0% found this document useful (0 votes)

92 views10 pagesMini Project PIC

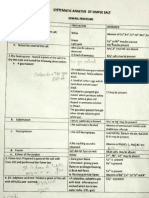

The document discusses urea, including its history, properties, synthesis, and use in various industrial processes and fertilizers. Urea is produced through a reaction between ammonia and carbon dioxide under high pressure and temperature. The document then describes the equipment used in urea production processes, including reactors, strippers, condensers, and decomposers.

Uploaded by

ady joffriyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

92 views10 pagesMini Project PIC

The document discusses urea, including its history, properties, synthesis, and use in various industrial processes and fertilizers. Urea is produced through a reaction between ammonia and carbon dioxide under high pressure and temperature. The document then describes the equipment used in urea production processes, including reactors, strippers, condensers, and decomposers.

Uploaded by

ady joffriyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd