Professional Documents

Culture Documents

Approval Document ASSET DOC LOC 145

Uploaded by

Amir IqbalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Approval Document ASSET DOC LOC 145

Uploaded by

Amir IqbalCopyright:

Available Formats

S IFI

CAJ 2409

AS

CL

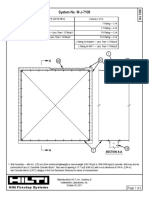

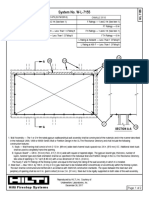

System No. C-AJ-2409

ED

F Rating - 3 Hr

Classified by

Underwriters Laboratories, Inc.

T Rating - 2 Hr

to UL 1479

A A

1 3B

3C

3A

3E

3F SECTION A-A

3D

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

April 26, 2017

Hilti Firestop Systems Page: 1 of 2

CAJ 2409

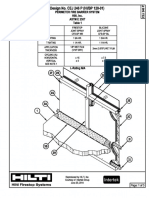

System No. C-AJ-2409

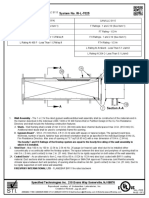

1. Floor or Wall Assembly — Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete. Wall

may also be constructed of any UL Classified Concrete Blocks*. Max diameter of opening is 14 in. (356 mm).

See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2. Flame Retardant Polypropylene Pipe (FRPP) — Nom 10 in. (254 mm) diameter (or smaller) flame retardant polypropylene pipe for use in closed

(process or supply) or vented (drain, waste or vent) piping systems installed concentrically or eccentrically within the firestop system. Annular

space between pie and periphery of opening to be min 0 in. (point contact) and max 3-3/8 in. (86 mm). Pipe to be rigidly supported on both sides

of floor or wall assembly.

3. Firestop System — The firestop system shall consist of the following:

A. Cover Plate — Min 0.046 in. (1.17 mm) (18 MSG) galv steel plate consisting of two pieces, overlapped min 1 in. (25 mm), cut to fit contour of

pipe with min 2 in. (51 mm) lap onto the bottom surface of floor assembly and both surfaces of wall assembly around perimeter of through

opening. Steel cover plate to be installed using 1/4 in. (6 mm) diam by 1-1/2 in. (38 mm) long expansion bolts in conjunction with steel nuts

and washers, spaced 6 in. (152 mm) O.C.

B. Fill, Void or Cavity Material* - Wrap Strip — Nom 3/16 in. (4.8 mm) thick by 1-3/4 in. (44 mm) wide intumescent wrap strip. Three layers of

wrap strip individually wrapped around pipe within opening where annular space exists and secured with tape. Wrap strip butted tightly against

top surface of cover plate in floor or both cover plates in walls.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — CP648-E- W45/1-3/4" Wrap Strip

C. Fill, Void or Cavity Materials* - Sealant — Min 4-1/2 in. (114 mm) thickness of fill material applied within the annulus, flush with both surfaces

of floor or wall.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — CP 620 Fire Foam

D. Fill, Void or Cavity Material* - Wrap Strip — Nom 3/16 in. (4.8 mm) thick by 1-3/4 in. (44 mm) wide intumescent wrap strip. Four layers of

wrap strip continuously wrapped around pipe with ends butted and held in place with tape. Two sets of four wrap strips butted tightly against

bottom surface of the floor or both surfaces of wall.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — CP648-E- W45/1-3/4" Wrap Strip

E. Steel Sleeve — Min 0.016 in. (0.4 mm) thick (28 MSG) galv steel sleeve having a min 1 in. lap along longitudinal seam. Length of sleeve to

be installed over wrap strip layers, extending 3-1/2 in. to 4 in. (89 to 102 mm) below bottom surface of floor or both surfaces of wall.

F. Steel Collar — Steel collar fabricated from coils of precut min 0.016 in. (0.4 mm) thick (No. 28 gauge) galv steel available from fill material

manufacturer. Collar shall be nom 1-3/4 in. (44 mm) deep with 1 in. (25 mm) wide by 2 in. (51 mm) long anchor tabs on 2 in. (51 mm) centers

for securement to the underside of floor or both surfaces of wall. In addition, collar contains retainer tabs 1/2 in. (13 mm) wide by 3/16 in. (4.8

mm) long, located opposite the anchor tabs. Lower collar shall be tightly wrapped over the sleeve and wrap strip, overlapping min 1 in. (25

mm) at seam and compressed with a min 0.028 in. (0.71 mm) thick stainless steel band located 1 in. (25 mm) above bottom of sleeve. The

retainer tabs are prebent 90 deg towards the pipe to retain the wrap strip. A second steel collar shall be tightly wrapped over the lower collar

and sleeve with a min 1 in. (25 mm) overlap at seam and compressed with a min 0.028 in. (0.71 mm) thick stainless steel band located 1 in.

(25 mm) below floor assembly or from both wall surfaces. Collar secured to bottom surface of the floor by means of min 1/4 in. (6 mm) diam by

1-1/4 (32 mm) in. long steel expansion bolts in conjunction with steel nuts and washers and to the steel cover plate with sheet metal screws in

conjunction with steel washers. Collar fastened to floor or wall at every other tab. Collars and steel sleeve secured together with steel sheet

metal screws spaced max 4 in. (102 mm) OC.

* Indicates such products shall bear the UL or cUL Certification Mark for jurisdictions employing the UL or cUL Certification (such as Canada),

respectively.

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

April 26, 2017

Hilti Firestop Systems Page: 2 of 2

You might also like

- Behaiviour of PE PipesDocument106 pagesBehaiviour of PE PipeskavoshyarpajouhanNo ratings yet

- FE Exam Chemical SpecsDocument3 pagesFE Exam Chemical SpecsChirack Singhtony SNo ratings yet

- 4360 GfaDocument3 pages4360 GfaEr Rajesh BuraNo ratings yet

- Guard Rails For Cargo ShipDocument8 pagesGuard Rails For Cargo ShipLyudmyla Bobina100% (1)

- U412 - 2 HourDocument4 pagesU412 - 2 Hourmaher58No ratings yet

- Fiberstrong Piping System Above Ground Installation ManualDocument32 pagesFiberstrong Piping System Above Ground Installation ManualIbrahim Habiba100% (1)

- Installation Manual - Galileo - EgyptDocument65 pagesInstallation Manual - Galileo - EgyptAhmed ElarabyNo ratings yet

- Basic Info TK-U.B.I Sleeves3Document17 pagesBasic Info TK-U.B.I Sleeves3Saradhi MedapureddyNo ratings yet

- For Learners: CSS 9 - Computer System ServicingDocument23 pagesFor Learners: CSS 9 - Computer System ServicingJevan Hope Baltazar100% (2)

- AE6106 ECU System Wiring Diagram - 01V180119Document1 pageAE6106 ECU System Wiring Diagram - 01V180119Store-BlackberryJhonnymarNo ratings yet

- R1150RT Elec DiagramDocument3 pagesR1150RT Elec DiagramJuan Garcia100% (2)

- Drill Pipe Design FundamentalsDocument7 pagesDrill Pipe Design FundamentalsNaser KhanNo ratings yet

- Strong Column Weak Beam Concept by Analy PDFDocument9 pagesStrong Column Weak Beam Concept by Analy PDFAmritanshu SrivastavaNo ratings yet

- CARTRIDGE FILTER TECHNICAL MANUALDocument30 pagesCARTRIDGE FILTER TECHNICAL MANUALabessiNo ratings yet

- Approval Document ASSET DOC LOC 716Document2 pagesApproval Document ASSET DOC LOC 716fazil yoosufNo ratings yet

- Approval Document ASSET DOC LOC 340Document2 pagesApproval Document ASSET DOC LOC 340aNo ratings yet

- Approval Document ASSET DOC LOC 709Document2 pagesApproval Document ASSET DOC LOC 709fazil yoosufNo ratings yet

- Firestop System for Concrete WallsDocument2 pagesFirestop System for Concrete WallshossamNo ratings yet

- System PDF Files - 1. UL and cUL Systems - cwd1033Document3 pagesSystem PDF Files - 1. UL and cUL Systems - cwd1033Emanuel Almeida PastlNo ratings yet

- System PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFEmanuel PastlNo ratings yet

- Caj 4107Document2 pagesCaj 4107Jorge OropezaNo ratings yet

- Firstop DesignDocument2 pagesFirstop DesignAmir IqbalNo ratings yet

- HILTI - Approval-document-ASSET-DOC-LOC-722Document1 pageHILTI - Approval-document-ASSET-DOC-LOC-722david messierNo ratings yet

- System PDF Files - 1. UL and cUL Systems - cws0002Document2 pagesSystem PDF Files - 1. UL and cUL Systems - cws0002Emanuel Almeida PastlNo ratings yet

- HWD0134Document2 pagesHWD0134Edwin Jalanoca LlaulliNo ratings yet

- CWD1004 - Curtain Wall Design - Firestopping - STIDocument2 pagesCWD1004 - Curtain Wall Design - Firestopping - STIMDNo ratings yet

- XHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQDocument4 pagesXHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQMd. Atiqul IslamNo ratings yet

- Flame StopDocument31 pagesFlame StopaNo ratings yet

- Sealant Fills Concrete Wall and Floor JointDocument1 pageSealant Fills Concrete Wall and Floor JointDaniel Soaloon SibaraniNo ratings yet

- Firestop Application Handbook (Macau) - Part-9 PDFDocument40 pagesFirestop Application Handbook (Macau) - Part-9 PDFSharoon S raoNo ratings yet

- Design Number 3MU/BPF 180-01: Perimeter Fire BarriersDocument2 pagesDesign Number 3MU/BPF 180-01: Perimeter Fire BarriersAbram SelimNo ratings yet

- Hilti Firestop DesignDocument3 pagesHilti Firestop DesignAristo OnanNo ratings yet

- CEJ114PDocument2 pagesCEJ114PGauri Calderon TrujilloNo ratings yet

- UntitledDocument2 pagesUntitledandy_ramblaNo ratings yet

- C-AJ-2834 - Through-Penetration Firestop Systems - UL Product IqDocument3 pagesC-AJ-2834 - Through-Penetration Firestop Systems - UL Product Iqchatgpt MohitNo ratings yet

- System No. CW-D-2025: Linear Opening Width - 8 In. Max Class II Movement Capabilities - 5% Vertical Shear (See Item 3)Document2 pagesSystem No. CW-D-2025: Linear Opening Width - 8 In. Max Class II Movement Capabilities - 5% Vertical Shear (See Item 3)aNo ratings yet

- Fire-Rated Wall Joint SystemDocument2 pagesFire-Rated Wall Joint SystemAnaMorenoNo ratings yet

- System PDF Files - 1. UL and cUL Systems - Caj2298 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - Caj2298 - DL PDFEmanuel PastlNo ratings yet

- Stopping StuffDocument28 pagesStopping StuffaNo ratings yet

- FS - Muro Cortina - ASSET-DOC-LOC-7765712Document3 pagesFS - Muro Cortina - ASSET-DOC-LOC-7765712S. Priscila Castillo V.No ratings yet

- Approval Document ASSET DOC LOC 299Document3 pagesApproval Document ASSET DOC LOC 299Anonymous a3K3WgNo ratings yet

- Approval Document ASSET DOC LOC 939Document2 pagesApproval Document ASSET DOC LOC 939andy_ramblaNo ratings yet

- Firestop CEJ 421 PDocument4 pagesFirestop CEJ 421 PErlanggaRizkiFauziNo ratings yet

- C Aj 2586 PDFDocument1 pageC Aj 2586 PDFEmanuel PastlNo ratings yet

- Model WS Specific Application Window Sprinklers Horizontal and Pendent Vertical Sidewall 5.6 K-Factor General DescriptionDocument8 pagesModel WS Specific Application Window Sprinklers Horizontal and Pendent Vertical Sidewall 5.6 K-Factor General DescriptionLe DucNo ratings yet

- UL HWD 0209Document2 pagesUL HWD 0209jlledwinestebanNo ratings yet

- ICC-ES Evaluation Report ESR-2218Document12 pagesICC-ES Evaluation Report ESR-2218Mark J LeingangNo ratings yet

- Hilti Firestop Submittal - Balamand UniversityDocument32 pagesHilti Firestop Submittal - Balamand UniversitybasbousrNo ratings yet

- Specification For Ducting of Ac PlantDocument7 pagesSpecification For Ducting of Ac PlantSubbarayan SaravanakumarNo ratings yet

- FlameOFF Fire Barrier PaintDocument2 pagesFlameOFF Fire Barrier PaintmurdicksNo ratings yet

- Rociador Cobertura Extendida k8.0Document6 pagesRociador Cobertura Extendida k8.0Anthony OneillNo ratings yet

- Fire Stop Design 673Document4 pagesFire Stop Design 673raviNo ratings yet

- TFP260 05 2017Document4 pagesTFP260 05 2017elraflesNo ratings yet

- F A 1017Document3 pagesF A 1017shama093No ratings yet

- Er-5414 (2001)Document7 pagesEr-5414 (2001)m0172No ratings yet

- System PDF Files - 1. UL and cUL Systems - wl7025 - DLDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - wl7025 - DLEmanuel PastlNo ratings yet

- HWD0194Document2 pagesHWD0194Ever Nina LauraNo ratings yet

- Horizontal Sidewall SprinklerDocument6 pagesHorizontal Sidewall SprinklerAhrian BenaNo ratings yet

- Metal Roof Systems in High-Wind Regions: Purpose: Metal Roofing OptionsDocument5 pagesMetal Roof Systems in High-Wind Regions: Purpose: Metal Roofing OptionsAlvaro MejiaNo ratings yet

- Ansi A13.1 1996Document13 pagesAnsi A13.1 1996Marco VeraNo ratings yet

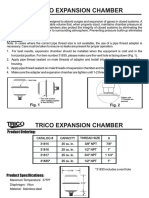

- Expansion ChamberDocument2 pagesExpansion ChamberGabriel DittamoNo ratings yet

- HDPE Pipe SpecificationsDocument2 pagesHDPE Pipe SpecificationsTonoy BanikNo ratings yet

- Series RFII - 5.6 K-Factor Royal Flush II Concealed Pendent Sprinklers Quick Response, Extended Coverage General DescriptionDocument4 pagesSeries RFII - 5.6 K-Factor Royal Flush II Concealed Pendent Sprinklers Quick Response, Extended Coverage General Descriptionbhima irabattiNo ratings yet

- ICC-ES Report Firestone TPO Roofing MaterialDocument16 pagesICC-ES Report Firestone TPO Roofing MaterialKoushik ThunuguntlaNo ratings yet

- 2.bien Phap Thi Cong Ong GioDocument19 pages2.bien Phap Thi Cong Ong GioQuang Do HoangNo ratings yet

- Total Wall NER-646Document13 pagesTotal Wall NER-646m0172No ratings yet

- Aluco21spec PDFDocument12 pagesAluco21spec PDFRené Galbraith BerraNo ratings yet

- C-AJ-2813 - Through-Penetration Firestop Systems - UL Product IqDocument3 pagesC-AJ-2813 - Through-Penetration Firestop Systems - UL Product Iqchatgpt MohitNo ratings yet

- Firstop DesignDocument2 pagesFirstop DesignAmir IqbalNo ratings yet

- Firestop System Details ASSET DOC LOC 2135392Document2 pagesFirestop System Details ASSET DOC LOC 2135392Amir IqbalNo ratings yet

- Approval Document ASSET DOC LOC 99Document1 pageApproval Document ASSET DOC LOC 99Amir IqbalNo ratings yet

- Approval Document ASSET DOC LOC 192Document1 pageApproval Document ASSET DOC LOC 192Amir IqbalNo ratings yet

- Tutorial 3: Upscaling Relative Permeability CurvesDocument6 pagesTutorial 3: Upscaling Relative Permeability CurvesCarlosEduardoAláMamaniNo ratings yet

- Capillary Viscometer Calculation NotesDocument2 pagesCapillary Viscometer Calculation NotesRichard NokyNo ratings yet

- Tare A 1Document2 pagesTare A 1Francisco Celestino Guajardo0% (1)

- Ese Reference BooksDocument3 pagesEse Reference BooksVivek SinghNo ratings yet

- 555 Audio Alarm ChartDocument4 pages555 Audio Alarm Chartnasty_beerNo ratings yet

- Orrcon National Product Brochure - Low ResDocument76 pagesOrrcon National Product Brochure - Low ResFederico.IoriNo ratings yet

- D100135X012Document12 pagesD100135X012Fernando GiadansNo ratings yet

- ALPEMA Normas (2000 - Rev. 1 e 2 de 2003 e 07)Document91 pagesALPEMA Normas (2000 - Rev. 1 e 2 de 2003 e 07)thiagoNo ratings yet

- Wps FormatDocument2 pagesWps FormatParminder SinghNo ratings yet

- Cylinder Head Gasket (Hatchback) - Installation (05 - 2013 - ) (Cylinder Head Assembly) - Yaris HeadDocument9 pagesCylinder Head Gasket (Hatchback) - Installation (05 - 2013 - ) (Cylinder Head Assembly) - Yaris HeadFran SanchezNo ratings yet

- Design of Gas Induction Reactors PDFDocument32 pagesDesign of Gas Induction Reactors PDFRavindra V. LakhapatiNo ratings yet

- Catálogo Binzel - Consumíveis (Spare Parts) 2008-2009Document158 pagesCatálogo Binzel - Consumíveis (Spare Parts) 2008-2009MauroDosSantosCostaNo ratings yet

- AMT 214 Reviewer (Oral)Document2 pagesAMT 214 Reviewer (Oral)Edjayde GodinezNo ratings yet

- METRIC THREAD TABLEDocument22 pagesMETRIC THREAD TABLEВлад ГреськоNo ratings yet

- Graphite India Specialty Division ProfileDocument13 pagesGraphite India Specialty Division ProfileMADDI MADHAV.No ratings yet

- Fatigue Wear: - Fatigue Is Attributed To MultipleDocument9 pagesFatigue Wear: - Fatigue Is Attributed To MultipleAnthropophobe NyctophileNo ratings yet

- MIG and TIG WeldingDocument2 pagesMIG and TIG WeldingshahzafNo ratings yet

- Lecture 11 - MDPE - Design of Support - Leg & Skirt SupportDocument47 pagesLecture 11 - MDPE - Design of Support - Leg & Skirt SupportPatel DhruvilNo ratings yet

- JKSSB JE Oct Papers PDFDocument230 pagesJKSSB JE Oct Papers PDFAnirudh KushwahaNo ratings yet

- Myvi ECUDocument4 pagesMyvi ECU张业No ratings yet