Professional Documents

Culture Documents

Approval Document ASSET DOC LOC 333

Uploaded by

aOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Approval Document ASSET DOC LOC 333

Uploaded by

aCopyright:

Available Formats

CWS 1007

SI

AS F I

CL

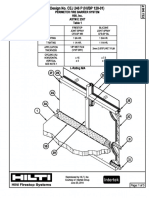

System No. CW-S-1007

ED

Classified by

Underwriters Laboratories, Inc.

to ASTM E2307

2C

3B

2A 1

3A

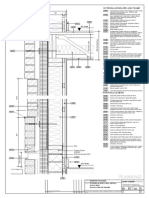

concrete. Floor assembly to be supported at perimeter edges by spandrel beams having a Restrained or Unrestrained Beam Rating of 2 hr.

1600-2400 kg/m3) structural concrete spandrel panels. Wall may also consist of min 4 in. (102 mm) thick steel-reinforced lightweight or normal

weight concrete tilt-up panels with a min 72 in. (1829 mm) vertical separation between window openings. Panels provided with steel dead load

anchors welded to steel reinforcing bars embedded in the concrete for attachment to the steel columns and spandrel beams. Panels also

provided with steel lateral anchors or braces. The dead load anchors which are located in the linear gap between the concrete floor slab and

the spandrel panel or tilt-up panel are to be spaced max 72 in. (1829 mm) OC. The top of the dead load anchor is to be recessed min 1/2 in.

(13 mm) from top surface of floor.

above top of floor.

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

May 30, 2014

Page: 1 of 2

CWS 1007

System No. CW-S-1007

shall incorporate the following construction features:

and the edge of the concrete floor slab. Safing material to be cut to a min 4-1/2 in. (114 mm) width and stacked to a thickness which is at least

25 percent greater than the width of the linear gap between the concrete spandrel or tilt-up panel and the edge of the concrete floor slab. The

safing material is compressed and inserted cut-edge-first into the linear gap such that its top surface is flush with the top surface of the floor

assembly. A max of one tightly-butted seam is permitted between dead load anchors. An additional min 1/2 in. (13 mm) thick piece of mineral

wool batt safing material to be installed to cover top surface of each dead load anchor.

material and lapping min 1 in. onto the top surface of the concrete floor and onto the concrete spandrel panel or tilt-up panel. When CFS-SP

SIL is used, min wet (and dry) thickness of spray is 2 mm.

CFS-SP WB Firestop Joint Spray

*Bearing the UL Classification Mark

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

May 30, 2014

Page: 2 of 2

You might also like

- National Structural Code of PH 7th EdDocument1,008 pagesNational Structural Code of PH 7th EdRustom Renz Nuñez63% (8)

- Spreader Bar Calculation PDFDocument2 pagesSpreader Bar Calculation PDFFernando Humberto100% (2)

- Brick Masonry DesignDocument34 pagesBrick Masonry DesignWan Rids50% (2)

- Post Tensioning SystemDocument13 pagesPost Tensioning SystemAbhijit JadhavNo ratings yet

- Masonry Support Systems and LintelsDocument36 pagesMasonry Support Systems and LintelsAchilleas21No ratings yet

- Penstocks: Figure: Typical Installaion of PenstocksDocument6 pagesPenstocks: Figure: Typical Installaion of PenstocksTharindu Nuwan JayakodyNo ratings yet

- Construction of Post Tension Slab System.: MaterialsDocument13 pagesConstruction of Post Tension Slab System.: Materialsdindo lauron100% (1)

- Simplified Version of Eurocode 3 For Usual BuildingsDocument236 pagesSimplified Version of Eurocode 3 For Usual BuildingsPanagiotis Xanthos0% (1)

- Ncma Tek: Segmental Retaining Wall Units TEK 2-4BDocument4 pagesNcma Tek: Segmental Retaining Wall Units TEK 2-4BJorge Luis Arevalo LopezNo ratings yet

- Deepwater Landing String DesignDocument6 pagesDeepwater Landing String Designrdos14No ratings yet

- Installation Guidance For Precast Concrete Headwalls PD81Document7 pagesInstallation Guidance For Precast Concrete Headwalls PD81sosi2020No ratings yet

- Method Statement of Utracon Post TensioningDocument7 pagesMethod Statement of Utracon Post TensioningIrshad Khan0% (1)

- Recess in Brick DetailDocument1 pageRecess in Brick DetailMartinNo ratings yet

- Approval Document ASSET DOC LOC 523Document1 pageApproval Document ASSET DOC LOC 523aNo ratings yet

- Rule of ThumbDocument2 pagesRule of ThumbJerome Balanoyos100% (5)

- The Behaviour of Profiled Steel Sheet/concrete Composite SlabsDocument275 pagesThe Behaviour of Profiled Steel Sheet/concrete Composite Slabsshak543100% (1)

- Analysis and Design of High Rise Building FramesDocument3 pagesAnalysis and Design of High Rise Building FramesRanvier Singh100% (1)

- InterviewDocument22 pagesInterviewsivacwi100% (1)

- Construction of FacadesDocument5 pagesConstruction of FacadesGunjan UttamchandaniNo ratings yet

- DIN en 1015-11-Flexural StrengthDocument3 pagesDIN en 1015-11-Flexural Strengthkhun_kaeNo ratings yet

- Alternative Wall TechnologiesDocument9 pagesAlternative Wall TechnologiesSACHIDANANDA SNo ratings yet

- Civil: Emerald Plaza-Detailed EstimateDocument5 pagesCivil: Emerald Plaza-Detailed EstimateVarun MattooNo ratings yet

- DocumentDocument9 pagesDocumentea_she3415No ratings yet

- Basic Info TK-U.B.I Sleeves3Document17 pagesBasic Info TK-U.B.I Sleeves3Saradhi MedapureddyNo ratings yet

- Approval Document ASSET DOC LOC 328Document2 pagesApproval Document ASSET DOC LOC 328aNo ratings yet

- System No. CW-D-2025: Linear Opening Width - 8 In. Max Class II Movement Capabilities - 5% Vertical Shear (See Item 3)Document2 pagesSystem No. CW-D-2025: Linear Opening Width - 8 In. Max Class II Movement Capabilities - 5% Vertical Shear (See Item 3)aNo ratings yet

- Approval Document ASSET DOC LOC 340Document2 pagesApproval Document ASSET DOC LOC 340aNo ratings yet

- System WJ 2256Document1 pageSystem WJ 2256Manoj SamNo ratings yet

- Ficha Técnica - ArmourJoint PDFDocument2 pagesFicha Técnica - ArmourJoint PDFDiego BarretoNo ratings yet

- Pressure Cells Types, Working Principle and ApplicationsDocument20 pagesPressure Cells Types, Working Principle and ApplicationsEncardio RiteNo ratings yet

- System PDF Files - 1. UL and cUL Systems - cwd1033Document3 pagesSystem PDF Files - 1. UL and cUL Systems - cwd1033Emanuel Almeida PastlNo ratings yet

- Fire Stop Design 673Document4 pagesFire Stop Design 673raviNo ratings yet

- Ruukki 41338 Instructiuni de Montaj Placarea Fatadei Peste PanouriDocument12 pagesRuukki 41338 Instructiuni de Montaj Placarea Fatadei Peste PanouriGhenoiu PaulNo ratings yet

- Approval Document ASSET DOC LOC 145Document2 pagesApproval Document ASSET DOC LOC 145Amir IqbalNo ratings yet

- ICC-ES Evaluation Report ESR-2218Document12 pagesICC-ES Evaluation Report ESR-2218Mark J LeingangNo ratings yet

- S-TR-CIVIL-MAS (Rev.0-2009)Document10 pagesS-TR-CIVIL-MAS (Rev.0-2009)Muhammad hussainNo ratings yet

- HWD0134Document2 pagesHWD0134Edwin Jalanoca LlaulliNo ratings yet

- Proposed Construction of Medical College, Rudrapur, Udhamsingh Nagar, Uttarakhand. Abstract of QuantityDocument1 pageProposed Construction of Medical College, Rudrapur, Udhamsingh Nagar, Uttarakhand. Abstract of QuantityNarayan BhosekarNo ratings yet

- Evaluation of Bond Strength Between Pavement LayersDocument31 pagesEvaluation of Bond Strength Between Pavement LayersKrishna Prakash NanduriNo ratings yet

- System PDF Files - 1. UL and cUL Systems - cws0002Document2 pagesSystem PDF Files - 1. UL and cUL Systems - cws0002Emanuel Almeida PastlNo ratings yet

- N Stress Floor SlabDocument4 pagesN Stress Floor SlabBen Sim NitroNo ratings yet

- MetalEdge SpecificationsDocument2 pagesMetalEdge SpecificationsDavid CuevaNo ratings yet

- Katalog CijeviDocument73 pagesKatalog CijeviTheLizardKingNo ratings yet

- Soil Mixing Wall - System PDFDocument12 pagesSoil Mixing Wall - System PDFclaudiotomasNo ratings yet

- Shear Behaviour of Ferrocement Plates: Ms. Madhuri N. Savale, Prof. P. M. AlandkarDocument5 pagesShear Behaviour of Ferrocement Plates: Ms. Madhuri N. Savale, Prof. P. M. Alandkarluvjoshi1989No ratings yet

- Masonry Su PDFDocument32 pagesMasonry Su PDFDanusha EgodawatteNo ratings yet

- Influence Height Lattice Work Contribution Shear Resistance Reinforced ConcretDocument10 pagesInfluence Height Lattice Work Contribution Shear Resistance Reinforced ConcretGuillermo AragonNo ratings yet

- On Brick Construction: Technical NotesDocument8 pagesOn Brick Construction: Technical NotesSharad SinghNo ratings yet

- Acoustic Plaster 2022.RAMDocument13 pagesAcoustic Plaster 2022.RAMArnoldo Schreiber JrNo ratings yet

- A Study On A Two-Way Post-Tensioned Concrete Waffle Slab - ScienceDirectDocument8 pagesA Study On A Two-Way Post-Tensioned Concrete Waffle Slab - ScienceDirectusman javedNo ratings yet

- Design Number 3MU/BPF 180-01: Perimeter Fire BarriersDocument2 pagesDesign Number 3MU/BPF 180-01: Perimeter Fire BarriersAbram SelimNo ratings yet

- XHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQDocument4 pagesXHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQMd. Atiqul IslamNo ratings yet

- CWD1004 - Curtain Wall Design - Firestopping - STIDocument2 pagesCWD1004 - Curtain Wall Design - Firestopping - STIMDNo ratings yet

- MS 01 107Document12 pagesMS 01 107Floyd AnthonyNo ratings yet

- 3 Installation - TpoDocument22 pages3 Installation - TpoDoni IrawanNo ratings yet

- Lab 4 ConstructionDocument16 pagesLab 4 Constructionkitsoobuseng17No ratings yet

- CH 1Document49 pagesCH 1Gurinder PalsinghNo ratings yet

- System No. HW-D-0403Document1 pageSystem No. HW-D-0403Daniel Soaloon SibaraniNo ratings yet

- Approval Document ASSET DOC LOC 336Document3 pagesApproval Document ASSET DOC LOC 336aNo ratings yet

- Proposed Construction of Medical College, Rudrapur, Udhamsingh Nagar, Uttarakhand. Abstract of QuantityDocument1 pageProposed Construction of Medical College, Rudrapur, Udhamsingh Nagar, Uttarakhand. Abstract of QuantityNarayan BhosekarNo ratings yet

- Is 400Document2 pagesIs 400ajazrajNo ratings yet

- Bostik Paneltack HM Dekton Tds en 2020Document5 pagesBostik Paneltack HM Dekton Tds en 2020Miguel ZuzaNo ratings yet

- Fire Stop InstallationDocument3 pagesFire Stop InstallationAristo OnanNo ratings yet

- 05 Titan Pieu InjectéDocument9 pages05 Titan Pieu Injectémichalakis483No ratings yet

- Mape ShieldDocument5 pagesMape ShieldEaswarakumar NNo ratings yet

- Rockwool Intumescent PillowsDocument3 pagesRockwool Intumescent PillowsBobana AdamovicNo ratings yet

- How Should Trench Section Be For HDPE Corrugated PipeDocument5 pagesHow Should Trench Section Be For HDPE Corrugated Pipelfpacheco100% (1)

- Approval Document ASSET DOC LOC 2179580Document4 pagesApproval Document ASSET DOC LOC 2179580aNo ratings yet

- Approval Document ASSET DOC LOC 518Document1 pageApproval Document ASSET DOC LOC 518aNo ratings yet

- Approval Document ASSET DOC LOC 524Document1 pageApproval Document ASSET DOC LOC 524aNo ratings yet

- Approval Document ASSET DOC LOC 537Document4 pagesApproval Document ASSET DOC LOC 537aNo ratings yet

- Approval Document ASSET DOC LOC 522Document1 pageApproval Document ASSET DOC LOC 522aNo ratings yet

- Approval Document ASSET DOC LOC 338Document3 pagesApproval Document ASSET DOC LOC 338aNo ratings yet

- Approval Document ASSET DOC LOC 319Document5 pagesApproval Document ASSET DOC LOC 319aNo ratings yet

- PstoDocument32 pagesPstoaNo ratings yet

- PtosDocument31 pagesPtosaNo ratings yet

- Stopping StuffDocument28 pagesStopping StuffaNo ratings yet

- Flame StopDocument31 pagesFlame StopaNo ratings yet

- Hot StopDocument30 pagesHot StopaNo ratings yet

- StoppingDocument45 pagesStoppingaNo ratings yet

- Types and Elements of Bridge DesignDocument49 pagesTypes and Elements of Bridge DesignPeter KpopLoversNo ratings yet

- Bridge Technical Note 2018 - 009 RC Panels For Reinforced Soil Structures Jan 2018Document1 pageBridge Technical Note 2018 - 009 RC Panels For Reinforced Soil Structures Jan 2018JunnoKaiserNo ratings yet

- Building Technology 5 (Waffle Slab or Grid Slab) PresentationDocument20 pagesBuilding Technology 5 (Waffle Slab or Grid Slab) PresentationJonica Mae JomadiaoNo ratings yet

- Kadaikkal InvoiceDocument12 pagesKadaikkal InvoiceCinema TheatreNo ratings yet

- CSI SAFE - Session 2: Structural Design InstituteDocument44 pagesCSI SAFE - Session 2: Structural Design InstituteOchini ChandrasenaNo ratings yet

- Amd1 - NA To SS EN 1992-1-1-2008Document5 pagesAmd1 - NA To SS EN 1992-1-1-2008chin_kbNo ratings yet

- 1-Reinforced Concrete Equations1Document5 pages1-Reinforced Concrete Equations1Mohamad DuhokiNo ratings yet

- Timber Portal Frames Vs TimberDocument8 pagesTimber Portal Frames Vs Timberferlya98angNo ratings yet

- Seismic Performance of Stairs in The Existing ReinDocument9 pagesSeismic Performance of Stairs in The Existing Reinl_pintoNo ratings yet

- Stage Construction e TabsDocument10 pagesStage Construction e TabsLim Wee BengNo ratings yet

- Brochures For Block MakingDocument3 pagesBrochures For Block MakingJefftzNo ratings yet

- 5574 2012 TranslatedDocument168 pages5574 2012 TranslatedVasileios ManginasNo ratings yet

- Unit 5 Part 1Document167 pagesUnit 5 Part 1Kaushal MehtaNo ratings yet

- Membina Dan Menyiapkan Sebuah Rumah Banglo Setingkat Di SI Perak 2Document4 pagesMembina Dan Menyiapkan Sebuah Rumah Banglo Setingkat Di SI Perak 2Mohd ShahrizanNo ratings yet

- Merchant-Rankine Approach For The Design of SteelDocument24 pagesMerchant-Rankine Approach For The Design of Steelel000011No ratings yet

- FLOORING - Installation ManualDocument28 pagesFLOORING - Installation ManualAlex GeronaNo ratings yet

- Design Catalogue: FOR Reconstruction of Earthquake Resistant HousesDocument191 pagesDesign Catalogue: FOR Reconstruction of Earthquake Resistant HousesNishan GajurelNo ratings yet

- Presentation Pavement Failures 1507355219 83810Document26 pagesPresentation Pavement Failures 1507355219 83810suraj shetNo ratings yet

- Borang Senarai KerosakanDocument81 pagesBorang Senarai Kerosakankellary liawNo ratings yet

- Buku Brochure Precast Concrete (A4) - Rev 08012016 - 2 PDFDocument40 pagesBuku Brochure Precast Concrete (A4) - Rev 08012016 - 2 PDFMuchtar Sufaat100% (1)