Professional Documents

Culture Documents

OK Tigrod NiCrMo-3 (OK 19.84) - EN

Uploaded by

baladiroyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OK Tigrod NiCrMo-3 (OK 19.84) - EN

Uploaded by

baladiroyaCopyright:

Available Formats

TIG RODS (GTAW)

NICKEL-BASED ALLOYS

OK Tigrod NiCrMo-3

Bare corrosion and heat-resisting Ni-Cr-Mo rods for welding of high alloyed heat-resisting and corrosion resisting

materials, 9%Ni-steels and similar steels with high notch toughness at low temperatures. Also for joining of dissimilar

metals of the types mentioned. The weld metal has very good mechanical properties at high and low temperatures.

Good resistance to pitting and stress corrosion.

Classifications Wire Electrode: SFA/AWS A5.14:ERNiCrMo-3, EN ISO 18274:S Ni 6625

Approvals: DNV For NV1.5Ni up to NV9Ni, VdTÜV 12460

Approvals are based on factory location. Please contact ESAB for more information.

Alloy Type: Alloyed nickel (Ni + 22 % Cr + 9 % Mo - 3.5 % Nb)

Typical Tensile Properties

Condition Yield Strength Tensile Strength Elongation

As welded 550 MPa 780 MPa 40 %

Typical Charpy V-Notch Properties

Condition Testing Temperature Impact Value

As welded -196 °C 100 J

Typical Wire Composition %

C Mn Si Ni Cr Mo Fe Nb+Ta

0.02 0.04 0.06 64.8 22.7 8.6 0.3 3.5

OK Tigrod NiCrMo-4

OK Tigrod NiCrMo-4 is a corrosion and heat resistant, nickel-chromium rod for TIG welding of high alloyed steel,

heat resistant steel, corrosion resistant steel, 9Ni steels and similar steels with high notch toughness at low temperatures.

Good resistance to stress corrosion.

Classifications Wire Electrode: SFA/AWS A5.14:ERNiCrMo-4, EN ISO 18274:S Ni 6276 (NiCr15Mo16Fe6W4)

Typical Wire Composition %

C Mn Si Ni Cr Mo Fe W

0.01 0.45 0.05 Bal. 15.5 16.1 5.8 3.5

esab.com 3-53

You might also like

- Pages de Esab Hanbook-3Document1 pagePages de Esab Hanbook-3Amin ThabetNo ratings yet

- OK Tigrod 12.62Document1 pageOK Tigrod 12.62ASHIK TNo ratings yet

- OK Tigrod 316LDocument1 pageOK Tigrod 316Lbevara santhoshkumarNo ratings yet

- MIP Bohler Welding Austria 364Document1 pageMIP Bohler Welding Austria 364c131508No ratings yet

- Exaton Ni59 (GMAW) : Nikkel Alapú Ötvözetek Fogyóelektródás Huzalok, És Pálcák (Gmaw/Gtaw)Document1 pageExaton Ni59 (GMAW) : Nikkel Alapú Ötvözetek Fogyóelektródás Huzalok, És Pálcák (Gmaw/Gtaw)kismikloshun55No ratings yet

- NL - NL FactSheet - Main 01Document1 pageNL - NL FactSheet - Main 01ronaldb322No ratings yet

- Barrettetig Catalogo Oerlikon 35035Document44 pagesBarrettetig Catalogo Oerlikon 35035mp303No ratings yet

- UTP For OffshoreDocument16 pagesUTP For Offshorekamals55No ratings yet

- OK Tigrod 12.61: Tig Rods (Gtaw) Mild Steel RodsDocument1 pageOK Tigrod 12.61: Tig Rods (Gtaw) Mild Steel RodsHusam AhmedNo ratings yet

- Doclib 4677 Autocraft 316lsi DatasheetDocument1 pageDoclib 4677 Autocraft 316lsi Datasheetamir moniriNo ratings yet

- Exaton Ni59 (GTAW) : Nikkel Alapú Ötvözetek Fogyóelektródás Huzalok, És Pálcák (Gmaw/Gtaw)Document1 pageExaton Ni59 (GTAW) : Nikkel Alapú Ötvözetek Fogyóelektródás Huzalok, És Pálcák (Gmaw/Gtaw)kismikloshun55No ratings yet

- Böhler Nibas 625 PW-FD: DescriptionDocument1 pageBöhler Nibas 625 PW-FD: DescriptionBBalopesabbNo ratings yet

- European Steel and Alloy Grades: G32Nicrmo8-5-4 (1.6570)Document2 pagesEuropean Steel and Alloy Grades: G32Nicrmo8-5-4 (1.6570)farshid KarpasandNo ratings yet

- Altigweld 5556Document1 pageAltigweld 5556Suresh DNo ratings yet

- Welding TrainingDocument87 pagesWelding Trainingeswar100% (1)

- OK Tigrod 19.49Document1 pageOK Tigrod 19.49Ali VarmazyarNo ratings yet

- Ficha Técnica CarborodDocument1 pageFicha Técnica CarborodAndres NuñezNo ratings yet

- Acero MadridDocument46 pagesAcero MadridviyfNo ratings yet

- ASTM Welding Tips A410 To A643Document20 pagesASTM Welding Tips A410 To A643MARIO HUAMANNo ratings yet

- Böhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantDocument1 pageBöhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantSerhii MishchenkoNo ratings yet

- Material InspectionDocument39 pagesMaterial Inspectionkrisman f siregarNo ratings yet

- Low & Medium Alloyed Rods Solid Wires Carborod Mo Oerlikon en TN130101Document1 pageLow & Medium Alloyed Rods Solid Wires Carborod Mo Oerlikon en TN130101Rus DanutNo ratings yet

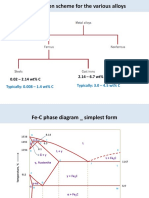

- Classification Scheme For The Various Alloys: 0.02 - 2.14 WT% C 2.14 - 6.7 WT% CDocument19 pagesClassification Scheme For The Various Alloys: 0.02 - 2.14 WT% C 2.14 - 6.7 WT% CAlex HalesNo ratings yet

- NI-182 Victory ENICRFE-3 Electrode Data SheetDocument1 pageNI-182 Victory ENICRFE-3 Electrode Data SheetgianNo ratings yet

- Basinox 318: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageBasinox 318: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaNo ratings yet

- Carbocast 1 - eDocument1 pageCarbocast 1 - eali torabiNo ratings yet

- 05042016000000A - Avesta 904L - CeDocument1 page05042016000000A - Avesta 904L - CeJorge Uribe RochaNo ratings yet

- Boehler CN 13 4-MC FDocument1 pageBoehler CN 13 4-MC FFilipe CordeiroNo ratings yet

- Section 12 - Welding Consumables - Low Alloy SteelsDocument68 pagesSection 12 - Welding Consumables - Low Alloy SteelsFriedrich SchwimNo ratings yet

- Catalogue Revolloy Welding ConsumablesDocument30 pagesCatalogue Revolloy Welding ConsumablesAdi SutardiNo ratings yet

- en - GB FactSheet - Main 01Document1 pageen - GB FactSheet - Main 01ronaldb322No ratings yet

- Metal Alloys Application and ProcessingDocument57 pagesMetal Alloys Application and ProcessingtbmariNo ratings yet

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- Welding Processes & InspectionDocument52 pagesWelding Processes & InspectionKaung Htet Cho100% (1)

- Aluminum A380Document4 pagesAluminum A380syuepiNo ratings yet

- Met 05 Nonferrous WeldingDocument16 pagesMet 05 Nonferrous WeldingRaghu vamshiNo ratings yet

- OK Tigrod 316LDocument1 pageOK Tigrod 316Laxisd47No ratings yet

- Thermanit Nimo C 24 (ERNiCrMo3) GTAWDocument1 pageThermanit Nimo C 24 (ERNiCrMo3) GTAWNiranjan Fakirchand YadavNo ratings yet

- 3dprint AM 625: Material TypeDocument1 page3dprint AM 625: Material TypeKara WhiteNo ratings yet

- CERTILAS EN Edition2023 315Document1 pageCERTILAS EN Edition2023 315Alireza KhodabandehNo ratings yet

- Microstructures of Iron-Carbon Alloys: Fine Pearlite 3000XDocument9 pagesMicrostructures of Iron-Carbon Alloys: Fine Pearlite 3000XVaishu 07No ratings yet

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- 11-14%Cr IIW Document - Part 2 PDFDocument21 pages11-14%Cr IIW Document - Part 2 PDFManuel CarreñoNo ratings yet

- OK Tigrod NiCu-7Document1 pageOK Tigrod NiCu-7Ali VarmazyarNo ratings yet

- Welding Methods & Technology.: V.R.Ekbote Ces (Insp), Ril (PG)Document52 pagesWelding Methods & Technology.: V.R.Ekbote Ces (Insp), Ril (PG)cyNo ratings yet

- European Steel and Alloy Grades: 20nicrmo2-2 (1.6523)Document2 pagesEuropean Steel and Alloy Grades: 20nicrmo2-2 (1.6523)farshid KarpasandNo ratings yet

- Carbofil Crmo9 (G Crmo9)Document1 pageCarbofil Crmo9 (G Crmo9)brunizzaNo ratings yet

- Kobel NicroDocument1 pageKobel NicroBHARAT KNo ratings yet

- UTP 3545 NB PDFDocument1 pageUTP 3545 NB PDFhqnscNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10149-2Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10149-2farshid KarpasandNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10277-2 EN 10162Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10277-2 EN 10162farshid KarpasandNo ratings yet

- Carbofil 3nimocr Oerlikon en TN130181Document1 pageCarbofil 3nimocr Oerlikon en TN130181rusf123No ratings yet

- Arc WeldingDocument29 pagesArc WeldinguditNo ratings yet

- UTP 6222 MoDocument1 pageUTP 6222 ModantegimenezNo ratings yet

- AK9ch - АК9ч Aluminium Casting Alloys gost standardDocument2 pagesAK9ch - АК9ч Aluminium Casting Alloys gost standardVivek GoudNo ratings yet

- ASME F and P Number Definitions..Document9 pagesASME F and P Number Definitions..Sankar KrishnanNo ratings yet

- E 8018 B2Document1 pageE 8018 B2ElMacheteDelHuesoNo ratings yet

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363No ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20From EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20No ratings yet

- All Steel Unibody Valve: Bulletin No. 84-00C For Use As Gauge ValveDocument2 pagesAll Steel Unibody Valve: Bulletin No. 84-00C For Use As Gauge ValvebaladiroyaNo ratings yet

- Astm A487 4 (A)Document1 pageAstm A487 4 (A)baladiroyaNo ratings yet

- AG Gauge Valves AEDocument51 pagesAG Gauge Valves AEbaladiroyaNo ratings yet

- DIN 797 Fund BoltDocument1 pageDIN 797 Fund BoltbaladiroyaNo ratings yet

- DIN 3570 Strap (U-Bolt)Document2 pagesDIN 3570 Strap (U-Bolt)baladiroyaNo ratings yet

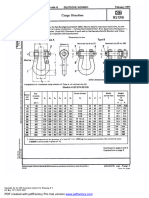

- DIN 82016 Cargo ShacklesDocument3 pagesDIN 82016 Cargo ShacklesbaladiroyaNo ratings yet

- DIN 1662 HexBoltFlngDocument11 pagesDIN 1662 HexBoltFlngbaladiroyaNo ratings yet

- XPPHCDocument14 pagesXPPHCbaladiroyaNo ratings yet

- ISO TR 10358-1993 ScanDocument54 pagesISO TR 10358-1993 ScanbaladiroyaNo ratings yet

- DIN 609 Hex Fit BoltDocument10 pagesDIN 609 Hex Fit BoltbaladiroyaNo ratings yet

- DIN 7157 - Fit TolerancesDocument5 pagesDIN 7157 - Fit TolerancesbaladiroyaNo ratings yet

- Weld-Overlay - Cladding - Solutions - 2017 - ENDocument36 pagesWeld-Overlay - Cladding - Solutions - 2017 - ENbaladiroyaNo ratings yet

- Chokes GH2Document12 pagesChokes GH2baladiroyaNo ratings yet

- Groove DimensionsDocument2 pagesGroove DimensionsbaladiroyaNo ratings yet

- DIN 3771-1 (O'ring)Document27 pagesDIN 3771-1 (O'ring)baladiroyaNo ratings yet

- Astm E165-NdtDocument20 pagesAstm E165-NdtbaladiroyaNo ratings yet

- Table-1-ASME-B36.10M-2015-pip ScheduleDocument18 pagesTable-1-ASME-B36.10M-2015-pip SchedulebaladiroyaNo ratings yet

- Catalog Spring Energized SealsDocument13 pagesCatalog Spring Energized SealsbaladiroyaNo ratings yet

- Terastandard - Bsi Bs Iso 5597 267Document26 pagesTerastandard - Bsi Bs Iso 5597 267baladiroyaNo ratings yet

- As568 Standard Size o RingsDocument6 pagesAs568 Standard Size o RingsbaladiroyaNo ratings yet

- Augusto 2012Document13 pagesAugusto 2012baladiroyaNo ratings yet

- Catalogo Valvole TrunnionDocument16 pagesCatalogo Valvole TrunnionbaladiroyaNo ratings yet

- 2016 1-CheckboxDocument1 page2016 1-CheckboxbaladiroyaNo ratings yet