Professional Documents

Culture Documents

ENAC-AlMg5 (Si) - ENAC-51400

Uploaded by

Irena NOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ENAC-AlMg5 (Si) - ENAC-51400

Uploaded by

Irena NCopyright:

Available Formats

5/2/2021 ENAC-AlMg5(Si) / ENAC-51400 - SteelNumber - Aluminium equivalent, chemical composition, properties

Steel Steel / Cast iron Alloy Buy / Worldwide

Home Search

Numbers Standards Standards Sell Equivalents

YOU HERE: Alloy Standards -> Aluminium - all grades OR Alloy Standards -> / EN 1706

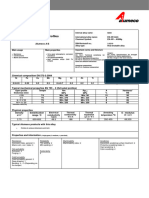

ENAC-AlMg5(Si) ( ENAC-51400 )

Grade : ENAC-AlMg5(Si)

Number: ENAC-51400

Classification: Aluminium alloy for casting

EN 1706: 2010 Aluminium and aluminium alloys. Castings. Chemical composition and

Standard:

mechanical properties

Equivalent

Go here

grades:

Chemical composition % of grade ENAC-AlMg5(Si) ( ENAC-51400 )

Fe Si Mn Ti Cu Mg Zn Others -

max 0.55 max 1.5 max 0.45 max 0.2 max 0.05 4.5 - 6.5 max 0.1 each 0.05; total 0.15 Al - remainder

New opportunities for buyers!

Post free buying requirement for ENAC-AlMg5(Si)

Mechanical properties of grade ENAC-AlMg5(Si) ( ENAC-51400 )

Rm - Tensile strength (MPa) (F) (S) 160

Rm - Tensile strength (MPa) (F) (K) 180

Rp0.2 0.2% proof strength (MPa) (F) (S) 100

Rp0.2 0.2% proof strength (MPa) (F) (K) 110

A - Min. elongation at fracture (%) (F) (S) 3

A - Min. elongation at fracture (%) (F) (K) 3

Brinell hardness (HBW): (F) (S) 60

Brinell hardness (HBW): (F) (K) 65

Equivalent grades of grade ENAC-AlMg5(Si) ( ENAC-51400 )

Warning! Only for reference

EU Germany Japan Inter

www.steelnumber.com/en/steel_alloy_composition_eu.php?name_id=1258#1 1/2

5/2/2021 ENAC-AlMg5(Si) / ENAC-51400 - SteelNumber - Aluminium equivalent, chemical composition, properties

EN DIN,WNr JIS ISO

3.3261 Al-Mg5Si1 AlMg5(Si)

ENAC-AlMg5(Si)

G-AlMg5Si

Temper designations

O Annealed

H Strain hardened

F Fabricated (as cast)

T Thermally treated to produce stable tempers other than F, O or H

T1 Cooled from an elevated temperature shaping process and naturally aged

Cooled from an elevated temperature shaping process, cold worked and

T2

naturally aged

T3 Solution heat treated, cold worked and naturally aged

T4 Solution heat treated and naturally aged

Cooled from an elevated temperature shaping process and then artificially

T5

aged

T6 Solution heat treated and then artificially aged

T7 Solution heat treated and then artificially overaged (stabilised)

T8 Solution heat treated, cold worked and then artificially aged

T9 Solution heat treated, artificially aged and then cold worked

W Solution heat treated (unstable temper)

EN 515:1993 Aluminium and aluminium alloys. Wrought products. Temper designations

Casting processes

S Sand casting

K Chill or permanent mould casting

D Pressure die casting

L Investment casting

Mechanical properties

ReH Minimum yield strength / Mindestwert der oberen Streckgrenze / Limite d elasticite minimale

Rm Tensile strength / Zugfestigkeit / Resistance a la traction

A Minimum elongation / Mindestwert der Bruchdehnung / Allongement minimal

J Notch impact test / Kerbschlagbiegeversuch / Essai de flexion par choc

ENAC-AlMg5(Si) ( ENAC-51400 ) Aluminium alloy for casting

Chemical composition. Equivalents of ENAC-AlMg5(Si) ( ENAC-51400 ).

Standards.1 Mechanical Properties. Hardness

European Steel and Alloy Grades / Numbers Searchable Database © 2011- 2021 All rights reserved. About

us. Contacts.

The contents from this Steel & Alloy Database may not be reproduced. The entire risk as to use of these content is

assumed by you the user

www.steelnumber.com/en/steel_alloy_composition_eu.php?name_id=1258#1 2/2

You might also like

- C15E2C - 1.1132 Non-Alloy Special Steel - Equivalent, Chemical Composition, PropertiesDocument2 pagesC15E2C - 1.1132 Non-Alloy Special Steel - Equivalent, Chemical Composition, PropertiesPaulo Henrique NascimentoNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10277-4 EN 10084 EN 10297-1Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10277-4 EN 10084 EN 10297-1farshid KarpasandNo ratings yet

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10207Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10207farshid KarpasandNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10263-3Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10263-3farshid KarpasandNo ratings yet

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- European Steel and Alloy Grades: 16nicrs4 (1.5715)Document2 pagesEuropean Steel and Alloy Grades: 16nicrs4 (1.5715)farshid KarpasandNo ratings yet

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- European Steel and Alloy Grades: Gx5Crnicu16-4 (1.4525)Document2 pagesEuropean Steel and Alloy Grades: Gx5Crnicu16-4 (1.4525)farshid KarpasandNo ratings yet

- European Steel and Alloy Grades: 50crmov13-15 (1.2355)Document2 pagesEuropean Steel and Alloy Grades: 50crmov13-15 (1.2355)farshid KarpasandNo ratings yet

- European Steel and Alloy Grades: G32Nicrmo8-5-4 (1.6570)Document2 pagesEuropean Steel and Alloy Grades: G32Nicrmo8-5-4 (1.6570)farshid KarpasandNo ratings yet

- European Steel and Alloy Grades: About Us EN 10120Document2 pagesEuropean Steel and Alloy Grades: About Us EN 10120farshid KarpasandNo ratings yet

- AK9ch - АК9ч Aluminium Casting Alloys gost standardDocument2 pagesAK9ch - АК9ч Aluminium Casting Alloys gost standardVivek GoudNo ratings yet

- Barrettetig Catalogo Oerlikon 35035Document44 pagesBarrettetig Catalogo Oerlikon 35035mp303No ratings yet

- JISG4051 S45C high carbon steel plateDocument1 pageJISG4051 S45C high carbon steel plateck19654840100% (1)

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10277-2 EN 10162Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10277-2 EN 10162farshid KarpasandNo ratings yet

- Ficha Tecnica Anillos Oval RingDocument8 pagesFicha Tecnica Anillos Oval RingAndres AlfonsoNo ratings yet

- en - GB FactSheet - Main 01Document1 pageen - GB FactSheet - Main 01ronaldb322No ratings yet

- European Steel and Alloy Grades: About Us EN 10209Document2 pagesEuropean Steel and Alloy Grades: About Us EN 10209farshid KarpasandNo ratings yet

- 04 - Posg - IE - Propiedades MecánicasDocument13 pages04 - Posg - IE - Propiedades MecánicasMisANo ratings yet

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- EN9 Carbon Steel Bright Bar - EN9 Forging - EN9 Round - Saaj SteelDocument3 pagesEN9 Carbon Steel Bright Bar - EN9 Forging - EN9 Round - Saaj SteelNaiduNo ratings yet

- Erdemir Product Catalogue PDFDocument278 pagesErdemir Product Catalogue PDFYogesh Gupta100% (1)

- European Steel and Alloy Grades: About Us EN 10207Document2 pagesEuropean Steel and Alloy Grades: About Us EN 10207farshid KarpasandNo ratings yet

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- Welding HandbookDocument441 pagesWelding HandbookGautam KumarNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10149-2Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10149-2farshid KarpasandNo ratings yet

- European Steel and Alloy Grades: S275JRC (1.0128)Document2 pagesEuropean Steel and Alloy Grades: S275JRC (1.0128)farshid KarpasandNo ratings yet

- European Steel and Alloy Grades: X1Crnimocun24-22-8 (1.4652)Document2 pagesEuropean Steel and Alloy Grades: X1Crnimocun24-22-8 (1.4652)farshid KarpasandNo ratings yet

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- Table of Material Properties For Structural Steel S235, S275, S355, S420Document4 pagesTable of Material Properties For Structural Steel S235, S275, S355, S420Arjun Soman100% (1)

- Ficha Técnica CarborodDocument1 pageFicha Técnica CarborodAndres NuñezNo ratings yet

- Thermanit Nimo C 24 (ERNiCrMo3) GTAWDocument1 pageThermanit Nimo C 24 (ERNiCrMo3) GTAWNiranjan Fakirchand YadavNo ratings yet

- Catalog Profile StandardDocument16 pagesCatalog Profile StandardBogdan AndreiNo ratings yet

- European Steel and Alloy Grades: Nicr22Fe18Mo (Dubl) (2.4665)Document2 pagesEuropean Steel and Alloy Grades: Nicr22Fe18Mo (Dubl) (2.4665)farshid KarpasandNo ratings yet

- HandbookDocument443 pagesHandbookyuszriNo ratings yet

- Connector LEMO M - SeriesDocument44 pagesConnector LEMO M - SeriesAmilcar LlantadaNo ratings yet

- FSX-414 Datasheet, FSX-414 Chemical, FSX-414 Heat Treatment PDFDocument2 pagesFSX-414 Datasheet, FSX-414 Chemical, FSX-414 Heat Treatment PDFJ. BangjakNo ratings yet

- Aluminium: Designation of Aluminium AlloyDocument20 pagesAluminium: Designation of Aluminium Alloymuhammed sabry tahaNo ratings yet

- HILCO E4043 ALUMINIL Si5 Welding Electrode - Data SheetDocument1 pageHILCO E4043 ALUMINIL Si5 Welding Electrode - Data SheetDieter van RooyenNo ratings yet

- 6005 ProfilesDocument1 page6005 ProfilesBPP-Tech PythonNo ratings yet

- S 960 QDocument2 pagesS 960 Qmohsen_267No ratings yet

- OK Tigrod NiCrMo-3 (OK 19.84) - ENDocument1 pageOK Tigrod NiCrMo-3 (OK 19.84) - ENbaladiroyaNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- Lec1 (DR-Abdelshafy 3/10/2018)Document3 pagesLec1 (DR-Abdelshafy 3/10/2018)Aladdin AdelNo ratings yet

- Metal Plates Property Table Metal Plate MaterialsDocument1 pageMetal Plates Property Table Metal Plate MaterialsaAa1234aAabNo ratings yet

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 4957Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 4957farshid KarpasandNo ratings yet

- Fluxofil 41 (T 55 6 1nimo B M, C 3 h5)Document1 pageFluxofil 41 (T 55 6 1nimo B M, C 3 h5)brunizzaNo ratings yet

- European Steel and Alloy Grades: 20nicrmo2-2 (1.6523)Document2 pagesEuropean Steel and Alloy Grades: 20nicrmo2-2 (1.6523)farshid KarpasandNo ratings yet

- Aluminum 413 FDocument2 pagesAluminum 413 Ftanto_deep_15No ratings yet

- EN 1676 Grade AB-44300: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearDocument3 pagesEN 1676 Grade AB-44300: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearMelvin B EkboteNo ratings yet

- Non-Ferrous Metals and Alloys: Al, Cu, ZN, MG, Ti, Ni, Co, W, V and Their Alloys - All Except of Fe andDocument26 pagesNon-Ferrous Metals and Alloys: Al, Cu, ZN, MG, Ti, Ni, Co, W, V and Their Alloys - All Except of Fe andmaniNo ratings yet

- 90MnCrV8!1!2842 - Steel Equivalent, Mechanical Properties, Chemical CompositionDocument1 page90MnCrV8!1!2842 - Steel Equivalent, Mechanical Properties, Chemical CompositionEduardo Guilherme BrandtNo ratings yet

- Aço X6NiCrTiMoVB25!15!2 - 1.4980 Austenitic SteelDocument2 pagesAço X6NiCrTiMoVB25!15!2 - 1.4980 Austenitic SteelMoacir MachadoNo ratings yet

- OK Tigrod 12.60: Tig Rods (Gtaw) Mild Steel RodsDocument1 pageOK Tigrod 12.60: Tig Rods (Gtaw) Mild Steel RodssankuNo ratings yet

- S500 Grade Steel SpecificationsDocument2 pagesS500 Grade Steel SpecificationsSmriti Agarwalla100% (1)

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363No ratings yet

- The Motivational Power of Science Discrepant EventsDocument8 pagesThe Motivational Power of Science Discrepant EventsJennifer Owens100% (1)

- REDA Continuum LF Product Sheet - 7483196 - 01Document1 pageREDA Continuum LF Product Sheet - 7483196 - 01Andi PermanaNo ratings yet

- Physical and Chemical Properties of Gelatin From Red Snapper Scales: Temperature EffectsDocument7 pagesPhysical and Chemical Properties of Gelatin From Red Snapper Scales: Temperature EffectsAMAANINo ratings yet

- 2nd National Conference BrochureDocument2 pages2nd National Conference Brochureak86No ratings yet

- 2. 超滤装置 UF Device Maintenance and Installation instructionsDocument30 pages2. 超滤装置 UF Device Maintenance and Installation instructionsHussnain NadeemNo ratings yet

- 1 Au NPs Thin Films Fabricated by Electrophoretic Deposition Method For Highly Sensitive SERS Application Odi YesDocument7 pages1 Au NPs Thin Films Fabricated by Electrophoretic Deposition Method For Highly Sensitive SERS Application Odi Yesben0706No ratings yet

- 115 Rock Drill Oil ApplicationsDocument2 pages115 Rock Drill Oil ApplicationsRandi Riki AdtiaNo ratings yet

- ASTM D1298 12b 2017Document4 pagesASTM D1298 12b 2017Aldo Yael Flores PeñuelasNo ratings yet

- Thermodynamic Evaluation and Optimization of The Li, Na, K, MG, Ca//F, CL Reciprocal System Using The Modified Quasi-Chemical ModelDocument14 pagesThermodynamic Evaluation and Optimization of The Li, Na, K, MG, Ca//F, CL Reciprocal System Using The Modified Quasi-Chemical ModelPérsio Mozart PintoNo ratings yet

- Bond Energy: Name - Chem Worksheet 16-2 H F F F HDocument1 pageBond Energy: Name - Chem Worksheet 16-2 H F F F HCHRISTOPHER NSENGIYUMVANo ratings yet

- Toseef 2023Document2 pagesToseef 2023moj mastiNo ratings yet

- Inv Chem 1Document24 pagesInv Chem 1Animesh kanjilalNo ratings yet

- Editable Welding Resume TemplateDocument6 pagesEditable Welding Resume TemplatejeyesbelmenNo ratings yet

- Flammability of A Gas MixtureDocument6 pagesFlammability of A Gas Mixturebldp03No ratings yet

- Inspector Technical QCDocument117 pagesInspector Technical QCESAVENo ratings yet

- Che Practice Questions: CPQ Set 1Document5 pagesChe Practice Questions: CPQ Set 1Jerome Javier0% (1)

- ColumnsDocument15 pagesColumnsAnonymous UOrBDcCJua0% (1)

- 1 s2.0 S0165993621003095 MainDocument11 pages1 s2.0 S0165993621003095 MainSebastian CasadiegoNo ratings yet

- 01 FTK Chemical BiotechDocument47 pages01 FTK Chemical BiotechJessica PhillipsNo ratings yet

- MEO Class 2 QuestionDocument2 pagesMEO Class 2 Questionsumitsinha8950% (2)

- H-Industrial Pumps Part 2Document28 pagesH-Industrial Pumps Part 2yerinNo ratings yet

- 9700 BIOLOGY: MARK SCHEME For The October/November 2015 SeriesDocument11 pages9700 BIOLOGY: MARK SCHEME For The October/November 2015 SeriesNerminNo ratings yet

- Experiment #4 Title: Testing of Reinforcing Steel BarsDocument9 pagesExperiment #4 Title: Testing of Reinforcing Steel BarsAnne Kristel Dela RosaNo ratings yet

- Astm d1298Document4 pagesAstm d1298Febrian IsharyadiNo ratings yet

- Aluminium vs. Upvc - Doc (An Intro of Reality)Document2 pagesAluminium vs. Upvc - Doc (An Intro of Reality)Harsh BhaiNo ratings yet

- Materials Booklet Gabbro PrecisionDocument16 pagesMaterials Booklet Gabbro Precisionphilip vargheseNo ratings yet

- A) Linear Sweep VoltammetryDocument2 pagesA) Linear Sweep VoltammetryGIRMA SELALE GELETANo ratings yet

- Synthesis of Zinc ChlorideDocument2 pagesSynthesis of Zinc ChlorideSyed KhidirNo ratings yet

- T1 1 E Automotive 072Document15 pagesT1 1 E Automotive 072Marian OstrowskiNo ratings yet

- Hydraulic Oil Iso VG 46Document1 pageHydraulic Oil Iso VG 46KarthikeyanNo ratings yet