Professional Documents

Culture Documents

900 Production Separators

900 Production Separators

Uploaded by

samandondonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

900 Production Separators

900 Production Separators

Uploaded by

samandondonCopyright:

Available Formats

900 Production Separators

Abstract

This section presents design principles, process considerations, and sizing for

production separators, including common oilfield separators and separator internal

components and their functions. It discusses flash calculations, separation theory,

fluid properties, and liquid/liquid separation. Also included is a discussion of the

input data needed for the PC “Bookware” programs for sizing separators.

Contents Page

910 Introduction 900-4

911 Objectives

912 General Background

920 Design of Production Separators 900-4

921 Introduction

922 Gas Plant Process Vessels and Compressor Knockout Drums

923 Oilfield Production Separators

924 Crude Oil Dehydration

930 PC Based Programs 900-5

931 Comparison with Company Design Procedure

932 Input to the Bookware Programs

933 Program Output

934 Cautions on Using the Bookware Programs

940 Common Oilfield Separators 900-8

941 Scrubbers

942 Gas Traps and Sand Traps

943 Three-Phase Horizontal Separators

944 Test Separators

945 Filter Separators (Coalescers)

946 Slug Catchers

Chevron Corporation 900-1 March 1990

900 Production Separators Pressure Vessel Manual

947 Steam Separators

948 Flash Separators

949 Flare Knockout or Vent Scrubbers

950 Separator Internal Components and Functions 900-12

951 Primary Separation Section and Inlet Diverters

952 Secondary Separation and Vessel Intervals

953 Mist Extractors

954 Serpentine Vanes

955 Dixon Plates

956 Centrifugal Mist Extractors

957 Vortex Breakers

958 Weir Buckets and Interface Controls

960 Design Principles and Process Considerations 900-21

961 Approximate Flash Calculations

962 Process Information and Facility Design

970 Separation Theory 900-31

971 Mechanisms of Particle Collection

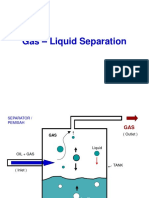

972 Gravity Separation

973 Centrifugal Force

974 Impingement and Coalescence

980 Fluid Properties 900-33

981 Formation and Characteristics of Oil-Water Mixture

982 Free Water

983 Fluid Equilibrium

984 Fluid Shear

985 Fluid Gravity vs Temperature

986 Multiphase Flow

990 Liquid/Liquid Separation 900-37

991 Liquid Retention Time

992 Factors That Affect Separation Efficiency

993 Pressure and Temperature

994 Viscosity

995 Foam

March 1990 900-2 Chevron Corporation

Pressure Vessel Manual 900 Production Separators

996 Emulsions

997 Flow Rate Surge or “Slugs”

998 Turbulence

999 Sour Service

Chevron Corporation 900-3 March 1990

900 Production Separators Pressure Vessel Manual

910 Introduction

This section presents general guidelines for the selection of oil/gas/water separation

systems. In upstream oilfield operations, separators are the primary process

elements in production systems. They separate the components of reservoir fluid

into segregated gas, crude oil, and water streams for further processing. A review of

the factors affecting production separation efficiency is presented along with sizing

procedures for primary production separators. This does not include detailed

process simulation procedures, economic evaluations, sizing methods for equip-

ment other than separators, or mechanical design of separators. The information in

this section is not intended to be used for final separator design, although it will

allow reasonable verifications of vendor's quotations.

911 Objectives

The objectives of this section are:

1. To acquaint the engineer with the factors that go into planning a crude oil sepa-

ration system.

2. To simplify recognition and selection of the correct vessel configuration for

any particular duty.

3. To provide procedures for selecting overall dimensions for two- and three-

phase separators.

912 General Background

Historically, vendors and engineering contractors perform much of the sizing for

pressure vessels. In many cases, vendors and contractors use proprietary vessel

design equations or programs to size vessels. To a large degree, most of these

programs are based on theoretical equations with limited field data to verify the

basic mathematical model. All crudes are different, and good modeling of perfor-

mance involves knowledge not only of vessels but of crude characteristics. Informa-

tion about crude oils is often vague and subject to change. Tools to accurately

determine what is going on in the separator are now being developed. The theory

presented below is the best current information, although empirical.

920 Design of Production Separators

921 Introduction

This section discusses several methods for sizing horizontal and vertical separators.

922 Gas Plant Process Vessels and Compressor Knockout Drums

The Company Design Procedure as outlined in Section 300 is well suited for

compressor knockout and process vessel design where quality phase separation is

March 1990 900-4 Chevron Corporation

Pressure Vessel Manual 900 Production Separators

considered essential. This method uses a conservative design approach that gener-

ally accommodates variations in either process fluctuations or nominal flowrate

increases. It is recommended that this design method be used first when comparing

vessel sizes with other design approaches.

923 Oilfield Production Separators

For oilfield production separators, less conservative design methods are commonly

used to provide adequate sizing of vessels, such as production gas traps or “pool”

traps. Methods similar to API 12J using K factors are generally employed for these

less critical bulk separation processes. In these applications the engineer is gener-

ally designing for rapid separation of gas and liquids, typically in the 1 to 3 minute

liquid hold-up range.

The separator sizing computer programs discussed in Section 930 can be used for

initial sizing. Final calculation is vessel-specific and must take local operating expe-

rience into account. The PC sizing programs presented in Section 930 require that

you know certain process information that is key to obtaining a good separator

design. In the event that process data are not available, program supplied default

values can be used as guidelines to arrive at a “first pass” separator size. Most

certainly the best design technique is to use field data (retention time, BS&W, etc.)

to determine input to the PC programs. With field data, the program should provide

a good method to predict comparative separator performance.

All methods should be used in conjunction with foam prediction methods. Foam

generation, in high viscosity crudes is common, and process considerations of

vessel design as outlined in Section 995 should be included in the final vessel

design.

924 Crude Oil Dehydration

Oil dehydration is a complex subject that does not always lend itself to a simple

discussion of retention time vs oil gravity. It will not be covered in this manual;

however, additional design information can be obtained by contacting: Chevron

Research and Technology Company (CRTC), Production & Process Facilities

Group.

930 PC Based Programs

The “Production Facility Bookware Series” is a series on PC Based Programs for

sizing separators. Module 101 is for two-phase separators; Module 102 is for three-

phase separators. Each module contains a personal computer program for designing

or rating a vertical or horizontal separator. Module 101 and 102 can be obtained by

contacting Chevron Research and Technology Company, Production & Process

Facilities Group. (See Reference 9 in the Reference section of this manual for more

information.)

Chevron Corporation 900-5 March 1990

900 Production Separators Pressure Vessel Manual

931 Comparison with Company Design Procedure

The main difference between the “Bookware” method discussed here and the

method recommended in Section 300 is in the correlations used for allowable vapor

velocity. Bookware uses a theoretical, droplet terminal settling velocity correlation

for vapor-liquid separation. The development is similar to that shown in Section

334 for liquid-liquid separation where the correlation used is based on data from

operating units (Equation 300-1 or 300-2).

For a vertical separator designed for 100 psig, specifying a liquid droplet diameter

of 250 microns causes the Bookware method to use about the same vapor velocity

as Equation 300-1 or 300-2. At 500 psig, a droplet diameter of 200 microns is

necessary to produce agreement; at 2000 psig, a droplet of 175 microns is needed.

For a horizontal separator, the allowable vapor velocity criterion applies despite the

fact that the liquid droplets settle in a direction perpendicular to the bulk flow of

vapor. In the Bookware procedure, the settling velocity of droplets is compared to

the height of the vapor space and the residence time of the vapor in the separator. In

other words, vapor moves in “plug flow” from the inlet end of the horizontal vessel

to the outlet end. A certain liquid droplet, moving at the horizontal velocity of the

vapor, settles from the top of the vapor space toward the vapor-liquid interface. If it

reaches the interface before reaching the outlet end, then all droplets of that size

will be removed by the separator. See the cautions below regarding using Bookware

for horizontal separators.

Liquid-liquid separation methods are similar in the Company and Bookware

procedures.

The Bookware procedures do not include demisters, coalescers, feed inlet shrouds,

baffles, and water boots.

932 Input to the Bookware Programs

Input data to the Bookware Programs include the following:

• Operating temperature and pressure

• Gas flow rate and either composition or specific gravity

• Oil flow rate and either specific gravity or API gravity

• Water flow rate, if present, and gravity

• Optionally, viscosities of the above phases, or they will be estimated by

internal correlations

• Maximum liquid droplet diameter in gas (default is 140 microns)

• Maximum water droplet diameter in oil (default is 500 microns)

• Maximum oil droplet diameter in water (default is 200 microns)

• Minimum oil retention time

March 1990 900-6 Chevron Corporation

Pressure Vessel Manual 900 Production Separators

• Minimum water retention time

• Upper and lower bounds on L/D ratio. (Default values are 4 and 2.)

• With a horizontal separator, the fraction of the volume occupied by liquid(s).

The default value is 0.5.

• Several mechanical items (with default values) used to estimate vessel weight

933 Program Output

The program develops a set of vessels of “standard” dimensions that satisfy the

separation and retention time requirements. Standard diameters are multiples of 6

inches; standard length increments are 1 foot. L/D varies from maximum to

minimum. For each vessel, the program gives a measure of the excess capacity it

provides. That excess may be in terms of gas or liquid rate, retention time, or

droplet size separated.

934 Cautions on Using the Bookware Programs

The following precautions should be observed when using the Bookware Programs:

• The criterion for acceptable vapor velocity in a horizontal vessel is that the

time necessary for a liquid droplet to settle from the top of the vessel to the

vapor-liquid interface shall be equal to the residence time of the vapor within

the vessel. This does not rule out use of a small fraction of vessel cross section

for vapor flow and high velocity of vapor. The result would be turbulence,

disturbance of the liquid surface, and reentrainment of liquid. Bookware

suggests liquid level at the vessel midpoint and cautions that L/D ratio higher

than 5.0 can result in reentrainment; this advice is not very specific. The user

of the program should apply the criteria of Section 351 to determine the cross

section for vapor flow, even if the Bookware program then indicates that the

vessel is oversized for vapor.

• A common practice is to state liquid gravity at standard conditions (60°F) and

then correct liquid density to operating temperature. The Bookware programs

do not adjust liquid gravities for temperature; therefore, the user should supply

liquid specific gravity at operating temperature (relative to water at 60°F).

• The programs do not adjust the fraction of horizontal vessel volume occupied

by liquid. If the user's (or the default) value is not optimal, a lot of vapor or

liquid volume can be unnecessary. The user should check the excess capacity

for vapor and liquid and adjust the liquid level appropriately.

• If total liquid volume in a three-phase separator is greater than what is needed

to satisfy hydrocarbon and water residence time requirements, the excess will

be allocated to oil and water in proportion to the original retention require-

ments. The user might prefer a different distribution.

Chevron Corporation 900-7 March 1990

900 Production Separators Pressure Vessel Manual

940 Common Oilfield Separators

Separators are used for many different applications. A few of the most common

services are described in this section. Figure 900-1 is a flow chart showing a typical

field separation plant.

Fig. 900-1 Typical Field Separation Plant

A production separator (also called a bulk separator or primary separator) is used to

separate one or more combined wellstreams at a well site, gathering center, plant or

offshore platform. It can be two- or three-phase. “Primary” separation indicates it is

the first process of separation the produced fluids have encountered. If located in a

plant, the production separator might be very large and handle the production from

a whole field. In large plants, several production separators are often used in

parallel.

941 Scrubbers

A scrubber is a separator used on very high gas/oil ratio (GOR) flow streams to

“scrub” small amounts of liquid from a gas stream. (See Figure 900-2.) Scrubbers

are usually two-phase, vertical vessels, although in larger applications horizontal

scrubbers are not uncommon.

March 1990 900-8 Chevron Corporation

Pressure Vessel Manual 900 Production Separators

Fig. 900-2 Impingement and Droplet Growth in a Typical Filter Coalescer

Suction and discharge scrubbers are placed upstream and downstream of gas

compressors. Fuel gas scrubbers remove residual liquid from gas just prior to its

use as a fuel. Pipeline scrubbers remove condensate from gas streams flowing

through long pipelines.

942 Gas Traps and Sand Traps

Gas Traps

A gas trap is a vertical separator that performs primary separation of gas from

liquid flow from the wellhead. The vessels are two-phase, with both process

streams proceeding to further processing. See Figure 900-3.

Chevron Corporation 900-9 March 1990

900 Production Separators Pressure Vessel Manual

Fig. 900-3 Typical Two-Phase Vertical Separator (Gas Trap)

Sand Traps

A sand trap is a device for removing sand from a produced well-stream. Sand traps

are typically used on high pressure gas wells, where sand production is common.

943 Three-Phase Horizontal Separators

A three-phase horizontal separator is the primary component used for oil/water bulk

separation. See Figure 900-4.

March 1990 900-10 Chevron Corporation

Pressure Vessel Manual 900 Production Separators

Fig. 900-4 Typical Three-Phase Horizontal Separator

944 Test Separators

A test separator is also called an Automated Well Test Unit (AWT), clean-up sepa-

rator, or a gage trap. A test separator determines the oil, water, and gas volumes of

each producing reservoir or well, and monitors well performance if the facility is

owned and operated by a single company. If the producing field has several co-

owners, the field may be “unitized” and the test separator may also be used to deter-

mine relative revenue payment to each co-owner. A minimum test separator would

separate the liquid and gas and measure both phases. The density of the liquids can

be measured by an accurate densimeter after the oil and water are completely sepa-

rated in a test container.

A conventional test separator may be horizontal or vertical. The test separator is

sized for the maximum “best” full well potential and anticipated gas and water

rates. The operating pressure of the test separator would be the same operating pres-

sure as the first stage separator. The size of the test separator is normally fixed by

the residence time required for oil/water separation.

945 Filter Separators (Coalescers)

Filter separator is a generic term which includes true filter-separators, filter

coalescers, and dry gas filters. They are used to separate liquid and solid contami-

nants from a gas or liquid stream when particle size is too small to be removed by a

conventional separator. See Figure 900-5.

946 Slug Catchers

A slug catcher, or surge drum is a separator designed to separate bulk liquid-gas

flow streams which are surging or slugging (see Section 970). The slug catcher may

also serve as a production separator, in which case further processing is generally

required. Properly designed, slug catchers should smooth out the intermittent flow.

Chevron Corporation 900-11 March 1990

900 Production Separators Pressure Vessel Manual

Fig. 900-5 Typical Filter Separator (Coalescer)

947 Steam Separators

Steam separators are used in geothermal projects or with steam generators; they are

simple separators which remove free water from steam, thus producing 100%

quality steam.

948 Flash Separators

A flash separator is a two-phase vessel with the primary purpose of degassing

liquid before it enters another process. An example would be a flash separator in

conjunction with an electrostatic coalescer or desalter where no free gas can be

tolerated. The fluid is first degassed in a flash separator which is elevated above the

coalescer so that once degassed the fluid will remain gas-free.

949 Flare Knockout or Vent Scrubbers

Flare scrubbers or vent scrubbers are placed in gas outlet streams from production

separators to remove any residual liquids left or any condensates that may have

formed in the line, prior to flaring or venting.

950 Separator Internal Components and Functions

The simple separation of gaseous and liquid hydrocarbon streams is normally

achieved by four distinct processes:

1. Primary phase separation of predominantly liquid hydrocarbons from those

that are predominantly gaseous.

2. Refine primary separation by removing the entrained hydrocarbon mist from

the gas.

March 1990 900-12 Chevron Corporation

Pressure Vessel Manual 900 Production Separators

3. Further refine the separation by removal of entrained bubbles from the liquid

phase so that, ideally, the liquid contains no more gas than would exist at equi-

librium at the pressure and temperature within the vessel.

4. Assure proper control by devices which will provide for the removal of the

separated gas and separated liquid phases from the vessel without allowing an

opportunity for reentrainment of one into the other.

The physical properties used to achieve these processes are gravity, centrifugal

force, and impingement. The effective combination of these properties, and their

governing principles, leads to efficient separator design. A description and explana-

tion of a horizontal two-phase separator illustrates how these physical properties

and principles are employed. (See Figure 900-6.)

Fig. 900-6 Basic Two-Phase Separator

The separator consists of three basic sections plus the controls, which correspond

with the four processes noted above. These are:

1. A primary separation section which controls or dissipates the energy of the

fluids as they leave the flow line and enter the vessel.

2. A secondary separation section (mist extraction or coalescing section) which

minimizes turbulence in the gas section.

3. A liquid collecting and removal section which prevents reentrainment of the

separated phases.

951 Primary Separation Section and Inlet Diverters

The entrance stream into the gas/oil separator is a high velocity, turbulent flow

stream with highly interspersed phases. The inlet mass of fluids has high

momentum due to the velocity at which it leaves the flow line. In the separating

vessel, which has a much larger diameter than the flow line, the natural velocity

for the same continuous flow rate is much less. Therefore, the inertia effects

entering the vessel must be quickly and effectively overcome so that natural gravity

Chevron Corporation 900-13 March 1990

900 Production Separators Pressure Vessel Manual

separation under lower velocity conditions can occur. To accomplish this, a care-

fully designed and compact device is required for producing controlled deceleration

of the incoming fluids. This device is usually referred to as a “momentum absorber.”

Downstream of the momentum absorber, liquid material with much entrained gas

separates generally downward. Above the liquid layer is a predominantly gaseous

material with much entrained liquid, moving either upward in a vertical separating

vessel or longitudinally in a horizontal vessel.

The configuration of the inlet device can take many shapes and should be given

careful consideration. Structural channel iron usually provides optimum results, but

angle iron, flat plates or dished heads have been considered optimum for certain

applications. Vertical vessels often employ a centrifugal inlet device. See Figure

900-7 for typical configurations of inlet devices.

Fig. 900-7 Typical Configurations of Inlet Devices

952 Secondary Separation and Vessel Intervals

The secondary separation section of a separator is important for efficient separator

design. Here the properties of gravity separation and impingement are combined

with the control of turbulence to achieve the required quality of liquid droplet sepa-

ration from the gas phase, and oil from water.

In two-phase separators, the primary function of the liquid retention section is to

allow free gas bubbles to separate from the liquid. This is accomplished by

providing sufficient residence time, free of excessive turbulence, to permit gravity

separation to occur. Typically no special internals are required for “degassing” the

liquid.

March 1990 900-14 Chevron Corporation

Pressure Vessel Manual 900 Production Separators

A second function of the liquid retention section in three-phase separators is to sepa-

rate oil and water. Depending on the degree of separation required, a liquid

coalescing element can be used, or no element can be used, allowing only separa-

tion by gravity.

953 Mist Extractors

The stainless steel wire mesh mist extractor, an impingement type extractor, is

perhaps the most common mist extractor. Most wire mesh mist extractor manufac-

turers furnish charts depicting proper velocity design. A common pad of wire mesh

used in production separators is 4 inches to 8 inches thick, having a density of 9

lb/ft3 (0.011 inch diameter stainless steel wire). (See Figure 900-8.)

Fig. 900-8 Wire Mesh Mist Extractor Configurations

Gas velocities entering a mist extractor usually are in the turbulent flow range, so

Newton's Law is applicable. Figure 900-9 shows various particle sizes found in

nature and the ease with which they are separated. A well-designed mist extractor

has no difficulty catching 10 micron particles. Mist extractors of poor design are on

the market that allow even 1000 micron particles to pass. Most arrangements of

angle iron pieces make poor mist extractors.

Fig. 900-9 Liquid Particle Characteristics

Chevron Corporation 900-15 March 1990

900 Production Separators Pressure Vessel Manual

The gas velocity for Newton's Law can be expressed as:

ρ L – ρ G 0.5

V G = K -------------------

ρG

(Eq. 900-1)

where:

K = C ( 1.74 gd )

(Eq. 900-2)

C = Drag Coefficient

g = Gravitational constant, ft/sec2

d = Average particle diameter, ft

Equation 900-2 is used to avoid reentrainment from the mist extractor. The K factor

is proportional to the drag force on a film of particle. If the K factor is too high in a

mist extractor, the film will not drain. A large amount of liquid is torn off the outlet

edge and, due to the high K factor, the particles created are smaller than normal and

are carried out.

Laboratory tests yield K factor curves such as shown in Figure 900-10. In ideal

circumstances, the K factor is not dependent on pressure or inlet liquid load;

however, this is rarely the case in actual field conditions. The curves are very steep

and one can easily choose a K factor value that is below all the reentrainment

curves. To illustrate, select a K factor of 0.35 on the curve in Figure 900-10. Most

separators have K factor values between 0.2 and 0.8.

The gas flow of a separator is usually limited to the K factor of the mist extractor.

Reentrainment is usually the biggest problem, not entrainment. Increasing velocity

increases centrifugal and impingement catching ability, but not gravity catching

ability.

A wire demister pad should not be used if wax will be present at the operating

temperature. If the crude is waxy and operates at a temperature near the cloud

point, wax may appear.

954 Serpentine Vanes

Serpentine vane extractors are lightweight and economical and need be only about

8 inches long. See Figure 900-11. These particular vanes have natural drainage

paths that do not reduce the cross-section areas. Thus, a high K factor can be used

safely in horizontal flow. Serpentine vanes have also been used in a vertical flow

configuration. Used in this way the K factor must be reduced because the perfor-

mance is limited by the ability of the separated liquid to drain downward counter-

current to the gas flow.

March 1990 900-16 Chevron Corporation

Pressure Vessel Manual 900 Production Separators

Fig. 900-10 Example: Carryover vs K-Factor Fig. 900-11 Serpentine Vane Mist Extractor

In the normal horizontal flow configuration, very high K factors can be used if suffi-

cient volume is available upstream for bulk liquid separation, and downstream to

allow for settling of liquid fly-off. Fly-off is liquid which has coalesced in the mist

extractor, then is blown off the trailing edge by the gas velocity. These droplets

must be large enough to settle rapidly, and this limitation determines the allowable

velocity, and therefore the K factor. Too high velocity of gas will prevent even these

relatively large coalesced droplets from settling, and they will become reentrained

in the gas stream.

If the process volume is not available upstream and downstream of the vanes, then

restrictions such as lower K factor and small allowable liquid loading are necessary.

This is the case in some cross-flow separator designs, both vertical and horizontal.

Wire mesh collects paraffin, hydrates, sand, and other solid particles, causing it to

plug rather easily; therefore, it is not generally recommended for primary wellhead

application, but is preferred for clean relatively high GOR applications. It can be

used in either vertical upflow or small horizontal configurations. Its allowable K

factor in horizontal flow is lower than for serpentine vanes because of its relatively

poor ability to drain itself of liquids. However, when conditions permit its use, wire

mesh can catch smaller particles than can the serpentine vane mist extractor.

955 Dixon Plates

A successful and widely used type of mist extractor for many years, Dixon plates

work on the principle of gravity separation. (See Figure 900-12.) They are used in

horizontal vessels as shown below. Reducing the area of each flow path with Dixon

plates reduces the turbulence, permitting gravity to separate the phases.

Dixon plates are slanted at a 45° angle so that a settling liquid droplet has only a

short distance to fall. Traditionally Dixon plates have been frequently used in

foamy crude oil applications because of the large surface area which aids foam

Chevron Corporation 900-17 March 1990

900 Production Separators Pressure Vessel Manual

Fig. 900-12 Parallel “Dixon” Plate Mist Extractor

decay. Relative to other mist extractors now available, Dixon plates are inferior in

performance and are heavier and more expensive.

956 Centrifugal Mist Extractors

This type of mist extractor utilizes the flow-stream momentum to create a high

velocity rotational flow. The resulting centrifugal acceleration causes a separation

of dense liquid from light gas. It allows high K factors, but is not as efficient as

element-type mist extractor designs for removing very small droplets of liquid

from gas.

Many other mist extractor designs are available, although many have poor perfor-

mance. In general, any mist extractor that greatly reduces flow area or otherwise

causes severe turbulence should be avoided.

957 Vortex Breakers

Large amounts of carry-over and gas slippage can often occur due to poor fluid

outlet design. Vortexing can also occur at the gas or liquid outlet. When a Coriolis

force or a nonuniform flow distribution starts a rotation motion, the available

energy at the mouth of the outlet produces and maintains a strong vortex. Excessive

pressure drop and poor separation are indicative of vortexing. These problems,

however, often are not detected. Fortunately, there are well-designed vortex

breakers that dampen rotation flow. Even with proper vortex breakers, the interface

can be sucked down into the drain if the liquid height above the drain is small and

the draining velocity is large. The minimum phase height needed to feed the drain

is a function of the drain diameter, draining velocity, and the ratio of phase densities

above and below the interface.

March 1990 900-18 Chevron Corporation

Pressure Vessel Manual 900 Production Separators

A useful guideline is to have a minimum of two times the nozzle diameter in liquid

depth if the interface is gas/liquid, and three times the nozzle diameter if the inter-

face is liquid/liquid, assuming the nozzles are sized for typical liquid velocities. If

these minimum dimensions are maintained and vortex breakers are installed over

the outlet nozzles, the problem of outlet reentrainment can be minimized. Figure

900-13 shows some common designs for vortex breakers. When the separator is

three-phase, additional considerations are necessary to control levels.

Fig. 900-13 Outlet Vortex Breaker Designs

958 Weir Buckets and Interface Controls

Three types of outlet control for three-phase separators are shown in Figure 900-14.

These arrangements can be used in horizontal or vertical vessels. The weir plate is

simple and relatively inexpensive; however, the interface controller is activated by

the difference in densities of oil and water. The controller must be sensitive. If the

liquids are slightly emulsified or the controller is not set properly, carry-over will

result (oil-in-water or water-in-oil).

The oil bucket acts as a “U” tube, blocking the oil from reaching the weir. Water

spills over the weir as it tries to attain the same hydrostatic pressure that the oil and

water height are creating on the other side of the bucket. One advantage of this

arrangement is that the controls sense the difference between liquid and gas;

however, more internal structure and vessel volume are required. Making the bucket

and weir adjustable adds flexibility.

The open pipe arrangement is a simple and inexpensive dumping method. However,

here too, interface control instrumentation must be sensitive to small changes in

density. It is also a disadvantage to have such a limited oil height above the oil

outlet. A slight drop in oil will cause gas to be sucked in, even with a nonvortexing

Chevron Corporation 900-19 March 1990

900 Production Separators Pressure Vessel Manual

Fig. 900-14 Three Types of Outlet Control for Three-Phase Separators

(a) Weir Plate

(b) Oil Bucket and Weir Plate

(c) Open Pipe

March 1990 900-20 Chevron Corporation

Pressure Vessel Manual 900 Production Separators

flow. Placing a horizontal pipe on top of the outlet as shown in Figure 900-14c will

help; the bottom of the pipe is slotted, allowing the oil level to drop within a few

inches of the slots without a problem. However, weir arrangements still give a

greater safety margin. When foam is present, a greater safety margin is essential

because the weight of foam distorts liquid level gage indications. A pad of emul-

sion and dirt may build up at the oil-water interface over a period of time distorting

liquid level gage readings and controller outputs. Therefore, a drain at this interface

may be specified. A toadstool interface collector is one of the better draining

devices.

960 Design Principles and Process Considerations

To size and design a separator, certain data and information must be known about

the process fluids and operating conditions. You need to know the service that the

separator is to perform and the performance requirements. Often it is helpful to

know something about the system into which the unit will fit. Special construction

and design specifications, if applicable, must be followed. Then all the information

must be interpreted to select the best design and to correctly size the separator.

Often design data are incomplete and assumptions must be made. Information

about type of service and the relationship to the whole system can be useful in

making good assumptions.

A range of different separator designs can be used or adapted to fit each need.

There are vertical and horizontal designs, longitudinal or cross flow, an assortment

of mist extractor types, and designs with and without slug catching sections.

961 Approximate Flash Calculations

Flash calculations are normally too involved to be done by hand. They are usually

done either on computer or in a programmable calculator. Sometimes it is necessary

to get a quick estimate of the volume of gas that is expected to be flashed from an

oil stream at various pressures.

Figure 900-15 was developed by flashing several crude oils of different gravities at

different pressure ranges. The curves are approximate. The actual shape depends on

the initial separation pressure, the number and pressure of intermediate flashes, and

the temperature.

Example: Suppose a 30° API crude with a GOR of 500 is flashed at 1,000 psia,

500 psia, and 50 psia before going to a stock tank. Roughly 50% of the gas, which

will eventually be flashed from the crude, or 250 ft 3/BBL will be liberated as gas in

the 1,000 psia separator. Another 25% (75% to 50%), or 125 ft3/BBL will be sepa-

rated at 500 psia and 23% (98% to 75%), or 115 ft3/BBL will be separated at

50 psia. The remaining 10 ft3/BBL (100% to 98%) will be vented from the stock

tank.

Note that Figure 900-15 is only to be used where a quick approximation is accept-

able. It cannot be used for estimating gas flashed from condensate produced in gas

wells.

Chevron Corporation 900-21 March 1990

900 Production Separators Pressure Vessel Manual

Fig. 900-15 Approximate Flash Calculation Chart. Use for approximation only

962 Process Information and Facility Design

Produced Fluid Data

1. The volumes (maximum and minimum) of all fluids requiring separation

should be obtained:

a. Gas, reported in million standard cubic feet/day (MMSCFD).

b. Oil, reported in barrels/day (BPD).

c. Water, reported in barrels/day (BPD).

Define these data on an individual well stream basis and on a total facilities basis. If

possible, the data should take the form of a detailed production forecast. See Figure

900-16 for a typical plot of a production facilities fluids forecast. Confirm whether

the data include any additional fluids from artificial lift or pressure maintenance

plans.

2. A complete laboratory analysis report of all hydrocarbon components and

water components, as well as the sampling conditions, is essential to optimize

the separation system.

3. Define the wellhead conditions for the following operating modes:

a. Flowing at start-up: pressure (psig); temperature (°F).

March 1990 900-22 Chevron Corporation

Pressure Vessel Manual 900 Production Separators

Fig. 900-16 Production Fluids Forecast

b. Flowing at economic limit: pressure (psig); temperature (°F)

c. Shut-in pressure at start-up (psig).

These data are largely dependent on reservoir characteristics and are influenced by

artificial lift and reservoir pressure maintenance plans.

4. Production characteristics should include, as applicable, information regarding

such characteristics as:

a. The quantity and characteristics of wax (%).

b. The tendency of the oil to form emulsions (settling time, minutes).

c. Quantity of sand carried by the inlet fluids (lb/1000 BBL).

d. Slugging from flow imbalances or pigging operations (% of production

flow rate).

e. Future reservoir composition for changing gas/oil/water ratios.

f. Quantity and composition of salts in inlet production fluids (lb/1000 BBL).

g. Acidity.

Required Export Characteristics

All production facilities will have a product quality specification that applies specif-

ically to that facility, whether it is for natural gas, condensate, or crude oil. These

Chevron Corporation 900-23 March 1990

900 Production Separators Pressure Vessel Manual

specifications are important decision points that, in many cases, will be paramount

in selecting the total separation system. Examples of criteria to be established are:

1. Gas gross heating value (Btu/ft3)

2. Gas inert components such as N2, CO2 (volume %)

3. Gas dew points for water and hydrocarbon (°F)

4. Moisture content (volume % for oil and lb/MMSCFD for gas)

5. Delivery pressure of export gas or oil (psig)

6. Oil BS&W content (%)

7. Gas sulfur content (grains/100 scf)

8. Oil vapor pressure (psia or Reid Vapor Pressure in psia)

9. Dissolved salts in crude oil (lb/1000 BBL)

10. Oil-in-water. Although it is not a product for export, the residual hydrocarbon

content in the final produced water stream must be known and should be

expressed in parts per million (ppm or mg/l).

Typical export specifications might be:

1. Oil

– 1% to 3% BS&W

– 20 lb salt/1000 BBL oil

– 11 to 13 psia Reid Vapor Pressure (RVP)

2. Gas

– 7 lb/MMSCF, water

– 0.25 grains/MMSCF, H2S

– 900 to 1300 Btu/1000 ft3, lower heating value (LHV)

Obviously, however, these specifications will be site and contract specific.

Future Conditions

The majority of production conditions can, with proper planning, be accommodated

to an acceptable level over the life of the facility. A common pattern for well

production shows, during the early stages, a larger gas/oil ratio (GOR) and smaller

amount of produced water and, in the later stages, a reversal of that condition. This

trend will not be experienced in the application of gas lift or water-flood programs,

where the requirement of those programs can usually be predicted and accounted

for in the design.

System Selection

The purpose of this section is to provide the user with a method to make initial

general decisions regarding the overall separation system. The discussion is general

March 1990 900-24 Chevron Corporation

Pressure Vessel Manual 900 Production Separators

in nature and emphasizes separator plans. Final system selection should be based

upon a weighted combination of field experience, process simulation, engineering

judgment, and an economic evaluation.

Selection of oil and gas treating systems generally results from optimization of

facility costs, product recovery, and operational considerations. Typically, the

process engineer utilizes the defined inlet stream and performs a preliminary mol-

balance for the system to establish: (1) the basic number of stages required to

achieve mandatory product specifications, and (2) system optimization to maximize

operational requirements while minimizing utility and facility costs. Preliminary

equipment sizes for process vessels can be obtained in some cases. However, for

detailed analysis, process equipment vendors should be contacted for the propri-

etary design aspects of such items as crude oil dehydrators or desalters. Correct and

careful input to the process conditions supplied to equipment vendors is essential,

especially when a “process guarantee” is part of the purchase contract. Use the

selection guidelines outlined in this section to establish the preliminary system.

Number of Separation Stages

Stage separation is the term given to the “step” reduction of pressure on the liquid

until it reaches the export point. The liquid flows from the first stage separator into

one or more lower stages and, finally, into the stock tank or pump station. Each

separator is considered one stage, as is the final pressure level.

Stage separation is used for two basic purposes:

• To increase stock tank recovery by minimizing vaporization (the more stages

used, the more stock tank oil produced from each barrel of reservoir oil)

• To reduce the amount of gas that the stock tank must handle

The question of how many stages (two, three, four or even five) remains to be

answered; economics is the key consideration, and the law of diminishing returns

applies. Actual production tests provide reliable solutions to the question. However,

in the absence of actual tests, calculations provide the only means to reasonably

determine the optimum number of stages and the optimum operating pressure of

each stage. This tedious operation is usually performed by computer (many flash

calculations are performed until the computer converges upon the optimum

solution).

A rule-of-thumb method for determining the optimum number of stages and oper-

ating pressure is given below. The first and last stage pressures are usually deter-

mined by other considerations. The second stage pressure equals the first stage

pressure divided by the pressure ratio, and so forth for each stage. The pressure

ratio per stage should not exceed the following, although in all rules-of-thumb,

exceptions will be found:

• 5—for gas-condensate production

• 7—for crude oil separation where the stock tank oil gravity is greater than

50° API

Chevron Corporation 900-25 March 1990

900 Production Separators Pressure Vessel Manual

• 10—for crude oil separation where the stock tank oil gravity is less than

40° API

Select the number of stages so as not to exceed the pressure ratios above. The

following equations are used to determine the optimum operating pressures of the

intermediate stages:

1

---

P1n

R = ------

Ps

(Eq. 900-3)

P m = Pm + 1 R ( P1 = P2 R )

(Eq. 900-4)

n – (m – 1)

P m = Ps R

(Eq. 900-5)

where:

n = Number of interstages = (number of stages -1)

R = Pressure ratio

P1 = First-stage pressure, psia

P2 = Second-stage pressure, psia

m = Arbitrary stage number

Pm = Pressure of stage m, psia

Ps = Stock tank pressure, psia

Application of the above equations to a three-stage separation problem where P1 =

400 psia and Ps = 14.2 psia gives:

400 0.5

R = ---------- = 5.3

14.2

(Eq. 900-6)

P2 =(14.2)(5.3)2-1 = 75.3 psia

As might be expected, there are many instances where the use of flash calculations

will not agree with the results of the above equations. These equations assume that

the ratio per stage should be constant, but a complete analysis of a separation

problem often shows that the ratio between the last stage and the stock tank or final

pressure is considerably smaller than between the other stages.

March 1990 900-26 Chevron Corporation

Pressure Vessel Manual 900 Production Separators

When accurate oil and gas analyses are available, computer simulations can predict

values very close to the optimum; field experimentation can provide further

refinement.

Flowing Wellhead Pressure (FWHP)

Flowing wellhead pressure sets the maximum operating pressure of the highest

stage pressure. The decline potential of the FWHP has a very great impact upon the

number of separation stages. On new field developments, when the reservoir

decline properties are unknown, value judgments are often made on the number and

pressure levels of stage separation. Multiple stages or trains of separation may be

necessary to provide different backpressures to various wells with differing FWHP.

FWHP is set by reservoir characteristics.

Factors Affecting Number of Separation Trains

The following factors must be considered when deciding on the number of separa-

tion trains.

1. Throughput

2. Number of reservoirs

3. Gas/oil ratio

4. Wax content

5. Sand content

6. Turndown requirements

7. Required on-line availability

8. Deck space and weight considerations (offshore applications)

The number of separation trains is influenced by total volumetric oil, gas, and water

throughput, a function of the peak crude production, anticipated water production

with time, and gas/oil ratio. Separator capacities may be limited by the physical size

and lifting weight of the vessel. (See Figure 900-16.)

More than one separation train may be justified if the reservoir production potential

is uncertain and an overdesigned topside facility has minor overall economic

impact. This decision requires an informed judgment based on the direction of

unproven reserves, and is beyond the scope of most engineering calculations. The

economic impact of two or three trains should be evaluated to provide management

with the information to make this decision.

Number of Reservoirs

The number of separation trains is also influenced by the number of production

reservoirs. If more than one reservoir is being produced, and the available flowing

wellhead pressure cannot match the other reservoir, a second separation train may

be needed. See Figure 900-17.

Chevron Corporation 900-27 March 1990

900 Production Separators Pressure Vessel Manual

Fig. 900-17 Typical Production System for Two Reservoirs of Different Pressures

If the available FWHP from the second reservoir is sufficient to match the second

stage of separation of the first reservoir, then the second reservoir production can be

separated in the second stage of a single train of production separators.

Gas/Oil Ratio (GOR)

The gas/oil ratio influences the diameter of separators and also the decision to

retain a single train. At a higher gas/oil ratio, vessel diameter may increase for the

same amount of crude produced because gas flow rates may control vessel size.

Wax Content

The wax content may influence the number of separation trains. Production could

be interrupted by shutdown of the separation train if wax buildup occurs and the

separation train vessels need to be steamed or cleaned in some other manner. Thus,

if wax content is high and processing conditions require heating, upsets in the

heating system could occur and more than one train of crude separation would be

favored.

A bucket-type liquid weir should be used when waxy crudes are expected. The

bucket weir eliminates buoyancy problems of level control when there is a small

difference in the specific gravity between the crude oil and water. Internal level

devices should be used. Wax could set up in the instrument bridle and prevent floats

and controls from working properly. If a vessel with external controls is to be used

for a waxy crude, the bridle should be heat traced to prevent waxy solids formation.

(See Figure 900-18.)

Sand Content

If the sand content of the reservoir fluid is severe and not controllable by gravel

packing at the reservoir face, cleanout of the crude separators may be required.

Under these maintenance conditions, more than one separation train would be

favored to avoid interrupting crude production.

Turndown

The turndown ability of a large single train of crude separation is a concern.

Although separation improves as the flow rate is reduced, control valves and associ-

ated instrumentation have a limited turndown. This problem can be overcome by

March 1990 900-28 Chevron Corporation

Pressure Vessel Manual 900 Production Separators

Fig. 900-18 Typical Horizontal Three-Phase Separator, Bucket and Weir Design

use of dual control valves on the liquid and gas outlets sized to accommodate the

full flow range. Another method to accommodate low flow rates is to use the test

separator as a startup separation vessel until full crude production permits the larger

single train operation.

Availability

Equipment components can be evaluated to determine statistical reliability, a factor

which may support the case for more than one train of separation. In the past,

however, this evaluation has not been an overwhelming reason to decide for two or

more trains. Other considerations, as discussed herein, will affect this decision.

Usually, redundancy of vessels does not in itself improve availability of the process

unless the characteristics of the fluid being processed force frequent cleanouts (e.g.,

sand, scale clogging). However, redundancy of instruments, such as valves, filters,

and pumps, can improve availability, since these items have relatively high failure

rates.

Space/Weight Considerations

Multiple train concepts usually are not as space or weight efficient as single train

concepts. However, “piggy backing” of vessels minimizes this difference in

restricted space applications, such as retrofit systems offshore.

Selection of Primary Separators

Selection of separator types for production facilities centers around configuration

(horizontal vs vertical) and the number of phase separations (as discussed below).

Chevron Corporation 900-29 March 1990

900 Production Separators Pressure Vessel Manual

Vertical vs Horizontal

There is relatively little difference between the total system cost of horizontal and

vertical configurations because of savings in plot area or structural loadings. The

list below compares advantages for each of these two types of separators.

• Vertical separators

– Have large liquid capacities.

– Are less susceptible to malfunction due to dirt, mud, wax, etc.

– Are much easier to clean out than horizontal vessels.

– Liquid level is easier to control.

– Are more efficient in liquid removal.

– Are very versatile in operation. A properly sized vertical separator can be

easily modified to almost any possible operational problem.

• Horizontal separators

– Have a much higher allowable gas velocity for the same cross-sectional

area.

– Are less costly per unit volume of gas capacity.

– Are easier to ship mounted on skid assemblies than vertical vessels.

– Have more area available for settling when oil and water are being

separated.

– Are easier to pipe up than vertical separators.

– Allow more surface area for the coalescence of very unstable foam.

– Have good flexibility.

– Series stages can often be stacked to minimize plot area.

– Have greater liquid/vapor interface area.

– Economic ratio of length to diameter (L/D) is usually 3.5 to 1 to 4.0 to 1

but may be 5 or more to 1 if liquid viscosity is a controlling factor.

Two-Phase vs Three-Phase

Two-phase units are used for very high gas/liquid ratios: e.g., early production units

with a “gas cap”; compressor suction and discharge scrubbers; gas/liquid applica-

tions for final Reid Vapor Pressure (RVP) control.

Three-phase units are often operated as two-phase units when high gas/oil ratios

and/or sanding problems are encountered in the early production stages. Significant

advantages may be gained from designing all primary separation units for three-

phase operation, because this approach provides significant flexibility for the

predictable changes in gas/oil/water ratios that will be encountered during the

facility life. Provided that all other technical parameters are equal, three-phase sepa-

rators are larger than two-phase separators.

March 1990 900-30 Chevron Corporation

Pressure Vessel Manual 900 Production Separators

970 Separation Theory

Oil/gas/water production from oil wells must be treated to meet requirements for

sales or safe transport. This is achieved with the use of separation systems, the heart

of which is the separator. A separator is a pressurized vessel used for separation of

oil, gas, and water. Additional equipment, such as pumps, dehydrators, etc., is often

required to achieve final treatment.

This section discusses basic separation theory and shows how this theory is applied

in the design of separation equipment. The discussion focuses on the equipment

and processes in common use in the oil-field, in plants, and in refineries.

Raw reservoir oil and gas fluids are multiple component hydrocarbon fluids which

usually are in a two-phase state (liquid and gas both present), with water and other

impurities also present. Separation of liquid and gas fluids and water removal are

necessary to meet pipeline specifications for the stable, dehydrated, single-phase

fluids. An optimum oil/gas/water separation system is one that achieves a compro-

mise between gas and oil product recovery at optimum operating temperatures and

pressures and at minimum cost. The selection of an optimum oil and gas separation

system requires an understanding of multicomponent system behavior, the princi-

ples of oil/gas/water separation, and separation efficiency factors.

971 Mechanisms of Particle Collection

The three basic separation methods are:

1. Gravity separation

2. Centrifugal force

3. Impingement and coalescence

For gas and liquid mixtures, the difference between the density of the two

substances is most often used in process applications to effect separation. There are

a number of ways density difference can be used to effect separation, such as by

gravity, or through centrifugal and impingement processes. The falling (or rising)

velocity of a particle or droplet in a viscous medium is a function of the forces

exerted on it. Whether these forces are from gravity or fluid momentum, the princi-

ples governing particle behavior, as a function of density, are the same.

972 Gravity Separation

Gravity separation is the most prevalent means of separation and takes advantage of

the difference in densities of the phases. A particle falling by gravity will accelerate

until drag forces balance gravitational forces. After that, it will continue to fall at a

constant velocity known as the terminal or free settling velocity, as given by the

equation below for rigid spherical particles.

Chevron Corporation 900-31 March 1990

900 Production Separators Pressure Vessel Manual

Turbulent Flow (Newton's Law)

0.5

4gD p ( ρ 1 – ρ g )

V t = -------------------------------------------

3 ( ρ g )C

(Eq. 900-7)

where:

C = Drag coefficient, dimensionless

Dp = Average particle diameter, ft

g = Acceleration due to gravity, 32 ft/sec2

Vt = Particle terminal velocity, ft/sec

ρ = Fluid density, lb/ft3

ρl = Density of liquid, lb/ft3

ρg = Density of gas, lb/ft3

Newton's Law defines the drag force resisting the motion of the particle during

turbulent flow as the drag coefficient, C. In the turbulent flow region (500 < Re

< 200,000), C has an average value of 0.44 for spheres.

Laminar Flow (Stokes' Law)

If the flow is laminar (viscous), the relationship developed by Stokes applies, and

Equation 900-8 defined for gas/liquid separation becomes:

2

gD p ( ρ 1 – ρ g )

V t = ------------------------------------

18µ

(Eq. 900-8)

where:

µ = Viscosity of gas, lb/ft • sec

973 Centrifugal Force

When a two-phase flowing stream changes direction, the phase having the greatest

mass density tends to continue in a straight line. The resulting collision of the more

dense material with the confining wall separates it from the less dense phase.

Stokes' Law may be applied to this process if the flow is laminar and the effect of

gravity, g, is replaced by a, the acceleration due to centrifugal force.

974 Impingement and Coalescence

Impingement occurs when an entrained particle strikes an obstruction in its normal

flow path rather than the containing wall as in centrifugal force separation. The

impinged obstruction acts as the collecting surface. As the fluid approaches an

March 1990 900-32 Chevron Corporation

Pressure Vessel Manual 900 Production Separators

impingement surface, such as a fiber, it curves around, but the momentum of the

entrained droplet tends to move it straight ahead to collide with the fiber.

The term entrainment refers to the small particles carried by the gas which require a

mist extractor to remove. Reentrainment is liquid which has been separated from

the gas, then picked up again and carried out.

The process of impingement of liquid droplets in a gas stream onto a solid surface

is used in a number of mist extractor designs (see Section 950 above). The liquid

droplets, being denser than the continuous gas phase, tend to continue to travel in

their direction of motion when the continuous gas phase is diverted by a solid

surface. This momentum of the entrained droplets causes impingement of the liquid

particles onto the solid surface.

After the particles have impinged on the solid surface, surface tension holds the

liquid particles onto the surface and prevents reentrainment; other particles

impinging on the surface cause coalescence, with subsequent gravity separation of

the liquid. See Figure 900-2.

980 Fluid Properties

981 Formation and Characteristics of Oil-Water Mixture

Water and oil are immiscible liquids, with water generally the heavier of the two.

Placed in a common container, the water easily separates from the oil by settling to

the bottom. In actual production, the water may indeed be easily separated from the

oil, while in other cases separation may be very difficult. Oil-water mixtures are

categorized into two general groups: free water mixtures and emulsions. Free water

is water which easily separates from the oil phase. Emulsified water is difficult to

separate, and its removal is sometimes costly and complex. Actually, the stability of

the mixtures is relative. A distinction between free water and emulsified water has

meaning only in relation to the mixture's response to various dehydration methods.

982 Free Water

Water produced with crude and considered “free” exists either as a continuous mass

or slug, or as an unstable dispersion of droplets suspended in the crude by turbu-

lence. Free water may be the natural contents of the producing formation, or it may

be drive water from a secondary recovery scheme (i.e., water flood, steam flood)

which penetrates into the producing zone. The water remains free when the inter-

face between the phases is sharp and the droplet size relatively large. The droplets

are free to move and respond readily to the separating effect of gravity; and if two

dispersed droplets of water collide, they coalesce easily.

In fact, the coalesced state of the drops is the more stable condition. This is easily

demonstrated by studying the shape of a water droplet. The spherical shape of the

droplet in the absence of external stress has the greatest volume for the least surface

area of any geometrical form. A droplet can momentarily take on some other shape,

Chevron Corporation 900-33 March 1990

900 Production Separators Pressure Vessel Manual

but that shape, being less stable than the spherical shape, does not continue to exist.

The ratio of volume to surface area is, therefore, an indication of relative stability.

This stability is explained by defining the term “free energy.” A droplet which is

other than spherical in shape is said to possess free energy which tends to dissipate

and force the droplet into a spherical shape. The coalesced state is more stable

because it has a smaller surface area for the same volume, and therefore less free

energy. Two uncoalesced droplets are said to have higher “free energy.”

983 Fluid Equilibrium

The most common application for gas-liquid separation and treating equipment is

on produced hydrocarbon flow streams. These hydrocarbon systems are produced

by withdrawing fluids from underground formations. A typical sample consists of a

mixture of many different hydrocarbon components. Those of low molecular

weight are often referred to as “light” components or “light ends.” They have

higher vapor pressures than the heavier components with greater molecular

weights. In the underground formation, the fluids may exist as both liquids and

gases; the equilibrium is determined by the formation pressure and temperature.

When a well is drilled and the fluids are produced, decreases in pressure in the

system cause more of the components to vaporize. This vaporization continues

throughout the production and processing sequence whenever the process pressure

drops below the fluid vapor pressure. If a fluid is at or above its vapor pressure, it is

said to be “stable” at the existing temperature and pressure, providing these condi-

tions persist long enough to allow completion of the equilibrium and phase

separation.

In cases where all or most of the produced hydrocarbons are light, they may exist

totally as a gas phase. The reservoir for these fluids is thought of as a gas reservoir

and “gas wells” are drilled into it. When the components are largely heavier, the

principal produced fluid is crude oil, although some gas is always vaporized from

the oil as it is produced. An oil well is one which produces crude oil, with natural

gas as a secondary product. The ratio of gas to hydrocarbon liquid produced stream

can vary from very low for a stream of heavy crude with almost no gas, to infinity

for a dry gas stream. This ratio is used frequently to describe a hydrocarbon stream.

Gas/oil ratio, abbreviated GOR, is given in English units as standard cubic feet of

gas per barrel of oil (scf of gas/bbl oil).

A produced oil-gas mixture flowing through a typical process system undergoes a

series of pressure changes. Friction losses create a continuous drop while flow-

through valves and other restrictions result in instantaneous decreases in pressure.

Simultaneous with these pressure variations, the fluid temperature is changing with

gradual ambient cooling and process heating or cooling. With changes in pressure

and temperature, the equilibrium between gas and oil is disturbed. With successive

stages, as the pressure drops, more gas will be released until the crude oil is stabi-

lized in a near gas free condition.

March 1990 900-34 Chevron Corporation

Pressure Vessel Manual 900 Production Separators

984 Fluid Shear

In a continuous phase, oil or water droplets exist in a relatively fragile condition. In

the process of moving these fluids, pressure decreases (or increases) across control

valves or dump valves, or pumps impart energy into the flowing fluid. As the parti-

cles in the fluid receive this energy, they break apart into many smaller particles.

Shear effects become significant when droplet sizes become so small that gravity

separation is no longer effective.

985 Fluid Gravity vs Temperature

When a produced hydrocarbon liquid is made up of a relatively large number of

heavy molecules, its specific gravity will be greater than for a liquid consisting of

primarily lighter molecules. A system of characterizing hydrocarbon liquids has

been developed and is in common use. Oil gravity is expressed in terms of “degrees

API.” The definition for this system is:

°API = (141.5/SG) - 131.5

(Eq. 900-9)

where:

°API = Degrees API

SG = Specific gravity of oil at 60°F and atmospheric pressure

A light oil has a higher API gravity than a heavy oil. If a fluid has a specific gravity

of 1.0, its API gravity is 10° API. Crude oils most commonly are in the range of

10° to 50° API.

As a general rule, heavy oils, that is those with low API gravity, are produced from

relatively low pressure formations, have a low GOR, and often a large amount of

produced water forming a very stable emulsion. Light oils are more likely produced

at high pressure with a higher volume of associated gas, and less water content, of

which a smaller portion is emulsified. As a general rule, low gravity (heavy) oils

exhibit a higher viscosity at a given temperature than higher gravity oils. Figure

900-19 shows typical viscosity curves for various gravities of crude oil. It should be

noted, however, that gravity and viscosity, while exhibiting a general relational

trend, are not directly related functions. The viscosities of several different oils of

the same gravity may vary widely.

986 Multiphase Flow

When gas, oil and water are present together, the stream is called a three-phase

stream. When a stream is called a two-phase flow stream, the emphasis is on a gas-

liquid mixture, but does not necessarily mean no water is present with the oil. It is

simply emphasizing the presence of only gas or only liquid. Therefore a flow

stream referred to as two-phase may actually be three-phase.

With two- or three-phase flow through long pipelines, bulk separation often occurs

between gas and liquid. Large “slugs” of liquid separated by large “bubbles” of gas

Chevron Corporation 900-35 March 1990

900 Production Separators Pressure Vessel Manual

Fig. 900-19 Typical Viscosity/Temperature Curves for Various Crude Oils

cause the flow to be intermittent. In very long, large lines, slug cycles of many

seconds are common. This can create problems in process equipment if not

accounted for in their design. On the other hand, in streams with high water

content, of medium or high gravity oil, and very low flow stream velocities with

little gas, water separation may occur in the line. The water may flow along the

bottom of the line causing a high rate of corrosion there.

Gas affects the formation of oil-water emulsions. As gas is flashed, agitation

occurs, beginning in the formation and continuing through producing and

processing. This agitation can be severe, adding a great deal of energy to the emulsi-

fying process.

Gas also affects the separation of oil and water. If gas bubbles are rising through an

oil-water mixture, turbulence is created which interferes with the settling of water

droplets. For that reason gas is usually separated first, then water. If the gas sepa-

rator is designed as a three-phase vessel to also remove water, that water removal is

usually of secondary importance and is expected to be very incomplete. A typical

process train has successive reductions in pressure and with each reduction a separa-

tion of gas. However, the amount of gas removed typically decreases at the lower

pressures so that at the last step, very little free gas is present. Corresponding sepa-

ration of water will be least efficient in the first stage of gas separation. The emul-

sion treater or oil dehydrator is usually the end process. The actual dehydration

must occur in as near to gas-free oil as possible. This process is not only necessary

for performance, but is also the most economical. Because water separation typi-

cally requires the largest process vessels, it is least expensive if the vessels are of

low pressure, which is the condition that exists at the end of the process train.

March 1990 900-36 Chevron Corporation

Pressure Vessel Manual 900 Production Separators

990 Liquid/Liquid Separation

991 Liquid Retention Time

The length of time a fluid particle in a flow stream remains in a vessel is called

retention time. The longer the liquid retention time in the separator, the more time

available for settling and coalescing water droplets from the oil, and the more effi-

cient the separation. Inasmuch as increased retention time is a function of separator

volume, more separator volume may aid the ability of the separator to handle

process surges and increase hold-up time ahead of downstream pumping.

The bulk average retention time of a process can be calculated by dividing the fluid

volume of the vessel by the volume flow rates of the fluid stream assuming plug

flow. For a given flow rate, a long retention time will require a larger vessel than a

short retention time. It is therefore economic to decrease the retention time as much

as the process performance will allow.

992 Factors That Affect Separation Efficiency

The following factors affect separation efficiency:

1. Particle diameter

2. Retention time

3. Gas velocities in process vessel

4. Gas and liquid densities

5. Pressure

6. Temperature

7. Viscosity

8. Flow rate surges

9. Foam

10. Emulsions

11. Turbulence

12. Surface and interfacial tension

Particle diameter is one of the most important properties affecting separation effi-

ciency because it is the predominant factor in determining the settling velocity in all

applications. Any design allowing high efficiency in the separation of small parti-

cles will allow a higher efficiency in the separation of larger particles if the

maximum liquid handling capacity is not exceeded.

In liquid/liquid separation, techniques are being developed for determining liquid

particle size and distribution. Particle size and distribution are constantly changing,

Chevron Corporation 900-37 March 1990

900 Production Separators Pressure Vessel Manual

as fluid flow in pipelines and separators is a dynamic process. Separation by gravity

is logically limited to particles of relatively large size.

An entrained liquid system is basically unstable, the particles either coalescing or

fragmenting if given sufficient time. The time needed to fragment or to coalesce is

inversely proportional to size and directly proportional to the amount of interpar-

ticle contact. Impingement separators are based upon interparticle contact.

993 Pressure and Temperature

As the operating pressure of a production separator increases, its wall thickness

must also increase dramatically. Thinner walled vessels may be obtained by using

higher-strength steels, by increasing the length-to-diameter ratios (not space-effi-

cient), or simply by limiting the stage pressure. As a rule of thumb, vendors of large

vessels should be able to fabricate wall thicknesses to 1.5 inches. Thicker walled

separators can be fabricated, but are expensive and need long delivery time. Pres-

sure also affects the actual flowing volume. An increase in pressure increases

capacity. Both the gas and liquid densities are affected because more of the lighter

components of the gas are driven into the liquid phase, thereby changing the density

of both phases.

By Stokes' Law (Equation 900-8), the settling velocity of water particles is

inversely proportional to the oil viscosity. The sensitivity to temperature of hydro-

carbon viscosity suggests that raising the process temperature would decrease the

viscosity, thereby increasing settling rates. Actually, heating crude oil to be sepa-

rated benefits the separation process in several ways and was the earliest aid used in

gravitational separation of water. Here are some of the ways that heating facilitates

the process:

• Higher process temperature lowers oil viscosity.

• Up to about 175°F the specific gravity difference between oil and water is

increased with increasing process temperature.

994 Viscosity

To properly size a separator, the viscosities of the oil and water phases must be

known. The oil phase viscosity will typically have a much larger influence on

vessel size than the water phase viscosity because oil viscosity is usually several

times greater than water viscosity. Oil viscosities also vary over a much wider range

and usually vary more with temperature. Due to these factors it is important to have

good oil viscosity data.

The best condition is to have oil viscosity versus temperature data for the particular

oil to be separated. Alternately, data from other wells in the same field can usually

be used without significant error. The viscosity versus temperature data may be

plotted as a straight line on special ASTM graph paper. Then the viscosity may be

predicted at any other temperature.

March 1990 900-38 Chevron Corporation

Pressure Vessel Manual 900 Production Separators

If two data points are known, the Walther equation may also be used instead of

ASTM graph paper. This equation plots as a straight line on ASTM graph paper.

The advantage of the Walther equation is that any calculator may be used to predict

oil viscosities without the special graph paper. To determine the oil viscosity at a

third temperature from two data points, the following three equations should be

solved in order:

ln [ ln ( µ 1 + 0.7 ) ] – ln [ ln ( µ 2 + 0.7 ) ]

M = ---------------------------------------------------------------------------------------

lnT 1 – lnT 2

(Eq. 900-10)

B = ln [ln (µ1 + 0.7)] - (M ln T1)

(Eq. 900-11)

µ3 = exp[exp(M ln T3 + B)] - 0.7

(Eq. 900-12)

where:

µn = Oil viscosity at Tn, centipoise, cp

Tn = Temperature corresponding to µn, °R

M = Slope of straight line

B = Intercept of straight line

For cases where only one datum point is available, Equations 900-11 and 900-12

may be used by assuming a value for the slope. This method predicts oil viscosities

with good accuracy over small temperature ranges of 20°F to 40°F. For most cases

the slope will have a value in the range of -3.5 to -4.0.

If no data are available, the oil viscosity may be estimated by a variety of methods

from the temperature and oil gravity. These methods, however, are not very accu-