Professional Documents

Culture Documents

Thermanit Nimo C 24 (ERNiCrMo3) GTAW

Uploaded by

Niranjan Fakirchand YadavOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermanit Nimo C 24 (ERNiCrMo3) GTAW

Uploaded by

Niranjan Fakirchand YadavCopyright:

Available Formats

Thermanit Nimo C 24

TIG rods, high-alloyed, stainless

Classifications

EN ISO 18274 AWS A5.14 Mat. No.

S Ni 6059 (NiCr23Mo16) ERNiCrMo-13 2.4607

Characteristics and typical fields of application

Nickel based alloy. High corrosion resistance in reducing and, above all, in oxidzing environments.

For joining and surfacing with matching and similar alloys and cast alloys.

For welding the cladded side of plates of matching and similar alloys.

Base materials

TÜV-certified parent metals

1.4565 – Alloy 24 – UNS S34565 – X2CrNiMnMoNbN25-18-5-4

2.4602 – Alloy C-22 – UNS N06022 – NiCr21Mo14W

2.4605 – Alloy 59 – UNS N06059 – NiCr23Mo16Al

2.4610 – Alloy C-4 – UNS N06455 – NiMo16Cr16Ti

2.4819 – Alloy C-276 – UNS N10276 – NiMo16Cr15W

Typical analysis of the TIG rods (wt.-%)

C Si Mn Cr Mo Ni Fe

wt-% 0.01 < 0.10 < 0.5 23.0 16.0 Bal. < 1.5

Structure: Austenite

Mechanical properties of all-weld metal

Heat- Yield strength Tensile strength Elongation Impact work

treatment R p0.2 Rm A (L 0 =5d 0 ) ISO-V KV J

MPa MPa % +20 °C

aw 450 700 35 120

Operating data

Polarity: Shielding gas: Marks: ø (mm) L mm

DC ( – ) (EN ISO 14175) I1 Ni 6059 / ERNiCrMo-13 1.6 1000

2.0 1000

2.4 1000

3.2 1000

Welding instruction

Materials Preheating Postweld heat treatment

Matching and similar metals None None. Otherwise solution annealing:

1120 °C (2048 °F)/water

Approvals

TÜV (06462), GL (NiCr23Mo16), CE

All information provided is based upon careful investigation and intensive research. 05/2014

However, we do not assume any liability for correctness and information is subject to change without notice. www.voestalpine.com/welding

You might also like

- A505-12 Standard Specification For Steel, Sheet and Strip, Alloy, Hot-Rolled and Cold-Rolled, General Requirements ForDocument13 pagesA505-12 Standard Specification For Steel, Sheet and Strip, Alloy, Hot-Rolled and Cold-Rolled, General Requirements Fortjt4779No ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- GHKLDocument36 pagesGHKLOvidiu GavrilasNo ratings yet

- Remington PowerHammer Model 476 ManualDocument20 pagesRemington PowerHammer Model 476 ManualStephen Girard50% (2)

- Howtocalculategatearearequireforhpdcdiecastingpart 191027122127Document17 pagesHowtocalculategatearearequireforhpdcdiecastingpart 191027122127Abdelkader Loussaief100% (3)

- General3 AnswerDocument4 pagesGeneral3 AnswerAnonymous 8bH7sXpcEHNo ratings yet

- DSI Underground Systems Catalogue US 01Document118 pagesDSI Underground Systems Catalogue US 01Sriram NambiNo ratings yet

- Technical Calculation and Estimator's Man Hour Manual - Marko Bulic's 20033Document3 pagesTechnical Calculation and Estimator's Man Hour Manual - Marko Bulic's 20033Rezza Aditya0% (1)

- 15Y603 Metal joining ASSIGNMENT PRESENTATIONDocument15 pages15Y603 Metal joining ASSIGNMENT PRESENTATIONLakshmi Kruthiga0% (1)

- Thermanit GE-316L PDFDocument1 pageThermanit GE-316L PDFsmpoe017No ratings yet

- ER316L Ss en 1Document1 pageER316L Ss en 1brayanNo ratings yet

- 11042016000000T - Thermanit 22 - 09 - Tig RodDocument1 page11042016000000T - Thermanit 22 - 09 - Tig RodKonrad MatuszkiewiczNo ratings yet

- T - Thermanit 25 - 09 CuT - de - en - 5Document1 pageT - Thermanit 25 - 09 CuT - de - en - 5NAVANEETH NAVANINo ratings yet

- 308H Tig Welding Wire for Stainless SteelsDocument1 page308H Tig Welding Wire for Stainless SteelsFilipe CordeiroNo ratings yet

- T - Thermanit ATS 4 - Ss - en - 5Document1 pageT - Thermanit ATS 4 - Ss - en - 5rusf123No ratings yet

- Thermanit Nicro 82: TIG Rods, Nickel-AlloyDocument2 pagesThermanit Nicro 82: TIG Rods, Nickel-AlloyMaximiliano Ezequiel LopezNo ratings yet

- Thermanit 22/09 Solid Wire For Joining Duplex Stainless SteelsDocument1 pageThermanit 22/09 Solid Wire For Joining Duplex Stainless SteelsbrayanNo ratings yet

- L1_34428_en__B_Boehler-AWS-ER309L_ss_en_1Document1 pageL1_34428_en__B_Boehler-AWS-ER309L_ss_en_1Edgar HornusNo ratings yet

- 19042016000000T - Union I CrMo 910 - Tig RodDocument1 page19042016000000T - Union I CrMo 910 - Tig RodRushita SolankiNo ratings yet

- Boehler EAS 4 M-IG - Tig RodDocument1 pageBoehler EAS 4 M-IG - Tig RodbrayanNo ratings yet

- item11-LNT NiCroMo 59.23Document1 pageitem11-LNT NiCroMo 59.23VVan TanNo ratings yet

- Boehler HL 75 T-MCDocument1 pageBoehler HL 75 T-MCBruno SantosNo ratings yet

- Thermanit NiMo 100 low-alloyed stick electrodeDocument1 pageThermanit NiMo 100 low-alloyed stick electrodebrayanNo ratings yet

- Join & Repair High-Carbon Steels with NiCr HLSDocument1 pageJoin & Repair High-Carbon Steels with NiCr HLSwalter091011No ratings yet

- Bohler AWS ER308LDocument1 pageBohler AWS ER308LbrayanNo ratings yet

- Bohler Aws Er308lDocument1 pageBohler Aws Er308lJuan ShunaNo ratings yet

- UTP A 6222 MoDocument1 pageUTP A 6222 MoKara WhiteNo ratings yet

- Alloy 318Document2 pagesAlloy 318Branko FerenčakNo ratings yet

- Consumables To Match Cast & Wrought Alloy 800: Astm Bs en & DinDocument3 pagesConsumables To Match Cast & Wrought Alloy 800: Astm Bs en & Dinankitniranjan1390No ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- item8-LNT NiCro60.20Document1 pageitem8-LNT NiCro60.20VVan TanNo ratings yet

- Böhler Cat 409 Cb-Ig: Classifi CationsDocument1 pageBöhler Cat 409 Cb-Ig: Classifi CationsBranko FerenčakNo ratings yet

- Boehler CN 13 4-MC - SWDocument1 pageBoehler CN 13 4-MC - SWSebastian AcostaNo ratings yet

- High-alloyed TIG rod for heat resistant steelsDocument1 pageHigh-alloyed TIG rod for heat resistant steelsSerhii MishchenkoNo ratings yet

- BÖHLER Alform® 960-IG: Standard Designations EN ISO 16834-A AWS A5.28Document1 pageBÖHLER Alform® 960-IG: Standard Designations EN ISO 16834-A AWS A5.28JORAMNo ratings yet

- T Thermanit GEW 316L-17 Se en 5Document1 pageT Thermanit GEW 316L-17 Se en 5PubcrawlNo ratings yet

- 29102015000000B - Boehler CN 22 9 N-IG - TRDocument1 page29102015000000B - Boehler CN 22 9 N-IG - TRAnibal QuezadaNo ratings yet

- SISTEMA DI GESTIONE CERTIFICATO DA ICIMDocument1 pageSISTEMA DI GESTIONE CERTIFICATO DA ICIMRhyan EdwinNo ratings yet

- NiCrFe alloy welding electrodeDocument1 pageNiCrFe alloy welding electrodeRoberto_PrrNo ratings yet

- Material properties comparison reportDocument4 pagesMaterial properties comparison reportMuhammad DiazNo ratings yet

- Boehler CN 13 4-MC FDocument1 pageBoehler CN 13 4-MC FFilipe CordeiroNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- B - Boehler NiMo 1-IG - de - en - 5Document1 pageB - Boehler NiMo 1-IG - de - en - 5cristian popescuNo ratings yet

- OK_Tigrod_316LDocument1 pageOK_Tigrod_316Lbevara santhoshkumarNo ratings yet

- Stainarc 309L-17 (Rev 1)Document1 pageStainarc 309L-17 (Rev 1)LIM hoon boonNo ratings yet

- European Steel and Alloy Grades: 20nicrmo2-2 (1.6523)Document2 pagesEuropean Steel and Alloy Grades: 20nicrmo2-2 (1.6523)farshid KarpasandNo ratings yet

- Bohler Dcms T-MCDocument1 pageBohler Dcms T-MCFlaviu-Andrei AstalisNo ratings yet

- B_Boehler-CN-25-9-CuT-IG_trDocument1 pageB_Boehler-CN-25-9-CuT-IG_tralbertorebellatoNo ratings yet

- Sdfs Dfsfs v4t Eg Gyt4fdg e Erert34 GG Efr DFGDGDFG DFG G Sfsfs Gsdfgsdfsdfsdgds FSF STGVDocument1 pageSdfs Dfsfs v4t Eg Gyt4fdg e Erert34 GG Efr DFGDGDFG DFG G Sfsfs Gsdfgsdfsdfsdgds FSF STGVsadiqNo ratings yet

- UNION ER90S-B3 TIG rodDocument1 pageUNION ER90S-B3 TIG rodbrayanNo ratings yet

- Böhler NiCu1 Ti T-FD wire for corrosion resistant steel weldingDocument1 pageBöhler NiCu1 Ti T-FD wire for corrosion resistant steel weldingbrayanNo ratings yet

- Ceweld - 316H TigDocument1 pageCeweld - 316H TigFilipe CordeiroNo ratings yet

- Ceweld - 316h TigDocument1 pageCeweld - 316h TigFilipe CordeiroNo ratings yet

- Tetra S 316L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra S 316L-G: Technical Data Sheet Cored Welding WirePeter TvardzíkNo ratings yet

- Avesta Tig 316-SiDocument1 pageAvesta Tig 316-SiMarco Andres Gonzalez SaavedraNo ratings yet

- Cw008a Cu-Of Version1Document1 pageCw008a Cu-Of Version1Gaka RtaNo ratings yet

- Nickel-base filler metals GTAW rodsDocument1 pageNickel-base filler metals GTAW rodsc131508No ratings yet

- European Steel and Alloy Grades: Nicr22Fe18Mo (Dubl) (2.4665)Document2 pagesEuropean Steel and Alloy Grades: Nicr22Fe18Mo (Dubl) (2.4665)farshid KarpasandNo ratings yet

- L1 8515 en Diamondspark Ni1 MC CU05120F 3241743 ENDocument1 pageL1 8515 en Diamondspark Ni1 MC CU05120F 3241743 ENbrayanNo ratings yet

- Thermanit 25-35 R-Tigrod High Alloyed-W Z 25 35 - 21072020030650Document1 pageThermanit 25-35 R-Tigrod High Alloyed-W Z 25 35 - 21072020030650Nima SharifiNo ratings yet

- en - GB FactSheet - Main 01Document1 pageen - GB FactSheet - Main 01ronaldb322No ratings yet

- High Strength Steel Welding Wire for Cr-Ni-Mo AlloysDocument1 pageHigh Strength Steel Welding Wire for Cr-Ni-Mo Alloysrusf123No ratings yet

- TNI2TIDocument2 pagesTNI2TIKureiNo ratings yet

- Böhler Eas 2 PW-FDDocument1 pageBöhler Eas 2 PW-FDHAKANNo ratings yet

- Inconel Electrode for Fabrication and RepairDocument1 pageInconel Electrode for Fabrication and RepairjmsmechNo ratings yet

- Ferrous Metals ModuleDocument1,090 pagesFerrous Metals ModulesreeramNo ratings yet

- Landscape Architects Pocket Book (Siobhan Vernon Rachel Tennant Nicola Garmory)Document369 pagesLandscape Architects Pocket Book (Siobhan Vernon Rachel Tennant Nicola Garmory)Gayathri RavichandranNo ratings yet

- Tim Morgan - The Village of FairfenDocument1 pageTim Morgan - The Village of FairfenThomasNo ratings yet

- BS en 10223-5 (1998)Document13 pagesBS en 10223-5 (1998)Олег СоловьевNo ratings yet

- General Information Hoa Phát Has 11 Company in Ownership of Hoa Phat Is Almost Absolute, Averaging Over 99%Document3 pagesGeneral Information Hoa Phát Has 11 Company in Ownership of Hoa Phat Is Almost Absolute, Averaging Over 99%Trung NguyenNo ratings yet

- Koleksi Senjata Ing Genshin ImpactDocument55 pagesKoleksi Senjata Ing Genshin ImpactM Ilham AfandiNo ratings yet

- Permintaan Material Data BaruDocument30 pagesPermintaan Material Data BaruM Iqbal AdmanNo ratings yet

- LCP Bridging™Document2 pagesLCP Bridging™Lokey EnNiNo ratings yet

- Reg 250, Reg 251, Reg 252, Reg 253Document2 pagesReg 250, Reg 251, Reg 252, Reg 253Deepak RajanNo ratings yet

- Standar AISI-1035 SteelDocument2 pagesStandar AISI-1035 SteelNurulImanPristiadiNo ratings yet

- PVC Coated Conduit SubmittalDocument1 pagePVC Coated Conduit Submittaladan valdovinosNo ratings yet

- Equivalent Material 1Document2 pagesEquivalent Material 1Dodi SuhendraNo ratings yet

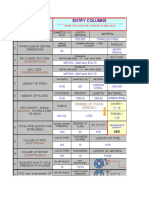

- Entry Columns: DescriptionDocument21 pagesEntry Columns: Descriptiondilema_pgNo ratings yet

- The Eiffel Tower: Tour Eiffel, Nickname La Dame de Fer, The Iron Lady) Is An IronDocument9 pagesThe Eiffel Tower: Tour Eiffel, Nickname La Dame de Fer, The Iron Lady) Is An IronВолодимир СмолаNo ratings yet

- Roca contact proposal for Balai Bomba Kuala TahanDocument7 pagesRoca contact proposal for Balai Bomba Kuala TahanAffendi Hj AriffinNo ratings yet

- MD Elements 04Document100 pagesMD Elements 04Prince JairoNo ratings yet

- Roofing With Corrugated Galvanized Steel SheetDocument7 pagesRoofing With Corrugated Galvanized Steel SheetDayalNo ratings yet

- Engineering Workshop Sheet Metal Tray Marking and Cutting GuideDocument46 pagesEngineering Workshop Sheet Metal Tray Marking and Cutting GuidebashairNo ratings yet

- Crosby - Hoist RingDocument3 pagesCrosby - Hoist RingYADAGIRI REDDYNo ratings yet

- 5 - Cast Iron and Tool SteelsDocument25 pages5 - Cast Iron and Tool Steelsbarry nancooNo ratings yet

- Ibong Tiririt (MDSP 7)Document51 pagesIbong Tiririt (MDSP 7)Gerald EspanillaNo ratings yet

- Cable To Metal Surface, Cathodic - CAHAAW3Document2 pagesCable To Metal Surface, Cathodic - CAHAAW3lhanx2No ratings yet