Professional Documents

Culture Documents

Comparison of Is 2062 & Sa 36 Criteria IS 2062 SA 36

Uploaded by

RajendraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comparison of Is 2062 & Sa 36 Criteria IS 2062 SA 36

Uploaded by

RajendraCopyright:

Available Formats

COMPARISON OF IS 2062 & SA 36

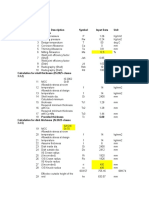

Criteria IS 2062 SA 36

Manufacture Steel shall be manufactured Steel shall be manufactured by one or

by any process of steel more of following processes - open

making except basemer hearth, basic oxygen or electric

process. It may be followed furnace.

by secondary refinement.

Chemical Ladle analysis with variation Plate upto and including Bar

Analysis (%) allowed in product analysis 40 mm

C 0.23 max 0.25 max 0.26 upto 20

mm

0.27 over 20

mm upto 40

mm

S 0.05 max. 0.05 max 0.05 Upto and

max including 40

mm

P 0.05 max 0.04 max 0.04

max

Mn 1.5 Nil upto 20 mm Nil upto 20

0.8 to 1.2 over 20 mm mm

upto 40 mm 0.6 to 0.9

over 20 mm

upto 40mm

Cu 0.2 to 0.35 max. when Cu 0.2 min. when Cu steel is specified.

steel is specified

Deoxidation Semikilled or killed

N Shall not exceed 0.012%

Freedom Minor surface defects may Plates may be conditioned by the

from defects be removed by grinding manufacturer or processor for the

provided that the thickness is removal of imperfections or

not reduced locally by more depressions on the top and bottom

than 4% with a max. of 3mm. surfaces by grinding provided the area

Reduction greater than 4% ground does not reduce the thickness

but not exceeding 7% may of the plate by:

be made only with the

agreement of purchaser. 1. more than 7% under the nominal

thickness for plates ordered to

Wt/ft2 but in no case more than 3.

2. below the permissible min.

thickness for plates ordered to

thickness in inches to mm.

Removal of After complete removal of The chipped, ground or gouged area

Criteria IS 2062 SA 36

defects defects and before welding, shall not exceed 2% the area of the

the thickness of the item is in surface being conditioned. After

no place reduced by more removal of any imperfections

than 20%. Welding carried preparatory to welding, the thickness of

out by an approved procedure plate at any location must not be

and by competent operators reduced by more than 30% of the

with approved electrodes and nominal thickness of the plate

weld is ground smooth to the (specification A 131/A 131 M restricts

correct nominal thickness. the reduction in thickness to 20% max.)

Subsequent to the finish The edges of plates may be

grinding the item may be conditioned by grinding, chipping or arc

required to be normalised or air gouging and welding. Prior to

otherwise heat treated at the welding the depth of depression

purchaser's discretion. measured from the plate edge inward

shall be limited to the thickness of plate

with a max. depth of 25 mm.

Mechanical properties

UTS 41.8 kgf/mm2 (thickness 20 mm to 40 40.78 to 56.07 kgf/mm2

mm for plates and thickness above 20

mm for bars)

Yield stress 25.48 kgf/mm2 min.upto 20 mm 25.48 kgf/mm2

24.4% kgf/mm2 min. - 20 to 40 mm

% Elogation 23% in gauge lg. 5.65 So 23% in 50 mm

min.

General note for IS: 2062

1. The steel covered by this standard is of guaranteed weldability. The

weldability test is applicable between 28 to 50 mm for sections below 28

mm shall be certified by the manufacturer as weldable based on the

chemical composition, provided the carbon content is below 0.22 percent.

2. Unless otherwise specified, plates above 12m shall be supplied in the

normalised condition. Sections, flats and bars shall be supplied in the hot-

rolled condition unless otherwise specified, subject to mutual agreement

between purchase and manufacturer.

Reference codes: IS 2062 1992, ASME Section IIA 1995

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Assignment-1 Quality Standards For Civil Engineering Materials (1) Low Heat Cement (IS 12600: 1989) : Physical Requirements SpecificationsDocument13 pagesAssignment-1 Quality Standards For Civil Engineering Materials (1) Low Heat Cement (IS 12600: 1989) : Physical Requirements SpecificationsKetul DesaiNo ratings yet

- Is: 2062-1981 Mild SteelDocument2 pagesIs: 2062-1981 Mild Steelsuresh kumarNo ratings yet

- HydraulicCylinderTubeST52 ST52 3Document1 pageHydraulicCylinderTubeST52 ST52 3rjramanathanNo ratings yet

- Astm A105 Flange SpecificationDocument2 pagesAstm A105 Flange SpecificationSales ITANo ratings yet

- Astm A105 Flange Specification PDFDocument2 pagesAstm A105 Flange Specification PDFSales ITANo ratings yet

- Type of Structure Concrete Over, MM: Minimum Cover Thickness For Cast-in-Place ConcreteDocument3 pagesType of Structure Concrete Over, MM: Minimum Cover Thickness For Cast-in-Place ConcreteRyeanKRumanoNo ratings yet

- Comparison of Steel GradesDocument3 pagesComparison of Steel GradesUsama AhmedNo ratings yet

- Astm A500 Pipe Tolerances (Round Tubing)Document1 pageAstm A500 Pipe Tolerances (Round Tubing)Anwarul AfrojNo ratings yet

- Nastri Lastre Rame ENGDocument4 pagesNastri Lastre Rame ENGSyed Wajahat BukhariNo ratings yet

- How To Get High Quality Boiler TubesDocument7 pagesHow To Get High Quality Boiler TubesYaneYangNo ratings yet

- ITEM 200 Latest 2004Document12 pagesITEM 200 Latest 2004Marinella AbellaNo ratings yet

- Edgen Murray ProductsDocument20 pagesEdgen Murray Productsafiqaziz86No ratings yet

- C1 CalcDocument1 pageC1 CalcJayar Valloyas MendietaNo ratings yet

- Cromax 280X: Hard Chrome BarDocument4 pagesCromax 280X: Hard Chrome BarpeterNo ratings yet

- Tolerances To en 10051 For Continuously Rolled HotDocument4 pagesTolerances To en 10051 For Continuously Rolled HotSorin LescaiNo ratings yet

- Flat Steel SpecsDocument8 pagesFlat Steel SpecscuongdcNo ratings yet

- Shaft Seals With A Type 5 Stop: Seal Design DescriptionDocument5 pagesShaft Seals With A Type 5 Stop: Seal Design DescriptionJoni HartonoNo ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument2 pagesS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument2 pagesS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- Manual HyperthermDocument4 pagesManual HyperthermMatias Ulloa SaavedraNo ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument2 pagesS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument2 pagesS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- Seamless Circular Tubes of Non-Alloy Steels With Special Quality RequirementsDocument2 pagesSeamless Circular Tubes of Non-Alloy Steels With Special Quality RequirementsWiryanto DewobrotoNo ratings yet

- Sor MehsanaDocument347 pagesSor Mehsanajitu2968100% (1)

- As 3678 Steel Grade 350Document3 pagesAs 3678 Steel Grade 350gsoaresrj80No ratings yet

- Electrolytically Galvanized Sheet: EMW Delivery Range Coils Slit Strip Cut-To-Size SheetDocument4 pagesElectrolytically Galvanized Sheet: EMW Delivery Range Coils Slit Strip Cut-To-Size SheetEvka AkováNo ratings yet

- Essar Steel Rockstar 400Document2 pagesEssar Steel Rockstar 400HimanshuNarayanSinghNo ratings yet

- Penthor 964: External StandardDocument2 pagesPenthor 964: External StandardAnjani kumarNo ratings yet

- Bearing and Sealing Components: For Mechanical EngineeringDocument24 pagesBearing and Sealing Components: For Mechanical EngineeringramakantinamdarNo ratings yet

- MDS Y20Document1 pageMDS Y20von18No ratings yet

- BS 6263 Tubes ToleranceDocument2 pagesBS 6263 Tubes TolerancePramod RaghuvanshiNo ratings yet

- AD383 NSCVol22 No5Document1 pageAD383 NSCVol22 No5er.wasimqadir7654No ratings yet

- Velocidades de Propagación Del Sonido en El MaterialDocument8 pagesVelocidades de Propagación Del Sonido en El MaterialJ.CarrascoNo ratings yet

- CL 425 MARINE Floating Hose - GasDocument1 pageCL 425 MARINE Floating Hose - GasTaufiqNo ratings yet

- EN24T, EN24 SteelDocument1 pageEN24T, EN24 SteelNILESH SHAHNo ratings yet

- DIN 11850-1985-OtklDocument7 pagesDIN 11850-1985-OtklVasko MandilNo ratings yet

- Biratnagar WTP CofinanceDocument2 pagesBiratnagar WTP CofinanceBhagwan Ratna KansakarNo ratings yet

- Intermediate SRDocument1 pageIntermediate SRvasanthiNo ratings yet

- ASTM A537 Class 1 Carbon Steel Plates Are Engineered To Be Used in Pressure Vessel ApplicationsDocument7 pagesASTM A537 Class 1 Carbon Steel Plates Are Engineered To Be Used in Pressure Vessel Applicationsvalli rajuNo ratings yet

- Gaskets - Graphite PDFDocument4 pagesGaskets - Graphite PDFSH1961No ratings yet

- Description and Application: 80%ar - 20%CO EN ISO 17632-A-T 42 4 M M 3 H5 AWS A5.18 E70C-6MDocument1 pageDescription and Application: 80%ar - 20%CO EN ISO 17632-A-T 42 4 M M 3 H5 AWS A5.18 E70C-6MMaheshNo ratings yet

- Welding Standard Ver1Document4 pagesWelding Standard Ver1Sowmen ChakrobortyNo ratings yet

- Klinger Graphite Laminate PSM: Key Features: BenefitsDocument2 pagesKlinger Graphite Laminate PSM: Key Features: BenefitsHammad KhanNo ratings yet

- Design: NB: Size Lists Give "On Line" Tolerances For Rod ApplicationsDocument2 pagesDesign: NB: Size Lists Give "On Line" Tolerances For Rod ApplicationsNal FivefivetwooneNo ratings yet

- C22 EngDocument1 pageC22 EngAlperen EkincioğluNo ratings yet

- Counter Top SpecsDocument12 pagesCounter Top Specsapi-3797031100% (3)

- Toaz - Info Visual Inspection Acceptance Criteria PRDocument1 pageToaz - Info Visual Inspection Acceptance Criteria PRErick AlvarezNo ratings yet

- D Civ Cab Ldpe - 00Document5 pagesD Civ Cab Ldpe - 00HARINo ratings yet

- General Information: 2.1. ConcreteDocument3 pagesGeneral Information: 2.1. ConcreteGeloNo ratings yet

- Annex 4.1 - Technical Specifications - Civil WorksDocument6 pagesAnnex 4.1 - Technical Specifications - Civil WorksMW ALSABRINo ratings yet

- Bars Technical Information Hot RolledDocument1 pageBars Technical Information Hot RolledsubrahNo ratings yet

- Alambron CHQDocument4 pagesAlambron CHQJavier GranadosNo ratings yet

- Ref To CSR Description of Item Nos. L B Sr. No.: Supply of MS Tube Size 40x40x4mm 1 2.25Document2 pagesRef To CSR Description of Item Nos. L B Sr. No.: Supply of MS Tube Size 40x40x4mm 1 2.25DidarNo ratings yet

- 20Mnv6 Hollow Bar: Iso Stocked Sizesiso ChartDocument3 pages20Mnv6 Hollow Bar: Iso Stocked Sizesiso ChartretrogradesNo ratings yet

- Conduit-Brochure 25mmDocument8 pagesConduit-Brochure 25mmMian M AsadNo ratings yet

- S355MLDocument2 pagesS355MLMohammed ShamilNo ratings yet

- Table 1 Chemical Requirements Table 2 Mechanical Requirements (Note (1) )Document1 pageTable 1 Chemical Requirements Table 2 Mechanical Requirements (Note (1) )karioke mohaNo ratings yet

- Generation Power: Dedicated To Engine Room Products, Technologies & NewsDocument5 pagesGeneration Power: Dedicated To Engine Room Products, Technologies & NewsRajendraNo ratings yet

- S - Ten MaterialDocument24 pagesS - Ten MaterialRajendraNo ratings yet

- Modern Power SystemsDocument63 pagesModern Power SystemsRajendraNo ratings yet

- Transient Behavior - CirculationDocument12 pagesTransient Behavior - CirculationRajendraNo ratings yet

- WHRB Cement ArticleDocument2 pagesWHRB Cement ArticleRajendraNo ratings yet

- Understand The Basics of Centrifugal Pump Operations (CEP)Document5 pagesUnderstand The Basics of Centrifugal Pump Operations (CEP)Ari Firmansyah100% (1)

- Understand The Basics of Centrifugal Pump Operations (CEP)Document5 pagesUnderstand The Basics of Centrifugal Pump Operations (CEP)Ari Firmansyah100% (1)

- Linceed Oil - VpCI - 422 Method ApplicationDocument2 pagesLinceed Oil - VpCI - 422 Method ApplicationRajendraNo ratings yet

- Understand The Basics of Centrifugal Pump Operations (CEP)Document5 pagesUnderstand The Basics of Centrifugal Pump Operations (CEP)Ari Firmansyah100% (1)

- Understand The Basics of Centrifugal Pump Operations (CEP)Document5 pagesUnderstand The Basics of Centrifugal Pump Operations (CEP)Ari Firmansyah100% (1)

- Washing of EcoDocument2 pagesWashing of EcoRajendraNo ratings yet

- Chapter 641Document10 pagesChapter 641Asif HaqNo ratings yet

- DesuperheaterDocument5 pagesDesuperheaterKrishna KumarNo ratings yet

- ABMA Boiler 402 PDFDocument74 pagesABMA Boiler 402 PDFJose Miguel Penedo67% (3)

- End CorrosionDocument4 pagesEnd Corrosiondafteri11No ratings yet

- Nace ApplicationDocument6 pagesNace ApplicationRajendraNo ratings yet

- Water Wash Procedure For EconomizerDocument3 pagesWater Wash Procedure For EconomizerRajendra100% (1)

- Material Selection Sour SeDocument2 pagesMaterial Selection Sour SeRajendraNo ratings yet

- Comp SA36, IS 2062, SA516 GR 60Document2 pagesComp SA36, IS 2062, SA516 GR 60RajendraNo ratings yet

- Fire Tube Boiler DesignDocument3 pagesFire Tube Boiler DesignRajendraNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Nace ApplicationDocument6 pagesNace ApplicationRajendraNo ratings yet

- Area Classifications: North American Standards IEC & CENELEC (Europe) StandardsDocument1 pageArea Classifications: North American Standards IEC & CENELEC (Europe) StandardsRajendraNo ratings yet

- Acmefil Engineering Systems Pvt. Ltd. Customer List: Spray DryerDocument22 pagesAcmefil Engineering Systems Pvt. Ltd. Customer List: Spray DryerDhvanit JoshiNo ratings yet

- Edexcel AS Chemistry Note 2 - Writing Balance Chemical EquationsDocument5 pagesEdexcel AS Chemistry Note 2 - Writing Balance Chemical EquationsSajaniNo ratings yet

- Organic and Biodynamic Wines Quality and Characteristics: A ReviewDocument7 pagesOrganic and Biodynamic Wines Quality and Characteristics: A ReviewJessicaEsparzaEstrada100% (1)

- Carbon Dioxide Adborption Into Promoted Potassium Carbonate SolutionsDocument13 pagesCarbon Dioxide Adborption Into Promoted Potassium Carbonate SolutionsLucia RojasNo ratings yet

- Exercises For Lecture Biochemical Process Engineering: Indicates Exercises As HomeworkDocument37 pagesExercises For Lecture Biochemical Process Engineering: Indicates Exercises As HomeworkAllalannNo ratings yet

- N-Type Solar Cells Advantages, Issues, and Current ScenariosDocument10 pagesN-Type Solar Cells Advantages, Issues, and Current ScenarioshakimkorichiNo ratings yet

- Organophosphat Poison Group 19Document42 pagesOrganophosphat Poison Group 19AarthiNo ratings yet

- Reducing Interferences in Cyanide AnalysisDocument52 pagesReducing Interferences in Cyanide AnalysisWanessa IwanowNo ratings yet

- (9781585286584 - ASHP® Injectable Drug Information™) Preliminary MaterialDocument24 pages(9781585286584 - ASHP® Injectable Drug Information™) Preliminary MaterialSathundorn NuntaNo ratings yet

- Appendix7 I-131Document4 pagesAppendix7 I-131Crizzz001No ratings yet

- Safety Data Sheet (SDS) : Section 1 - IdentificationDocument8 pagesSafety Data Sheet (SDS) : Section 1 - IdentificationkhurshedlakhoNo ratings yet

- Industrial Training RecordDocument31 pagesIndustrial Training RecordPrint SolutionNo ratings yet

- 501 Stocks Filtered 23-09-2022Document26 pages501 Stocks Filtered 23-09-2022MohammadRahemanNo ratings yet

- Astm D 7678-11Document9 pagesAstm D 7678-11Duy Tran100% (2)

- Design Fabrication and Testing of Waste Plastic Pyrolysis PlantDocument10 pagesDesign Fabrication and Testing of Waste Plastic Pyrolysis PlantMatthues Ace MartinezNo ratings yet

- Appendix Tables - Moran Shapiro Fundamentals Engineering Thermodynamics 7th TXTBKDocument96 pagesAppendix Tables - Moran Shapiro Fundamentals Engineering Thermodynamics 7th TXTBKÁlvaro ArangoNo ratings yet

- Liquid Chromatography - Normal Phase: P Jandera, Univerzita Pardubice, Pardubice, Czech RepublicDocument12 pagesLiquid Chromatography - Normal Phase: P Jandera, Univerzita Pardubice, Pardubice, Czech RepublicEuderDiasNo ratings yet

- Worksheet 1Document16 pagesWorksheet 1All photos CloudNo ratings yet

- 12.1 Coordination & Response, 12.2 Nervous System, 12.3 Neurones & ResponseDocument4 pages12.1 Coordination & Response, 12.2 Nervous System, 12.3 Neurones & ResponseHAJAR LENNo ratings yet

- KN KN KN: Design As Per Bs en 1999 1 1Document1 pageKN KN KN: Design As Per Bs en 1999 1 1Giri DharanNo ratings yet

- Dosage Calculation Med SurgDocument2 pagesDosage Calculation Med SurgAubrey Silencio BalahayNo ratings yet

- Geotextiles and Geomembranes: Properties, Production and Engineering ApplicationsDocument16 pagesGeotextiles and Geomembranes: Properties, Production and Engineering Applicationssai srinivasNo ratings yet

- Periodic Properties and Trends PDFDocument20 pagesPeriodic Properties and Trends PDFShivansh Awasthi XII B2No ratings yet

- Rock Mechanics - Unit - 3 PDFDocument11 pagesRock Mechanics - Unit - 3 PDFAkshay MehtaNo ratings yet

- VOC Compliant 2K PUR Coatings in Low ... - Bayercoatings - deDocument32 pagesVOC Compliant 2K PUR Coatings in Low ... - Bayercoatings - desriatul2006No ratings yet

- Che F214 1070 20230810082847Document3 pagesChe F214 1070 20230810082847ArchNo ratings yet

- Evaluation of Winter Annuals For Biomass Production in Rotation With Traditional Summer Row Crops in The Southeast United StatesDocument11 pagesEvaluation of Winter Annuals For Biomass Production in Rotation With Traditional Summer Row Crops in The Southeast United StatesInternational Network For Natural SciencesNo ratings yet

- 11 Transport in Plants - PPT - PPSXDocument4 pages11 Transport in Plants - PPT - PPSXrohit singhNo ratings yet

- PM Model Exam Set-VI (2078-6-9) SolDocument8 pagesPM Model Exam Set-VI (2078-6-9) SolPrepladder ChayNo ratings yet

- BDA Advises Hexion On Sale of China Phenolic Resins Plant To Red AvenueDocument3 pagesBDA Advises Hexion On Sale of China Phenolic Resins Plant To Red AvenuePR.comNo ratings yet