Professional Documents

Culture Documents

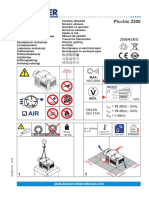

Installation and Operating Instructions: Busch Produktions GMBH Schauinslandstr. 1 79689 Maulburg Germany 0870133276

Installation and Operating Instructions: Busch Produktions GMBH Schauinslandstr. 1 79689 Maulburg Germany 0870133276

Uploaded by

JORGE OTALORAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation and Operating Instructions: Busch Produktions GMBH Schauinslandstr. 1 79689 Maulburg Germany 0870133276

Installation and Operating Instructions: Busch Produktions GMBH Schauinslandstr. 1 79689 Maulburg Germany 0870133276

Uploaded by

JORGE OTALORACopyright:

Available Formats

Installation and

Operating Instructions

Vacuum Pumps

Mink MM 1324, 1202, 1252, 1322, 1200, 1250, 1320 AV

Busch Produktions GmbH

Schauinslandstr. 1

79689 Maulburg

Germany

0870133276 / 140804 / Original instructions / Modifications reserved

Table of Contents Preface

Preface ........................................................................................... 2

Product Description ...................................................................... 3 Congratulations on your purchase of the Busch vacuum pump. With

Use ............................................................................................. 3 watchful observation of the field’s requirements, innovation and

Principle of Operation ................................................................. 3 steady development Busch delivers modern vacuum and pressure

Cooling ....................................................................................... 4 solutions worldwide.

Start Controls.............................................................................. 4 These operating instructions contain information for

Safety ............................................................................................. 4

Intended Use .............................................................................. 4 − product description,

Safety Notes ............................................................................... 4

Noise Emission ........................................................................... 4 − safety,

Transport ....................................................................................... 4

Transport in Packaging ............................................................... 4 − transport,

Transport without Packaging....................................................... 4 − storage,

Storage ........................................................................................... 5

Short-term Storage ..................................................................... 5 − installation and commissioning,

Conservation .............................................................................. 5

Installation and Commissioning ................................................... 5 − maintenance,

Installation prerequisites ............................................................. 5

Mounting Position and Space................................................. 5 − overhaul,

Suction Connection ................................................................ 6

Gas Discharge ....................................................................... 6 − troubleshooting and

Electrical Connection / Controls ............................................. 6

Installation .................................................................................. 6 − spare parts

Mounting a NEMA-Motor with BoWex-Coupling ..................... 6 of the vacuum pump.

Mounting ................................................................................ 7

Checking Synchronising Gear Oil .......................................... 7 Version drive with integrated frequency inverter:

Connecting Electrically........................................................... 7

Connection Scheme Three-Phase Motor............................. 7 The drive with integrated frequency inverter is subject to a

Connecting Lines/Pipes ......................................................... 8 separate instruction manual.

Recording of Operational Parameters .................................... 8

Operating Notes ......................................................................... 8 For the purpose of these instructions, “handling” the vacuum pump

Use ........................................................................................ 8 means the transport, storage, installation, commissioning, influence

Conveying Condensables Vapours ........................................ 9 on operating conditions, maintenance, troubleshooting and overhaul

Maintenance................................................................................... 9 of the vacuum pump.

Maintenance Schedule ............................................................... 9

Monthly ............................................................................... 9 Prior to handling the vacuum pump these operating

Every 3 Months: .................................................................. 9 instructions shall be read and understood. If anything remains

Every 6 Months: .................................................................. 9 to be clarified please contact your Busch representative!

Every Year: ....................................................................... 10

Every 20000 Operating Hours, At the Latest after 6 Years:10 Keep these operating instructions and, if applicable, other

Changing Synchronising Gear Oil ............................................. 10 pertinent operating instructions available on site.

Overhaul....................................................................................... 10

Removal from Service ................................................................. 10

Temporary Removal from Service............................................. 10

Recommissioning ..................................................................... 10

Dismantling and Disposal ......................................................... 10

Troubleshooting .......................................................................... 12

Sectional Drawing ....................................................................... 15

Spare Parts .................................................................................. 16

Spare parts Kits ........................................................................... 16

Accessories ................................................................................. 16

Oil ................................................................................................. 16

EC-Declaration of Conformity..................................................... 17

Technical Data ............................................................................. 18

Busch - All over the World in Industry ....................................... 20

Preface MM 1324, 1202, 1252, 1322, 1200, 1250, 1320 AV

page 2 0870133276 / 140804

a Eye bolt

b Terminal box

c Directional arrow

d Cooling air outlet

e Oil sight glass

f Oil drain plug

g Suction connection (with inlet

air filter)

h Inlet air filter (optional)

i Cooling air inlet

j Position of condensate drain

cock (optional for version

“Aqua”)

k Gas discharge

l Acoustic enclosure

m Cylinder

n Rotor

o Non return valve

p Suction connection (without

inlet air filter)

Vacuum pumps MM 1324 AV Version “Aqua” are thermally suitable

Product Description for continuous operation at intake pressures down to 200 hPa abs

(200 mbar abs). By means of process control and/or vacuum relief

valves it must be made sure that the minimum allowed intake

pressure will not be underrun.

Use

Vacuum pumps MM 1202 AV, MM 1200 AV, MM 1252 AV and

The vacuum pump is intended for MM 1250 AV are thermally suitable for continuous operation at

intake pressures down to 100 hPa abs (100 mbar abs). By means of

− the suction

process control and/or vacuum relief valves it must be made sure

of that the minimum allowed intake pressure will not be underrun.

− air and other dry, non-aggressive, non-toxic and non-explosive Vacuum pumps MM 1322 AV and MM 1320 AV (version

gases 600…3600 min-1) are thermally suitable for continuous operation at

intake pressures down to 150 hPa abs (150 mbar abs). MM 1320 AV

Conveying media with a lower or higher density than air leads to an (version 600…4200 min-1) are thermally suitable for continuous

increased thermal and/or mechanical load on the vacuum pump and operation at intake pressures down to 200 hPa abs (200 mbar abs).

is permissible only after prior consultation with Busch. By means of process control and/or vacuum relief valves it must be

made sure that the minimum allowed intake pressure will not be

Max. allowed temperature of the inlet gas: 40 °C

underrun.

Standard-version:

Version “Aqua”:

The gas shall be free from vapours that would condensate under

The safety valve on the vacuum pump protects the vacuum

the temperature and pressure conditions inside the vacuum

pump against overheating only. It is not designed for frequent

pump.

use and must therefore not be used as a system pressure

Version “Aqua”: regulating valve.

The vacuum pump features the corrosion protection coating

CPC and is capable of conveying water vapour ➔ page 9: Principle of Operation

Conveying Condensable Vapours). Conveyance of other

vapours shall be agreed upon with Busch. Conveyance of water The vacuum pump works on the claw principle.

or other liquids in liquid phase increases the power consumption The components are dimensioned such, that on the one hand there

and shall therefore be avoided (risk of drive overload). is never contact between the two claws or between a claw and the

The vacuum pump is intended for the placement in a non-potentially cylinder, on the other hand the gaps are small enough to keep the

explosive environment. clearance loss between the chambers low.

Max. permissible number of startings per hour: 12 In order to avoid the suction of solids, the vacuum pump is equipped

with a screen (715) in the suction connection.

Vacuum pumps MM 1324 AV standard-version are thermally

suitable for continuous operation down to ultimate pressure. In order to avoid reverse rotation after switching off, the vacuum

pump is equipped with a non-return valve (o, 714).

MM 1324, 1202, 1252, 1322, 1200, 1250, 1320 AV Product Description

0870133276 / 140804 page 3

The vacuum pump compresses the inlet gas absolutely oil-free. A

lubrication of the pump chamber is neither necessary nor allowed. Noise Emission

For the sound pressure level in free field according to EN ISO 2151

Cooling ➔ page 18: Technical Data.

The vacuum pump is cooled by CAUTION

− radiation of heat from the surface of the vacuum pump

The vacuum pump emits noise of high intensity in a narrow

− the air flow from the fan wheel of the drive motor band.

− the process gas Risk of damage to the hearing.

− the air flow from the fan wheel on the shaft of the vacuum

Persons staying in the vicinity of a non noise insulated vacuum

pump

pump over extended periods shall wear ear protection.

Start Controls

The vacuum pump comes without start controls. The control of the

vacuum pump is to be provided in the course of installation.

Transport

Transport in Packaging

Safety Packed on a pallet the vacuum pump is to be transported with a

forklift.

Intended Use

Definition: For the purpose of these instructions, “handling” the Transport without Packaging

vacuum pump means the transport, storage, installation,

In case the vacuum pump is packed in a cardboard box with inflated

commissioning, influence on operating conditions, maintenance,

cushions:

troubleshooting and overhaul of the vacuum.

♦ Remove the inflated cushions from the box

The vacuum pump is intended for industrial use. It shall be handled

only by qualified personnel. In case the vacuum pump is packed in a cardboard box cushioned

with rolled corrugated cardboard:

The allowed media and operational limits (➔➔ page 3: Product

➔ page 5:

Description) and the installation prerequisites (➔ ♦ Remove the corrugated cardboard from the box

Installation Prerequisites) of the vacuum pump shall be

In case the vacuum pump is laid in foam:

observed both by the manufacturer of the machinery into which

the vacuum pump is to be incorporated and by the operator. ♦ Remove the foam

The maintenance instructions shall be observed. In case the vacuum pump is bolted to a pallet or a base plate:

Prior to handling the vacuum pump these installation and ♦ Remove the bolting between the vacuum pump and the

operating instructions shall be read and understood. If anything pallet/base plate

remains to be clarified please contact your Busch

representative! In case the vacuum pump is fastened to the pallet by means of

tightening straps:

Safety Notes ♦ Remove the tightening straps

The vacuum pump has been designed and manufactured according

to state-of-the-art methods. Nevertheless, residual risks may remain. CAUTION

These operating instructions highlight potential hazards where

appropriate. Safety notes are tagged with one of the keywords Do not walk, stand or work under suspended loads.

DANGER, WARNING and CAUTION as follows:

• Make sure that the eyebolt (a, 615) is in faultless condition

(replace a damaged, e.g. bent eyebolt with a new one)

DANGER

• Make sure that the eye bolt (a, 615) is fully screwed in and

Disregard of this safety note will always lead to accidents tightened by hand

with fatal or serious injuries.

• Attach lifting gear securely to the eyebolt (a, 615) on the

synchronising gear

When the vacuum pump is equipped with a very heavy drive motor

WARNING

and would hang very inclined (>10°) on the synchron ising gear

eyebolt alone:

Disregard of this safety note may lead to accidents with

fatal or serious injuries. ♦ Attach lifting gear securely to the eyebolts on the

synchronising gear (a, 615) and the drive motor

In case the drive motor comes without an eyebolt or the eyebolt on

CAUTION the drive motor is located at an unfavourable position:

Disregard of this safety note may lead to accidents with minor ♦ Loop a belt/rope with suitable length and strength around

injuries or property damage. the flange of the drive motor

• Attach the lifting gear to a crane hook with safety latch

• Lift the vacuum pump with a crane

Safety MM 1324, 1202, 1252, 1322, 1200, 1250, 1320 AV

page 4 0870133276 / 140804

In case the vacuum pump was bolted to a pallet or a base plate:

♦ Remove the stud bolts from the rubber feet

Installation and

Commissioning

Storage

Installation prerequisites

Short-term Storage

CAUTION

• Make sure that the suction connection and the gas discharge

are closed (leave the provided plugs in)

In case of non-compliance with the installation prerequisites,

• Store the vacuum pump particularly in case of insufficient cooling:

− If possible in original packaging, Risk of damage or destruction of the vacuum pump and

adjoining plant components!

− indoors,

− dry, Risk of injury!

− dust free and The installation prerequisites must be complied with.

− vibration free.

• Make sure that the integration of the vacuum pump is carried

out such that the essential safety requirements of the Machine

Conservation Directive 2006/42/EC are complied with (in the responsibility of

the designer of the machinery into which the vacuum pump is

In case of adverse ambient conditions (e.g. aggressive atmosphere, to be incorporated; ➔ page 17: note in the EC-Declaration of

frequent temperature changes) conserve the vacuum pump Conformity)

immediately. In case of favourable ambient conditions conserve the

vacuum pump if a storage of more than 3 months is scheduled.

Mounting Position and Space

• Make sure that all ports are firmly closed; seal all ports that are

not sealed with PTFE-tape, gaskets or o-rings with adhesive • Make sure that the environment of the vacuum pump is not

tape potentially explosive

Note: VCI stands for “volatile corrosion inhibitor”. VCI-products (film, • Make sure that the following ambient conditions will be

paper, cardboard, foam) evaporate a substance that condenses in complied with:

molecular thickness on the packed good and by its electro-chemical

properties effectively suppresses corrosion on metallic surfaces. − ambient temperature: 0 … 40 °C

However, VCI-products may attack the surfaces of plastics and − ambient pressure: atmospheric

elastomers. Seek advice from your local packaging dealer! Busch

uses CORTEC VCI 126 R film for the overseas packaging of large • Make sure that the environmental conditions comply with the

equipment. protection class of the drive motor (according to the nameplate)

• Wrap the vacuum pump in VCI film • Make sure that the vacuum pump will be placed or mounted

horizontally

• Store the vacuum pump

• Make sure that the base for placement / mounting base is even

− If possible in original packaging,

• Make sure that in order to warrant a sufficient cooling there will

− indoors, be a clearance of minimum 1 m between the vacuum pump

− dry, and nearby walls

− dust free and • Make sure that no heat sensitive parts (plastics, wood,

cardboard, paper, electronics) will touch the surface of the

− vibration free. vacuum pump

For commissioning after conservation: • Make sure that the installation space or location is vented such

that a sufficient cooling of the vacuum pump is warranted

• Make sure that all remains of adhesive tape are removed from

the ports

CAUTION

• Commission the vacuum pump as described in the chapter

Installation and Commissioning (➔ page 5)

During operation the surface of the vacuum pump may reach

temperatures of more than 70 °C.

Risk of burns!

• Make sure that the vacuum pump will not be touched

inadvertently during operation, provide a guard if appropriate

• Make sure that the sight glass (e, 76) of the synchronising gear

will remain accessible

In case the synchronising gear oil change is planned to be carried

out on location:

♦ Make sure that the drain port (f, 80) and the filling port (72)

of the synchronising gear will remain easily accessible

MM 1324, 1202, 1252, 1322, 1200, 1250, 1320 AV Installation and Commissioning

0870133276 / 140804 page 5

Suction Connection • Make sure that the line size of the discharge line over the entire

length is at least 2”

In case the length of the discharge line exceeds 2 m it is prudent to

CAUTION use larger line sizes in order to avoid a loss of efficiency and an

overload of the vacuum pump. Seek advice from your Busch

Intruding foreign objects or liquids can destroy the vacuum representative!

pump.

• Make sure that the discharge line either slopes away from the

In case the inlet gas can contain dust or other foreign solid particles: vacuum pump or provide a liquid separator or a drip leg with a

drain cock, so that no liquids can back up into the vacuum

♦ Make sure that a suitable filter (5 micron or less) is pump

installed upstream the vacuum pump

• Make sure that the suction line fits to the suction connection Electrical Connection / Controls

(g/p) of the vacuum pump

• Make sure that the stipulations acc. to the EMC-Directive

• Make sure that the gas will be sucked through a vacuum-tight 2004/108/EC and Low-Voltage-Directive 2006/95/EC as well as

flexible hose or a pipe the EN-standards, electrical and occupational safety directives

and the local or national regulations, respectively, are complied

In case of using a pipe: with (this is the responsibility of the designer of the machinery

♦ Make sure that the pipe will cause no stress on the into which the vacuum pump is to be incorporated; ➔ page 17:

vacuum pump’s connection, if necessary use an note in the EC-Declaration of Conformity).

expansion joint • Make sure that the power supply for the drive motor is

• Make sure that the line size of the suction line over the entire compatible with the data on the nameplate of the drive motor

length is at least as large as the suction connection (g/p) of the • Make sure that an overload protection according to EN 60204-1

vacuum pump is provided for the drive motor

In case the length of the suction line exceeds 2 m it is prudent to use

• Make sure that the drive of the vacuum pump will not be

larger line sizes in order to avoid a loss of efficiency and an overload

affected by electric or electromagnetic disturbance from the

of the vacuum pump. Seek advice from your Busch representative!

mains; if necessary seek advice from the Busch service

In case the vacuum pump shall be maintained after shutdown of the

In case of mobile installation:

vacuum pump:

♦ Provide the electrical connection with grommets that serve

♦ Provide a manual or automatic operated valve (= non-

as strain-relief

return valve) in the suction line

Version “Aqua”, if very humid process gases and/or adverse

operating cycles bear the risk, that condensates remain in the

Installation

vacuum pump:

♦ Provide a shut-off valve, a drip-leg and a drain cock in the

Mounting a NEMA-Motor with BoWex-

suction line, so that condensates can be drained from the Coupling

suction line

For certain markets the vacuum pump is available without motor, but

♦ Provide a valve for the unthrottled suction of ambient air with a NEMA-adaptor flange and a BoWex-coupling.

(ambient air valve) between the shut-off valve and the

vacuum pump (in order to dry the vacuum pump after

process end)

♦ For non ultimate-pressure-proof vacuum pumps provide a

vacuum relief valve (suitable for continuous operation) for

the throttled aspiration of ambient air during warming up

♦ Make sure that the anti-pulsation chamber is equipped

with a condensate drain cock (j) (optional; if the

condensate drain cock is missing contact the Busch

service)

• Make sure that the suction line does not contain foreign

objects, e.g. welding scales

Gas Discharge

The discharged gas must flow without obstruction. It is not

permitted to shut off or throttle the discharge line or to use it as

a pressurised air source.

The following guidelines for the discharge line do not apply, if the • Remove the NEMA-adaptor flange (I) from the vacuum pump

aspirated air is discharged to the environment right at the vacuum

pump. • Pull the elastomer part (V) together with the hub (III) off the

shaft of the vacuum pump

• Make sure that the discharge line fits to the gas discharge (k) of

the vacuum pump • Mount the NEMA-adaptor flange (I) on the motor (the bolts (II)

are not part of the Busch scope of delivery)

In case of using a pipe:

• Undo the cylinder screws (VI) and remove the elastomer

♦ Make sure that the pipe will cause no stress on the part (V) from the hub (III)

vacuum pump’s connection, if necessary use an

expansion joint • Make sure that the parallel key is inserted into the motor shaft

Installation and Commissioning MM 1324, 1202, 1252, 1322, 1200, 1250, 1320 AV

page 6 0870133276 / 140804

• Push the hub (III) onto the motor shaft such that the mounting

face of the hub (III) will be located 16±1 mm before the Connection Scheme Three-Phase Motor

mounting face of the NEMA-adaptor flange (I) (➔ sketch)

Delta connection (low voltage):

• Fasten the hub (III) on the motor shaft using the set screw (IV)

• Apply thread locking agent on the threads of the cylinder

screws (VI)

• Mount the elastomer part (V) on the hub (III) with the cylinder

screws (VI) and tighten the cylinder screws with 14 Nm

• Mount the motor on the vacuum pump

Mounting

• Make sure that the installation prerequisites (➔ page 5) are

complied with

• Set down or mount the vacuum pump at its location Star connection (high voltage):

Checking Synchronising Gear Oil

The vacuum pump is delivered with oil filled synchronising gear.

The level shall be slightly above the middle of the sight glass (e, 76).

• Check on the sight glass (e, 76) that the proper amount of oil is

filled

Connecting Electrically

WARNING Double star connection, multi-voltage motor with 9 terminals (low

voltage):

Risk of electrical shock, risk of damage to equipment.

Electrical installation work must only be executed by

qualified personnel that knows and observes the following

regulations:

- IEC 364 or CENELEC HD 384 or DIN VDE 0100, respectively,

- IEC-Report 664 or DIN VDE 0110,

- BGV A2 (VBG 4) or corresponding national accident

prevention regulation.

CAUTION

Star connection, multi-voltage motor with 9 terminals (high voltage):

The connection schemes given below are typical. Depending on

the specific order or for certain markets deviating connection

schemes may apply.

Risk of damage to the drive motor!

The inside of the terminal box shall be checked for drive motor

connection instructions/schemes.

Note: For the connection of a drive with integrated frequency

inverter see the separate operating instructions!

• Electrically connect the drive motor

• Connect the protective earth conductor Double star connection, multi-voltage motor with 12 terminals (low

voltage):

MM 1324, 1202, 1252, 1322, 1200, 1250, 1320 AV Installation and Commissioning

0870133276 / 140804 page 7

Delta connection, multi-voltage motor with 12 terminals (middle

voltage): Operating Notes

Use

CAUTION

The vacuum pump is designed for operation under the

conditions described below.

In case of disregard risk of damage or destruction of the

vacuum pump and adjoining plant components!

Risk of injury!

Star connection, multi-voltage motor with 12 terminals (high voltage):

The vacuum pump must only be operated under the conditions

described below.

The vacuum pump is intended for

− the suction

of

− air and other dry, non-aggressive, non-toxic and non-explosive

gases

Conveying media with a lower or higher density than air leads to an

increased thermal and/or mechanical load on the vacuum pump and

is permissible only after prior consultation with Busch.

CAUTION

Max. allowed temperature of the inlet gas: 40 °C

Operation in the wrong direction of rotation can destroy the

Standard-version:

vacuum pump in short time

The gas shall be free from vapours that would condensate under

Prior to starting-up it must be made sure that the vacuum pump the temperature and pressure conditions inside the vacuum

is operated in the proper direction (clockwise rotating field). pump.

Version “Aqua”:

Version with three-phase motor:

The vacuum pump features the corrosion protection coating

♦ Determine the intended direction of rotation with the

arrow (c) (stuck on or cast) CPC and is capable of conveying water vapour ➔ page 9:

Conveying Condensable Vapours). Conveyance of other

♦ “Bump” the drive motor vapours shall be agreed upon with Busch. Conveyance of water

or other liquids in liquid phase increases the power consumption

♦ Watch the fan wheel of the drive motor and determine the and shall therefore be avoided (risk of drive overload).

direction of rotation just before the fan wheel stops

The vacuum pump is intended for the placement in a non-potentially

If the rotation must be changed: explosive environment.

♦ Switch any two of the drive motor wires (three-phase Max. permissible number of startings per hour: 12

motor)

Vacuum pumps MM 1324 AV standard-version are thermally

suitable for continuous operation down to ultimate pressure.

Connecting Lines/Pipes

Vacuum pumps MM 1324 AV Version “Aqua” are thermally suitable

• Connect the suction line for continuous operation at intake pressures down to 200 hPa abs

• Connect the discharge line (200 mbar abs). By means of process control and/or vacuum relief

valves it must be made sure that the minimum allowed intake

Installation without discharge line: pressure will not be underrun.

♦ Make sure that the gas discharge (k) is open Vacuum pumps MM 1202 AV, MM 1200 AV, MM 1252 AV and

MM 1250 AV are thermally suitable for continuous operation at

• Make sure that all provided covers, guards, hoods etc. are intake pressures down to 100 hPa abs (100 mbar abs). By means of

mounted process control and/or vacuum relief valves it must be made sure

that the minimum allowed intake pressure will not be underrun.

• Make sure that the cooling air inlets and outlets are not covered

or obstructed and that the cooling air flow is not affected Vacuum pumps MM 1322 AV and MM 1320 AV (version

adversely in any other way 600…3600 min-1) are thermally suitable for continuous operation at

intake pressures down to 150 hPa abs (150 mbar abs). MM 1320 AV

Recording of Operational Parameters (version 600…4200 min-1) are thermally suitable for continuous

operation at intake pressures down to 200 hPa abs (200 mbar abs).

As soon as the vacuum pump is operated under normal operating By means of process control and/or vacuum relief valves it must be

conditions: made sure that the minimum allowed intake pressure will not be

underrun.

• Measure the drive motor current and record it as reference for

future maintenance and troubleshooting work Version “Aqua”:

The safety valve on the vacuum pump protects the vacuum

pump against overheating only. It is not designed for frequent

use and must therefore not be used as a system pressure

regulating valve.

Installation and Commissioning MM 1324, 1202, 1252, 1322, 1200, 1250, 1320 AV

page 8 0870133276 / 140804

Maintenance

CAUTION

During operation the surface of the vacuum pump may reach DANGER

temperatures of more than 70 °C.

In case the vacuum pump conveyed gas that was

Risk of burns! contaminated with foreign materials which are dangerous

to health, harmful material can reside in filters.

The vacuum pump shall be protected against contact during

operation, it shall cool down prior to a required contact or heat Danger to health during inspection, cleaning or

protection gloves shall be worn. replacement of filters.

Danger to the environment.

CAUTION Personal protective equipment must be worn during the

handling of contaminated filters.

The vacuum pump emits noise of high intensity in a narrow

band. Contaminated filters are special waste and must be

disposed of separately in compliance with applicable

Risk of damage to the hearing. regulations.

Persons staying in the vicinity of a non noise insulated vacuum

pump over extended periods shall wear ear protection. CAUTION

• Make sure that all provided covers, guards, hoods etc. remain During operation the surface of the vacuum pump may reach

mounted temperatures of more than 70 °C.

• Make sure that protective devices will not be disabled Risk of burns!

• Make sure that cooling air inlets and outlets will not be covered

or obstructed and that the cooling air flow will not be affected • Prior to disconnecting connections make sure that the

adversely in any other way connected pipes/lines are vented to atmospheric pressure

• Make sure that the installation prerequisites (➔ page 5:

Installation Prerequisites) are complied with and will remain Maintenance Schedule

complied with, particularly that a sufficient cooling will be

ensured Note: The maintenance intervals depend very much on the

individual operating conditions. The intervals given below shall be

considered as starting values which should be shortened or

Conveying Condensables Vapours extended as appropriate.

Particularly heavy duty operation, such like high dust loads in the

Version “Aqua”: environment or in the process gas, other contaminations or ingress

of process material, can make it necessary to shorten the

maintenance intervals significantly.

CAUTION

Due to the corrosion protection coating CPC the vacuum pump Monthly

is capable of conveying water vapour.

• Make sure that the vacuum pump is shut down and locked

against inadvertent start up

Very humid process gases and/or adverse operating cycles can

lead to residual condensates, though, which cause corrosion. In case an inlet air filter (h) is installed:

If this is the case, it is necessary to counteract residual ♦ Check the inlet air filter (h), if necessary replace

condensates by warming up the vacuum pump, conveyance of In case of operation in a dusty environment:

ambient air after process end and regular draining of the anti-

pulsation chamber ♦ Clean as described under ➔ page 9: Every 6 Months

♦ Close the shut-off valve in the suction line Every 3 Months:

♦ Warm up the vacuum pump for approx. 10 minutes • Make sure that the vacuum pump is shut down and locked

At process start: against inadvertent start up

♦ Open the shut-off valve in the suction line • Check the level and the colour of the synchronising gear oil

At the process end: The level shall be slightly above the middle of the sight glass (e, 76).

♦ Close the shut-off valve in the suction line The level of the synchronising gear should stay constant over the

lifetime of the oil. If the level does fall, the gear is leaky and the

♦ Open the ambient air valve vacuum pump requires repair (Busch service).

♦ Operate the vacuum pump for another approx. 10 minutes

Every 6 Months:

♦ Close the ambient air valve

• Make sure that the housing is free from dust and dirt, clean if

♦ Regularly drain condensate from the anti-pulsation necessary

chamber (j)

• Make sure that the vacuum pump is shut down and locked

against inadvertent start up

• Remove the acoustic enclosure

MM 1324, 1202, 1252, 1322, 1200, 1250, 1320 AV Maintenance

0870133276 / 140804 page 9

Note: Make sure that the foam mats do n o t get soaked with water • Dispose of the used oil in compliance with applicable

regulations

• Clean the fan cowlings, fan wheels, the ventilation grilles and

cooling fins

• Mount the acoustic enclosure Overhaul

Every Year:

CAUTION

• Make sure that the vacuum pump is shut down and locked

against inadvertent start up In order to achieve best efficiency and a long life the vacuum

pump was assembled and adjusted with precisely defined

In case an inlet air filter (h) is installed:

tolerances.

♦ Replace the inlet air filter (h)

This adjustment will be lost during dismantling of the vacuum

• Check the inlet screen (715), clean if necessary pump.

Every 20000 Operating Hours, At the Latest after It is therefore strictly recommended that any dismantling of the

vacuum pump that is beyond of what is described in this manual

6 Years:

shall be done by Busch service.

Note: The change interval of 20000 operating hours is valid for

Busch approved gear oils only. The change interval depends very

much on the operating conditions. Borderline operation may reduce DANGER

the change interval down to approximately 5000 operating hours or

6 months. Other gear oils may reduce the change interval. In case the vacuum pump conveyed gas that was

contaminated with foreign materials which are dangerous

Changing Synchronising Gear Oil to health, harmful material can reside in pores, gaps and

internal spaces of the vacuum pump.

• Make sure that the vacuum pump is shut down and locked

against inadvertent start up Danger to health during dismantling of the vacuum pump.

Danger to the environment.

Prior to shipping the vacuum pump shall be

decontaminated as good as possible and the contamination

status shall be stated in a “Declaration of Contamination”

(form downloadable from www.busch-vacuum.com).

Busch service will only accept vacuum pumps that come with a

completely filled in and legally binding signed “Declaration of

Contamination” (form downloadable from www.busch-vacuum.com).

Removal from Service

Temporary Removal from Service

• Prior disconnecting pipes/lines make sure that all pipes/lines

are vented to atmospheric pressure

• Remove the eyebolt (a, 615) Recommissioning

• Remove the lid (424) • Observe the chapter Installation and Commissioning

(➔ page 5)

• Undo the venting valve (72) for venting

• Place a drain tray underneath the drain plug (f, 80) Dismantling and Disposal

• Open the drain plug (f, 80) and drain the oil

• Make sure that the seal ring on the drain plug (f, 80) is DANGER

serviceable, replace if necessary

In case the vacuum pump conveyed gas that was

• Firmly reinsert the drain plug (f, 80) together with the seal ring contaminated with foreign materials which are dangerous

• Remove the venting valve (72) completely to health, harmful material can reside in pores, gaps and

internal spaces of the vacuum pump.

• Fill in new gear oil until the level is slightly above the middle of

the sight glass (e, 76) Danger to health during dismantling of the vacuum pump.

• Make sure that the seal ring on the venting valve (72) is Danger to the environment.

undamaged, if necessary replace the venting valve (72)

During dismantling of the vacuum pump personal

• Firmly reinsert the venting valve (72) together with the seal ring

protective equipment must be worn.

• Mount the lid (424)

The vacuum pump must be decontaminated prior to

• Reinsert the eyebolt (a, 615) disposal.

Overhaul MM 1324, 1202, 1252, 1322, 1200, 1250, 1320 AV

page 10 0870133276 / 140804

• Drain the oil

• Make sure that materials and components to be treated as

special waste have been separated from the vacuum pump

• Make sure that the vacuum pump is not contaminated with

harmful foreign material

According to the best knowledge at the time of printing of this

manual the materials used for the manufacture of the vacuum pump

involve no risk.

• Dispose of the used oil in compliance with applicable

regulations

• Dispose of the vacuum pump as scrap metal

MM 1324, 1202, 1252, 1322, 1200, 1250, 1320 AV Removal from Service

0870133276 / 140804 page 11

Troubleshooting

WARNING

Risk of electrical shock, risk of damage to equipment.

Electrical installation work must only be executed by qualified personnel that knows and observes the following regulations:

- IEC 364 or CENELEC HD 384 or DIN VDE 0100, respectively,

- IEC-Report 664 or DIN VDE 0110,

- BGV A2 (VBG 4) or corresponding national accident prevention regulation.

CAUTION

During operation the surface of the vacuum pump may reach temperatures of more than 70 °C.

Risk of burns!

Let the vacuum pump cool down prior to a required contact or wear heat protection gloves.

Problem Possible Cause Remedy

The vacuum pump does not reach the usual The vacuum system or suction line is not leak- Check the hose or pipe connections for

pressure tight possible leak

The drive motor draws a too high current

(compare with initial value after

commissioning)

Evacuation of the system takes too long

In case a vacuum relief valve/regulating Adjust, repair or replace, respectively

system is installed:

The vacuum relief valve/regulating system is

misadjusted or defective

The screen (715) in the suction connection Clean the screen (715)

(g/p) is partially clogged

If cleaning is required too frequently install a

filter upstream

In case a filter (h) is installed on the suction Clean or replace the inlet air filter (h),

connection (g/p): respectively

The filter (h) on the suction connection (g/p)

is partially clogged

Partial clogging in the suction, discharge or Remove the clogging

pressure line

Long suction, discharge or pressure line with Use larger diameter

too small diameter

The valve disk of the inlet non-return valve is Disassemble the inlet, clean the screen (715)

stuck in closed or partially open position and the valve (o, 714) as required and

reassemble

Internal parts are worn or damaged Repair the vacuum pump (Busch service)

The gas conveyed by the vacuum pump Process components evaporating under Check the process, if applicable

smells displeasing vacuum

The vacuum pump does not start The drive motor is not supplied with the Supply the drive motor with the correct voltage

correct voltage or is overloaded

The drive motor starter overload protection is Compare the trip level of the drive motor

too small or trip level is too low starter overload protection with the data on the

nameplate, correct if necessary

In case of high ambient temperature: set the

trip level of the drive motor starter overload

protection 5 percent above the nominal drive

motor current

One of the fuses has blown Check the fuses

The connection cable is too small or too long Use sufficiently dimensioned cable

causing a voltage drop at the vacuum pump

Troubleshooting MM 1324, 1202, 1252, 1322, 1200, 1250, 1320 AV

page 12 0870133276 / 140804

The vacuum pump or the drive motor is Make sure the drive motor is connected from

blocked the power supply

Remove the fan cover

Try to turn the drive motor with the vacuum

pump by hand

If the unit is still frozen: remove the drive

motor and check the drive motor and the

vacuum pump separately

If the vacuum pump is blocked:

Repair the vacuum pump (Busch service)

The drive motor is defective Replace the drive motor (Busch service)

(the proper function of the fan wheel requires

the precise adjustment of the coupling on the

motor shaft and the pump shaft; therefore the

motor can be mounted by the Busch service

only)

The vacuum pump is blocked Solid foreign matter has entered the vacuum Repair the vacuum pump (Busch service)

pump

Make sure the suction line is equipped with a

screen

If necessary additionally provide a filter

Corrosion in the vacuum pump from remaining Repair the vacuum pump (Busch service)

condensate

Check the process

Observe the chapter Conveying Condensable

Vapours (➔ page 9)

Version with three-phase motor: Repair the vacuum pump (Busch service)

The vacuum pump was run in the wrong When connecting the vacuum pump make

direction sure the vacuum pump will run in the correct

direction (➔ page 6 Installation)

The drive motor is running, but the vacuum The coupling between the drive motor and the Replace the coupling element

pump stands still vacuum pump is defective

(the proper function of the fan wheel requires

the precise adjustment of the coupling on the

motor shaft and the pump shaft; therefore the

motor can be mounted by the Busch service

only)

The vacuum pump starts, but labours or runs Loose connection(s) in the drive motor Check the proper connection of the wires

noisily or rattles terminal box against the connection diagram

The drive motor draws a too high current Version with three-phase motor: (particularly on motors with six coils)

(compare with initial value after

commissioning) Not all drive motors coils are properly Tighten or replace loose connections

connected

The drive motor operates on two phases

only

Version with three-phase motor: Verification and rectification ➔ page 5:

Installation and Commissioning

The vacuum pump runs in the wrong direction

Foreign objects in the vacuum pump Repair the vacuum pump (Busch service)

Stuck bearings

The vacuum pump runs very noisily Defective bearings Repair the vacuum pump (Busch service)

Worn coupling element Replace the coupling element

Low oil level in the synchronising gear The synchronising gear is leaky

Repair the vacuum pump (Busch service)

Synchronising gear damaged due to operation Repair the vacuum pump (Busch service)

with low oil level

MM 1324, 1202, 1252, 1322, 1200, 1250, 1320 AV Troubleshooting

0870133276 / 140804 page 13

The vacuum pump is very hot Insufficient air ventilation Make sure that the cooling of the vacuum

pump is not impended by dust/dirt

Clean the fan cowlings, the fan wheels, the

ventilation grilles and the cooling fins

Install the vacuum pump in a narrow space

only if sufficient ventilation is ensured

Ambient temperature too high Observe the permitted ambient temperatures

Temperature of the inlet gas too high Observe the permitted temperatures for the

inlet gas

Mains frequency or voltage outside tolerance Provide a more stable power supply

range

Partial clogging of filters or screens Remove the clogging

Partial clogging in the suction, discharge or

pressure line

Long suction, discharge or pressure line with Use larger diameter

too small diameter

Troubleshooting MM 1324, 1202, 1252, 1322, 1200, 1250, 1320 AV

page 14 0870133276 / 140804

Sectional Drawing

MM 1324, 1202, 1252, 1322, 1200, 1250, 1320 AV Sectional Drawing

0870133276 / 140804 page 15

81 Seal ring for plug with magnet 1 0482 137 352

Spare Parts Inlet flange, lower part,

714 1 0915 000 670

Note: When ordering spare parts or accessories acc. to the table with non-return valve

below please always quote the type (“Type”) and the serial no.

(“No”) of the vacuum pump. This will allow Busch service to check if 715 Screen 1 0534 000 041

the vacuum pump is compatible with a modified or improved part. Filter cartridge, paper, for inlet

- 1 0532 000 004

The exclusive use of the genuine spare parts and consumables filter (optional)

is a prerequisite for the proper function of the vacuum pump Filter cartridge, polyester, for inlet

and for the granting of warranty, guarantee or goodwill. - 1 0532 121 864

filter (optional)

Your point of contact for service and spare parts in the United

Kingdom:

Busch (UK) Ltd.

Spare parts Kits

Hortonwood 30-35

Telford Spare parts kit Part no.

Shropshire

TF1 7YB Overhaul kit (incl. set of seals, marking “VT” and

0993 134 022

Tel: 01952 677 432 “DT”; insert for flexible coupling for Rotex only)

Fax: 01952 677 423 Set of seals (marking “DT”) 0990 134 021

Your point of contact for service and spare parts in Ireland:

Busch Ireland Ltd.

A10-11 Howth Junction Business Centre

Accessories

Kilbarrack, Dublin 5

Tel: +353 (0)1 8321466 Accessories Description Part no.

Fax: +353 (0)1 8321470

inlet-side, horizontal,

Your point of contact for service and spare parts in the USA: Inlet air filter with paper cartridge, to 0945 000 071

separate solids

Busch Inc.

516-B Viking Drive to protect against solids

Virginia Beach, VA 23452 Liquid and dust

and liquids on the 0962 117 387

Tel: 1-800-USA-PUMP (872-7867) separator STF 0250

suction side

Your point of contact for service and spare parts in Canada: to protect against

Liquid separator

Busch Vacuum Technics Inc. condensate and liquids 0965 117 784

LSS 0250

1740, Boulevard Lionel Bertrand on the suction side

Boisbriand (Montréal) to protect against

Québec J7H 1N7 Liquid separator condensate and liquids

Tel: 450 435 6899 0965 117 780

LSA 0250 on the suction side, with

Fax: 450 430 5132 automatic draining

Your point of contact for service and spare parts in Australia:

Busch Australia Pty. Ltd.

30 Lakeside Drive

Oil

Broadmeadows, Vic. 3047

Tel: (03) 93 55 06 00 Denomination VS150

Fax: (03) 93 55 06 99

ISO-VG 150

Your point of contact for service and spare parts in New Zealand:

Base PAO

Busch New Zealand Ltd.

Unit D, Arrenway Drive Density [g/cm³] 0.846

Albany, Auckland 1311

Kinematic viscosity at 40 °C 150

P O Box 302696

[mm²/s]

North Harbour, Auckland 1330

Tel: 0-9-414 7782 Kinematic viscosity at 100 °C 19.8

Fax: 0-9-414 7783 [mm²/s]

Find the list of Busch companies all over the world (by the time of Flashpoint [°C] 236

the publication of these installation and operating instructions) on

➔ page 20 (rear cover page). Pourpoint [°C] -54

Find the up-to-date list of Busch companies and agencies all over Part number 1 l packaging 0831 164 883

the world on the internet at www.buschvacuum.com.

Part number 5 l packaging 0831 164 884

Filling quantity, approx. [l] 1

Pos. Part Qty Part no.

72 Venting valve (=oil fill plug) with 1

0543 107 407

seal ring

76 Sight glass 1 0583 000 001

77 Seal ring for sight glass 1 0480 000 271

80 Plug with magnet and seal ring 1 0415 134 870

Spare Parts MM 1324, 1202, 1252, 1322, 1200, 1250, 1320 AV

page 16 0870133276 / 140804

EC-Declaration of Conformity

Note: This Declaration of Conformity and the -mark affixed to the nameplate are valid for the vacuum pump within the Busch-scope of delivery.

When this vacuum pump is integrated into a superordinate machinery the manufacturer of the superordinate machinery (this can be the operating

company, too) must be conduct the conformity assessment process acc. to the Directive Machinery 2006/42/EC for the superordinate machine,

issue the Declaration of Conformity for it and affix the -mark.

For maintenance of this Declaration of Conformity of vacuum pumps without a drive may only be used a drive with awritten consent of Busch.

We

Busch Produktions GmbH

Schauinslandstr. 1

79689 Maulburg

Germany

Declare that the vacuum pumps MM 1324, 1202, 1252, 1322, 1200, 1250, 1320 AV

In accordance with the European Directives:

− “Machinery” 2006/42/EC,

− “Electromagnetic Compatibility” 2004/108/EC,

Have been designed and manufactured to the following specifications:

Standard Title of the Standard

Harmonised Standards

EN ISO 12100 Safety of machinery –General principles for design –Risk assessment and risk reduction

EN ISO 13857 Safety of machinery - Safety distances to prevent hazard zones being reached ba the upper and lower limbs

EN 1012-1 Compressors and vacuum pumps - Safety requirements - Part 1 and 2

EN 1012-2

EN ISO 2151 Acoustics - Noise test code for compressors and vacuum pumps - Engineering method (grade 2)

EN 60204-1 Safety of machinery - Electrical equipment of machines - Part 1: General requirements

EN 61000-6-1 Electromagnetic compatibility (EMC) - Generic immunity standards

EN 61000-6-2

EN 61000-6-3 Electromagnetic compatibility (EMC) - Generic immunity standards

EN 61000-6-4

Manufacturer Person authorized to compile

the technical file

Dr.-Ing. Karl Busch Andrej Riwe

General Director Technical writer

Maulburg, 04.08.2014

MM 1324, 1202, 1252, 1322, 1200, 1250, 1320 AV EC-Declaration of Conformity

0870133276 / 140804 page 17

Technical Data

For motor connection parameters see nameplate

Synchronising gear oil filled ex-works

Sound pressure level (EN ISO 2151)

Ultimate pressure standard version

Ultimate pressure version “Aqua”

Ambient temperature range

Synchronising gear oil qty

Nominal suction capacity

at 400 hPa (=mbar) abs.

suction pressure [db(A)]

[hPa abs = mbar abs]

[hPa abs = mbar abs]

Nominal motor rating

Ambient pressure

Nominal speed

Frequency

Weight

[min-1]

[m3/h]

[kW]

Type

[Hz]

[kg]

[°C]

[l]

3.0

50 1500 160 70 ~250

MM 1324 AV 60 200* 4.0

… 280

60 4.2 1800 192 74

4.2

50 3000 200 75

4.3

MM 1202 AV ~235

5.2

60 3600 240 79

100* 5.5

5.0

see nameplate

50 3000 250 75 ~240

atmospheric

MM 1252 AV 5.1

… 285

0 … 40

60 6.8 3600 300 79

1

6.0

50 3000 300 77 ~275

MM 1322 AV 150* 6.0

… 310

60 6.5 3600 360 82

max. ~240

MM 1200 AV

240

100* 5.5 79

600- max. ~250

MM 1250 AV

3600** 300

50/60

max.

MM 1320 AV 150* 8.1 82

360

~310

600- max.

MM 1320 AV 200* 8.1 86

4200** 420

*to be limited by means of process control and/or vacuum relief valves

**see nameplate of the vacuum pump

Technical Data MM 1324, 1202, 1252, 1322, 1200, 1250, 1320 AV

page 18 0870133276 / 140804

MM 1324, 1202, 1252, 1322, 1200, 1250, 1320 AV blank page

0870133276 / 140804 page 19

Busch - All over the World in Industry www.buschvacuum.com

Argentina France Italy Singapore

Busch France S.A.S. Busch Italia S.r.l. Busch Vacuum Singapore Pte Ltd

Busch Argentina S.R.L.

16, Rue du Bois Chaland Via Ettore Majorana, 16 20 Shaw Road

Santo Domingo 3076 20054 Nova Milanese

91090 Lisses Unit 01-03 Ching Shine Building

C1293AGN-Capital Federal Tel: +33 16989 8989 Tel: +39 0362 370 91

Buenos Aires Singapore 367956

Fax: +33 16989 8958 Fax: +39 0362 370 999 Tel: +65 6488 0866

Tel: +54 11 4302 8183 e-mail: busch@busch.fr e-mail: info@busch.it Fax: +65 6288 0877

Fax: +54 11 4301 0896

e-mail: busch@busch.com.sg

e-mail: info@busch-vacuum.com.ar Germany Japan

Dr.-Ing. K. Busch GmbH Nippon Busch K.K.

Australia Schauinslandstr. 1 1-23-33, Megumigaoka South Africa

Busch Australia Pty. Ltd. 79689 Maulburg Hiratsuka City, Kanagawa Busch Vacuum South Africa (Pty) Ltd.

30 Lakeside Drive Tel: +49 76 22 6 81-0 Japan 259-1220 Denver

Broadmeadows, Vic. 3047 Fax: +49 76 22 6 81-194 Tel: +81 463-50-4000 Johannesburg

Tel: +61 3 93 55 06 00 e-mail: info@busch.de Fax: +81 463-50-4004 Tel: +27 11 856 0650/6

Fax: +61 3 93 55 06 99 e-mail: info@busch.co.jp Fax: +27 11 856 0625

e-mail: sales@busch.com.au Dr.-Ing. K. Busch GmbH e-mail: joe.jagger@busch.co.za

Niederlassung Nord Korea

Austria Ernst-Abbe-Str. 1-3 Busch Korea Ltd.

25451 Quickborn 248-2, Ichi-ri, Majang-Myun, Spain

Busch Austria GmbH

Industriepark Nord Tel: +49 41 06 7 99 67-0 Icheon-si, Kyunggi-Do Busch Ibérica S.A.

2100 Korneuburg Fax: +49 41 06 7 99 67-77 Tel: +82 31 321 8114 Pol. Ind. Coll de la Manya

Tel: +43 2262 / 756 65-0 Fax: +82 31 321 8877 C/ Jaume Ferran, 6-8

Fax: +43 2262 / 756 65-20 e-mail: busch@buschkorea.co.kr 08403 Granollers

Dr.-Ing. K. Busch GmbH Tel: +34 93 861 61 60

e-mail: busch@busch.at Niederlassung West Malaysia Fax: +34 93 840 91 56

Nordring 35 e-mail: busch@buschib.es

Belgium 64807 Dieburg Busch Malaysia Sdn Bhd.

4&6, Jalan Taboh 33/22, Seksyen 33

Busch N.V. Kruinstraat 7 Tel: +49 60 71 92 82-0

Shah Alam Technology Park Sweden

9160 Lokeren Fax: +49 60 71 14 71

40400 Shah Alam

Tel: +32 9 / 348 47 22

Dr.-Ing. K. Busch GmbH Selangor Darul Ehsan Busch Vakuumteknik AB

Fax: +32 9 / 348 65 35

Außenstelle Neuenrade Tel: +60 3 5122 2128 Bråta Industriområde

e-mail: info@busch.be

Breslauer Str. 36 Fax +60 3 5122 2108 435 33 Mölnlycke

58809 Neuenrade e-mail: busch@busch.com.my Tel: +46 31-338 00 80

Brazil Fax: +46 31-338 00 89

Tel: +49 23 92 50 29 92

Busch do Brasil Ltda. Fax: +49 23 92 50 72 11 Mexico e-mail: info@busch.se

Rod. Edgard Máximo Zambotto, Km 64 Busch Vacuum Mexico S. de R.L. de C.V.

13240-000 Jarinu-SP Dr.-Ing. K. Busch GmbH Tlaquepaque 4865, Los Altos

Tel: +55 11-4016 1400/5277 Niederlassung Süd-Ost

Switzerland

Monterrey, Nuevo Leon

Fax: +55 11-4016 5399 Gewerbestraße 3 Mexico 64370 Busch AG Waldweg 22

e-mail: vendas@buschdobrasil.com.br 90579 Langenzenn Tel: +52 81 8311-1385 4312 Magden

Tel: +49 91 01 90 25-0 Fax: +52 81 8311-1386 Tel: +41 61 / 845 90 90

Canada Fax: +49 91 01 90 25-25 e-mail: info@busch.com.mx Fax: +41 61 / 845 90 99

Busch Vacuum Technics Inc. e-mail: info@buschag.ch

1740, Lionel Bertrand Dr.-Ing. K. Busch GmbH Netherlands

Boisbriand, Québec J7H 1N7 Außenstelle Zella-Mehlis

Busch B.V. Pompmolenlaan 2 Taiwan

Tel: +1 450 435 6899 Am Rain 11

3447 GK Woerden

Fax: +1 450 430 5132 98544 Zella-Mehlis Busch Taiwan Corporation

Tel: +31 348-462300

e-mail: info@busch.ca Tel: +49 36 82 46 92 71 1F. No. 69, Sec. 3, Beishen Road

Fax: +31 348-422939

Fax: +49 36 82 46 92 73 Shenkeng Township,

e-mail: info@busch.nl

Chile Dr.-Ing. K. Busch GmbH

Taipei County 222

Busch Chile S. A. New Zealand Tel: +886 2 2662 0775

Außenstelle Meitingen-Ostendorf

Calle El Roble N° 375-G Busch New Zealand Ltd. Fax: +886 2 2662 0796

Grüntenweg 8

Lampa - Santiago Unit D, 41 Arrenway Drive e-mail: info@busch.com.tw

86405 Meitingen-Ostendorf

Tel: +56 2 3765136 Tel: +49 82 71 426-341 Albany, Auckland 1330

Fax: +56 2 7387092 Fax: +49 82 71 426-342 Tel: +64 9 414 7782 Thailand

e-mail: info@busch.cl Fax: +64 9 414 7783

e-mail: sales@busch.co.nz Busch Vacuum (Thailand) Co., Ltd.

China Hungary 888/30 Moo19, Soi Yingcharoen,

Norway Bangplee-Tamru Road,

Busch Vacuum (Shanghai) Co., Ltd Busch Vacuum Kft. Bangpleeyai, Bangplee,

No.5, Lane 195 Xipu Road Bentonit u. 8 Busch Vakuumteknikk AS Samutprakarn 10540

Songjiang Industrial Estate East New Zone 1225 Budapest Hestehagen 2 Tel: +66 2-382-5428

Shanghai 201611 PRC Tel: +36 1 207 6135 1440 Drøbak Fax: +66 2-382-5429

Tel: +86 (0)21 67600800 Fax: +36 1 207 6136 Tel: +47 64 98 98 50 e-mail: info@busch.co.th

Fax: +86 (0)21 67600700 e-mail: busch@busch-vacuum.hu Fax: +47 64 93 66 21

e-mail: busch@busch-china.com e-mail: busch@busch.no

India Turkey

Czech Republic Busch Vacuum India Pvt Ltd.

Poland VAKUTEK

Busch Vakuum s.r.o. Plot No. 110, Sector 7 Busch Polska Sp. z o.o. Emlak Kredi Ishani No: 179

PraZákova 10 PCNTDA, Bhosari Ul. Chopina 27 34672 Üsküdar-Istanbul

619 00 Brno-Horní Heršpice Pune 411026 87-800 W toctawek Tel: +90 216 310 0573

Tel: +420 543 42 48 55 Tel: +91 206410 2886 Tel: +48 54 2315400 Fax: +90 216 343 5126

Fax: +420 543 42 48 56 Fax: +91 202711 2838 Fax: +48 54 2327076 e-mail: vakutek@ttnet.net.tr

e-mail: info@buschpumps.cz e-mail: sales@buschindia.com e-mail: busch@busch.com.pl

Denmark Ireland Portugal United Kingdom

Busch Vakuumteknik A/S Parallelvej Busch Ireland Ltd. Busch Ibérica S.A., Sucursal em Portugal Busch (UK) Ltd

11 A10-11 Howth Junction Business Centre Zona Industrial Norte, Fracção B, Armazém 2 Hortonwood 30

8680 Ry Kilbarrack, Dublin 5 3750-753 Raso de Travassô - Agueda Telford Shropshire TF1 7YB

Tel: +45 87 88 07 77 Tel: +353 1 832 1466 Aveiro, Portugal Tel: +44 1952 677 432

Fax: +45 87 88 07 88 Fax: +353 1 832 1470 Tel: +351 234 648 070 Fax: +44 1952 677 423

e-mail: info@busch.dk e-mail: sales@busch.ie Fax: +351 234 648 068 e-mail: sales@busch.co.uk

e-mail: geral@buschib.pt

Finland Israel USA

Russia

Busch Vakuumteknik Oy Busch Israel Ltd. Busch Vacuum Russia OOO Busch LLC

Sinikellontie 4 1 Mevo Sivan Street

Kotlyakovskaya str., 6/9 516-B Viking Drive

01300 Vantaa Qiryat Gat 82022, Israel

115201 Moscow Virginia Beach, VA 23452

Tel: +358 9 774 60 60 Tel: +972 (0)8 6810485

Tel: +7 495 6486726 Tel: +1 757 463-7800

Fax: +358 9 774 60 666 Fax +972 (0)8 6810486

Fax: +7 495 6486724 Fax: +1 757 463 7407

e-mail: info@busch.fi e-mail: service_sales@busch.co.il

e-mail: info@busch.ru e-mail: marketing@buschusa.com

Busch - All over the World in Industry

page 20

0870133276

You might also like

- Kaeser Compressor Sigma Control ManualDocument154 pagesKaeser Compressor Sigma Control Manualsancsa_7483% (12)

- SF3015G3 Ipg1500wDocument22 pagesSF3015G3 Ipg1500wCelia AfonsoNo ratings yet

- GHS 730VSD User ManualDocument124 pagesGHS 730VSD User ManualRenārs BērtiņšNo ratings yet

- Model 2000 Parts List PDFDocument36 pagesModel 2000 Parts List PDFCarlos TorradoNo ratings yet

- Secador TZE 650 - 500Document51 pagesSecador TZE 650 - 500nestor coaquiraNo ratings yet

- GD D807 Blower PartsDocument2 pagesGD D807 Blower PartsManuelG.CastilloR.No ratings yet

- Busch Instruction Manual Mink MM 1104-1142 BV ATEX Gastight en 0870141675Document56 pagesBusch Instruction Manual Mink MM 1104-1142 BV ATEX Gastight en 0870141675Vinícius BardellaNo ratings yet

- Compressor Controller E-Log - Parameters Adjusting.: For Distributors Use Only!Document1 pageCompressor Controller E-Log - Parameters Adjusting.: For Distributors Use Only!Renārs BērtiņšNo ratings yet

- Paul Foster Case - 32 Paths Lessons 1-17 - 1950 PDFDocument316 pagesPaul Foster Case - 32 Paths Lessons 1-17 - 1950 PDFGracchus Dionysus100% (20)

- Installation and Operating Instructions: ATEX-VersionDocument56 pagesInstallation and Operating Instructions: ATEX-VersionJORGE OTALORANo ratings yet

- Quincy QT Series Model QT-5Document18 pagesQuincy QT Series Model QT-5mkaukolaNo ratings yet

- Roto Z Fluid enDocument2 pagesRoto Z Fluid enвлад камрNo ratings yet

- ARO Ac Controllers enDocument6 pagesARO Ac Controllers enemre_bozkurtNo ratings yet

- Manual de Pecas CompressorDocument196 pagesManual de Pecas Compressorpablo da silva oliveiraNo ratings yet

- ABAC Formula 5.5 22kWDocument6 pagesABAC Formula 5.5 22kW1976gt500No ratings yet

- Start C PDFDocument16 pagesStart C PDFRomanCHubaNo ratings yet

- Manual de PartesDocument56 pagesManual de PartesFernando Fernandez100% (1)

- Compresores A TornilloDocument10 pagesCompresores A TornilloGerardo Bois100% (1)

- EC Centrifugal Module: K3G630-AB21-02Document6 pagesEC Centrifugal Module: K3G630-AB21-02Sharath KotaNo ratings yet

- P37 To P275 High Pressure Piston Air Compressor English Tcm795-3514985Document12 pagesP37 To P275 High Pressure Piston Air Compressor English Tcm795-3514985Jozsef MagyariNo ratings yet

- BOM EB-421C Parte EBC.2 Serie 1511-1512Document7 pagesBOM EB-421C Parte EBC.2 Serie 1511-1512José Guillermo Càrdenas Hernandez100% (1)

- Ficha TecnicaDocument4 pagesFicha TecnicaRodrigo LeónNo ratings yet

- Aib Ga30-55cDocument42 pagesAib Ga30-55cJose CoelhoNo ratings yet

- Listado Filtros CompresoresDocument224 pagesListado Filtros CompresoresDiana MuñozNo ratings yet

- L-Series Single Stage Base-Mounted and Tank Mounted CompressorsDocument92 pagesL-Series Single Stage Base-Mounted and Tank Mounted CompressorsJorge Luis Galezo Muñoz100% (1)

- Etaline SYTDocument52 pagesEtaline SYTjprakashusNo ratings yet

- Ba 155 GBDocument56 pagesBa 155 GBdubarNo ratings yet

- Atlas Copco 17.01.2020Document1 pageAtlas Copco 17.01.2020osteanuNo ratings yet

- Filtro Por Modelo de CompresorDocument101 pagesFiltro Por Modelo de Compresorcasa casaNo ratings yet

- Optaf Option Board Manual Spx9000 Vfds 99856Document40 pagesOptaf Option Board Manual Spx9000 Vfds 99856Juracy Carneiro de MenezesNo ratings yet

- QPNC0300, QPNC0360, QPNC0500, QPNC0600: Air Dryer Parts ListDocument15 pagesQPNC0300, QPNC0360, QPNC0500, QPNC0600: Air Dryer Parts ListJose VidalNo ratings yet

- Compressor MSW 60 Max Two Stages 175 PsigDocument2 pagesCompressor MSW 60 Max Two Stages 175 PsigJoel Leandro Ibarra CoriaNo ratings yet

- Esm 2,3,4,5Document28 pagesEsm 2,3,4,5Tina ManousiNo ratings yet

- FX 400-2000Document8 pagesFX 400-2000francisco jose arruda de sousaNo ratings yet

- NEW SILVER 5.5-10 230-400-50-60 20-07-2017 1127340125 ING PartsDocument15 pagesNEW SILVER 5.5-10 230-400-50-60 20-07-2017 1127340125 ING PartsCarlos Ferreira100% (1)

- Spare Part List HC HCL HCH 6100 8100Document28 pagesSpare Part List HC HCL HCH 6100 8100yoye1968100% (1)

- Parts List QPNC 75 To QPNC 250Document12 pagesParts List QPNC 75 To QPNC 250Javier CevallosNo ratings yet

- User'S, Maintenance and Spare Parts Manual: Refrigerating Air DryerDocument67 pagesUser'S, Maintenance and Spare Parts Manual: Refrigerating Air DryerValentin Bogdan100% (1)

- Catalog Donaldson EngDocument10 pagesCatalog Donaldson EngLatDatNo ratings yet

- Ingersoll Rand System Automation X4I Operator's Manual: More Than Air. AnswersDocument68 pagesIngersoll Rand System Automation X4I Operator's Manual: More Than Air. AnswersIRWIN_DSOUZANo ratings yet

- CAGI RS37i-A125Document1 pageCAGI RS37i-A125Marco ChablaNo ratings yet

- DMC Dryer Controller: Models Available DMC 11 DMC 14 DMC 15 With ProbesDocument1 pageDMC Dryer Controller: Models Available DMC 11 DMC 14 DMC 15 With ProbesPradeep Jha100% (1)

- Catálogo de Secadores de AireDocument12 pagesCatálogo de Secadores de AiredavidnpsNo ratings yet

- BD480 Onwards APF156 875Document28 pagesBD480 Onwards APF156 875jackyt09No ratings yet

- Stock List PDFDocument4 pagesStock List PDFAL Wahid SpareNo ratings yet

- Operating Instructions: Belt-Driven Screw Compressors S 40-2 ... S 341 SF 40-2 ... SF 220 SeriesDocument72 pagesOperating Instructions: Belt-Driven Screw Compressors S 40-2 ... S 341 SF 40-2 ... SF 220 SeriesmatrixtnNo ratings yet

- Quincy Compressor Model 325Document39 pagesQuincy Compressor Model 325gonzalobovedaNo ratings yet

- Bearing-Conn Rod Kit PDFDocument1 pageBearing-Conn Rod Kit PDFKapil TiwariNo ratings yet

- NCA 25-24 GSD, Apr 2008Document50 pagesNCA 25-24 GSD, Apr 2008HernanNo ratings yet

- Hes 1250 2015Document74 pagesHes 1250 2015SAUL OSPINONo ratings yet

- ZE4 APFS902571ASLv00Document217 pagesZE4 APFS902571ASLv00MARKNo ratings yet

- Edwards Rv8 Vacuum Pump ManualDocument58 pagesEdwards Rv8 Vacuum Pump Manualterryphi100% (1)

- C13579-80-Bill of MaterialsDocument19 pagesC13579-80-Bill of MaterialsBrender Victor100% (1)

- 1cvugrjrg 825000Document156 pages1cvugrjrg 825000BrayanNo ratings yet

- Brochure Hifocus 160iDocument6 pagesBrochure Hifocus 160iTecnovi CoporationNo ratings yet

- 1614 9521 00Document1 page1614 9521 00UbanAirlanggaNo ratings yet

- Atos Dhe SP 667 PDFDocument4 pagesAtos Dhe SP 667 PDFWashington Lorenzo Lama MayorgaNo ratings yet

- Manual Wayne 3G7221P-8JKDocument96 pagesManual Wayne 3G7221P-8JKAlejandro AdriasolaNo ratings yet

- Busch Dolphin LX 0430 B 190 KG Compact Liquid Ring Vacuum PumpDocument19 pagesBusch Dolphin LX 0430 B 190 KG Compact Liquid Ring Vacuum Pumpruizinho 1No ratings yet

- Busch Mink MM 1104-1142 BP Manual enDocument20 pagesBusch Mink MM 1104-1142 BP Manual enmakremNo ratings yet

- Busch Instruction Manual Seco SV SD 1005-1008 C en 0870135648Document16 pagesBusch Instruction Manual Seco SV SD 1005-1008 C en 0870135648julio vargasNo ratings yet

- Installation and Operating InstructionsDocument20 pagesInstallation and Operating InstructionsJORGE OTALORANo ratings yet

- Bombas BuschDocument20 pagesBombas BuschJorge Agustin González SaraibaNo ratings yet

- Za160-500 (1999)Document52 pagesZa160-500 (1999)Renārs BērtiņšNo ratings yet

- LOGIK-9 Operation Manual (HZ-L9M.V1.23 10 - 2019)Document31 pagesLOGIK-9 Operation Manual (HZ-L9M.V1.23 10 - 2019)Renārs Bērtiņš100% (1)

- Compressor Controller Pro-Log - Parameters Adjusting.: For Distributors Use Only!Document2 pagesCompressor Controller Pro-Log - Parameters Adjusting.: For Distributors Use Only!Renārs BērtiņšNo ratings yet

- Centropelet Zv16: Technical InstructionsDocument28 pagesCentropelet Zv16: Technical InstructionsRenārs BērtiņšNo ratings yet

- Elektronikon Instr. IDocument74 pagesElektronikon Instr. IRenārs BērtiņšNo ratings yet

- CPC40 SPL PDFDocument72 pagesCPC40 SPL PDFRenārs BērtiņšNo ratings yet

- Refrigerant Compressed Air Dryers: Atlas CopcoDocument40 pagesRefrigerant Compressed Air Dryers: Atlas CopcoRenārs BērtiņšNo ratings yet

- Ingersoll Rand AC105D Operators ManualDocument97 pagesIngersoll Rand AC105D Operators ManualRenārs Bērtiņš100% (2)

- USER MANUAL Cyclon330-345Document66 pagesUSER MANUAL Cyclon330-345Renārs BērtiņšNo ratings yet

- CPC40 SPLDocument72 pagesCPC40 SPLRenārs Bērtiņš0% (1)

- Installation and Operating Instructions: Busch Produktions GMBH Schauinslandstr. 1 79689 Maulburg GermanyDocument28 pagesInstallation and Operating Instructions: Busch Produktions GMBH Schauinslandstr. 1 79689 Maulburg GermanyRenārs BērtiņšNo ratings yet

- Smart TV E-Manual: Downloaded From Manuals Search EngineDocument156 pagesSmart TV E-Manual: Downloaded From Manuals Search EngineRenārs BērtiņšNo ratings yet

- Samsung 4 G Smart CameraDocument178 pagesSamsung 4 G Smart CameraRenārs BērtiņšNo ratings yet

- Becker PICCHIO 2200Document6 pagesBecker PICCHIO 2200Renārs BērtiņšNo ratings yet

- LG Lifeband Touch: User ManualDocument50 pagesLG Lifeband Touch: User ManualRenārs BērtiņšNo ratings yet

- Biography of Srila PrabhupadaDocument2 pagesBiography of Srila Prabhupadamapl2891No ratings yet

- Anti-Isthmus Autoimmunity in A Novel Feline Acquired Alopecia Resembling Pseudopelade of HumansDocument10 pagesAnti-Isthmus Autoimmunity in A Novel Feline Acquired Alopecia Resembling Pseudopelade of HumansjenNo ratings yet

- Ligoo Manual and DiagramDocument54 pagesLigoo Manual and DiagramAngelito Ramos100% (1)

- School Based First Aid Training: Learning Material ForDocument79 pagesSchool Based First Aid Training: Learning Material ForSarah Agudo FernandezNo ratings yet

- Manila Activity 1 Group 6Document5 pagesManila Activity 1 Group 6BOTIN, Kiarrah KatrinaNo ratings yet

- Maintaining The Good Maternal Body Expressing Milk As A WayDocument11 pagesMaintaining The Good Maternal Body Expressing Milk As A Wayadri90No ratings yet

- 1b - Physical Transformations of Pure SubstancesDocument21 pages1b - Physical Transformations of Pure SubstancesakuhayuNo ratings yet

- Article-PDF-s. Madhusudhan S. M. Laxmikanth Pradeep Chandra Shetty-330Document3 pagesArticle-PDF-s. Madhusudhan S. M. Laxmikanth Pradeep Chandra Shetty-330saia windaNo ratings yet

- LED Strip Light Power Supply CalculatorDocument3 pagesLED Strip Light Power Supply CalculatorNadeem Muhammad NadzNo ratings yet

- S36-23302 SIE Service Offshore 12pp.Document7 pagesS36-23302 SIE Service Offshore 12pp.Uhrin ImreNo ratings yet

- Case Study No 3Document5 pagesCase Study No 3ERICKA GRACE DA SILVANo ratings yet

- The Therapeutic PrisonDocument16 pagesThe Therapeutic PrisonjavvnNo ratings yet

- DUNGEONS ExtendidoDocument112 pagesDUNGEONS ExtendidoEdgardo De La CruzNo ratings yet

- EPRI - Research On Concrete For Nuclear PlantsDocument2 pagesEPRI - Research On Concrete For Nuclear Plantsvggupta2No ratings yet

- Role of Perception in Effective CommunicationDocument16 pagesRole of Perception in Effective CommunicationMecha0250% (2)

- ENG 2014 Differential EquationsDocument18 pagesENG 2014 Differential EquationsJc San PedroNo ratings yet

- Tata Steel PowerDocument37 pagesTata Steel PowerChetana DiduguNo ratings yet

- HSE ProcedureDocument27 pagesHSE ProcedureKannan LakshmananNo ratings yet

- Kunci Jawaban Basic Ac MaterialDocument5 pagesKunci Jawaban Basic Ac Materialdyan dyanNo ratings yet

- Raghuram Rajan: The Man of The Moment!!!!!!!!!!!!!!Document9 pagesRaghuram Rajan: The Man of The Moment!!!!!!!!!!!!!!Vikram SanthanamNo ratings yet

- PracticeTests AnswerKey FCEDocument16 pagesPracticeTests AnswerKey FCEpabloNo ratings yet

- SAP Central Business Configuration OverviewDocument20 pagesSAP Central Business Configuration OverviewSam Moto30No ratings yet

- Should Teachers Give Homework Over The WeekendDocument7 pagesShould Teachers Give Homework Over The Weekendafnaoabfuddcdf100% (1)

- What Can I Do For Pakistan As A StudentDocument3 pagesWhat Can I Do For Pakistan As A StudentAlina Arif100% (1)

- Victor Kilui Wabwile Final ThesisDocument76 pagesVictor Kilui Wabwile Final ThesisarzaianNo ratings yet

- DNP805 Module 4 AssignmentDocument3 pagesDNP805 Module 4 AssignmentDoreenNo ratings yet

- Strahlenfolter Stalking - TI - MICROWAVE MIND CONTROL by DR Rauni Leena LuukanenDocument3 pagesStrahlenfolter Stalking - TI - MICROWAVE MIND CONTROL by DR Rauni Leena LuukanenHans-Georg-JakobsonNo ratings yet

- OSFILEDocument100 pagesOSFILEPratik YadavNo ratings yet

- Human Behavior Lesson 1Document31 pagesHuman Behavior Lesson 1Christine BawitNo ratings yet