Professional Documents

Culture Documents

Design Sheet 4. Power Distribution & Tension Member Belt Conveyor

Uploaded by

mamatsulsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Sheet 4. Power Distribution & Tension Member Belt Conveyor

Uploaded by

mamatsulsCopyright:

Available Formats

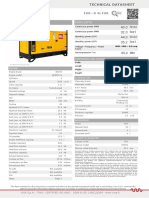

DESIGN SHEET PT. BANDO INDONESIA 4.

Power Distribution & Tension Member

BELT CONVEYOR 03-May-21 Power Distribution Tension Member

User PT. INDEXIM COALINDO Power to move empty belt (P1) 52.58 kW Effective Tension (FP) 8568.20 kg

Line No. OLC - 1A Power to move load on level (P2) 94.73 kW Slake Side Tension (F2) 4275.53 kg

Belt Type SUNCON (Ascent Conveyor) 111.69 kW (Ascent Conveyor) 563.79

mm mm mm Power to lift load (P3) Slope Tension (F3) kg 563.79 kg

Belt Spec 2000 x EP - 1250 4P x 10.0 x 4.0 x L Mtr (Descent Conveyor) kW (Descent Conveyor)

Grade FR - 300T Power to move tripper (P4) 0.00 kW (Carrier Idler) 3180.83

Sag Tension (F4) kg 3180.83 kg

Power to Pull Out Material (Ph) 0.00 kW (Return Idler) 956.25

1. Ilustration Line Conveyor Max Tension Fmax (1) 12843.74

kg 12843.74 kg

Total Axle Power Motor (Pt) 259.0 kW (Fmax) Fmax (2) 12312.82

Max Tension (Fmax. x Sf / B) 977.95 kg/cm

Tension belt (T x B) 195589.88 -

Belt tension calculation ( kg/cm ) 978 Safety factor 15

Belt Direction

H = 12.81 Belt tension design ( kg/cm ) 1250 Safety factor 19

5. Result & Miscellaneous Information

12°

224.47 L'= 58.51 30.18 Calc. Correction of Material Belt Conveyor Design Calc. Drive & Takeup Travel

Coefficient Sec. Area (K) 0.135 - Belt Strength 1250 kg/cm Min. Required Power Motor 310.8 kW

L = 313.16

Unit : mtr Coefficient Inclination (S) 0.93 - Carcass Type Polyester – Nylon Min. Gear Box Ratio (n:1) 20 -

2. Basic Information Cross sectional area (A) 0.413 m ² Code of Carcass (EP/P) 300 4 Mass of Counterweight (WT) 8.55 Ton

Operating Condition Material Constant Value Weight Material Loaded (Wm) 288.29 kg/mtr Cover Rubber FR - 300T

Belt Width (B) 2000 mm Name Coal Belt Width (B) 200 cm Correction Peak Capacity (Qt) 3622 TPH Thickness Top Cover 10.0 mm

Rated Capacity (Q) 3152 TPH Lump Size Max. 100 mm Belt Weight Standard (W1) 51 kg/mtr Impact Energy (Ef) 0 kgm Thickness Bottom Cover 4.0 mm

Peak Capacity (Qt)* 3200 TPH Characteristic Dry Weight without material (W) 160.00 kg/mtr Total Thickness Belt 20.80 mm

Speed Conveyor (v) 185 m/min Oil or Chemicals No Friction Factor of Idler (f) 0.03 - Mass of Belt 49.92 kg/mtr

Center to Center Distance (L1) 314.55 m Bulk Density ( ρ) 0.85 t/m ³ Corr. value C to Conveyor (Lo) 49.00 m Min. Total Length of Belt 633 m

Horisontal Length (L) 313.16 m Temperature AMB °C Fric.Coef. belt & mat. (u) 0.4 - Splicing Joint Hot Splice

Horisontal of Conveyor Slope (L') 58.51 m Surcharge Angle ( β) 10 ° Fric.Coef. belt & drive pulley ( μ) 0.35 - Min. Step Length (S) 300 mm

Vertical Height (H) 12.81 m Height of fall material (H) 0 m Drive factor (1 / ( eµq- 1 )) 0.499 - Min. Length of Splicing (L) 1525 mm

Inclination 12 °

Type Line Conveyor Concave Convex Recommendation Pulley Recommendation Roller Transition Distance & Convex Radius

Width of Hopper (b) 0 m Min. Dia Head Pulley ( Ø) 650 mm Min. Dia Carrier Roller (Ø) 159 mm Min. Transition Distance at

HOPPER

0 mm

Length of Hopper (c) 0 m Min. Dia Drive Pulley (Ø) 650 mm Min. Dia Return Roller (Ø) 159 mm First Through Roller

Height of Hopper (h) 0 m Min. Dia Tail Pulley (Ø) 553 mm Max. Pitch Junction Carrier Roller 42 mm Min. Radius Convex (Re) 47.80 m

1.80 Min. Dia Tension Pulley (Ø) 553 mm Min. Face Width Carrier Roller 3 x 760 mm Curve Convex Length (L) 9.94 m

3. Equipment Details Min. Dia Bend Pulley (Ø) 455 mm Min. Face Width Return Roller 1 x 2280 mm Determination Number of Idler

12 Pcs

Drive Unit Pulley Roller Min. Dia Snub Pulley (Ø) 455 mm Rev. per minute Roller 371 rpm at Convex Position (n)

Arc of contact ( q ) 180 ° Dia. Head Pulley ( Ø) 774 mm Pitch Carrier Roller (Lc) 1.5 m Min. Face Width of Pulley 2200 mm Determination Pitch of Idler at

0.9 m

Power to Move Tripper (P4) 0 kW Dia. Drive Pulley (Ø) 774 mm Pitch Return Roller (Lr) 3.0 m Rev. per minute Drive Pulley 76 rpm Convex Position (P)

Speed Motor (N) 1500 rpm Dia. Tail Pulley (Ø) 630 mm Pitch Impact Roller - m

Actual Power Motor - kW Dia. Tension Pulley (Ø) 630 mm Through angle Carrier Roller 35 ° 6. Belt Conveyor Construction

Drive Location Head Dia. Bend Pulley (Ø) 774 mm Dia. Carrier Roller (Ø) - mm Drawings Remarks

Type Drive Single Dia. Snub Pulley (Ø) 420 mm Dia. Return Roller (Ø) - mm

No. Description

Pulley Surface Lagging Face Width of Pulley - mm Face Width Carrier Roller - mm B

Condition of Pulley Dry Tension Pulley Location Intermediate Face Width Return Roller - mm 1 Top Cover = 10.0 mm

Type of Tension Pulley Horizontal GTU Pitch Junction Carrier Roller - mm 2 Canvas EP-1250 / 4 ply

Distance First through Roller - mm 3 Bottom Cover = 4.0 mm

T

First through angle Roller 0 ° B Belt Width = 2000 mm

T Thickness Belt Conveyor = ± 20.80mm

1 2 3

Input Data Calculation Input Data Calculation

Result Calculation Result Calculation

Page 1/2 Page 2/2

You might also like

- Isuzu FXZ26 360 TipperDocument2 pagesIsuzu FXZ26 360 TipperHugo RodriguezNo ratings yet

- Hitachi Lx15-7 Part3Document1 pageHitachi Lx15-7 Part3AlastarNo ratings yet

- EX40UDocument467 pagesEX40UALEJO100% (3)

- T40000 Series Powershift TransmissionDocument2 pagesT40000 Series Powershift TransmissionIamandei Elena50% (2)

- Instalasi Fire Gas Detector System (FGDS) Tanki Floating Roof Refinery Unit Ii DumaiDocument3 pagesInstalasi Fire Gas Detector System (FGDS) Tanki Floating Roof Refinery Unit Ii DumaiAji Abi-nya FathanNo ratings yet

- R134a HXWC Series Water Cooled Screw Flooded Chillers Cooling Capacity 200 To 740 Tons 703 To 2603 KW Products That Perform PDFDocument16 pagesR134a HXWC Series Water Cooled Screw Flooded Chillers Cooling Capacity 200 To 740 Tons 703 To 2603 KW Products That Perform PDFmohamad chaudhariNo ratings yet

- AlternatorsDocument6 pagesAlternatorssamuelompo100% (1)

- Allison M6610&S6610 Series PDFDocument2 pagesAllison M6610&S6610 Series PDFluisedonossaNo ratings yet

- AQUATOOL A Generalized Decision Support System For Water Resources Planning and Operational Management 1996 Journal of HydrologyDocument23 pagesAQUATOOL A Generalized Decision Support System For Water Resources Planning and Operational Management 1996 Journal of Hydrologyhoc_kinowNo ratings yet

- Conveyor CalculationDocument40 pagesConveyor CalculationAnonymous 5XvUbWynnNo ratings yet

- Ejemplo Ketle HTRIDocument6 pagesEjemplo Ketle HTRICami Vander MeyNo ratings yet

- Results PDFDocument1 pageResults PDFRajNo ratings yet

- Conveyor CalculationDocument46 pagesConveyor CalculationBuditama Chandranegara100% (1)

- Spesifikasi Dump Truck FAW TrucksDocument3 pagesSpesifikasi Dump Truck FAW TrucksZhang YixingNo ratings yet

- Dana TransmisionDocument2 pagesDana TransmisionMarcel BaqueNo ratings yet

- Specifications: (Stationary) (Mobile) (Hauling)Document2 pagesSpecifications: (Stationary) (Mobile) (Hauling)ЮрийNo ratings yet

- Pramac GBW45Document3 pagesPramac GBW45Simba WahyudiNo ratings yet

- Dynapac CC 122Document1 pageDynapac CC 122CDECOSSGNo ratings yet

- Foundation System For Compound WallDocument4 pagesFoundation System For Compound Wallsebafo3580No ratings yet

- 8600 Series Product Brochure 1Document2 pages8600 Series Product Brochure 1p8bn5drd9zNo ratings yet

- Heavy Equipment - Spek EX3600-5Document5 pagesHeavy Equipment - Spek EX3600-5David HalomoanNo ratings yet

- Fiche Moteur PubDocument2 pagesFiche Moteur PubandreNo ratings yet

- Pekerjaan CHF 5 Vol KW Dim (MM) II Procurement/Fabrication Weight Each (KG)Document9 pagesPekerjaan CHF 5 Vol KW Dim (MM) II Procurement/Fabrication Weight Each (KG)bagus handokoNo ratings yet

- 4JZ150UAZVA2KD Data Sheet Rev 0 201008MPDocument6 pages4JZ150UAZVA2KD Data Sheet Rev 0 201008MPCarlos AlvarezNo ratings yet

- Ìaissos - Report - Outdoor Catalog DataDocument1 pageÌaissos - Report - Outdoor Catalog DataNguyen PhamNo ratings yet

- Hitachi Lx15-7 Part4Document1 pageHitachi Lx15-7 Part4AlastarNo ratings yet

- EER-1 Emergency ListDocument2 pagesEER-1 Emergency ListkalaiNo ratings yet

- Technical Data of The Fan: RZR 13-1400: To Motor: Siemens-IE3 1LE1003-1CC23-4AB4/IE3Document3 pagesTechnical Data of The Fan: RZR 13-1400: To Motor: Siemens-IE3 1LE1003-1CC23-4AB4/IE3mahmadwasiNo ratings yet

- Technical Data of The Fan: RZR 13-1250: To Motor: Siemens-IE3 1LE1003-1CC03-4AB4/IE3Document3 pagesTechnical Data of The Fan: RZR 13-1250: To Motor: Siemens-IE3 1LE1003-1CC03-4AB4/IE3mahmadwasiNo ratings yet

- Sandy Drifterz, Vcet: Madurai, Tamil NaduDocument15 pagesSandy Drifterz, Vcet: Madurai, Tamil NaduNaveenNo ratings yet

- 02 MIDEA Cassette Inverter (3.0-5.0 Ton)Document2 pages02 MIDEA Cassette Inverter (3.0-5.0 Ton)Mohd TabishNo ratings yet

- Visa 41kvaDocument1 pageVisa 41kvaAMEUR ELOUADHANENo ratings yet

- Technical Data of The Fan: RZR 11-0900: To Motor: Siemens-IE3 1LE1003-1AB42-2AB4/IE3Document3 pagesTechnical Data of The Fan: RZR 11-0900: To Motor: Siemens-IE3 1LE1003-1AB42-2AB4/IE3mahmadwasiNo ratings yet

- More Care. Built In.: Volvo Motor GradersDocument10 pagesMore Care. Built In.: Volvo Motor GradersAndresNo ratings yet

- Infinair Fan Data SheetDocument2 pagesInfinair Fan Data SheetInsertec LtdaNo ratings yet

- ALPHA α-EM4100-A driving system parametersDocument1 pageALPHA α-EM4100-A driving system parametersplamenNo ratings yet

- 40 Ton Capacity CRANE WHEEL LOAD DATADocument1 page40 Ton Capacity CRANE WHEEL LOAD DATARajveer SinghNo ratings yet

- Specifications Petroleum: Th48-E70 TransmissionDocument2 pagesSpecifications Petroleum: Th48-E70 TransmissionVikranth ReddyNo ratings yet

- General Characteristics: 3029DFS29 G3Document6 pagesGeneral Characteristics: 3029DFS29 G3Praveen SreedharanNo ratings yet

- GALAXY - F 120 GX - GX - 400V - 50Hz - enDocument1 pageGALAXY - F 120 GX - GX - 400V - 50Hz - enTawfikNo ratings yet

- Technical Data of The Fan: RZR 13-1120: To Motor: Siemens-IE3 1LE1003-1CC03-4AB4/IE3Document3 pagesTechnical Data of The Fan: RZR 13-1120: To Motor: Siemens-IE3 1LE1003-1CC03-4AB4/IE3mahmadwasiNo ratings yet

- X800UC2Document5 pagesX800UC2Charles FequiereNo ratings yet

- Aer 24 03 0605 VGDocument2 pagesAer 24 03 0605 VGhussamalsaadanyNo ratings yet

- General Characteristics: 3029DFS29 G3Document4 pagesGeneral Characteristics: 3029DFS29 G3Xuân Huy NguyễnNo ratings yet

- 4.000 HWDP With XT39 (4.875 X 2.5625 TJ) ConventionalDocument1 page4.000 HWDP With XT39 (4.875 X 2.5625 TJ) Conventionalsurendra kumarNo ratings yet

- FJ DT VRF S 2pipe 071205 VD002E14-NovoDocument2 pagesFJ DT VRF S 2pipe 071205 VD002E14-NovoSlobodan AnticNo ratings yet

- General Characteristics: 3029DFS29 G3Document4 pagesGeneral Characteristics: 3029DFS29 G3Xuân Huy NguyễnNo ratings yet

- Horizontal Lifeline System (HLLS) - 1 Span: A Rupt R FmaxDocument1 pageHorizontal Lifeline System (HLLS) - 1 Span: A Rupt R FmaxRajNo ratings yet

- 50 KVA Spec SheetDocument2 pages50 KVA Spec SheetAhmad El KhatibNo ratings yet

- 42 HWDP 5875 02Document2 pages42 HWDP 5875 02Alan MaidaNo ratings yet

- Technical Data of The Fan: RLM E6-6371-43-26-N: Specified Duty PointDocument3 pagesTechnical Data of The Fan: RLM E6-6371-43-26-N: Specified Duty PointmahmadwasiNo ratings yet

- Heavy Fuel Pushers EconomyDocument21 pagesHeavy Fuel Pushers EconomyLeonardo D AndreaNo ratings yet

- 28m+28m ULS Check 2.0m EccentricityDocument4 pages28m+28m ULS Check 2.0m Eccentricitysandeep patilNo ratings yet

- ChallengerDocument9 pagesChallengerFelipe HernandezNo ratings yet

- EtelDocument2 pagesEtelkatika01No ratings yet

- 4.5 L Engine Model: 4045TFM50 Rating: M3 - 135 HP (101 KW) at 2500 RPM M2 - 120 HP (90 KW) at 2400 RPM Application: MarineDocument3 pages4.5 L Engine Model: 4045TFM50 Rating: M3 - 135 HP (101 KW) at 2500 RPM M2 - 120 HP (90 KW) at 2400 RPM Application: Marineebey_endunNo ratings yet

- Load-Moment Interaction Diagram: CVENG 3312 HW9Document1 pageLoad-Moment Interaction Diagram: CVENG 3312 HW9John CookeNo ratings yet

- Performance Study For Reinforced Concrete Bridge Piers Considering Seismic Capacity and DemandDocument37 pagesPerformance Study For Reinforced Concrete Bridge Piers Considering Seismic Capacity and DemandAslam KyonNo ratings yet

- Bug Blower Motor Summary-SampleDocument1 pageBug Blower Motor Summary-SampleMohammad Reza NajafiNo ratings yet

- 19 DP 5 01 Ows Spec SheetDocument2 pages19 DP 5 01 Ows Spec SheetresapradistaNo ratings yet

- Lembar Spesifikasi Teknis: NO Part Name Description Specification Unit 1 Conveyor Profile ManufacturerDocument4 pagesLembar Spesifikasi Teknis: NO Part Name Description Specification Unit 1 Conveyor Profile ManufacturermamatsulsNo ratings yet

- Lembar Spesifikasi Teknis: NO Part Name Description Specification Unit 1 Conveyor Profile ManufacturerDocument4 pagesLembar Spesifikasi Teknis: NO Part Name Description Specification Unit 1 Conveyor Profile ManufacturermamatsulsNo ratings yet

- Lembar Spesifikasi Teknis: NO Part Name Description Specification Unit 1 Conveyor Profile ManufacturerDocument4 pagesLembar Spesifikasi Teknis: NO Part Name Description Specification Unit 1 Conveyor Profile ManufacturermamatsulsNo ratings yet

- Lembar Spesifikasi Teknis: NO Part Name Description Specification Unit 1 Conveyor Profile ManufacturerDocument4 pagesLembar Spesifikasi Teknis: NO Part Name Description Specification Unit 1 Conveyor Profile ManufacturermamatsulsNo ratings yet

- Lembar Spesifikasi Teknis: NO Part Name Description Specification Unit 1 Conveyor Profile ManufacturerDocument4 pagesLembar Spesifikasi Teknis: NO Part Name Description Specification Unit 1 Conveyor Profile ManufacturermamatsulsNo ratings yet

- Hot Splicing PT. Maruwai CoalDocument1 pageHot Splicing PT. Maruwai CoalmamatsulsNo ratings yet

- Conveyor Design Summary: Helix Technologies Pty LTDDocument23 pagesConveyor Design Summary: Helix Technologies Pty LTDmamatsulsNo ratings yet

- Tutorial AndroidDocument1 pageTutorial AndroidmamatsulsNo ratings yet

- The Basics of Electric Heat Trace TechnologyDocument8 pagesThe Basics of Electric Heat Trace Technologyvladimir rosas ayalaNo ratings yet

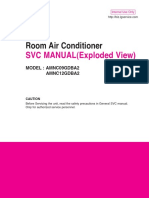

- Service Manual - Amnc09gdba2, Amnc12gdba2Document6 pagesService Manual - Amnc09gdba2, Amnc12gdba2U Kyaw San OoNo ratings yet

- Third Periodic TestDocument4 pagesThird Periodic TestCrizelda AmarentoNo ratings yet

- 638 - Servoregler Technical - ManualDocument123 pages638 - Servoregler Technical - ManualemfiNo ratings yet

- Question Bank 4th SemesterDocument16 pagesQuestion Bank 4th SemesterJeevanandam ShanmugasundaramNo ratings yet

- Pitcher TemplateDocument1 pagePitcher Templatem.usmanNo ratings yet

- FSU Electronics PrelabDocument7 pagesFSU Electronics Prelabcamaguey5No ratings yet

- Hya3-6 M6 InsDocument3 pagesHya3-6 M6 InssuhuanajNo ratings yet

- Acessórios Cloro Gás - VaccupermDocument28 pagesAcessórios Cloro Gás - Vaccupermbalzac1910% (1)

- Pega Interview PreperationDocument35 pagesPega Interview PreperationPramodh SSNo ratings yet

- Denture Base MaterialsDocument117 pagesDenture Base MaterialsLalit KumarNo ratings yet

- Answer To The Question No: (A) : Pattern Recognition Is The Process of Recognizing Patterns by UsingDocument4 pagesAnswer To The Question No: (A) : Pattern Recognition Is The Process of Recognizing Patterns by UsingKhaled faisalNo ratings yet

- UM - HX204 - EN User ManualDocument32 pagesUM - HX204 - EN User Manuals7631040No ratings yet

- DistilationDocument29 pagesDistilationkindenewNo ratings yet

- Properties of Gray Cast Iron - Engineer's HandbookDocument2 pagesProperties of Gray Cast Iron - Engineer's Handbookkus satria dNo ratings yet

- Notes: Edited by William AdkinsDocument6 pagesNotes: Edited by William Adkinsjorge mario durango petroNo ratings yet

- BUshed Pin TypeDocument48 pagesBUshed Pin TypeAkshayNo ratings yet

- Aviation Service ManualDocument28 pagesAviation Service ManualArmo MoralesNo ratings yet

- Neeraj Pal 2Document1 pageNeeraj Pal 2NeerajPalNo ratings yet

- GravimetryDocument31 pagesGravimetrysvsaikumarNo ratings yet

- Monitoreo de BombasDocument6 pagesMonitoreo de Bombasroberdani12No ratings yet

- Modul Ke-4 Perhitungan Sieve AnalisisDocument36 pagesModul Ke-4 Perhitungan Sieve AnalisisFredi CherboundNo ratings yet

- ArticleDocument10 pagesArticlePrachiNo ratings yet

- Mechanics of Solids by Crandall, Dahl, Lardner, 2nd ChapterDocument118 pagesMechanics of Solids by Crandall, Dahl, Lardner, 2nd Chapterpurijatin100% (2)

- Plcforum - Uz.ua: (LINK) : Eplan P8 2.0.5.4602 + CrackDocument26 pagesPlcforum - Uz.ua: (LINK) : Eplan P8 2.0.5.4602 + Crackphth411100% (1)

- Research MethodsDocument10 pagesResearch MethodsAhimbisibwe BenyaNo ratings yet

- Edited C Spectra - APT and DEPTDocument4 pagesEdited C Spectra - APT and DEPTKasun RatnayakeNo ratings yet

- Mini Project 2B 6th SemesterDocument28 pagesMini Project 2B 6th SemesterRohit Singh RajputNo ratings yet