Professional Documents

Culture Documents

LEAN - Diagnosis - Before and After: BFR Aftr X

Uploaded by

Sayantan RahaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LEAN - Diagnosis - Before and After: BFR Aftr X

Uploaded by

Sayantan RahaCopyright:

Available Formats

LEAN - Diagnosis - Before and After

BFR AFTR

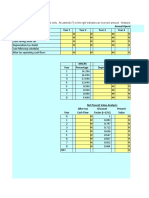

1.0 Inventory Response X

0%-6% ###

For the categories of Finished Goods, Work-In-Process 7%-55% ###

(WIP) and Purchased/Raw Materials, what portion of middle

1.1 and upper managers can state from memory the current 56%-80% X ###

turnover and the purpose of each type? 81%-93% ###

94%-100% ###

0-3 ###

4-6 ###

What is the overall inventory turnover, including Finished

1.2 Goods, WIP and Purchased/Raw material? 7-12 X ###

13-24 ###

25+ ###

<=1.0 ###

1.1-2.0 ###

What is the ratio of Inventory Turnover to the industry

1.3 average? 2.1-4.0 ###

4.1-8.0 ###

8.1+ X ###

###

2.0 The Team Approach Response X X

Exploitive ###

Bureaucratic ###

2.1 What is the organization type? Consultive ###

Participative X ###

Highly Participative ###

Individual Incentive ###

Hourly Wage ###

How are workers on the factory floor

2.2 compensated? Group Incentive ###

Salary X ###

Salary+Annual Bonus ###

Transfers & Layoffs Every

Retraining Year

Reduce ###

2.3 To what extent do people have job security? Layoffs ###

Layoffs Are Rare X ###

31%+ ###

14%-30% ###

2.4 What is the annual personnel turnover 7%-11% X ###

3%-6% ###

0%-2% ###

<5% ###

What percentage of personnel (ALL Personnel) 6%-10% ###

2.5 have received at least eight hours of 11%-30% ###

teambuilding training? 31%-90% X ###

91%-100% ###

<5% ###

What percentage of personnel are active 6%-10% ###

2.6 members of formal work teams, quality teams, 11%-30% ###

or problem-solving teams? 31%-90% X ###

91%-100% ###

Efforts Consulting www.effortsconsulting.com 9879391004

###

3.0 Processes Response X X

4+ ###

How many large-scale machines or single- 3 ###

3.1 process areas are in the plant through which 2 X ###

50% or more of different products must pass? 1 ###

0 ###

Large Scale ###

How would you rate the overall bias of the

3.2 plant's process selection with respect to scale? Medium/Mixed X ###

Small Scale ###

Very Difficult ###

How easy is it to shift output when the product

3.3 mix changes? Moderately Difficult X ###

Easy ###

Very Difficult ###

How easy is it to alter the total production rate

3.4 by +/-15%? Moderately Difficult X ###

Easy ###

96%-100% ###

91%-95% ###

What is management's target operating capacity

3.5 for individual departments or machines? 86%-90% X ###

76%-85% ###

50%-75% ###

How would you rate the overall bias of the Complex Technologies ###

3.6 plant's process selection with respect to Moderate/Mixed X ###

technology level? Simple Technologies ###

###

4.0 Maintenance Response X X

Describe equipment records and data. Include Non-Existent ###

4.1 records of uptime, repair history, and spare Substantially Complete X ###

parts. Include repair and parts manuals. Complete & Accurate ###

71%-90% ###

Excluding new installations and construction 51%-70% ###

4.2 projects, what percentage of maintenance hours 26%-50% ###

is unplanned, unexpected, or emergency? 11%-25% X ###

0%-10% ###

No PM ###

1%-10% Coverage ###

Does maintenance have and follow a defined

4.3 preventive schedule? 11%-30% Coverage ###

31%-90% Coverage X ###

91%+ Coverage ###

Frequently ###

Do equipment breakdowns limit or interrupt

4.4 production? Occasionally X ###

Rarely ###

Unknown ###

0%-75% ###

What is the overall average availability of plant

4.5 equipment? 76%-90% X ###

91%-95% ###

96%-100% ###

Efforts Consulting www.effortsconsulting.com 9879391004

###

5.0 Layout & Handling Response X X

71%-100% ###

46%70% ###

What portion of total space is used for storage

5.1 and material handling? 30%-45% X ###

16%-30% ###

0%-15% ###

71%-100% ###

What portion of the plant space is organized by

46%70% X ###

5.2 function or process type? 30%-45% ###

16%-30% ###

0%-15% ###

Pallet-size (or larger) loads, long

distances (>100'),complex flow

patterns, confusion, & lost

material ###

How would you characterize material

5.3 movement? Mostly tote-size loads, bus-route

transport, & intermediate

distances ###

Tote-size or smaller loads, short X

distances (<25'), simple & direct

flow pattern ###

Messy, Filthy, Confused ###

###

How would you rate overall housekeeping and

5.4 appearance of the plant? Some dirt, Occasional Mess X ###

###

Spotless , Neat, & Tidy ###

Impossible to see any logic or

flow sequence.

###

Most processes are apparent with

How well could a stranger walking through your

5.5 plant identify the processes and their sequence? some study. Most sequences are X

visible. ###

Processes and their sequences

are immediately visible.

###

Efforts Consulting www.effortsconsulting.com 9879391004

###

6.0 Suppliers Response X X

2.5+ X ###

1.6-2.4 ###

What is the average number of suppliers for

6.1 each raw material or purchased item? 1.3-1.7 ###

1.2-1.4 ###

1.0-1.1 ###

1-11 ###

12-17 ###

On average, how often, in months, are items put

6.2 up for re-sourcing? 18-23 X ###

24-36 ###

36+ ###

0% ###

What portion of raw material & purchased parts 1%-10% X ###

6.3 comes from qualified suppliers with no need for 11%-30% ###

incoming inspection? 31%-70% ###

70%-100% ###

0% ###

What portion of raw material and purchased 1%-10% X ###

6.4 items is delivered directly to the point of use 11%-30% ###

without incoming inspection or storage? 31%-70% ###

70%-100% ###

0% ###

1%-10% ###

What portion of raw materials and purchased

6.5 parts is delivered more than once per week? 11%-30% ###

31%-70% ###

70%-100% X ###

###

7.0 Setups Response X X

61+ ###

29-60 ###

What is the average overall setup time (in

7.1 minutes) for major equipment? 16-30 X ###

10-15 ###

0-9 ###

0% ###

1%-6% ###

What portion of machine operators have had

7.2 formal training in Rapid Setup techniques? 7%-18% X ###

19%-42% ###

43%-100% ###

Not at All

###

To what extent are managers and workers

7.3 measured and judged on setup performance? Informal Tracking & Review

###

Setups Tracked, Performance In

Job Description X

###

Efforts Consulting www.effortsconsulting.com 9879391004

###

8.0 Quality Response X X

0%-6% X ###

7%-55% ###

What portion of total employees have had basic

8.1 SPC training? 56%-80% ###

81%-93% ###

94%-100% ###

0% ###

What portion of operations are controlled with

1%-10% X ###

8.2 Statistical Process Control (SPC) 11%-30% ###

31%-70% ###

71%-100% ###

0% X ###

What portion of the SPC that is done is 1%-10% ###

8.3 accomplished by operators as opposed to 11%-30% ###

Quality or Engineering specialists? 31%-70% ###

71%-100% ###

0% ###

1%-10% X ###

8.4 What is the overall defect rate? 11%-30% ###

31%-70% ###

71%-100% ###

###

9.0 Scheduling/Control Response X X

0% X ###

What portion of work-in-process flows directly 1%-10% ###

9.1 from one operation to the next without 11%-35% ###

intermediate storage? 36%-85% ###

86%-100% ###

0% ###

What portion of work-in-process is under

1%-10% X ###

9.2 Kanban or Broadcast control 11%-35% ###

36%-85% ###

86%-100% ###

0%-50% ###

51%-70% ###

9.3 What is the on-time delivery performance? 71%-80% ###

81%-95% ###

95%-100% X ###

Efforts Consulting www.effortsconsulting.com 9879391004

Lean Section Points and Target

Insert number here that reflects the relative

importance of the section in relation to

other sections. Total of all sections should

Section score in equal 100%

Raw point total by percent of maximum

section. possible score.

Calculates the target per

for that section based on

weight.

STRATEGIC

SECTION # OF SECTION SECTION IMPACT SECTION

SECTION POINTS QUEST AVG % FACTOR TARGET

1.0 Inventory 8 3 2.67 67% 12.0% 92.3%

2.0 Teams 18 6 3.00 75% 11.0% 84.6%

3.0 Process 12 6 2.00 50% 11.0% 84.6%

4.0 Maintenance 12 5 2.40 60% 8.0% 61.5%

5.0 Layout 11 5 2.20 55% 11.1% 85.5%

6.0 Supplier 8 5 1.60 40% 10.0% 76.9%

7.0 Setup 8 3 2.67 67% 11.1% 85.5%

8.0 Quality 4 4 1.00 25% 13.0% 100.0%

9.0 Scheduling 5 3 1.67 42% 13.0% 100.0%

SUM: 100% Sum of impact factors. This must

MAX: 13.0% equal 100%. Change impact

factor input as required.

Efforts Consulting www.effrtsconsulting.com Email:info@effortsconsulting.com Cotact: 9879391004

ere that reflects the relative

he section in relation to

Total of all sections should

Calculates the target percentage score

for that section based on relative

weight.

mpact factors. This must

00%. Change impact

put as required.

Efforts Consulting www.effrtsconsulting.com Email:info@effortsconsulting.com Cotact: 9879391004

Lean Profile

1.0 Inventory

100.0%

9.0 Scheduling 2.0 Teams

50.0%

8.0 Quality 3.0 Process

ACT

0.0%

UAL

7.0 Setup 4.0 Maintenance

6.0 Supplier 5.0 Layout

You might also like

- Lean AssessmentDocument14 pagesLean AssessmentLean Training100% (11)

- Hse Stress Tool ExampleDocument13 pagesHse Stress Tool Examplejavier LorenzoNo ratings yet

- Project Framework 2021 enDocument87 pagesProject Framework 2021 enLuz GarciaNo ratings yet

- Thumb Rules For Engineering CostsDocument1 pageThumb Rules For Engineering CostsAziz SaputraNo ratings yet

- Problem 17 26Document4 pagesProblem 17 26saad bin sadaqatNo ratings yet

- Problem 16 49Document4 pagesProblem 16 49saad bin sadaqatNo ratings yet

- Kinney Raiborn Cost AnalysisDocument64 pagesKinney Raiborn Cost AnalysisChammy TeyNo ratings yet

- IT Specialist Descripcion de PuestoDocument7 pagesIT Specialist Descripcion de PuestoMireya RochaNo ratings yet

- SAP Business ByDesign Sizing Assessment ToolDocument13 pagesSAP Business ByDesign Sizing Assessment ToolSarras InfoNo ratings yet

- Data Entry Raw Difference Standardised Effect SizeDocument11 pagesData Entry Raw Difference Standardised Effect SizeCésar Rafael Marins CostaNo ratings yet

- Job Description: Manufacturing EngineerDocument9 pagesJob Description: Manufacturing EngineerMireya RochaNo ratings yet

- Assignment3: 1) Identify Percentage of Missing Values in Each Column and Display The SameDocument30 pagesAssignment3: 1) Identify Percentage of Missing Values in Each Column and Display The SameSujit MohapatraNo ratings yet

- TCO For Software App TemplateDocument5 pagesTCO For Software App TemplateSFGov100% (1)

- MOS GameDocument1 pageMOS GameRajesh1 SrinivasanNo ratings yet

- Activity # 2 - KPIT Cummins Infosystems Ltd.Document6 pagesActivity # 2 - KPIT Cummins Infosystems Ltd.Arun C PNo ratings yet

- Key Achievements / Career AchievementsDocument4 pagesKey Achievements / Career Achievementssundad0602No ratings yet

- Data Entry Raw Difference Standardised Effect SizeDocument6 pagesData Entry Raw Difference Standardised Effect SizegotteNo ratings yet

- Capex Depreciation: #REF! Projec T'S ReqmtDocument2 pagesCapex Depreciation: #REF! Projec T'S Reqmtjam mallillinNo ratings yet

- References Q13KQ - 1438493364Document14 pagesReferences Q13KQ - 1438493364Ahmed EbrahimNo ratings yet

- Xelpmoc DesignDocument18 pagesXelpmoc DesignvishalNo ratings yet

- SHS Template 4 SECONDARY With QR Code School 1Document12 pagesSHS Template 4 SECONDARY With QR Code School 1PatzAlzateParaguyaNo ratings yet

- Cash FlowDocument55 pagesCash FlowHj Salgado OlivaresNo ratings yet

- Maintenance Coordinator Descripcion de PuestoDocument8 pagesMaintenance Coordinator Descripcion de PuestoMireya RochaNo ratings yet

- Investment Banking ExcelDocument28 pagesInvestment Banking ExcelJohn ChiwaiNo ratings yet

- Balanced Scorecard & IT Balanced ScorecardDocument26 pagesBalanced Scorecard & IT Balanced ScorecardLukmanHakim100% (1)

- Template RR OGB 2021 - Format NON Upload BulkDocument24 pagesTemplate RR OGB 2021 - Format NON Upload BulkSyaiful Nur hamzahNo ratings yet

- PM 04 01 MAP - Dev TRANSICOLD Ph1 10931Document196 pagesPM 04 01 MAP - Dev TRANSICOLD Ph1 10931SREEDHARNo ratings yet

- Revised PYSPESO 10 BTEC Form A BTEC Monthly Report Rev 01 2021-1-1Document1 pageRevised PYSPESO 10 BTEC Form A BTEC Monthly Report Rev 01 2021-1-1Janna AlardeNo ratings yet

- Abeterjobinterviewquestions PDFDocument12 pagesAbeterjobinterviewquestions PDFKamal VirkNo ratings yet

- IT Coord: Job DescriptionDocument8 pagesIT Coord: Job DescriptionMireya RochaNo ratings yet

- The Management Accountant's Role in Today's Retail EnvironmentDocument34 pagesThe Management Accountant's Role in Today's Retail Environmentapi-3705877No ratings yet

- Data Entry Raw DifferenceDocument11 pagesData Entry Raw DifferenceJose Carlos Celedon RiveroNo ratings yet

- Please Only Change Blue Cells. Click On This Button To Print Entire WorksheetDocument9 pagesPlease Only Change Blue Cells. Click On This Button To Print Entire WorksheetSandy ZhengNo ratings yet

- TtcInnovations Return On Investment CalculatorDocument8 pagesTtcInnovations Return On Investment Calculatorabubakar siddiqueNo ratings yet

- Department of Labor and Employment: Republic of The Philippines Intramuros, ManilaDocument21 pagesDepartment of Labor and Employment: Republic of The Philippines Intramuros, ManilaDOLE West Leyte Field OfficeNo ratings yet

- Start-Up Capital EstimateDocument4 pagesStart-Up Capital EstimateDuane Allan SmithNo ratings yet

- Direct Assistance Grant Scheme: FinalDocument1 pageDirect Assistance Grant Scheme: FinalbuzoalfaNo ratings yet

- Nota Importante: Clean Energy Project Analysis SoftwareDocument11 pagesNota Importante: Clean Energy Project Analysis SoftwareGustavo Lino100% (1)

- Durian SolutionsDocument27 pagesDurian SolutionsPrakhar Khandelwal25% (4)

- Fixed Asset and Depreciation ScheduleDocument5 pagesFixed Asset and Depreciation ScheduleDarkchild HeavensNo ratings yet

- Managerial Accounting Student - 5e 05-55Document1 pageManagerial Accounting Student - 5e 05-55SamerNo ratings yet

- Effect Size CalculatorDocument7 pagesEffect Size CalculatorSusan Henseleit ParisNo ratings yet

- Frontlit, Backlit & Vinyl Flex Banner Manufacturing For AdvertisingDocument52 pagesFrontlit, Backlit & Vinyl Flex Banner Manufacturing For AdvertisingSusheel GautamNo ratings yet

- Commerce Department SESSION: 1 2021/2022 Dpa10023-Computer Application in Accounting Laboratory Exercise 1 (5%)Document3 pagesCommerce Department SESSION: 1 2021/2022 Dpa10023-Computer Application in Accounting Laboratory Exercise 1 (5%)Nur MaisarahNo ratings yet

- Analytical Calibration Using A Log-Log Linear Curve Fit.: Calibration Data Application To UnknownsDocument8 pagesAnalytical Calibration Using A Log-Log Linear Curve Fit.: Calibration Data Application To UnknownsIsmael Morales PuenteNo ratings yet

- Banking Event EBSDocument39 pagesBanking Event EBSAbhijit SinhaNo ratings yet

- Gantt Chart Excel 2Document8 pagesGantt Chart Excel 2Andres Mauricio Guevara RiverosNo ratings yet

- Horizon Budget TemplateDocument3 pagesHorizon Budget TemplateSilviu JidovuNo ratings yet

- Rab Drainase Batu Kumbung 1Document49 pagesRab Drainase Batu Kumbung 1basir83abdulNo ratings yet

- Software Development Estimate Template: COMPANY NAME, Project Title, Project ManagerDocument4 pagesSoftware Development Estimate Template: COMPANY NAME, Project Title, Project ManagerAli ZaidiNo ratings yet

- Furniture Repair Shop Chart of Accounts AssetsDocument6 pagesFurniture Repair Shop Chart of Accounts AssetsRechelleRuthM.DeiparineNo ratings yet

- Change Management Metrics ToolDocument54 pagesChange Management Metrics ToolLaksamana Yuda Citra HandikaNo ratings yet

- Case 08-31Document8 pagesCase 08-31saad bin sadaqatNo ratings yet

- On-Demand vs. On-Premises TCO Calculator: Cost CategoriesDocument4 pagesOn-Demand vs. On-Premises TCO Calculator: Cost CategoriesLuc BrunNo ratings yet

- Dokumen - Tips Introduction To Managerial Accounting GNBDocument48 pagesDokumen - Tips Introduction To Managerial Accounting GNBImran Riaz MalikNo ratings yet

- Blank IPCR QuarterlyDocument4 pagesBlank IPCR QuarterlyAyni ReyesNo ratings yet

- The HERO Transformation Playbook: The step-by-step guide for delivering large-scale changeFrom EverandThe HERO Transformation Playbook: The step-by-step guide for delivering large-scale changeNo ratings yet

- Digital Customer Experience Engineering: Strategies for Creating Effective Digital ExperiencesFrom EverandDigital Customer Experience Engineering: Strategies for Creating Effective Digital ExperiencesNo ratings yet

- Content Continued 2018 European Polymer JournalDocument11 pagesContent Continued 2018 European Polymer JournalSayantan RahaNo ratings yet

- Evaluation of World-Class Manufacturing Systems: A Case of Indian Automotive IndustriesDocument24 pagesEvaluation of World-Class Manufacturing Systems: A Case of Indian Automotive IndustriesSayantan RahaNo ratings yet

- 2019 Adidas Global Supplier ListDocument127 pages2019 Adidas Global Supplier ListSayantan RahaNo ratings yet

- Inspection Procedures For Quality Assurance in CuttingDocument26 pagesInspection Procedures For Quality Assurance in CuttingSayantan RahaNo ratings yet

- Misusage of Statistics in Medical ResearchDocument7 pagesMisusage of Statistics in Medical ResearchSayantan RahaNo ratings yet

- GP Confirmation - GandhinagarDocument2 pagesGP Confirmation - GandhinagarSayantan RahaNo ratings yet

- Costing Sheet For Knit GarmentsDocument3 pagesCosting Sheet For Knit GarmentsSayantan Raha100% (1)

- Button Attaching Juki mb1800BDocument6 pagesButton Attaching Juki mb1800BSayantan RahaNo ratings yet

- Black and White Corporate Company Annual ReportDocument10 pagesBlack and White Corporate Company Annual ReportSayantan RahaNo ratings yet

- To Reduce or Absorb Supply Chain Complexity: A Conceptual Model and Case StudyDocument26 pagesTo Reduce or Absorb Supply Chain Complexity: A Conceptual Model and Case StudySayantan RahaNo ratings yet

- ZIGZAG JUKI Lz2290aDocument10 pagesZIGZAG JUKI Lz2290aSayantan RahaNo ratings yet

- Buttonholing Machine Juki Lbh1790anDocument4 pagesButtonholing Machine Juki Lbh1790anSayantan RahaNo ratings yet

- FLATBED Sewing Machine JUKI-lu2800v7 (For Non Apparel)Document4 pagesFLATBED Sewing Machine JUKI-lu2800v7 (For Non Apparel)Sayantan RahaNo ratings yet

- Industry 4.0 Revolution in Clothing and Apparel Factories: Apparel 4.0Document17 pagesIndustry 4.0 Revolution in Clothing and Apparel Factories: Apparel 4.0Sayantan RahaNo ratings yet

- Cobots in Folding MethodDocument9 pagesCobots in Folding MethodSayantan RahaNo ratings yet

- Computerized Embroidery Machine - Best Embroidery Machines (PDFDrive)Document206 pagesComputerized Embroidery Machine - Best Embroidery Machines (PDFDrive)Sayantan RahaNo ratings yet

- Cobot Programming For Collaborative Industrial Tasks: An OverviewDocument37 pagesCobot Programming For Collaborative Industrial Tasks: An OverviewSayantan RahaNo ratings yet

- Human-Robot Technology Collaboration (Cobot) & How It Will Be Profitable For Apparel IndustriesDocument3 pagesHuman-Robot Technology Collaboration (Cobot) & How It Will Be Profitable For Apparel IndustriesSayantan RahaNo ratings yet

- Hexoskin Patent PDFDocument34 pagesHexoskin Patent PDFSayantan RahaNo ratings yet

- Room Rental AgreementDocument3 pagesRoom Rental AgreementgrandoverallNo ratings yet

- Assignment On Safety and MobilityDocument8 pagesAssignment On Safety and Mobilitysushant.sapkota1710No ratings yet

- Rg10 BasicDocument4 pagesRg10 BasicallieNo ratings yet

- 106 - Sika Waterproofing MortarDocument2 pages106 - Sika Waterproofing MortarZack de la RezaNo ratings yet

- 15-23 MEP GuidelinesDocument9 pages15-23 MEP GuidelinesChandrakant Tiwari100% (1)

- DR Narendra Kumar Assistant ProfessorDocument16 pagesDR Narendra Kumar Assistant ProfessorAbdiweli AbubakarNo ratings yet

- Complete CatalogueDocument86 pagesComplete CatalogueDaredevil CreationsNo ratings yet

- GEA31885 TM2500 BrochureDocument8 pagesGEA31885 TM2500 Brochureryan23No ratings yet

- Splitted Biogas Plant Project - Group 6 (1) - 1Document5 pagesSplitted Biogas Plant Project - Group 6 (1) - 1SOUNAK BANDYOPADHYAYNo ratings yet

- Collective MarketingDocument13 pagesCollective MarketingMart RuralNo ratings yet

- WEF AM13 Participants 34ezx6jlxk PDFDocument76 pagesWEF AM13 Participants 34ezx6jlxk PDFMeggie Gathee KimariNo ratings yet

- V 62Document2 pagesV 62aimatsuccessNo ratings yet

- Application Form For CSWIP Ten Year Re-Certification (Overseas)Document10 pagesApplication Form For CSWIP Ten Year Re-Certification (Overseas)Anwar MohiuddinNo ratings yet

- InvoisDocument54 pagesInvoisAnonymous Ff1qA9RLCNo ratings yet

- 128 Psid 97Document2 pages128 Psid 97YIN YIN HTWE100% (17)

- Formation Damage and StimulationDocument16 pagesFormation Damage and Stimulationxion_mew2No ratings yet

- Ease and Wizz 2.0.5 Read MeDocument5 pagesEase and Wizz 2.0.5 Read MeJanio MachadoNo ratings yet

- Rubric For Human Impact Ecuadorian EcosystemDocument3 pagesRubric For Human Impact Ecuadorian EcosystemJohn OsborneNo ratings yet

- Town of Riverhead Update On COVID-19 PDFDocument16 pagesTown of Riverhead Update On COVID-19 PDFRiverheadLOCALNo ratings yet

- G1312-90010 BinaryPumpSL User EbookDocument168 pagesG1312-90010 BinaryPumpSL User EbookJeff Ong Soon HuatNo ratings yet

- BaricitinibDocument4 pagesBaricitinibfitrirahmarianiNo ratings yet

- Biscuit Order Swami EntpDocument1 pageBiscuit Order Swami EntprajasmudafaleNo ratings yet

- Proglaze® SSG: Single-Component, Neutral-Cure, Silicone Sealant For Structural GlazingDocument2 pagesProglaze® SSG: Single-Component, Neutral-Cure, Silicone Sealant For Structural GlazingTung ThanhNo ratings yet

- MAX1204 5V, 8-Channel, Serial, 10-Bit ADC With 3V Digital InterfaceDocument24 pagesMAX1204 5V, 8-Channel, Serial, 10-Bit ADC With 3V Digital InterfaceGeorge BintarchasNo ratings yet

- Readme Red AlertDocument10 pagesReadme Red AlertHuy NguyenNo ratings yet

- Ashrae Certification Brochure PDFDocument4 pagesAshrae Certification Brochure PDFAsiful islamNo ratings yet

- ARI - CAPEX FFE FormDocument2 pagesARI - CAPEX FFE FormWaleed AhmedNo ratings yet

- Magi 2.0 - Part 1: Household CompositionDocument46 pagesMagi 2.0 - Part 1: Household CompositionHJ ParkNo ratings yet

- Export AssistanceDocument15 pagesExport AssistanceGaurav AgrawalNo ratings yet

- 2021 Annual ReportDocument734 pages2021 Annual ReportAbhilasha SinhaNo ratings yet