Professional Documents

Culture Documents

WM Cy 2021 - I CT

WM Cy 2021 - I CT

Uploaded by

rubilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WM Cy 2021 - I CT

WM Cy 2021 - I CT

Uploaded by

rubilCopyright:

Available Formats

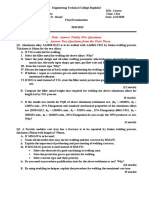

Department of Metallurgical and Materials Engineering

National Institute of Technology, Tiruchirappalli – 620 015

MT 602 – Welding Metallurgy

Assessment – I

Answer All Questions (5 x 4 = 20 Marks)

Time: 1 Hr Date: 01.03.2021

1. Large aluminium sheets 1.6 mm thick are butt welded using GTAW with

alternating current. The current, voltage, and welding speed are 100A, 10V,

and 2mm/s, respectively. Calculate the peak temperatures at distance of 1.0

and 2.0 mm from the fusion boundary. Assume 50% arc efficiency.

2. Estimate the HAZ width of the carbon steel weldment for the following

welding conditions.

V = 20V, I =200A, s= 5 mm/s, preheating temperature = 200oC and Tempered

Temperature = 430oC, Tm = 1510oC, t = 5 mm/sec, ρC = 0.0044 J/mm3 oC,

η =0.9.

3 Predict the cooling rate of the following welding conditions.

V = 25V, I = 250A, s = 7 mm/s, t = 12 mm, η =0.9, ρC = 0.0044 J/mm 3 oC,

k = 0.028 J/mm oC s.

4. (a) Will decreasing welding speed help reduce weld porosity in gas–tungsten

arc welds of aluminium if the source of hydrogen is on the workpiece surface?

(b) What about if the source of hydrogen is in the shielding gas? Explain why

or why not.

5. A steel container was welded by SAW with a filler wire containing 1.38% Mn

and 0.05% Si and a flux containing 11.22% SiO2 and 1.15% MnO. Is the

electrode tip Mn content expected to be greater or smaller than the wire Mn

content and why? What about the Si content?

**********

You might also like

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- CWEng SampleQuestionsDocument8 pagesCWEng SampleQuestionsSungJun ParkNo ratings yet

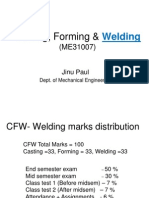

- Casting, Forming & WeldingDocument90 pagesCasting, Forming & WeldingmahdiNo ratings yet

- Aws Cwi QuestionDocument8 pagesAws Cwi Questionfrenskiran75% (4)

- Solutions Manual to accompany Engineering Materials ScienceFrom EverandSolutions Manual to accompany Engineering Materials ScienceRating: 4 out of 5 stars4/5 (1)

- Die Casting Metallurgy: Butterworths Monographs in MaterialsFrom EverandDie Casting Metallurgy: Butterworths Monographs in MaterialsRating: 3.5 out of 5 stars3.5/5 (2)

- Wi Cswip 3.1 Part 21Document8 pagesWi Cswip 3.1 Part 21Ramakrishnan AmbiSubbiahNo ratings yet

- Study On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelDocument8 pagesStudy On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelIJMERNo ratings yet

- Automation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingFrom EverandAutomation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingP D BoydNo ratings yet

- MT 301 - HT - 2023-AssignmentDocument1 pageMT 301 - HT - 2023-AssignmentSanjay GanapaNo ratings yet

- Laser-TIG Welding of Titanium AlloysDocument8 pagesLaser-TIG Welding of Titanium AlloysRobert ShinNo ratings yet

- 2020 - Key Engineering Materials Vol.867Document8 pages2020 - Key Engineering Materials Vol.867Dava GhaniNo ratings yet

- Answer Two Questions From The First ThreeDocument13 pagesAnswer Two Questions From The First ThreeMalik AlsaadiNo ratings yet

- 2020 - Materials Science Forum 991Document7 pages2020 - Materials Science Forum 991Dava GhaniNo ratings yet

- 2022-Dec ME-312 53Document2 pages2022-Dec ME-312 53Aakash TiwariNo ratings yet

- Thermit Welding of Chromium Vanadium RailsteelDocument8 pagesThermit Welding of Chromium Vanadium Railsteelsantu_23No ratings yet

- 2k19 5th Sem Papers - Watermark-1Document15 pages2k19 5th Sem Papers - Watermark-1Vishal kumarNo ratings yet

- 2018 Ques 5th SemDocument15 pages2018 Ques 5th SemVishal kumarNo ratings yet

- MECH 6541 - Quiz 2 2017Document15 pagesMECH 6541 - Quiz 2 2017Abhay Shankar MishraNo ratings yet

- Temper Bead Welding of S460N Steel in Wet Welding ConditionsDocument10 pagesTemper Bead Welding of S460N Steel in Wet Welding ConditionsNickesh ShahNo ratings yet

- Advanced Manufacturing ScienceDocument3 pagesAdvanced Manufacturing Sciencemukesh3021No ratings yet

- Final 2021Document3 pagesFinal 2021mohamed.hassan031No ratings yet

- Effects of Normalizing Processes On Microstructure and Impact Toughness in Ti-Bearing Weld Metal of Multilayer MAG Welded HSLA SteelDocument6 pagesEffects of Normalizing Processes On Microstructure and Impact Toughness in Ti-Bearing Weld Metal of Multilayer MAG Welded HSLA Steelarjun prajapatiNo ratings yet

- Brief Review On Dissimilar Welding Using Cold Metal TransferDocument10 pagesBrief Review On Dissimilar Welding Using Cold Metal TransferSrinivas KosuriNo ratings yet

- Manukau Institute of Technology: Faculty of Mechanical Engineering and TradesDocument5 pagesManukau Institute of Technology: Faculty of Mechanical Engineering and Tradesrohit22eNo ratings yet

- The Effect of Groove Welding On Mechanical PropertDocument8 pagesThe Effect of Groove Welding On Mechanical PropertMuhammad Zuhairy jabarNo ratings yet

- 19 Ijmperdapr201719Document10 pages19 Ijmperdapr201719TJPRC PublicationsNo ratings yet

- Conventional Casting WeldingDocument190 pagesConventional Casting WeldingprabhjotbhangalNo ratings yet

- SheetDocument3 pagesSheetBarun BeheraNo ratings yet

- Spot WeldingDocument13 pagesSpot Weldingshanmukha MechanicalNo ratings yet

- Materials and Design: B.C. Shang, Z.M. Yin, G. Wang, B. Liu, Z.Q. HuangDocument5 pagesMaterials and Design: B.C. Shang, Z.M. Yin, G. Wang, B. Liu, Z.Q. HuangAntonio Alonso Diaz ArriagaNo ratings yet

- Effect of Energy Input On Microstructure and Hardness of TIG Welded AISI 430-Ferritic Stainless SteelDocument8 pagesEffect of Energy Input On Microstructure and Hardness of TIG Welded AISI 430-Ferritic Stainless SteelAshish Kumar AgrawalNo ratings yet

- Adv - Design of Weldments Seme1 2004Document4 pagesAdv - Design of Weldments Seme1 2004mukesh3021No ratings yet

- Analysis of Welding Strength S45C Material in Spot Welding ProcessDocument8 pagesAnalysis of Welding Strength S45C Material in Spot Welding ProcessBRAYAN ALEJANDRO REYES VILLANUEVANo ratings yet

- Whisker Free Tin Jan Feb White Paper DownloadDocument6 pagesWhisker Free Tin Jan Feb White Paper DownloadRajashekhar MahantinamathNo ratings yet

- Electron Microscopy and Microanalysis of Steel Weld Joints After Long Time Exposures at High TemperaturesDocument10 pagesElectron Microscopy and Microanalysis of Steel Weld Joints After Long Time Exposures at High TemperaturesJEANNINA BULEJE CASTILLONo ratings yet

- Elrefaey 2010Document7 pagesElrefaey 2010mojtaba nNo ratings yet

- Variations The Diameter Tip of Electrode On The ReDocument12 pagesVariations The Diameter Tip of Electrode On The ReThaharNo ratings yet

- TRAS2017 FullPaper ID01Document4 pagesTRAS2017 FullPaper ID01Kittichai SojiphanNo ratings yet

- Jurnal KEM.948.23 Muslimin, FMDocument10 pagesJurnal KEM.948.23 Muslimin, FMZinsaisal BakriNo ratings yet

- Effects of TIG Welding Process On Microstructure, Electrical Resistance and Mechanical Properties of Nichrome 8020Document8 pagesEffects of TIG Welding Process On Microstructure, Electrical Resistance and Mechanical Properties of Nichrome 8020rezaNo ratings yet

- Assignment: 3 Chapter: Metal Joining Process: Sr. No QuestionsDocument1 pageAssignment: 3 Chapter: Metal Joining Process: Sr. No QuestionsSp PatelNo ratings yet

- Influence of Alloying Conditions On The Properties of White Cast IronDocument6 pagesInfluence of Alloying Conditions On The Properties of White Cast IronSarvar TursunbaevNo ratings yet

- 316L Mixing Design For ATIG Morphology and Microstructure Study of 316L Stainless SteelDocument8 pages316L Mixing Design For ATIG Morphology and Microstructure Study of 316L Stainless SteelMohamed TAHDECHTNo ratings yet

- KEM.545.182Document7 pagesKEM.545.182katfyNo ratings yet

- D and H NewDocument37 pagesD and H NewBharat AhirNo ratings yet

- Assignment Metal CuttingDocument2 pagesAssignment Metal CuttingthakurkalidassNo ratings yet

- Experimental Investigation For Welding Aspects of Stainless Steel 310 For The Process of TIG Welding PDFDocument7 pagesExperimental Investigation For Welding Aspects of Stainless Steel 310 For The Process of TIG Welding PDFfaisalNo ratings yet

- Study On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelDocument8 pagesStudy On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelAngga Pamilu PutraNo ratings yet

- Metals 10 01121Document14 pagesMetals 10 01121dietersimaNo ratings yet

- Cavitation Erosion Resistance of Two Steels With The Same Percentage of Chromium and Nickel But Different Carbon ContentDocument7 pagesCavitation Erosion Resistance of Two Steels With The Same Percentage of Chromium and Nickel But Different Carbon Contentaloliveira7811No ratings yet

- 1 2 Resistance and Special Welding Q A For StudentsDocument10 pages1 2 Resistance and Special Welding Q A For StudentsRavinder AntilNo ratings yet

- Explosion WeldingDocument6 pagesExplosion WeldingRabindra DashNo ratings yet

- ME 352 - All Problem Class - 14-18 BatchDocument125 pagesME 352 - All Problem Class - 14-18 BatchEntertainment GamingNo ratings yet

- Bai Tap - Vat Lieu Hoc - Phan Tinh Chat - NTS - v1Document26 pagesBai Tap - Vat Lieu Hoc - Phan Tinh Chat - NTS - v1Hoàng BeeNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- WCS Assignment 1Document10 pagesWCS Assignment 1rubilNo ratings yet

- Technology Development in Welding - Orbital Welding: NtroductionDocument6 pagesTechnology Development in Welding - Orbital Welding: NtroductionrubilNo ratings yet

- Pipeline Weldability IMPORTANTDocument14 pagesPipeline Weldability IMPORTANTrubilNo ratings yet

- Wat AssignmentDocument16 pagesWat AssignmentrubilNo ratings yet

- Welding Engineering: M.Tech. DegreeDocument16 pagesWelding Engineering: M.Tech. DegreerubilNo ratings yet