Professional Documents

Culture Documents

Continuously Variable Transmission (CVT) : Engine Testing and Instrumentation

Uploaded by

Fábio Bresciani ValverdeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Continuously Variable Transmission (CVT) : Engine Testing and Instrumentation

Uploaded by

Fábio Bresciani ValverdeCopyright:

Available Formats

Continuously variable transmission (CVT)

Engine Testing and Instrumentation 1

CVT

• CVT allows for the operation at the lowest possible speed and highest possible

load, partially avoiding the low efficiency region of the engine map.

• A continuously variable transmission (CVT) transfers power through a range

of speed/torque ratios from engine input to output, continuously without

interruption

• Contrast with either manual or conventional automatic transmissions that use

discrete ratios and normally disengage when changing ratio

• The CVT category includes infinitely variable transmissions (IVT) that give a

zero output speed within the operating range

Engine Testing and Instrumentation 2

Simple Friction Drive

Low Output Speed

(Low gear selected)

Constant input speed

Engine driven

input shaft drives

disc with friction Output shaft

surface connects to wheels

Engine Testing and Instrumentation 3

Friction Drive: High Speed

High output speed

(top gear, high ratio)

Constant input speed

Movement between

ratios takes place

without steps and

gives a continuous

change of ratio

Engine Testing and Instrumentation 4

Friction Drive: Zero Output

Geared Neutral with input rotating gives IVT

Zero output speed when

disc moved to

Constant input speed line up with centre of

rotation of input shaft

Reverse output speed

possible if output disc

moved below input

centre line

Engine Testing and Instrumentation 5

Vehicle Layout

b - Input disc

c - Output disc

Engine Testing and Instrumentation 6

Disc Friction Drive CVT

FIRST CAR: Tenting,

France 1891

GWK of Maidenhead

1910-1931, two seat cyclecars

Engine Testing and Instrumentation 7

CVT Categories & Targets

• Successful CVT will resolve the compromises in reliability, durability,

efficiency, and controllability with low cost

• Implementation of commercially produced CVTs transmit drive through

friction

• Variable pulleys with flexible belt or chain

– sliding friction

• Traction drives with rotating surfaces

– rolling contact, shear friction

Engine Testing and Instrumentation 8

Variable Pulley

• Variable pulley systems are based on the common v-belt pulley fixed ratio

layout with power transfer through a flexible element connecting between two

pairs of pulley sheaves.

• Flexible element may be a belt or chain

• Sheave movement usually controlled by hydraulic or electrical means

Engine Testing and Instrumentation 9

Variable Pulley Drive

Constant input speed

Small radius of

flexible belt

Low Ratio

Large radius of

flexible belt results

in slower speed

Engine Testing and Instrumentation 10

Mid Ratio: Speed 1:1

FIXED

SIDE

FIXED

SIDE

Engine Testing and Instrumentation 11

DAF Variomatic Rubber V-Belts

• Introduction in 1958

• Over 1 million DAF and Volvo

cars produced in 20 year

period

• Shown is DAF 55 drive used

with 1100 cc Renault engine

from 1968

Engine Testing and Instrumentation 12

Metal V-Belt Construction

Introduced by Van Doorne’s Transmissie in 1987

Engine Testing and Instrumentation 13

Metal V-Belt Transmission

• Production from 1987-

2000 about 3 million

• In the last 4 years about

4.5 million produced

• Example shown is a ZF

–CFT23 with torque

converter input

Engine Testing and Instrumentation 14

Vehicle applications for

Bosch-VDT Belt in 2004

Engine Testing and Instrumentation 15

LuK/PIV-Reimers chain Audi Multitronic

Engine Testing and Instrumentation 16

Traction Drives

• Many physical alternative layouts that give the mechanical geometry changes

suitable to give a CVT.

• “Traction” requires transmission through a fluid film under elasto-

hydrodynamic lubrication (EHL) conditions.

Engine Testing and Instrumentation 17

The Toroidal Drive Concept

Engine Testing and Instrumentation 18

Half Toroid Construction

Engine Testing and Instrumentation 19

Jatco/ NSK Half Toroid

• Fitted as production item in Nissan Gloria and Cedric from 1999, home market

only

• 3 L petrol engine

• Input rating 210 kW, and 390 Nm

• CVT ratio range 4.4:1

• Torque converter as a starting device

• Model upgrade in 2004

Engine Testing and Instrumentation 20

Full Toroid

Hunt Patent

Hayes Variator

Engine Testing and Instrumentation 21

Full Toroid Transmission

Austin 16

1932

Engine Testing and Instrumentation 22

Torotrak IVT Layout

Torotrak use a

“split path” layout

with an epicyclic

gear on the output

side. This gives a

geared neutral and

hence infinite ratio

and also a reverse,

hence is an IVT.

Engine Testing and Instrumentation 23

Torotrak IVT In-line Transmission

Engine Testing and Instrumentation 24

CVT Benefits

• No gear shift

• Continuous transmission of torque

• Control of engine speed independently of vehicle speed

• Ability to operate engine at peak power over wider range of vehicle speeds

• Ability to operate at most fuel efficient point for required output power

Engine Testing and Instrumentation 25

Control Objectives

• Good fuel economy

• Good driver feel – driveability

• Easy driving as an automatic

• Comfort and smoothness for passengers

• Performance – acceleration capability

• Electronic control enables these

Engine Testing and Instrumentation 26

Williams (FW 15C) Van Doorne LG1

• Power: 600 kW

• Input speed: 15 000 rev/min

• Input torque: 600 Nm

• Ratio range: 2.5:1

• Pulley centres: 160 mm

• FIA ban: 1993

Engine Testing and Instrumentation 27

Acceleration Comparisons: Porsche Boxster

Engine speed [rev/min]

Vehicle speed [km/h]

Manual

Tiptronic

CVTip in D

Engine Testing and Instrumentation 28

CVT Disadvantages

• Mechanical efficiency of variator

• Parasitic efficiency of transmission system and controller

• Compromise between fuel economy and torque margin to achieve driveability

(avoid elastic band feel)

Engine Testing and Instrumentation 29

CVT Efficiency

• All CVT variators have losses due to the power transfer which appears as a

speed or slip loss across the variator

• CVTs are hydraulically controlled and the pump takes power as in a

conventional automatic transmission

• Efficiency is more variable for CVT than geared discrete ratio systems

Engine Testing and Instrumentation 30

Engine map

Good fuel economy

WOT- wide open throttle

(maximum torque line)

IOL – ideal operating line,

gives best economy for

CVT operation

Wide ratio range needed to

achieve ideal engine operation

Engine Testing and Instrumentation 31

Fuel Consumption Figures

Comparison of fuel consumption figures for CVT relative to equivalent automatics shows a

5-10% improvement for 4 to 5 ratio variants.

However, the table shows comparison for equivalent manual transmission vehicles over the

European Drive Cycle (+ve in red is worse)

Urban 12% 22.7% 10.5% 8.1% 10.4% 6.1% -4.8% -5.0%

Extra- 13.8% 12.1% 10.0% -3.9% 0.0 4.8% -1.3% 5.0%

urban

Combined 13.2% 16.4% 8.3% 1.7% 4.9% 4.9% -2.3% 0.0

Engine Testing and Instrumentation 32

Driveability Compromise

• Driveability describes the longitudinal dynamic behaviour of a vehicle in

response to driver inputs, in a comprehensive range of driving situations, and

the related driver subjective perception of that behaviour

• Less torque available immediately with a CVT than with a gear transmission

Engine Testing and Instrumentation 33

Driveability Compromise

Good fuel economy

WOT- wide open throttle

(maximum torque line)

IOL – ideal operating line,

Torque gives best economy for

margin CVT operation

Engine Testing and Instrumentation 34

Solutions for Improved Driveability

• Torque boosters

– flywheel

– integrated electrical machine (motor/generator)

• Control – modified calibration

• Match the CVT with the most appropriate engine

• Modify engine characteristics to those of the transmission by design and/or

control

Engine Testing and Instrumentation 35

Zero Inertia Concept

Engine Testing and Instrumentation 36

CVT Mild Hybrid Architecture

DC/DC

Converter

+ -

EM Inverter

Control Current Battery

CVT or IVT

Differential

Throttle,

Pressure,

Fuel,

Clutch

Spark Pressure

Electric

Driver ECU Machine TCU

Demand

Motor/Generator

CAN Bus

Engine Testing and Instrumentation 37

Engine Matching

• Diesel engines have higher torque and lower speed range than petrol

• Modify engine systems to develop higher torque at low speeds – interest in this

as engine downsizing for conventional transmissions too

• Use of lean burn techniques to operate engine more efficiently at higher speeds

– experimental studies have shown both improvement in steady fuel

consumption and transient response

• Development of homogeneous charge compression ignition (HCCI) and

controlled auto ignition (CAI) is also appropriate for CVTs

Engine Testing and Instrumentation 38

Market Share in 2004

Region Manual Automatic CVT

Europe 84% 14% 2%

N. America 9% 90% 1%

Asia 40% 52% 8%

Japan 20% 65% 15%

Engine Testing and Instrumentation 39

Market Predictions

• ZF – increase from 2% share of sales in 2002 to 4.4% in 2012

• ZF – CVT will occupy 10 % of market for automatic transmissions in 10 years

• Jatco – increase from 8% share of sales in 2003 to 45% by 2010

• CSM Worldwide – increase in N. America to 3% by 2009

Engine Testing and Instrumentation 40

Comments

• CVT has a bright future

• Market share increasing

• Research and development still required

– Improve efficiency

– Torque booster

– Engine integration

– System control

• CVT driveability is key to customer acceptance, particularly in

Europe

• CVTs share some driveability characteristics with hybrid vehicles

• Control and calibration with new concepts and an integrated

approach to total powertrain calibration can give driveability

solutions

Engine Testing and Instrumentation 41

You might also like

- Continuously Variable Transmission: Presentation by Sixth Semester (2012) Under The Guidance ofDocument30 pagesContinuously Variable Transmission: Presentation by Sixth Semester (2012) Under The Guidance ofAbhishek GhoshNo ratings yet

- Step Less TransmissionDocument5 pagesStep Less TransmissionAsif ali H.Dhalayat100% (1)

- Continuously Variable CVTDocument17 pagesContinuously Variable CVTsnwagh0% (1)

- Hybrid Transaxles and TransmissionsDocument109 pagesHybrid Transaxles and Transmissionscossatot100% (8)

- Continuously Variable Transmission: LD College of EngeneeringDocument16 pagesContinuously Variable Transmission: LD College of Engeneeringvishnu13141No ratings yet

- Module 5Document154 pagesModule 5Jarin TNo ratings yet

- A Seminar ON Retrofitting of A Hydraulic Continously Variable Transmission To A Rear Wheel Drive AutomobileDocument23 pagesA Seminar ON Retrofitting of A Hydraulic Continously Variable Transmission To A Rear Wheel Drive AutomobileLungmuaNa RanteNo ratings yet

- Koyo's Approach To Continuously Variable Transmissions (CVT) For AutomobilesDocument0 pagesKoyo's Approach To Continuously Variable Transmissions (CVT) For AutomobilesSaurabh MeenaNo ratings yet

- Transmission System of HevDocument11 pagesTransmission System of HevNukul MahajanNo ratings yet

- CVTDocument18 pagesCVTRon Farm100% (1)

- Mech CVTDocument15 pagesMech CVTsachin guptaNo ratings yet

- Mech CVTDocument15 pagesMech CVTOmar AhmedNo ratings yet

- L60F L350FDocument6 pagesL60F L350FBabu SubramaniamNo ratings yet

- Continuously Variable Transmission - CVTDocument18 pagesContinuously Variable Transmission - CVTPratheep Srinivas100% (3)

- Development of The Next-Generation Half-Toroidal CVT With Geared Neutral and Power-Split Systems For 450 N-M EnginesDocument9 pagesDevelopment of The Next-Generation Half-Toroidal CVT With Geared Neutral and Power-Split Systems For 450 N-M EnginesAbhishekJadhav100% (1)

- Analysis, Design and Application of Continuously Variable Transmission (CVT)Document7 pagesAnalysis, Design and Application of Continuously Variable Transmission (CVT)ChiragNo ratings yet

- Continuously Variable Transmission: LD College of EngeneeringDocument16 pagesContinuously Variable Transmission: LD College of Engeneeringswapnil pandeNo ratings yet

- Automotive EngineeringDocument62 pagesAutomotive EngineeringMD JuniorNo ratings yet

- Seminar ReportDocument29 pagesSeminar ReportMoa JamirNo ratings yet

- I 0 VtecDocument13 pagesI 0 VtecGuru GowdaNo ratings yet

- 9 C.Brockbank TorotrakDocument10 pages9 C.Brockbank TorotrakMohamed Ez El DinNo ratings yet

- Semi Automatic Transmission ReportDocument52 pagesSemi Automatic Transmission ReportPranav EkhandeNo ratings yet

- Control Sysems in Automobiles1 TTLM1Document18 pagesControl Sysems in Automobiles1 TTLM1tselothaiilemariamNo ratings yet

- Automatic TrasnmissionDocument57 pagesAutomatic Trasnmissionmohamed A.abdeltwabNo ratings yet

- Series IV MKII Rigid Hauler Tractors Broch18281215 EnglishWebDocument20 pagesSeries IV MKII Rigid Hauler Tractors Broch18281215 EnglishWebAlejandro QuiñonezNo ratings yet

- Auto 5sem ATEDocument97 pagesAuto 5sem ATEatulsemiloNo ratings yet

- Technical Report 1Document15 pagesTechnical Report 1Santosh Raj0% (2)

- Mivec: MIVEC (Mitsubishi Innovative Valve Timing Electronic Control System)Document5 pagesMivec: MIVEC (Mitsubishi Innovative Valve Timing Electronic Control System)alibababujanglapokNo ratings yet

- Multiair EngineDocument19 pagesMultiair EngineMahaManthra0% (2)

- Project Review 2 18-04-2019Document25 pagesProject Review 2 18-04-2019Narra Vivek168No ratings yet

- Continuously Variable Transmissions (CVT) :: The Holy Grail of Automotive Transmission Systems?Document26 pagesContinuously Variable Transmissions (CVT) :: The Holy Grail of Automotive Transmission Systems?Mohit RajNo ratings yet

- Guia de Especificaciones InglesDocument56 pagesGuia de Especificaciones Inglesjalvarez_385073No ratings yet

- Continuously Variable Transmissions2Document29 pagesContinuously Variable Transmissions2Faris AbdullahNo ratings yet

- Cat 793FDocument4 pagesCat 793Fyoungk225812No ratings yet

- Gear BoxDocument91 pagesGear BoxLohithaNo ratings yet

- Lift Trucks: Fluid Power in MotionDocument6 pagesLift Trucks: Fluid Power in Motionharshal161987No ratings yet

- Continuous Variable TransmissionDocument18 pagesContinuous Variable TransmissionMamesh100% (1)

- Control and Operating Behavior of Continuously Variable Chain TransmissionsDocument32 pagesControl and Operating Behavior of Continuously Variable Chain Transmissionsravikiran1955No ratings yet

- Attn 0205 AjDocument35 pagesAttn 0205 AjFelix TecateNo ratings yet

- Safari - Feb 4, 2024 at 11:36 PM 2Document1 pageSafari - Feb 4, 2024 at 11:36 PM 2syansyncNo ratings yet

- Voith Coupling EngDocument12 pagesVoith Coupling Engrikumohan100% (1)

- Multitronic 01JDocument100 pagesMultitronic 01JAlex DosofteiNo ratings yet

- Chris BaylissDocument24 pagesChris BaylissBorislav GeorgievNo ratings yet

- DocumentDocument36 pagesDocumentAnonymous iIuKiy00PNo ratings yet

- SSP 228 - Part1 - Variable Automatic Gearbox Multitronic R 01JDocument12 pagesSSP 228 - Part1 - Variable Automatic Gearbox Multitronic R 01JfibelenitoNo ratings yet

- Audi 01J Multitronic CVTDocument99 pagesAudi 01J Multitronic CVTenes_br95% (21)

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- Designing and Tuning High-Performance Fuel Injection SystemsFrom EverandDesigning and Tuning High-Performance Fuel Injection SystemsRating: 3.5 out of 5 stars3.5/5 (7)

- AC Electric Motors Control: Advanced Design Techniques and ApplicationsFrom EverandAC Electric Motors Control: Advanced Design Techniques and ApplicationsFouad GiriNo ratings yet

- Swap LS Engines into Chevelles & GM A-Bodies: 1964-1972From EverandSwap LS Engines into Chevelles & GM A-Bodies: 1964-1972Rating: 4.5 out of 5 stars4.5/5 (3)

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Rating: 1 out of 5 stars1/5 (3)

- VW Transporter T4 Workshop Manual Diesel 2000-2004From EverandVW Transporter T4 Workshop Manual Diesel 2000-2004Rating: 5 out of 5 stars5/5 (5)

- Power Electronics and Electric Drives for Traction ApplicationsFrom EverandPower Electronics and Electric Drives for Traction ApplicationsNo ratings yet

- 10 Chapter1Document23 pages10 Chapter1ankit407No ratings yet

- 8 Mission MappingDocument21 pages8 Mission Mappingankit407No ratings yet

- 1 Hybrid Evolutionary Algorithms: Methodologies, Architectures, and ReviewsDocument17 pages1 Hybrid Evolutionary Algorithms: Methodologies, Architectures, and Reviewsankit407No ratings yet

- FP5003 V06-LF1Document21 pagesFP5003 V06-LF1ankit407No ratings yet

- Iterated Graph Cuts For Image SegmentationDocument10 pagesIterated Graph Cuts For Image Segmentationankit407No ratings yet

- Topic: Choppers: Class: 5 Sem. (EE)Document89 pagesTopic: Choppers: Class: 5 Sem. (EE)ankit407No ratings yet

- Simple Fuzzy PID Controllers For DC-DC Converters: K.-W. Seo and Han Ho ChoiDocument6 pagesSimple Fuzzy PID Controllers For DC-DC Converters: K.-W. Seo and Han Ho Choiankit407No ratings yet

- Application of Fuzzy Logic To Control The DC-DC ConverterDocument6 pagesApplication of Fuzzy Logic To Control The DC-DC Converterankit407No ratings yet

- Design of Pid Controller For PLC: J. Paulusová, L. KörösiDocument8 pagesDesign of Pid Controller For PLC: J. Paulusová, L. Körösiankit407No ratings yet

- PMDC Motor Chopper Control by MATLABDocument10 pagesPMDC Motor Chopper Control by MATLABAllwayLLGNo ratings yet

- Reduction in Harmonics in Marble Industry: Prakash Sundaram, Shimi S.L., Dr.S.ChatterjiDocument7 pagesReduction in Harmonics in Marble Industry: Prakash Sundaram, Shimi S.L., Dr.S.Chatterjiankit407No ratings yet

- Artificial Neurons, Neural Networks and ArchitecturesDocument48 pagesArtificial Neurons, Neural Networks and Architecturesankit407No ratings yet

- A Current-Source Active Power Filter With A New DC Filter StructureDocument8 pagesA Current-Source Active Power Filter With A New DC Filter Structureankit407No ratings yet

- Power Quality Improvement Using A Fuzzy Logic Control of A Series Active FilterDocument9 pagesPower Quality Improvement Using A Fuzzy Logic Control of A Series Active Filterankit407No ratings yet

- CRS Report For Congress: Nuclear Power Plants: Vulnerability To Terrorist AttackDocument6 pagesCRS Report For Congress: Nuclear Power Plants: Vulnerability To Terrorist Attackankit407No ratings yet

- Yamaha Xjr1300 Parts CatalogueDocument75 pagesYamaha Xjr1300 Parts Cataloguesumeemtariq100% (1)

- Discovery Series II Workshop Manual - 3rd EditionDocument1,647 pagesDiscovery Series II Workshop Manual - 3rd EditionCraig Arthur80% (5)

- Vješanje ElementiDocument180 pagesVješanje Elementi27mdraganNo ratings yet

- Adly ATV-300SU (I) 9261-2006 ServiceDocument95 pagesAdly ATV-300SU (I) 9261-2006 ServicestuderkNo ratings yet

- Tpi 008 de enDocument116 pagesTpi 008 de enRoberto Perez100% (1)

- Johnson Evinrude 1 PDFDocument50 pagesJohnson Evinrude 1 PDFJPNo ratings yet

- Catalogo Partes rtr-160 2012-2014 0 PDFDocument81 pagesCatalogo Partes rtr-160 2012-2014 0 PDFJOSE FRANCONo ratings yet

- Drive Shaft / Propeller Shaft: PreparationDocument4 pagesDrive Shaft / Propeller Shaft: PreparationRodrigo RubioNo ratings yet

- JOST Parts CatalogDocument44 pagesJOST Parts CatalogeloyabnerNo ratings yet

- 1200 STX-R ServicemanualDocument289 pages1200 STX-R Servicemanualgoblinmarine100% (2)

- Product Bulletin 27Document23 pagesProduct Bulletin 27RANAIVOARIMANANANo ratings yet

- (Prosukusi) Setiyadi CaptainkuDocument9 pages(Prosukusi) Setiyadi Captainkujrock_juliusNo ratings yet

- Swk1200 ManualDocument40 pagesSwk1200 ManualbgarvosNo ratings yet

- Nissan TD42 Service ManualDocument7 pagesNissan TD42 Service ManualFerran Alfonso52% (25)

- Piaggio NRG Power DT (EN)Document171 pagesPiaggio NRG Power DT (EN)ManuallesNo ratings yet

- Iso 6157-1-1988Document12 pagesIso 6157-1-1988Djaffar SalahouiNo ratings yet

- Exec 162fDocument91 pagesExec 162fJohnny cespedesNo ratings yet

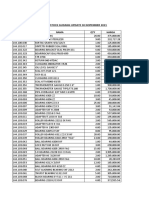

- Stock Gudang Update 30 Nopember 2021Document32 pagesStock Gudang Update 30 Nopember 2021Alif AlifNo ratings yet

- Winterhalter PT 500Document31 pagesWinterhalter PT 500Ahmed SofaNo ratings yet

- As 3635-1990 Unified (ISO Inch) Screw Threads Associated Gauges and Gauging PracticeDocument8 pagesAs 3635-1990 Unified (ISO Inch) Screw Threads Associated Gauges and Gauging PracticeSAI Global - APACNo ratings yet

- CATALOGO LT 151 HUSI2010 - AAaa - 96041020600Document19 pagesCATALOGO LT 151 HUSI2010 - AAaa - 96041020600Jhonatan ComakNo ratings yet

- Akışkanlar Mek.Document6 pagesAkışkanlar Mek.Sai PranayNo ratings yet

- Nec AmpacitiesDocument2 pagesNec AmpacitiesmicrajacutNo ratings yet

- Ducato Databook SpecificationsDocument1 pageDucato Databook Specificationsearl34No ratings yet

- Inspection For Useability: Truck, Medium, Mc2 - Unimog 4X4 - All TypesDocument8 pagesInspection For Useability: Truck, Medium, Mc2 - Unimog 4X4 - All TypesmichaelNo ratings yet

- Worthington Manual PDFDocument71 pagesWorthington Manual PDFsubrataNo ratings yet

- JCB Isuzu 4jj1Document599 pagesJCB Isuzu 4jj1hallex80% (5)

- Aft-Catalog s3 SecDocument10 pagesAft-Catalog s3 SecwemersonsrNo ratings yet

- YALE - Wire Rope Electric HoistsDocument44 pagesYALE - Wire Rope Electric HoistsJogi Oscar SinagaNo ratings yet

- Piston Ring Types: Compression RingsDocument2 pagesPiston Ring Types: Compression RingsSergei KurpishNo ratings yet