tidak Pah [ew | kw Molor kw)

i : | Ze! dev bv Mole, Com’ J

os Zp < Emo > Pipa PaTah Focax? STpG2R STrensty kaze It

2 Misalnyd

GQ) PerTiayddn 2

Holer se 71 Oso bPia

Zp i Pa.

$4 _' sTrength ollewdnsi ble kth}

Pane)? SIPEIE FAT KO |

Pippnvs bise thon afin Pitek ?

| b2HiTong

Tae = P6000 x

Zio» /7.b00 CHL ca0 Mifet

WA = (eVGA 2M = 28% cor”

a7

Tee,

fgttm = s2éooGr~ bp

32.4 cm

nee

]

|

C) Hasif 2 Zric2vt) < Ens (324)

ostpaseteo 504 Tidok bise [Tenis tips |*eo|%¢ Com) = ceed

5 3. PaaP

i Po fees. Bod atl | 28! | zee

Alpen £7438 G0 fol | __ pont | | ro? | 525

&, Sim?) bra | 739? | 26 | a7F | |

2 eee [Pare nee al see

NO,

rr

[RG, (ers) DEPT. |

Ph. P/M

Core Plannine Pi pe

Sere Confer

SChaw

©) Tip 1 Toraus Motor

Ht _Kecuratan

Epi > Eno > Pika tidak Pala [sew © Kw Motor

. Zuai Z dovi kw Meter Coot

Le Ep < Emo 7 Pits Ptah uae! stpeer sire Kea

2 _Misalnyd

Q) PerTinyaan s Holer Se yee

: STrength aiewans) She _Ckeahe hi

Y i Pd Conf Jt

\

i

sotpm .fipanyrd STPER INTO |

natin Teve& 2

5) Hi fang

te = 76000 x "forte = 1 oath |

_ Xe * 47.800 Cnt /sado Kife = 22.4 co? :

L

Zp}: @Aax (eaten = 28% cunt

c) Hast) 2 Beier’) < Zia (324)

. erpase tao Bod Tidek bise | Tanis fils [Poca] 94 cons Zo?

: eal

rere | at | nF Leet

i # 23 | see

et

Plann Seckow

-— BT SEMEN NUSANTARA

PO. Box. 35, Phone 21521 - 21528, 22025

Cable address : SEMENUSA CILACAP

Telex : PTSN. CLP, 22333 & 72495

CILACAP - INDONESIA,

een

Processing Dep \ From: LS

Meagenak —Tteprovewe“K transport machine afters coven Bag flte

Date: 30- Tuly — eu

pears

|

Cetera de pera kk]

(after dsperbeik

Bip filler bet / ‘

Ke Pesce ony i

EF potery fecher Z

5 “4

wohovr_side

Seres conveyor side = 327

Beli» of 4M

yolor rhatiow wakta Iwi? My

ne 2 soot

Yekctton of owk pk sheaf: Mh

___tta = hs Yo = 50 FP

~ PT SEMEN NUSANIARA i

PO. Box. 35, Phone 21521 - 21528, 22025

Cable address : SEMENUSA CILACAP

Telex : PTSN. CLP, 22333 & 22495

CILACAP - INDONESIA

fF

Planag- Secktow Dae: j99-July “Fe

PM Seiten _ a

Processingy Dep | From: LX

Mengeneh iteproveme-K_ditanspor®” machine after couen Baz filter

(before de prbki J ater dperboit ]

_ “) —¥

Be fe kp / Bay fll Byer

i + Aikscrey conteyor _ —

a Rotary fecer™ =

q AAA cores comeyev

choke

i iT apy “of screw _conveyov"] ait i

{0 Copackypordam a _ (before inprovewrn tt.) 1 i

__ rotation of screw _comuy ae

[its whore bT

Sete conveyor side + 327

Paw of QM? Yo

__tetor eo waka: Mh

Tw BORE, BOB? poole

Yiettow of uk pekt shat: Ma

fa = Nx Yo = bv T™

A 3 «loz = tet

eo Sen

wdtlese7 +

Ly rate of coming meter

~~ pT SEMEN RUSANTARA

PO. Box. 35, Phone 2152 ~ 21528, 22025

Cable address : SEMENUSA CILACAP

Telex : PTSN. CLP. 22333 & 22495

CILACAP - INDONESIA

Plana — Sechtow | pate: 307 Tuy ~B°

PM Lae | anal 7 oer

Processing Dep \ From: (QC

ject =

comin Dag

Mengeneh ivproveme-T transport _vachine after

(afer Aperbsitt see

Linfire BP petok ]

es s p=

4 BER Toy Nr Byer

[ABABA Hh Setty a AVS

EE petery feeder repens

we Tet seven come

eS

=

yor (exstin

[ Goyoctiy of screw _comeyal

oh). Gopacthy _pertama,

ghton_ ot screw _couwyey.

uN

pererreree He Peet 1 whose

Le box By = 202 Hh) Seres conveyer 5)

ce Bee [Bog at

oto rebrbtow witkta tai = fh

T= BOSE - BEE « 1500

foteton of ouk pk shefh : Ma

_ ty = Nhe fp = 90 T _

Ti vote of cari watersa|

SS

Yon of screw conveyer ih). (MT peter ale

a eee ie ay ete

ge seas 2 RUAN Fr eae Sv ena

Tolakow of owt pk shefh 3

V2. 2 Grey 2 op Sip resem ae

“LGpaty of Biay feeder ]

()_Gpacth

Whine of Bilary fede fog Bis

Pee see ores .

OVD «20.9 FD fy Mh x Px 08% $7 Hd

B welek safely (comeektwi_adah sifek sleek)

2 O = 55.7%) x08 = a¥y 7327 %

Lo wea vete of camyiege material

eae ae

*

] eee "euane ‘s/c.

! . a a

ame aa

D

d= |,

P = OBD = O08 x3 = 290.

€ . Vp? + Cro®

i V290% +(3s9 x89) >

= Vs7600 7 7azes +

= BIE

ih 363,7

3/4.

= 7,36

sf 6400"

D = qoo-e

d= Mae .

P = 0,BD = 08x 400 = S20 &

g % Mera « My

= [azo + (3/4 x1/4,3

= Vi02 400 #128 52,8/

?

= F8/,

(/)- #81 53,)

3/4.

®- 400 + (153,/ ~ 1/43)

= 423,38

400 CD)

epege tee

Sarees ee

7 ES fee uso

«Vee Fiabs eo

= KB

(Pr) 363,3

@ —_ HZ,36

3/9

2 HO +(N7,36~32/) =

‘

a e S Nop

= | 320° + (3/9 x#4,3> /

= Vi02 900 12.8952, 8/ {

x

ce ey, fe RAN eg

(dix Bl = psa Susp soem ae

t

Co.

DAFTAR DOCUMENT ARSIP PERENCANAAN DI MIC DEPT.

I. PERHITUNGAN MOMEM INERTIA (GD )

1. Impeller cooler fan no 1

2. EP Kiln fan motor.

I. PIPING

J. Modification dust pipe Bfi storage silo.

2. Modification dust pipe Bi nol di atas DCC no 2.

3. Piping air compressor at storage silo,

TL ROTARY VALVE

1.Kapasity up rotary Valve 309 dan 310 pada cosl mill.

2.Pothitungan RV @ 500 pada Raw Mill.

3.Check clearence RV pada Raw Mill.

IV. PERHITUNGAN

1. Pinion gear pada portal scraper step I dan 2.

2. Reducer gear belt feeder coal,

3. Gear untuk reducer H/P fon

4, Mencari jumlah gigi sprocket.

5. Spie.

ERHITUNGAN EXPANTION JOINT

1. Fxp.Joint for duet cooling tower.

2. Exp.Join! for duct cyclon no 3 SP Tower.

3. Exp Joint for duct Cyclon no 4 SP Tower.

VI. PERHITUNGAN GRATE

1. Grate cooler no 1.

2. Coneoting Rod for grate cooler.

VIL PERENCANAAN ALAT-ALAT TRANSPORT.

A. BELT CONVEYOR

1.Mengurangi kecepatan B/C: 1 clay dryer.

2, Mengurangi speed B/C 3 clay di bawah clay crusher.

3. BIC 3 dan BIC 5 clay receiving.

4, Perhitungan slag B transport system (B/C 350 mm).

5. BIC clinker go down.

6. Improvement of B/C clinker go down,

7. Check kapasity BIC clinker no 1 cement mil.

8. Check B/C gypsum no 2 coment mill.

9. Kapasitas up B/C 1 cement.

B, SCREW CONVEYOR

1, Planing pipe screw conveyor.

2, Pembuatan blade,

3. Improvement SC after cement bag. iter

Cc. MOTOR

1. Penggantian motor BIC after portal scraper.

‘Meneari kapasity. motor (kw).

Motor untuk B/C cement

Kapasitas motor untuk B/C clay.

Kapasitas motor untuk B/C cement.

veer

Vill. PERHITUNGAN KEKUATAN

A. BAHAN/MATERIAL :

1. Dasar-dasar perhitungan kekuatan bahan,

2. Instalation of magnetic separator at head B/C after portal

3. Instalation of magnetic separator at head B/C 3 clinker.

4. Erection of chain block Upper lathe Mackine at work shop MIC (hoist.

5. Kekuatan baja.

6. Jack support.

7. Pips support lime stone.

8. Konstruksi_ gudang trumix Jogjakarta,

eee 9. Kekuatan Wire Rope.

7 10, Kekuatan Ron Bar.

11, Kekuaton shaft.

12. Kekuatan a, Kayo,

b. HBeam.

c. 1 Beam.

4, Canal (C) dan siku (L).

B. KEKUATAN CONCRETE :

1. T Block.

2. Dinding.

3. Cor.

C. KEKUATAN WELDING

IX, OTHERS

_Perhitungan rencana pintu automatic di pos I.

mn.

Iv.

DAFTAR DOCUMENT ARSIP PERENCANAAN DIM/C DEPT

PERHITUNGAN MOMEM INERTIA (GD )

1. Impeller cooler fan no 1

2. BP Kiln fan motor.

PIPING

1. Modification dust pipe Bfi storage silo

2. Modification dust pipe Bfi nol di atas DCC no 2.

3. Piping air compressor at storage silo,

ROTARY VALVE

|-Kapasity up rotary valve 309 dan 310 pada coal mill,

2.Perhitungan RV @ 500 pada Raw Mill,

3.Check clearence RV pada Raw Mill,

PERHITUNGAN

1. Pinion gear pada portal scraper step 1 dan 2,

2, Reducer gear belt feeder coal,

3. Gear untuk reducer HYP fan,

4. Mencati jumlah gigi sprocket,

5. Spie.

PERHITUNGAN EXPANTION JOINT

1. Exp.Joint for duct cooling tower.

2. Exp.Joint for duct cyclon no 3 SP Tower,

3. Exp.toint for duct Cyclon no 4 SP Tower,

PERHITUNGAN GRATE

1. Grate cooler no 1

, 2. Coneoting Rod for grate cooler.

va.

PERENCANAAN ALAT-ALAT TRANSPORT

A. BELT CONVEYOR :

1 Mengurangi kecepatan B/C.1 clay dryer.

2. Mengurangi speed B/C 3_clay di bawah clay crusher.

3. BIC 3 dan BIC 5 clay receiving, iS

$ Rethitungan slag B transport system (B/C'350 mmm,

5. BIC clinker go down, Fs

6 Improvement of B/C clinker go down.

7. Check kapasity B/C clinker no 1 cement mill,

8. Check B/C gypsum no 2 cement mill,

9. Kapasitas up B/C 1 cement.

B. SCREW CONVEYOR

1, Planing pipe screw conveyor.

2. Pembuatan blade,

3: Improvement SC after cement bag filter

A Reemungon Capeciy Up enue Geavayer. 5p

pore omen

os

i

¢. MOTOR

1. Penggantian motor B/C after portal scraper.

2. Mencari kapasity. motor (kW).

3, Motor untuk B/C cement.

4, Kapasitas motor untuk B/C clay.

5. Kapasitas motor ‘untuk B/C cement.

VIM. PERHITUNGAN KEKUATAN

A. BAHAN/MATERIAL :

1. Dasat-dasar perhitungan kekuatan bahan.

2. Instalation of magnetic separator at head B/C after portal.

3, Instalation of magnetic separator at head B/C 3 olinker.

Erection of chain block Upper lathe Machine at work shop M/C (hoist).

Kekuatan baja.

6. Jack support.

7. Pipe support lime stone.

8. Konstruksi_ gudang trumix Jogjakarta

9. Kekuatan Wire Rope.

10, Kekuatan Ron Bar.

11. Kekuatan shaft.

12, Kekuatan a. Kayo.

b, HBeam.

¢. [Beam.

4, Canal (C) dan siku (L).

B, KEKUATAN CONCRETE :

1. TBlock.

2, Dinding.

3. Cor.

¢, KEKUATAN WELDING

1X, OTHERS

Perhitungan rencana pintu automatic di pos F

KEADAAN

TINDAKAN

* Capacity up Rv. 309 & 310

fredBm > GM —> Phe > py Qa.

"RE y

‘SEKARANG

Kondisi feed coal mill tidak bisa tin,

ei, dimana

pada feed 11 ty

» injector sudah haunting menye

babkan pembakaran didalam icin kurang stabil ,

Coal mill sebeear 20 % ,

Pnansk day

Dimana capacity “sebe lum 215 th Menjadi —

eapacity up +22 th.

Dg. jalan ganti Sprocket pada RV. side dari

BS.100 x au?

menjadi RS.100 x 19NP |,

CMhat lomp nen).

kecupntan, 2% ffm —» F°+ Pm

Rv Rete dpabas melt

? cs

~Sgail

abet

CAPACITY _UP_RV.209 ERV.3I0_ COAL.

tear a :

Ls 400 tee

em

eet

capaclty OF RY

Q>= Carrying capacity th. \

_ D> Blade damelr om -

a: Pipe afomeer om |

ee Panjoms blade om

No « Rotayy fra. REM-

(fe Bae ceasity Yu

ere frequensr

3

Motor y9-ada cekaravg + GM : arkwx Yeo x 6px put put 33. pm -

Sprocket motor side RS 00x 17 NT

cue RM Side RS Wo x QANT = lama .

Putaran RY 309 sekavany + 24 RRM Cop. vp- arte —> agrv 30. RpM-

creck sprocwweT RY. > a

17 x 33 = Kax 30 kas

sprocket RS.wo « 19 ul

-.- Q sekarang , ewe, Cerec)

xe Ny = Fax Na

17d wyig SF:

Sach en ee

cHeck capatty RY? UP aot

op ime lade

Q:% Lyre a2 xix box (hx) eh

= onekoa*- 0277 - Coon.x 10x! fe 0.4 x Cox (0.4 %0,90)x 30 +

Q = 078 Co — 0,012) x 0,4% 60% 0,36 x 30 > Qranruart),

a

CHECK. KEKUATAN GHAtN + ray

- aakw > Pa = fee? ea) baa 9, 03 Kw -

tg

fra rons Pa By anges ake 1B m/nth

,

GUNN Ye. DIPAKAL p- RV. SIDE Re wo x de

RANE

CHECK KDNDIst GEAR MOTOR, yo ADA SEKA

Gu 22 Kix Yao x output epin 33,3 x 20V x OP

Rating Current = 5,7 Ampere -

Getty = Bo =p

Load ate 2 34 -v— UP ao% = so pe -{(riae)

GEAR MOTOR Bisa peed Yo LAMA De Bs id

feesina Pagel:

untar CAP. up 780), :

vee sing Ale ASPD 2g! MEME

_cukep uipeRcepAT 3270 - SARGORET

197

- Moreh TE7AP 9

50

He OX

a ll

ROTARY FEE

ie FAR | wo

semen) BEANE ede) ae |__ ah

of

| sof

asad] ot .|

was ons

1 so esta)

aeust on | 40 | 1550

‘ sn_S88) are,

‘ wedeyed Lt] in tacero| ons |_4a Vous 30 | saz20|

> | ast io lease ae

th ugs9|_eeteans| 25 | so | seo Lit

| sys] 22 l 0 Lessney 228

I Gh) e

b Dolan. ory 20s CH= sopnf ott

Ro effecie AAU Je ony 1misbyBR OD

eee Go

E+ HR PLLILE C20)

he Byatt tnamy

=

pobshenh BLE

Ps70 6

esrb taal

OR

: 2 BLOM Pn)

os

et

Ley

a

142,

1199,

18

(3004,

&r

EATS AER EL, FIM

FO ORE ar oe \s’

PCa Yodan. Sobl » G0 tng

LT DD e

[= 97 x lot. ky > apvxiotn 2 - by.p38 k

fe

Pe a

fe i4.tleor- foctor barcksi” - 4bt/. \

1

Pa sn yxdtlay + 3,08 Kw.

120;

a OR Fi Joa. x 3, 09 74

i < FO2E : ; i

on ay TY el

GAEL = Ce a. mg Shon cary.

Fe 1357 kof Z 2300 Af >ok .

> R00 ~

ups QxDx@D ae

ead

~ A KOGXLY

KAGE + =o, ok KP > 01 By < LLG

4 OGL Y at OOLSY

eaten

erie A) OOLSE

ane

carey. cae.

BUNDE dA

pee. ois

_pmopns Bare => 4 ~

fpereROrArSy free, =) ape

Rube Denrsery 3 tm?

Rotary. bust Bin)

2 EChad aa

yn xbox

2.036 4 IL. 60x60,

| CRASHING «S.C. 6600 UNDER, cyclo. MILL

LIRNT, ROTATION SPEED MENURUT PBEL we

u/ 6c ploo

SB opm (may) vax zbesgxas

Bye 3326

2S

SS Wor (NTIS)

PE CD") 6x Px x Lx.

h—-. 52.288 (0.6 *= 01398") x60%2.98 2592 0.8 XO, x OL,

3 Tx.

—

Sry

CR Mite FEE.

HORSE POWER (HP) Pear

Bay SAMPLERS

MM cApeIty ~SHs PC

pa fhCi de) boy tx mt uoby OB.

2

ee a

jp —__--= 9,785 Loos

é 203) xbox O29 O18 xO yKO8

= 0/0385 7/4.

Kondisi Sckarangs

Pada waktu operasi Normal (Raw Mill operasi )

Rotary Valve Under Cyclone Raw “eal pada waktu Gap sudah

besar(aus Max ) Draft culup besars

Akibatnya operasi, Box Sampler tidak normal,untuk hasil t

Sampling material after Mill kurang mewakili/ada masalan. |

indakan,

+ Under Cyclone Noi&2 perlu dipasang 8 ¢.9/600

Material By pass Masuk screw baru diterima oleh

Box Sampler.

Sue

STS eee

2, Material S Cp 600 bisa pakei Ex.Wijaya pura.

Lay Out ferlampir.

jentar

|

Sapam Gebelom OF eos

C BBL She ttut, “ya.

lAdvisor | Dept Mer|Sect Mer | Petuges.

SS

RW Ceanan a ee

DS ee eld

Pe nee aeons

dain 20°¢

Receeeeeeoee ao aanaaaaITSIEED Pert

HanTr Py ray Proo

Bn Si od “Bx 2) ~- 0,1 Panne :

Pe a %

‘ henomet Femme A

. an

TE Coofer Ep .

i

Hinder [Sore

Uda Z0°C

130°C

J

[ane Eee 0.37 om

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Investment Plan 2020 2021Document1 pageInvestment Plan 2020 2021ErvinNo ratings yet

- Cara Planning Screw Conveyor 1Document6 pagesCara Planning Screw Conveyor 1ErvinNo ratings yet

- For The Best Experience, Open This PDF Portfolio in Acrobat 9 or Adobe Reader 9, or LaterDocument1 pageFor The Best Experience, Open This PDF Portfolio in Acrobat 9 or Adobe Reader 9, or LaterErvinNo ratings yet

- The Analysis of Crack Lamella Apron Conveyor 332-Ac1: Case Study ReportDocument51 pagesThe Analysis of Crack Lamella Apron Conveyor 332-Ac1: Case Study ReportErvin100% (1)

- Modul 03. Perlakuan Panas Untuk Meningkatkan Kekuatan LogamDocument31 pagesModul 03. Perlakuan Panas Untuk Meningkatkan Kekuatan LogamErvinNo ratings yet

- Trouble-Shooting Five Common Belt Conveyor Buildup ProblemsDocument2 pagesTrouble-Shooting Five Common Belt Conveyor Buildup ProblemsTamal Tanu RoyNo ratings yet

- Fracture Class Notes - Important PDFDocument34 pagesFracture Class Notes - Important PDFbathinsreenivasNo ratings yet

- Stress & Strain Relationship - Strain Theory & Practice: Strength Basic KnowledgeDocument3 pagesStress & Strain Relationship - Strain Theory & Practice: Strength Basic KnowledgeErvinNo ratings yet

- Detail Clarification of Bid Evaluation: Renovasi Interior Maintenance Dept. LT 04Document3 pagesDetail Clarification of Bid Evaluation: Renovasi Interior Maintenance Dept. LT 04ErvinNo ratings yet

- Investment Order Strength Team 2020Document2 pagesInvestment Order Strength Team 2020ErvinNo ratings yet

- Irregular Verb ListDocument0 pagesIrregular Verb Listapi-230048937100% (2)

- Model 1Document1 pageModel 1Sharath ChandraNo ratings yet

- Could Have vs Can Have - When to Use EachDocument1 pageCould Have vs Can Have - When to Use EachErvinNo ratings yet

- NO No. Material Nama Material Merk Type Ukuran QTYDocument4 pagesNO No. Material Nama Material Merk Type Ukuran QTYErvinNo ratings yet

- SupposeDocument2 pagesSupposeErvinNo ratings yet

- Who Owns EnglishDocument21 pagesWho Owns EnglishErvinNo ratings yet

- TN 515Document12 pagesTN 515Ionut Cornel VidaNo ratings yet

- Present Continuous (Part 1) - Understanding the Present Continuous TenseDocument4 pagesPresent Continuous (Part 1) - Understanding the Present Continuous TenseErvinNo ratings yet

- Who Owns EnglishDocument21 pagesWho Owns EnglishErvinNo ratings yet

- PrepositionsDocument2 pagesPrepositionsErvinNo ratings yet

- Stating Your PurposeDocument2 pagesStating Your PurposeErvinNo ratings yet

- Reliability Centered Maintenance Made SimpleDocument55 pagesReliability Centered Maintenance Made SimpleErvinNo ratings yet

- Mechanics of Structures-1Document13 pagesMechanics of Structures-1ErvinNo ratings yet

- Me A Chapter 1Document92 pagesMe A Chapter 1arandersNo ratings yet

- NAMA: Muhamad Ervin Khariri (04) Kelas: XII TP 3Document3 pagesNAMA: Muhamad Ervin Khariri (04) Kelas: XII TP 3ErvinNo ratings yet

- Center of GravityDocument5 pagesCenter of GravityErvinNo ratings yet

- Bolt Torque ChartDocument1 pageBolt Torque Chartidxh756No ratings yet

- Grafik Perbandingan Temperature Terhadap WaktuDocument2 pagesGrafik Perbandingan Temperature Terhadap WaktuErvinNo ratings yet

- American Fastener TablesDocument7 pagesAmerican Fastener TablesAhmed BdairNo ratings yet