Professional Documents

Culture Documents

Installation Operation and Maintenance Manual

Uploaded by

AbdulSattarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Operation and Maintenance Manual

Uploaded by

AbdulSattarCopyright:

Available Formats

Installation Operation and Maintenance Manual

IMM Passive Harmonic Filter

Passive Harmonic filter

Group:Chillers

This manual applies to following low voltage chiller and its derived

& modified models Date:2018.12

Chiller series: NEW NO.: Z8050038-02

HTS 063、079、087、100、113、126 OLD NO.: Z8050038-01

TSC 079、087、100、113、126

HSC 063、079、087、100、113、126

HTV M、 L、 G

ZWUV 4H、4I、4J、5K、5M、6N

WXE

Thanks for purchasing DAIKIN chiller.

The Manual specifies safety, installation and maintenance precautions.

Please read through the manual before installation and operation.

For future reference, please be sure to keep it safe.

Science and Technology Create Natural

Maintenance Manual of Passive Filter

The normal operation of this product is based on correct use, installation and maintenance. The filter shall be

operated in accordance with the parameters required by the nameplates.

Users should carefully read this manual and follow the requirements strictly.

● Filter can only be installed in indoor places which are suitable for electric equipments operation.

● Ensure the filter is installed, operated and maintained by the professional qualified electrical engineers.

● Ensure secure connection of the electrical equipment at site and the applicability and safety of working

procedures.

● Any operations related to filter must abide by the terms of the manual.

Caution

This sign indicate that the failure to take precaution in filter installation and operation can

lead to equipment damage, personnel casualties and property lose. Please pay special

attention to items with this sign.

Warning

Always follow the specifications in the installation manual and safety operation

practice.

As voltage danger may cause electric shock and fire hazard, be sure to cut off the power prior to work

on the device.

For any questions concerning this manual, we are pleased to provide further information.

All rights reserved. DAIKIN reserves the right of modification to this manual. Any misuse or abuse,

including copies, piracy or taking out partial context of this manual to any third parties is prohibited.

Contents

1. Introduction........................................................................................................................................... 1

2. Storage/Handling.................................................................................................................................. 5

3. Delivery Inspection............................................................................................................................... 5

4. Operating Environment......................................................................................................................... 6

5. Installation............................................................................................................................................ 7

5.1 Hoisting and Transportation...................................................................................................... 7

5.2 Installation................................................................................................................................. 8

5.3 Packing Instruction.................................................................................................................... 9

Science and Technology Create Natural

Maintenance Manual of Passive Filter

5.4 External Dimension................................................................................................................... 9

5.5 Field Connection..................................................................................................................... 14

6. The Operation of filter........................................................................................................................ 16

6.1 The Device Arrangement of filter............................................................................................ 16

6.2 The Operation of filter............................................................................................................. 16

7. Trouble Shooting................................................................................................................................. 18

8. Maintenance........................................................................................................................................ 19

8.1 Daily inspection and maintenance................................................................................................ 19

8.2 Periodic inspection and Maintenance........................................................................................... 20

Science and Technology Create Natural

Maintenance Manual of Passive Filter

Science and Technology Create Natural

0

Maintenance Manual of Passive Filter

Introduction

This manual includes the related information for filter ’s installation and operation. Please read the manual

carefully for correct use of the product.

Same as our other products, filter can be further designed and technically adjusted for different purposes upon

customized requirement. Therefore, the information provided by this manual may not include information about

the special requirements.

In addition to this manual, the user can usually get the latest technical documentation (electrical diagram,

assembly, installation drawings and information regarding different configuration) by consulting DAIKIN

technical support engineer, especially for special requirements which is different from standard products. Only

the same spare parts can be used for maintenance operation.

Table 1-1:filter’s Specification and Basic Parameter.

Table 1-1 Specification and Basic Parameter

Rated Current Rated Voltage Frequency

Model

A V Hz

AUHF-125-400-50-D-E1-HP 175 380/400 50

AUHF-150-400-50-D-E1-HP 210 380/400 50

AUHF-175-400-50-D-E1-HP 246 380/400 50

AUHF-200-400-50-D-E1-HP 282 380/400 50

AUHF-225-400-50-D-E1-HP 317 380/400 50

AUHF-250-400-50-D-E1-HP 352 380/400 50

AUHF-275-400-50-D-E1-HP 389 380/400 50

AUHF-300-400-50-D-E1-HP 426 380/400 50

AUHF-325-400-50-D-E1-HP 456 380/400 50

AUHF-350-400-50-D-E1-HP 492 380/400 50

AUHF-375-400-50-D-E1-HP 538 380/400 50

AUHF-400-400-50-D-E1-HP 584 380/400 50

AUHF-425-400-50-D-E1-HP 622 380/400 50

AUHF-450-400-50-D-E1-HP 661 380/400 50

AUHF-500-400-50-D-E1-HP 741 380/400 50

AUHF-550-400-50-D-E1-HP 787 380/400 50

AUHF-600-400-50-D-E1-HP 833 380/400 50

AUHF-650-400-50-D-E1-HP 900 380/400 50

AUHF-700-400-50-D-E1-HP 967 380/400 50

AUHF-750-400-50-D-E1-HP 1037 380/400 50

AUHF-800-400-50-D-E1-HP 1106 380/400 50

AUHF-900-400-50-D-E1-HP 1234 380/400 50

AUHF-950-400-50-D-E1-HP 1304 380/400 50

AUHF-1000-400-50-D-E1-HP 1373 380/400 50

AUHF-1100-400-50-D-E1-HP 1512 380/400 50

AUHF-125-400-60-D-E1-HP 175 380/400 60

AUHF-150-400-60-D-E1-HP 210 380/400 60

AUHF-175-400-60-D-E1-HP 246 380/400 60

AUHF-200-400-60-D-E1-HP 282 380/400 60

AUHF-225-400-60-D-E1-HP 317 380/400 60

AUHF-250-400-60-D-E1-HP 352 380/400 60

AUHF-275-400-60-D-E1-HP 389 380/400 60

AUHF-300-400-60-D-E1-HP 426 380/400 60

AUHF-325-400-60-D-E1-HP 456 380/400 60

AUHF-350-400-60-D-E1-HP 492 380/400 60

AUHF-375-400-60-D-E1-HP 538 380/400 60

AUHF-400-400-60-D-E1-HP 584 380/400 60

AUHF-425-400-60-D-E1-HP 622 380/400 60

AUHF-450-400-60-D-E1-HP 661 380/400 60

AUHF-500-400-60-D-E1-HP 741 380/400 60

AUHF-550-400-60-D-E1-HP 787 380/400 60

AUHF-600-400-60-D-E1-HP 833 380/400 60

AUHF-650-400-60-D-E1-HP 900 380/400 60

AUHF-700-400-60-D-E1-HP 967 380/400 60

AUHF-750-400-60-D-E1-HP 1037 380/400 60

AUHF-800-400-60-D-E1-HP 1106 380/400 60

AUHF-900-400-60-D-E1-HP 1234 380/400 60

AUHF-950-400-60-D-E1-HP 1304 380/400 60

AUHF-1000-400-60-D-E1-HP 1373 380/400 60

AUHF-1100-400-60-D-E1-HP 1512 380/400 60

Science and Technology Create Natural

1

Maintenance Manual of Passive Filter

Rated Current Rated Voltage Frequency

Model

A V Hz

AUHF-150-440-50-D-E1-HP 175 415/440 50

AUHF-175-440-50-D-E1-HP 210 415/440 50

AUHF-200-440-50-D-E1-HP 246 415/440 50

AUHF-225-440-50-D-E1-HP 282 415/440 50

AUHF-250-440-50-D-E1-HP 317 415/440 50

AUHF-275-440-50-D-E1-HP 352 415/440 50

AUHF-300-440-50-D-E1-HP 389 415/440 50

AUHF-350-440-50-D-E1-HP 426 415/440 50

AUHF-375-440-50-D-E1-HP 456 415/440 50

AUHF-400-440-50-D-E1-HP 492 415/440 50

AUHF-425-440-50-D-E1-HP 538 415/440 50

AUHF-450-440-50-D-E1-HP 584 415/440 50

AUHF-475-440-50-D-E1-HP 622 415/440 50

AUHF-500-440-50-D-E1-HP 661 415/440 50

AUHF-600-440-50-D-E1-HP 741 415/440 50

AUHF-650-440-50-D-E1-HP 787 415/440 50

AUHF-700-440-50-D-E1-HP 833 415/440 50

AUHF-750-440-50-D-E1-HP 900 415/440 50

AUHF-800-440-50-D-E1-HP 967 415/440 50

AUHF-900-440-50-D-E1-HP 1037 415/440 50

AUHF-950-440-50-D-E1-HP 1106 415/440 50

AUHF-1000-440-50-D-E1-HP 1234 415/440 50

AUHF-1100-440-50-D-E1-HP 1304 415/440 50

AUHF-1150-440-50-D-E1-HP 1373 415/440 50

AUHF-1200-440-50-D-E1-HP 1512 415/440 50

AUHF-150-440-60-D-E1-HP 175 415/440 60

AUHF-175-440-60-D-E1-HP 210 415/440 60

AUHF-200-440-60-D-E1-HP 246 415/440 60

AUHF-225-440-60-D-E1-HP 282 415/440 60

AUHF-250-440-60-D-E1-HP 317 415/440 60

AUHF-275-440-60-D-E1-HP 352 415/440 60

AUHF-300-440-60-D-E1-HP 389 415/440 60

AUHF-350-440-60-D-E1-HP 426 415/440 60

AUHF-375-440-60-D-E1-HP 456 415/440 60

AUHF-400-440-60-D-E1-HP 492 415/440 60

AUHF-425-440-60-D-E1-HP 538 415/440 60

AUHF-450-440-60-D-E1-HP 584 415/440 60

AUHF-475-440-60-D-E1-HP 622 415/440 60

AUHF-500-440-60-D-E1-HP 661 415/440 60

AUHF-600-440-60-D-E1-HP 741 415/440 60

AUHF-650-440-60-D-E1-HP 787 415/440 60

AUHF-700-440-60-D-E1-HP 833 415/440 60

AUHF-750-440-60-D-E1-HP 900 415/440 60

AUHF-800-440-60-D-E1-HP 967 415/440 60

AUHF-900-440-60-D-E1-HP 1037 415/440 60

AUHF-950-440-60-D-E1-HP 1106 415/440 60

AUHF-1000-440-60-D-E1-HP 1234 415/440 60

AUHF-1100-440-60-D-E1-HP 1304 415/440 60

AUHF-1150-440-60-D-E1-HP 1373 415/440 60

AUHF-1200-440-60-D-E1-HP 1512 415/440 60

AUHF-150-480-50-D-E1-HP 175 460/480 50

AUHF-200-480-50-D-E1-HP 210 460/480 50

AUHF-225-480-50-D-E1-HP 246 460/480 50

AUHF-250-480-50-D-E1-HP 282 460/480 50

AUHF-275-480-50-D-E1-HP 317 460/480 50

AUHF-300-480-50-D-E1-HP 352 460/480 50

AUHF-350-480-50-D-E1-HP 389 460/480 50

AUHF-375-480-50-D-E1-HP 426 460/480 50

AUHF-400-480-50-D-E1-HP 456 460/480 50

AUHF-425-480-50-D-E1-HP 492 460/480 50

AUHF-450-480-50-D-E1-HP 538 460/480 50

AUHF-500-480-50-D-E1-HP 584 460/480 50

AUHF-550-480-50-D-E1-HP 622 460/480 50

AUHF-600-480-50-D-E1-HP 661 460/480 50

AUHF-650-480-50-D-E1-HP 741 460/480 50

AUHF-700-480-50-D-E1-HP 787 460/480 50

AUHF-750-480-50-D-E1-HP 833 460/480 50

AUHF-800-480-50-D-E1-HP 900 460/480 50

AUHF-900-480-50-D-E1-HP 967 460/480 50

AUHF-1000-480-50-D-E1-HP 1037 460/480 50

AUHF-1050-480-50-D-E1-HP 1106 460/480 50

Science and Technology Create Natural

2

Maintenance Manual of Passive Filter

Rated Current Rated Voltage Frequency

Model

A V Hz

AUHF-1100-480-50-D-E1-HP 1234 460/480 50

AUHF-1200-480-50-D-E1-HP 1304 460/480 50

AUHF-1300-480-50-D-E1-HP 1373 460/480 50

AUHF-1400-480-50-D-E1-HP 1512 460/480 50

AUHF-150-480-60-D-E1-HP 175 460/480 60

AUHF-200-480-60-D-E1-HP 210 460/480 60

AUHF-225-480-60-D-E1-HP 246 460/480 60

AUHF-250-480-60-D-E1-HP 282 460/480 60

AUHF-275-480-60-D-E1-HP 317 460/480 60

AUHF-300-480-60-D-E1-HP 352 460/480 60

AUHF-350-480-60-D-E1-HP 389 460/480 60

AUHF-375-480-60-D-E1-HP 426 460/480 60

AUHF-400-480-60-D-E1-HP 456 460/480 60

AUHF-425-480-60-D-E1-HP 492 460/480 60

AUHF-450-480-60-D-E1-HP 538 460/480 60

AUHF-500-480-60-D-E1-HP 584 460/480 60

AUHF-550-480-60-D-E1-HP 622 460/480 60

AUHF-600-480-60-D-E1-HP 661 460/480 60

AUHF-650-480-60-D-E1-HP 741 460/480 60

AUHF-700-480-60-D-E1-HP 787 460/480 60

AUHF-750-480-60-D-E1-HP 833 460/480 60

AUHF-800-480-60-D-E1-HP 900 460/480 60

AUHF-900-480-60-D-E1-HP 967 460/480 60

AUHF-1000-480-60-D-E1-HP 1037 460/480 60

AUHF-1050-480-60-D-E1-HP 1106 460/480 60

AUHF-1100-480-60-D-E1-HP 1234 460/480 60

AUHF-1200-480-60-D-E1-HP 1304 460/480 60

AUHF-1300-480-60-D-E1-HP 1373 460/480 60

AUHF-1400-480-60-D-E1-HP 1512 460/480 60

Installation, delivery, operation and maintenance operation must be performed by

experienced personnel with Operational qualification.

1. Storage/Handling

filter must be stored at indoor place of dry and ventilated, moisture proof and non-corrosive gases erosion

surroundings.

filter shall be prevented from inversion, collision, rollover, heavy vibration and drench during handling.

Science and Technology Create Natural

3

Maintenance Manual of Passive Filter

2. Delivery Inspection

Caution:

Ensure the circuit breaker is in shut-off mode before any operations

On delivery, please ensure the package integrity. The product description and the data on the nameplate should be

in consistent of the details of the order. Make sure all the items on the shipping list are delivered.

Please make sure DAIKIN’s technical personnel is on site when unpacking filter. Any damages or abnormal

situation found during unpacking need to be acknowledged by technical engineers.

Only DAIKIN confirmed items listed in the order will be put into the package of the box.

Following documents will be found in the package:

IOMM

User Manual

The factory inspection report

Main components certificate:Passive filter

3. Operating Environment

According to the IEC60076-6 Power Transformer -Part 6: Reactors" and other related standards, the list of

normal operation environment parameters and electrical parameters of the filter are shown below:

Installation location: Indoor, no regular heavy vibration, no direct sunlight, no rain.

Altitude: 0 to 1000 meters. Over 1000 meters, current output capacity derating1% for every 100

meters.

Operation ambient temperature: -5 to +40℃, as environment temperature of filter panel.

Storage temperature: -8 to +55℃.

Maximum temperature difference daily range: +25℃.

Relative humidity: The humidity should not be exceed 95%,No condensation. The humidity shall not

exceed 50% when highest temperature is 40℃.

Gradation for surface pollution: Level 2 with no conductive dust, non-corrosive, no combustible gas,

no oil mist and salt.

Earthquake intensity: 7 magnitude fortification.

Input power: rated voltage±10%, voltage imbalance is ≤1%, background voltage distortion ≤ 0.5%

(Note: If the background voltage beyond this range, the filtering effect may not reach).

Input frequency: rated frequency±2%.

Science and Technology Create Natural

4

Maintenance Manual of Passive Filter

Note:

1) Rapid temperature change in of high humidity situation can cause condensation.

2) Insulation breakdown or corrosion of the metal parts may happen when filter working in high

humidity and condensation situation. Proper measures should be taken to cope with this situation.

3) If filter’s operation environment exceeds its limit, higher failure rates and shorter life of components

and filter is occurred.

4) If the filter need to be operated under special conditions, users should consult DAIKIN.

4. Installation

The shell temperature in filter could reach 60℃in operation. So filter installed is not allowed to touch with any

material unable to bear such high temperature.

4.1 Hoisting and Transportation

5.1.1There are two or four lugs at the top of reactor in the filter , which is designed for easy installation and

transfer purpose, as shown in figure 5-1. Please ensure that all hooks can hook the rings firmly. The

process of hoisting needs to be carried out with extra care and caution.

The maximum weight of the filter is up to 2000 kg, please use the load capacity of more than 2000 kg

of spreader to hoisting the filter.

Note:

1) When lifting the filter, access the lifting lugs by removing the top enclosure cover (Because the filter is

heavy, please use all of the reactor lugs to lift ).

2) For the filters below 400kg, there are 2 ring lugs (one ring lug on each steel panel); 4 ring lugs for the

filters with 400kg and above.

Lifting lugs

Science and Technology Create Natural

5

Maintenance Manual of Passive Filter

Figure 5-1 filter Lifting Sketch

5.1.2 When using forklift to move the filter from the bottom, make sure the forklift leg much insert full

length and moving carefully. The filter may be skidded or moved on rollers but care must be taken

not to damage the base or tip it over. When rollers are used under larger units, skids must be used to

distribute the stress over the base.

4.2 Installation

Improper installation of filter may cause deformation of cabinet and looseness of components due to

vibration and other consequences. Location of the filter should be made with consideration given to

accessibility, ventilation and atmospheric conditions. Installation locations should be free of contaminants

including dust, fertilizer, excessive moisture, corrosive gases, flammable materials or chemical fumes.

filtered air may be considered to reduce maintenance where air born contaminants are a problem.

Sufficient distance (according to Figure 5-2) from walls and other obstructions should be provided to permit

unrestricted opening of hinged and removable doors, covers and panels for the purpose of wiring

terminations, inspection, maintenance and testing. Also, proper ventilation requires at least 500mm

clearance at all ventilation openings. Ambient temperature must not exceed 40 ℃.

Do not stacks or install above other heat source equipment .

According to different cabinet specification, please construct in accordance with the section 5.4 installation

base before starting construction.

Installation foundation specification .

1) Installation foundation is U-steel .

2) Roughness of U-steel per meter is not greater than 1 mm .

3) The filter is fixed on the basic U-steel by binding bolt .

Figure 5-2 Installation Space

4.3 Packing Instruction

To ensure dust proof and moisture proof, each filter is sealed with plastic film before packing. Please be

Science and Technology Create Natural

6

Maintenance Manual of Passive Filter

careful when unpacking filter in order to avoid damage of the cabinet and components. Remove the packing

before putting filter into operation.

4.4 External Dimension

According to the different capacity of the filter , the enclosure has different sizes which are shown in Table

5-1 and Figure5-3.

Table 5-1: External and Mounting Dimension(unit: mm)

Width*Height*Depth Mounting Hole Dim. Connection Connection Hole

Model Dim. (D*E) Busbar & Qty.

(A*B*C)

AUHF-125-400-50-D-E1-HP 568*1016*584 508*508 6*25 1 - Φ14

AUHF-150-400-50-D-E1-HP 568*1016*584 508*508 6*25 1 - Φ14

AUHF-175-400-50-D-E1-HP 664*1143*636 483*546 6*25 1 - Φ14

AUHF-200-400-50-D-E1-HP 664*1143*636 483*546 6*25 1 - Φ14

AUHF-225-400-50-D-E1-HP 664*1143*636 483*546 6*25 1 - Φ14

AUHF-250-400-50-D-E1-HP 664*1143*636 483*546 6*40 1 - Φ14

AUHF-275-400-50-D-E1-HP 664*1143*636 483*546 6*75 2- Φ14

AUHF-300-400-50-D-E1-HP 664*1143*636 483*546 6*75 2- Φ14

AUHF-325-400-50-D-E1-HP 814*1308*750 597*597 6*75 2- Φ14

AUHF-350-400-50-D-E1-HP 814*1308*750 597*597 6*75 2- Φ14

AUHF-375-400-50-D-E1-HP 814*1308*750 597*597 6*75 2- Φ14

AUHF-400-400-50-D-E1-HP 814*1308*750 597*597 6*75 2- Φ14

AUHF-425-400-50-D-E1-HP 1004*1499*867 813*610 6*75 2- Φ14

AUHF-450-400-50-D-E1-HP 1004*1499*867 813*610 8*80 4- Φ14

AUHF-500-400-50-D-E1-HP 1004*1499*867 813*610 8*80 4- Φ14

AUHF-550-400-50-D-E1-HP 1004*1499*867 813*610 8*80 4- Φ14

AUHF-600-400-50-D-E1-HP 1004*1499*867 813*610 8*80 4- Φ14

AUHF-650-400-50-D-E1-HP 1004*1499*867 813*610 10*80 4- Φ14

AUHF-700-400-50-D-E1-HP 1004*1499*867 813*610 10*80 4- Φ14

AUHF-750-400-50-D-E1-HP 1119*1676*965 914*660 10*80 4- Φ14

AUHF-800-400-50-D-E1-HP 1119*1676*965 914*660 10*80 4- Φ14

AUHF-900-400-50-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

AUHF-950-400-50-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

AUHF-1000-400-50-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

AUHF-1100-400-50-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

AUHF-125-400-60-D-E1-HP 568*1016*584 508*508 6*25 1- Φ14

AUHF-150-400-60-D-E1-HP 568*1016*584 508*508 6*25 1- Φ14

AUHF-175-400-60-D-E1-HP 664*1143*636 483*546 6*25 1- Φ14

AUHF-200-400-60-D-E1-HP 664*1143*636 483*546 6*25 1- Φ14

AUHF-225-400-60-D-E1-HP 664*1143*636 483*546 6*25 1- Φ14

AUHF-250-400-60-D-E1-HP 664*1143*636 483*546 6*40 1- Φ14

AUHF-275-400-60-D-E1-HP 664*1143*636 483*546 6*75 2- Φ14

AUHF-300-400-60-D-E1-HP 664*1143*636 483*546 6*75 2- Φ14

Science and Technology Create Natural

7

Maintenance Manual of Passive Filter

Width*Height*Depth Mounting Hole Dim. Connection Connection Hole

Model Dim. (D*E) Busbar & Qty.

(A*B*C)

AUHF-325-400-60-D-E1-HP 814*1308*750 597*597 6*75 2- Φ14

AUHF-350-400-60-D-E1-HP 814*1308*750 597*597 6*75 2- Φ14

AUHF-375-400-60-D-E1-HP 814*1308*750 597*597 6*75 2- Φ14

AUHF-400-400-60-D-E1-HP 814*1308*750 597*597 6*75 2- Φ14

AUHF-425-400-60-D-E1-HP 1004*1499*867 813*610 6*75 2- Φ14

AUHF-450-400-60-D-E1-HP 1004*1499*867 813*610 8*80 4- Φ14

AUHF-500-400-60-D-E1-HP 1004*1499*867 813*610 8*80 4- Φ14

AUHF-550-400-60-D-E1-HP 1004*1499*867 813*610 8*80 4- Φ14

AUHF-600-400-60-D-E1-HP 1004*1499*867 813*610 8*80 4- Φ14

AUHF-650-400-60-D-E1-HP 1004*1499*867 813*610 10*80 4- Φ14

AUHF-700-400-60-D-E1-HP 1004*1499*867 813*610 10*80 4- Φ14

AUHF-750-400-60-D-E1-HP 1119*1676*965 914*660 10*80 4- Φ14

AUHF-800-400-60-D-E1-HP 1119*1676*965 914*660 10*80 4- Φ14

AUHF-900-400-60-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

AUHF-950-400-60-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

AUHF-1000-400-60-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

AUHF-1100-400-60-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

AUHF-150-440-50-D-E1-HP 568*1016*584 508*508 6*25 1- Φ14

AUHF-175-440-50-D-E1-HP 664*1143*636 483*546 6*25 1- Φ14

AUHF-200-440-50-D-E1-HP 664*1143*636 508*508 6*25 1- Φ14

AUHF-225-440-50-D-E1-HP 664*1143*636 483*546 6*25 1- Φ14

AUHF-250-440-50-D-E1-HP 664*1143*636 483*546 6*40 2- Φ14

AUHF-275-440-50-D-E1-HP 664*1143*636 483*546 6*40 2- Φ14

AUHF-300-440-50-D-E1-HP 664*1143*636 483*546 6*40 2- Φ14

AUHF-350-440-50-D-E1-HP 814*1308*750 483*546 6*40 2- Φ14

AUHF-375-440-50-D-E1-HP 814*1308*750 483*546 6*40 2- Φ14

AUHF-400-440-50-D-E1-HP 814*1308*750 597*597 8*50 2- Φ14

AUHF-425-440-50-D-E1-HP 814*1308*750 597*597 8*50 2- Φ14

AUHF-450-440-50-D-E1-HP 814*1308*750 597*597 8*50 2- Φ14

AUHF-475-440-50-D-E1-HP 1004*1499*867 597*597 8*50 2- Φ14

AUHF-500-440-50-D-E1-HP 1004*1499*867 597*597 8*50 2- Φ14

AUHF-600-440-50-D-E1-HP 1004*1499*867 813*610 10*76 4- Φ14

AUHF-650-440-50-D-E1-HP 1004*1499*867 813*610 10*76 4- Φ14

AUHF-700-440-50-D-E1-HP 1004*1499*867 813*610 10*76 4- Φ14

AUHF-750-440-50-D-E1-HP 1119*1676*965 813*610 10*76 4- Φ14

AUHF-800-440-50-D-E1-HP 1119*1676*965 813*610 10*76 4- Φ14

AUHF-900-440-50-D-E1-HP 1119*1676*965 813*610 10*76 4- Φ14

AUHF-950-440-50-D-E1-HP 1119*1676*965 914*660 10*76 4- Φ14

AUHF-1000-440-50-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

AUHF-1100-440-50-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

AUHF-1150-440-50-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

Science and Technology Create Natural

8

Maintenance Manual of Passive Filter

Width*Height*Depth Mounting Hole Dim. Connection Connection Hole

Model Dim. (D*E) Busbar & Qty.

(A*B*C)

AUHF-1200-440-50-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

AUHF-150-440-60-D-E1-HP 568*1016*584 508*508 6*25 1- Φ14

AUHF-175-440-60-D-E1-HP 664*1143*636 483*546 6*25 1- Φ14

AUHF-200-440-60-D-E1-HP 664*1143*636 508*508 6*25 1- Φ14

AUHF-225-440-60-D-E1-HP 664*1143*636 483*546 6*25 1- Φ14

AUHF-250-440-60-D-E1-HP 664*1143*636 483*546 6*40 2- Φ14

AUHF-275-440-60-D-E1-HP 664*1143*636 483*546 6*40 2- Φ14

AUHF-300-440-60-D-E1-HP 664*1143*636 483*546 6*40 2- Φ14

AUHF-350-440-60-D-E1-HP 814*1308*750 483*546 6*40 2- Φ14

AUHF-375-440-60-D-E1-HP 814*1308*750 483*546 6*40 2- Φ14

AUHF-400-440-60-D-E1-HP 814*1308*750 597*597 8*50 2- Φ14

AUHF-425-440-60-D-E1-HP 814*1308*750 597*597 8*50 2- Φ14

AUHF-450-440-60-D-E1-HP 814*1308*750 597*597 8*50 2- Φ14

AUHF-475-440-60-D-E1-HP 1004*1499*867 597*597 8*50 2- Φ14

AUHF-500-440-60-D-E1-HP 1004*1499*867 597*597 8*50 2- Φ14

AUHF-600-440-60-D-E1-HP 1004*1499*867 813*610 10*76 4- Φ14

AUHF-650-440-60-D-E1-HP 1004*1499*867 813*610 10*76 4- Φ14

AUHF-700-440-60-D-E1-HP 1004*1499*867 813*610 10*76 4- Φ14

AUHF-750-440-60-D-E1-HP 1119*1676*965 813*610 10*76 4- Φ14

AUHF-800-440-60-D-E1-HP 1119*1676*965 813*610 10*76 4- Φ14

AUHF-900-440-60-D-E1-HP 1119*1676*965 813*610 10*76 4- Φ14

AUHF-950-440-60-D-E1-HP 1119*1676*965 914*660 10*76 4- Φ14

AUHF-1000-440-60-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

AUHF-1100-440-60-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

AUHF-1150-440-60-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

AUHF-1200-440-60-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

AUHF-150-480-50-D-E1-HP 568*1016*584 508*508 6*25 1- Φ14

AUHF-200-480-50-D-E1-HP 568*1016*584 508*508 6*25 1- Φ14

AUHF-225-480-50-D-E1-HP 568*1016*584 508*508 6*25 1- Φ14

AUHF-250-480-50-D-E1-HP 664*1143*636 483*546 6*40 1- Φ14

AUHF-275-480-50-D-E1-HP 664*1143*636 483*546 6*40 1- Φ14

AUHF-300-480-50-D-E1-HP 664*1143*636 483*546 6*40 1- Φ14

AUHF-350-480-50-D-E1-HP 814*1308*750 597*597 6*40 2- Φ14

AUHF-375-480-50-D-E1-HP 814*1308*750 597*597 6*40 2- Φ14

AUHF-400-480-50-D-E1-HP 814*1308*750 597*597 8*50 2- Φ14

AUHF-425-480-50-D-E1-HP 814*1308*750 597*597 8*50 2- Φ14

AUHF-450-480-50-D-E1-HP 814*1308*750 597*597 8*50 2- Φ14

AUHF-500-480-50-D-E1-HP 814*1308*750 597*597 8*50 2- Φ14

AUHF-550-480-50-D-E1-HP 814*1308*750 597*597 8*50 2- Φ14

AUHF-600-480-50-D-E1-HP 1004*1499*867 813*610 8*50 2- Φ14

AUHF-650-480-50-D-E1-HP 1004*1499*867 813*610 8*50 4- Φ14

Science and Technology Create Natural

9

Maintenance Manual of Passive Filter

Width*Height*Depth Mounting Hole Dim. Connection Connection Hole

Model Dim. (D*E) Busbar & Qty.

(A*B*C)

AUHF-700-480-50-D-E1-HP 1004*1499*867 813*610 10*76 4- Φ14

AUHF-750-480-50-D-E1-HP 1004*1499*867 813*610 10*76 4- Φ14

AUHF-800-480-50-D-E1-HP 1119*1676*965 914*660 10*76 4- Φ14

AUHF-900-480-50-D-E1-HP 1119*1676*965 914*660 10*76 4- Φ14

AUHF-1000-480-50-D-E1-HP 1119*1676*965 914*660 10*100 4- Φ14

AUHF-1050-480-50-D-E1-HP 1119*1676*965 914*660 10*100 4- Φ14

AUHF-1100-480-50-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

AUHF-1200-480-50-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

AUHF-1300-480-50-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

AUHF-1400-480-50-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

AUHF-150-480-60-D-E1-HP 568*1016*584 508*508 6*25 1- Φ14

AUHF-200-480-60-D-E1-HP 568*1016*584 508*508 6*25 1- Φ14

AUHF-225-480-60-D-E1-HP 568*1016*584 508*508 6*25 1- Φ14

AUHF-250-480-60-D-E1-HP 664*1143*636 483*546 6*40 1- Φ14

AUHF-275-480-60-D-E1-HP 664*1143*636 483*546 6*40 1- Φ14

AUHF-300-480-60-D-E1-HP 664*1143*636 483*546 6*40 1- Φ14

AUHF-350-480-60-D-E1-HP 814*1308*750 597*597 6*40 2- Φ14

AUHF-375-480-60-D-E1-HP 814*1308*750 597*597 6*40 2- Φ14

AUHF-400-480-60-D-E1-HP 814*1308*750 597*597 8*50 2- Φ14

AUHF-425-480-60-D-E1-HP 814*1308*750 597*597 8*50 2- Φ14

AUHF-450-480-60-D-E1-HP 814*1308*750 597*597 8*50 2- Φ14

AUHF-500-480-60-D-E1-HP 814*1308*750 597*597 8*50 2- Φ14

AUHF-550-480-60-D-E1-HP 814*1308*750 597*597 8*50 2- Φ14

AUHF-600-480-60-D-E1-HP 1004*1499*867 813*610 8*50 2- Φ14

AUHF-650-480-60-D-E1-HP 1004*1499*867 813*610 8*50 4- Φ14

AUHF-700-480-60-D-E1-HP 1004*1499*867 813*610 10*76 4- Φ14

AUHF-750-480-60-D-E1-HP 1004*1499*867 813*610 10*76 4- Φ14

AUHF-800-480-60-D-E1-HP 1119*1676*965 914*660 10*76 4- Φ14

AUHF-900-480-60-D-E1-HP 1119*1676*965 914*660 10*76 4- Φ14

AUHF-1000-480-60-D-E1-HP 1119*1676*965 914*660 10*100 4- Φ14

AUHF-1050-480-60-D-E1-HP 1119*1676*965 914*660 10*100 4- Φ14

AUHF-1100-480-60-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

AUHF-1200-480-60-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

AUHF-1300-480-60-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

AUHF-1400-480-60-D-E1-HP 1232*1905*1095 1041*699 10*100 4- Φ14

Science and Technology Create Natural

10

Maintenance Manual of Passive Filter

Front View Left View

Figure 5-3a filter Outline Drawing

Bottom View

Figure 5-3b filter Mounting Dim.

4.5 Field Connection

Input & Output Entrance: Top In and Top Out, field connection is necessary. Power cable connection refers to

Table 5-2.

Input Terminal: A1,B1,C1

Output Terminal:A2,B2,C2

Same as our other electrical equipments, all local safety standards must be followed when install DAIKIN

filters, including all applicable electrical codes.

INPUT

AUHF FILTER VFD MOTOR

Figure 5-4 Typical VFD System with filter

As for the power line diameter specifications, please refer to the recommended wire diameter as per Table 5-2. It

is recommended to use BVR VVR, YJVR linear without solid tube. The length upper limit of the incoming cable

must be satisfied with the voltage range of filter panel:±10% of the nominal voltage.

Table 5-3 Power cable diameter

Science and Technology Create Natural

11

Maintenance Manual of Passive Filter

Rated Current Cable Length Inlet Wire Rated Current Cable Length Inlet Wire

(A) (m) Cross Area (mm2) (A) (m) Cross Area (mm2)

<15 120 <15 200 x 2

175 661

≥15 ≥120 ≥15 ≥250 x 2

<15 120 <15 250 x 2

210 741

≥15 ≥120 ≥15 ≥325 x 2

<15 120 <15 250 x 2

246 787

≥15 ≥150 ≥15 ≥325 x 2

<15 150 <15 325 x 2

282 833

≥15 ≥200 ≥15 ≥325 x 3

<15 200 <15 325 x 3

317 900

≥15 ≥200 ≥15 ≥325 x4

<15 200 <15 300 x 4

352 967

≥15 ≥250 ≥15 ≥325 x 4

<15 200 <15 300 x 4

389 1037

≥15 ≥250 ≥15 ≥325 x 4

<15 250 <15 300 x 4

426 1106

≥15 ≥325 ≥15 ≥325 x 4

<15 250 <15 300 x 4

456 1234

≥15 ≥325 ≥15 ≥325 x 4

<15 325 <15 300 x 4

492 1304

≥15 ≥400 ≥15 ≥325 x 4

<15 325 <15 325 x 4

538 1373

≥15 ≥400 ≥15 ≥325 x 4

<15 200 x 2 <15 350 x 4

584 1512

≥15 ≥200 x 2 ≥15 ≥350 x 4

<15 200 x 2

622

≥15 ≥250 x 2

5. The Operation of filter

5.1 The Device Arrangement of filter

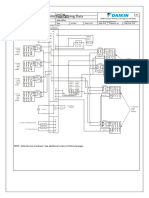

The electrical components of the filter are shown in figure 6-1 image, they are for reference only.

Science and Technology Create Natural

12

Maintenance Manual of Passive Filter

Figure 6-1 Components arrangement of filter

5.2 The Operation of filter

6.2.1 Site confirmation

Before energization, an internal inspection should be conducted with emphasis on loose or broken

connections, damaged or displaced parts, cracked insulators, dirt or foreign material, or evidence of

moisture. While servicing the filter, all relevant safety standards must be followed, including all

applicable local electrical codes and standards for Electrical Safety in the Workplace.

6.2.2 Before Energization

A circuit breaker should be in place in the upstream of the filter.

Verify that the external feeder circuit breaker is in the OFF/OPEN position so that unit is de-energized.

Testing the impedance of the each phase of filter, to make sure the impedance more than 10MΩ

relatively to earth.

Clean, vacuum, and clear interior of enclosure of any extra hardware and debris.

Check whether filter occur frost, condensation water, if occur frost, condensation , it is strictly

prohibited to power the filter on.

Verify proper three-phase wiring of filter power wires, ground, and upper circuit breaker.

Check all capacitors for swelling, leaking, or extruded vents; replace if necessary. Verify all fuses for

integrity and rating.

If the filter has been sitting idle for 6 months or longer before first energization, it is recommended that

the maintenance procedure described in 8 is performed prior to startup.

6.2.3 Initial start-up and run:

If test measurements are to be taken, connect any test equipment before energization.

It is recommended that any test instruments be connected such that all enclosure panels can be installed

properly and can be fully enclosed. Consider using meters with remote wireless displays if possible.

When energizing, use appropriate personal protection equipment (PPE) and other precautions as required by

local agency. On stand-by operation, though no output current, input reactive current still exists.

Note:

1)A filter should only be loaded in accordance with its nameplate rating.

2)The reactive offload current is about 20% of rated current.

3) The filter flows through the external harmonic current, so it is inevitable to have 70~80 dB of

noise.

Science and Technology Create Natural

13

Maintenance Manual of Passive Filter

6. Trouble Shooting

Note:

1) To prevent accident, maintaining and repairing the filter can only be carried out 5 minutes

after the power-off of breaker and inverter. At the same time, take safety measures of

isolation and preventing the power supply.

2) Any faulty maintenance for the filter should be carried out by operational personnel with

qualification or DAIKIN's service personnel.

3) It is strictly prohibited to maintain the filter when any one end of inlet or outlet end is

charged.

4) No switch on is allowed before finding out the cause and solve the problem of a breaker

tripping.

5) In cases of following problems, Pls. contact DAIKIN's service personnel.

i. Problem: No power to filter

Possible cause: Power to the filter is turned off.

ii. Problem: Capacitor phase currents are unbalanced by more than 10%.

a. Possible cause: One or more capacitors have failed.

b. Possible cause: One or more capacitor fuses have blown.

iii. Problem: Harmonic mitigation performance does not seem to match

performance guarantee.

a. Possible cause: ITHD measurement is being used instead of ITDD.

b. Possible cause: One or more capacitors have failed.

Science and Technology Create Natural

14

Maintenance Manual of Passive Filter

c. Possible cause: One or more capacitor fuses have blown.

d. Possible cause: High background voltage distortion.

iv. Problem: filter output voltage is not within specification

a. Possible cause: filter input voltage is not within specification.

b. Possible cause: One or more capacitors have failed.

Caution:

1) Ensure that power to the filter has been turned off and safely isolated before replacing

blown fuses.

2) In case of filter failure, Pls. contact DAIKIN's service personnel.

7. Maintenance

Note:

1) The maintenance of filter shall be conducted by by operational personnel with

qualification or DAIKIN's service personnel to ensure proper maintenance job.

2) Ambient temperature, humidity, dust, vibration and the ageing of internal components can

cause hidden fault to the filter. To ensure the filter a long-term and steady operation,

regularly maintain is necessary in both operation and storage situation.

Caution:

The filter carries high voltage in running. Wrong operation may cause serious personal injury.

Firmly cutting off power supply to the inverter and wait for power light go out for five minutes

or more, then maintenance operations can be started.

8.1 Daily inspection and maintenance

Daily inspection and maintenance can find all kinds of abnormal situation in time. By finding and eliminating

the hidden faults in early stage, ensure the filter in normal running status and extend the life cycle of the filter.

For the daily inspection and maintenance, please refer to below table 8-1.

Note:

1) The filter should be placed in the environment as described in the chapter 4.

2) When the filter is in operation, ensure the closure of the cupboard.

3) After the filter transported the scene of the customer, if there is infrastructure construction

around the filter, unpacking the filter is prohibited.

4) When starting infrastructure construction around the installed filter, should stop the run of

filter, and make effective protection for the filter by shield, to prevent debris, sand, dust,

etc coming into the filter.

Table 8-1 Daily Examine and Maintenance

Science and Technology Create Natural

15

Maintenance Manual of Passive Filter

Inspection Item Inspection Contents Pass Criteria

Run environment (1)Temperature, humidity (1) temperature: 40℃ or less; Humidity: 95%Rh or less;

(2)Dust or oil mist No condensation or water drop.

(3)Gasses (2) No electro conductive dust or no oil mist

(4)Install environment (3) No flammable gases or no corrosive gases

(4) Installation environment with good ventilation. Duct

without blocking

Reactor (1) Temperature rising (1) wind with abnormal temperature of air outlet

(2) Noise (2) No abnormal noise, no smell

Capacitor

(3) Cable wire, terminal (3) Fasten screws, no loose

(4) Cleanliness (4) The shell and terminal of filter is clean and tidy, air

inlet and outlet is unobstructed

Enclosure (1) Cleanliness (1) Surface and inside of panel is dry, clean and tidy

(2) Air inlet and outlet (2) Air inlet and outlet is unobstructed

Input or output (1) Input voltage (1) Within specification range of input voltage of the filter

specification (2) Less s than rated current of the filter

(2) Output current

Note:

Before entering or working on the filter, it should be de-energized, properly grounded and

isolated. Only qualified service technicians should be allowed to maintain the filter. While

servicing the filter, all relevant safety standards must be followed, including all local applicable

electrical codes and Standard for Electrical Safety in the Workplace.

8.2 Periodic inspection and Maintenance

The filter has no moving or active parts and therefore requires only minimal periodic maintenance when installed

in a clean and well ventilated environment. Inspection shall include (but not limited to) the contents of the table

8-2. The table 8-3 is the inspection schedule of maintenance. The table 8-4 is the inspection schedule of device

replacing. Annual maintenance is recommended. This should include:

8.2.1 Visual inspection for evidence of loose connections, dirt, moisture, rusting, corrosion, and

deterioration of the insulation, varnish or paint.

8.2.2 Inspection for the 3 phase current of capacitors, phase current difference should be not over 10%.

8.2.3 Excessive accumulations of dirt on the reactor windings or insulators and capacitor terminals should

be removed to permit free circulation of air and to guard against the possibility of insulation

breakdown.

Note:

humidity effect: If a filter shut down exceeding 24 hours occurs during a period of high humidity

that could cause condensation within the reactor, precautions should be taken. The filter needs to

be placed with desiccant If leave it unused for a long time.

Table 8-2 Working content of regular maintenance

Science and Technology Create Natural

16

Maintenance Manual of Passive Filter

Inspection Item Procedure Pass Criteria

Check whether the surface and inside has Surface and inner of cabinet body

Examination of cabinet sundries, frost, air inlet and outlet blocking of is dry, clean, air inlet and outlet of

fan fan is unobstructed

Check the bolts are tightened; Installed tightly;

Inside components Check the cable connected tightly Bolts are tightened ;

Check components appearance Appearance no abnormal

Bolt of bus and Check whether bolt connection of bus and Solid connection, no loose, no

ground system ground system are tighten burning mark on the surface

Table 8-3 Maintenance and Examine Time Table

Standard 6 2

Beginning 1 year 7 years 15 years

Replacement months years Evaluation Criteria

of

Intervals

Operation 2500(h) 5000(h) 8000(h) 40000(h)

Inspection Items

Daily Inspection 1) Temperature is 40℃ or less. Shall be free from condensation, electro conductive

dust, oil mist, flammable gases and corrosive gases

2) Enclosure: There must be no abnormally temperature by exhaust part.

When the filter is run, air suction part and/or exhaust part is clogged. And any

foreign material is affixed to them

Cabinet: must be dry, clean, dust free, and ventilated (inlet and/or exhaust). When

breaker is on, air suction part and/or exhaust part is clogged

3) Input-output specification: Input voltage is within the range, and output current must

be under rating value

Control circuit wiring ● △ ○ ▲ Connection is loose, with burn

scar and pungent smell

Reactor ● ○ ▲ There is burn scar , abnormal

appearance

Capacitor If the capacitance drop is more

● ○ ▲ than 5% of the nominal , the

capacitor should be replaced

Fuse ● △ ○ ▲ Open

Bolt of bus and ● △ ○ ▲ There is no slackness and no

ground system ark scar.

Fastener bolt ● △ ○ ▲ Loose

Control Transformer ● ○ ▲ There is burn scar, pungent

smell or wrong output.

Note1) ●: Items need to be checked before first time run of the filter.

○: Periodic inspection. Replace the parts if abnormal appears or reaching proofreading standard.

△: Recommend to replace parts as per proofreading standard after first time run.

▲: Suggest to replacing as per proofreading standard after the last replacing.

Note2) The replaced parts depend on the interval time and the run time. Take the first as the standard.

Note3) The daily and monthly checking items are performed and recorded by the customers. The rest checking

items must be carried out by DAIKIN ’s professional service personnel.

Table 8-4 Replace the timetable on a regular basis

Standard replacement of fixed number of year(Note)

Science and Technology Create Natural

17

Maintenance Manual of Passive Filter

Vulnerable 1 2 3 4 5 6 7 8 9 10

parts

electrolytic replace

capacitor

fuse replace

Note : To ambient temperature of 40℃, load rate at 80% when the presumption of life as a benchmark,

sometimes in the surrounding temperature is higher than that of 40℃ or have a lot of dust environment, standard

replacement years will shorten.

Service Flow

The proper maintenance prolongs service life and enhances performance of the AC system .

The maintenance starts basically as the chiller starts. 3 to 4 weeks after the first start-up, it must

be overall inspected, followed by periodical maintenance.

DAIKIN provides diversified maintenance service according to different customer needs .

Contact Methods

Company address: No. 33 ChechengRoad, Economical and Technology Development District, Wuhan ,

Hubei, China

Post Code:430056

Science and Technology Create Natural

18

Maintenance Manual of Passive Filter

★ The printing may deviates from the real products, please refer to the real object when purchasing .

★ All material is carefully reviewed. In case of any printing errors, DAIKIN bears no responsibility.

★ Models, parameters and performance may change due to product improvement without further notification.

Please refer to the nameplate for detail.

Science and Technology Create Natural

19

You might also like

- Instruction Manual: ES65 / ES100 / ES200 / ES300 and ES630 Single Stage Rotary Vane PumpsDocument56 pagesInstruction Manual: ES65 / ES100 / ES200 / ES300 and ES630 Single Stage Rotary Vane PumpsJVH1978No ratings yet

- 01 PJ Commercial and Industrial Cold Water Electric.2Document40 pages01 PJ Commercial and Industrial Cold Water Electric.2Santiago AlbarranNo ratings yet

- 7004324r7 057-810-00 MaxQ 4450Document40 pages7004324r7 057-810-00 MaxQ 4450Jesus OrozcoNo ratings yet

- Forma 8600 Series ULT Chest Freezer ManualDocument116 pagesForma 8600 Series ULT Chest Freezer ManualasdjoadreNo ratings yet

- 0455 675 101 GBDocument26 pages0455 675 101 GBramadan.seydNo ratings yet

- 7004348r13-LT2087X1 - MaxQ 5000Document42 pages7004348r13-LT2087X1 - MaxQ 5000David ThNo ratings yet

- Liquid Cooled Optispeed™ Compressor Speed Drive: Operation ManualDocument32 pagesLiquid Cooled Optispeed™ Compressor Speed Drive: Operation ManualghilesNo ratings yet

- Side-Power: SXP80/185T & SXP100/185T External Sternthruster AssemblyDocument16 pagesSide-Power: SXP80/185T & SXP100/185T External Sternthruster AssemblyLin LinNo ratings yet

- Yamaha DSP Ax2600 RX v2600Document155 pagesYamaha DSP Ax2600 RX v2600Winslow-1132No ratings yet

- Ir8500 85 85 7200 8070-pcDocument316 pagesIr8500 85 85 7200 8070-pcAntonio Carlos MottaNo ratings yet

- Diodo Mur460Document7 pagesDiodo Mur460marnoonpvNo ratings yet

- Butt Welder ManualDocument21 pagesButt Welder Manualkazambo78No ratings yet

- Chiller 201.26-rp1Document72 pagesChiller 201.26-rp1MJZENo ratings yet

- Soft Drive 200 DesignDocument22 pagesSoft Drive 200 DesignMine RHNo ratings yet

- Thermo - Scientific - Precision - Circulating - Water - Baths - Model 260 - 265 - 270 - Operating - and - Maintenance - Manual Rev - NDocument54 pagesThermo - Scientific - Precision - Circulating - Water - Baths - Model 260 - 265 - 270 - Operating - and - Maintenance - Manual Rev - NelduNo ratings yet

- VFDs++for+HVAC+Application+ +Standard+or+PackagedDocument6 pagesVFDs++for+HVAC+Application+ +Standard+or+PackagedLuis MorenoNo ratings yet

- Manual Sps 4001b Single Probe Autocalibration Sequencer Rosemount en 1127750Document70 pagesManual Sps 4001b Single Probe Autocalibration Sequencer Rosemount en 1127750cocot 666No ratings yet

- DBS3900 Spare Parts CatalogDocument131 pagesDBS3900 Spare Parts CatalogleonardomarinNo ratings yet

- Electronic Expansion Valve Controller - Bi Polar Valves - 351456002-1Document16 pagesElectronic Expansion Valve Controller - Bi Polar Valves - 351456002-1Manu JimDiNo ratings yet

- Apb430v2 (Despiece)Document44 pagesApb430v2 (Despiece)Luis GarzonNo ratings yet

- Kohler 400REOZD Detroit Diesel Series 60 Engine Spec SheetDocument4 pagesKohler 400REOZD Detroit Diesel Series 60 Engine Spec SheetJoanne CordesNo ratings yet

- Grundfos Lista Preturi 2011Document416 pagesGrundfos Lista Preturi 2011Dragos GheorgheNo ratings yet

- 990 380 Is 800CA 1400CA Opeartor Manual Rev GDocument254 pages990 380 Is 800CA 1400CA Opeartor Manual Rev GSita Rama Raju PNo ratings yet

- Drystar Edp80 SeriesDocument82 pagesDrystar Edp80 SeriesManoj BNo ratings yet

- HF 2500A Rev H Opearation ManualDocument168 pagesHF 2500A Rev H Opearation ManualsunhuynhNo ratings yet

- ESAB 453ccDocument32 pagesESAB 453ccdavid bolivarNo ratings yet

- Xerox Phaser 6121MFP ServiceManualDocument131 pagesXerox Phaser 6121MFP ServiceManualdreiusNo ratings yet

- Yamaha DSP Ax630 Se HTR 5560 Rds RX v630 Rds RX v730 RdsDocument114 pagesYamaha DSP Ax630 Se HTR 5560 Rds RX v630 Rds RX v730 RdsgondifNo ratings yet

- ELT 4000 Y1-03-0333 Rev HDocument75 pagesELT 4000 Y1-03-0333 Rev Hjosue jetavionicsNo ratings yet

- Yamaha RXV1500Document125 pagesYamaha RXV1500Saeid PourfarzibNo ratings yet

- Yamaha RX-V765 Htr-6270 SM (ET)Document156 pagesYamaha RX-V765 Htr-6270 SM (ET)hifi-electronicNo ratings yet

- Yamaha xp7000 5000 Power Amplifier Service Manual PDFDocument92 pagesYamaha xp7000 5000 Power Amplifier Service Manual PDFRomlly Voice Elektro100% (3)

- Is 300CA Rev D Operation ManualDocument208 pagesIs 300CA Rev D Operation ManualsunhuynhNo ratings yet

- AV Receiver Service ManualDocument125 pagesAV Receiver Service ManualRobertas PutinasNo ratings yet

- Manual de Mantenimiento BS2640.180Document28 pagesManual de Mantenimiento BS2640.180Roberto Daniel Sanchez MelgarejoNo ratings yet

- CBF en Genie Ring Manual Ac800fDocument56 pagesCBF en Genie Ring Manual Ac800fEnrique Francisco Wekwert100% (1)

- Solar Pumping Inverter User Manual: Designed & Manufactured by Shenzhen ADA Power Electronics Co., LTDDocument20 pagesSolar Pumping Inverter User Manual: Designed & Manufactured by Shenzhen ADA Power Electronics Co., LTDWaliallah SafiNo ratings yet

- RX V1600 PDFDocument151 pagesRX V1600 PDFavreceivertechNo ratings yet

- Maxq 6000 Stackable Incubated Refrigerated Shaker User Manual 7004352Document40 pagesMaxq 6000 Stackable Incubated Refrigerated Shaker User Manual 7004352Irwin RodriguezNo ratings yet

- Hfe Yamaha RX E410 E810 ServiceDocument57 pagesHfe Yamaha RX E410 E810 Serviceanthony leonardNo ratings yet

- FAA - AC - 150 - 5345 - 47c - Transformador de IsolamentoDocument18 pagesFAA - AC - 150 - 5345 - 47c - Transformador de IsolamentoRonaldo FirmoNo ratings yet

- Totaline Compressor GuideDocument24 pagesTotaline Compressor GuideArnaldo OcamposNo ratings yet

- User Manual Acer 2.0 A ADocument104 pagesUser Manual Acer 2.0 A ATolo M.G.No ratings yet

- Fan Uc Manuals 1793Document93 pagesFan Uc Manuals 1793Erik Hernandez100% (1)

- Labgard Class II, Type A2 Laminar Flow Biological Safety CabinetDocument44 pagesLabgard Class II, Type A2 Laminar Flow Biological Safety CabinetCeleynes RTNo ratings yet

- Basic 250 EngDocument9 pagesBasic 250 EngPurushothaman JayabalanNo ratings yet

- Certificate of Compliance: Certificate Number Report Reference Issue DateDocument5 pagesCertificate of Compliance: Certificate Number Report Reference Issue DateBryan S. AlejandroNo ratings yet

- Labgard® Es Energy Saver Class Ii Laminar Flow Biosafety Cabinet Models Nu-543-300E/400E/500E/600E Bench/Console Operation and Maintenance ManualDocument72 pagesLabgard® Es Energy Saver Class Ii Laminar Flow Biosafety Cabinet Models Nu-543-300E/400E/500E/600E Bench/Console Operation and Maintenance ManualAnalis LabNo ratings yet

- Fuji - SC - DatasheetDocument7 pagesFuji - SC - Datasheetcyrano1091No ratings yet

- Light Force LT-050B Weld Head: Operation ManualDocument46 pagesLight Force LT-050B Weld Head: Operation ManualsunhuynhNo ratings yet

- Panal DrowingDocument136 pagesPanal DrowingMuhammad azeemNo ratings yet

- Maintain Petrol Pressure WashersDocument16 pagesMaintain Petrol Pressure WashershrmlynNo ratings yet

- 7004352r11-LT2120X1 MaxQ 6000Document40 pages7004352r11-LT2120X1 MaxQ 6000David ThNo ratings yet

- 2016 - ProductsBrochure WebDocument46 pages2016 - ProductsBrochure WebHassen LazharNo ratings yet

- RSI H2 Series - VFD ManualDocument396 pagesRSI H2 Series - VFD ManualIsidro PortugalNo ratings yet

- MaxQ 3000 Benchtop Open-Air Platform Shakers ManualDocument30 pagesMaxQ 3000 Benchtop Open-Air Platform Shakers ManualR SmithNo ratings yet

- Wil o 419065Document25 pagesWil o 419065Youghorta TirNo ratings yet

- TM 10-6640-229-13P Precision General Purpose Water Baths Model TS-66518 Aw-9Document31 pagesTM 10-6640-229-13P Precision General Purpose Water Baths Model TS-66518 Aw-9AdvocateNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- n°07-WHS-Issue 1Document123 pagesn°07-WHS-Issue 1AbdulSattarNo ratings yet

- Lenze AC Tech SMV Quick Start GuideDocument2 pagesLenze AC Tech SMV Quick Start GuideAbdulSattarNo ratings yet

- 1-1 LBSW Iklc21Document90 pages1-1 LBSW Iklc21AbdulSattarNo ratings yet

- Turbochill: Air Cooled Chiller 500 KW - 1100 KWDocument28 pagesTurbochill: Air Cooled Chiller 500 KW - 1100 KWmodussarNo ratings yet

- ResponseDocument1 pageResponseAbdulSattarNo ratings yet

- WMC D SinglePtDocument2 pagesWMC D SinglePtAbdulSattarNo ratings yet

- ALARMES - SMMSi Service ManualDocument370 pagesALARMES - SMMSi Service ManualSprinlg100% (1)

- Data Sheet750-315 300-000 09.02.2022Document12 pagesData Sheet750-315 300-000 09.02.2022AbdulSattarNo ratings yet

- TM Daikin 50Hz EuroventDocument143 pagesTM Daikin 50Hz EuroventericyuenNo ratings yet

- EWAD-C-PS - PL Product Flyer - ECPEN15-428 - 5 - Product Catalogues - EnglishDocument2 pagesEWAD-C-PS - PL Product Flyer - ECPEN15-428 - 5 - Product Catalogues - EnglishAbdulSattarNo ratings yet

- RKS50E2V1B and RKS60E2V1B Wiring Diagram and Parts List (Less than 40 charsDocument51 pagesRKS50E2V1B and RKS60E2V1B Wiring Diagram and Parts List (Less than 40 charsAbdulSattarNo ratings yet

- Copeland-Scroll - Compressors-for-Air-Conditioning-Applications PDFDocument28 pagesCopeland-Scroll - Compressors-for-Air-Conditioning-Applications PDFSetiawan Indrajaya SoeradjiNo ratings yet

- FHP Upm IDocument10 pagesFHP Upm IAbdulSattarNo ratings yet

- Untitled - FHP ManufacturingDocument52 pagesUntitled - FHP ManufacturingAbdulSattarNo ratings yet

- Efficient condenserless cooling units with up to 959.4 kW capacityDocument3 pagesEfficient condenserless cooling units with up to 959.4 kW capacityAbdulSattarNo ratings yet

- In-the-Ceiling Type Indoor Unit SpecsDocument3 pagesIn-the-Ceiling Type Indoor Unit SpecsAbdulSattarNo ratings yet

- Pack-P Ar 1 1 0 0 - 3 5 0 0: Instructions BookletDocument16 pagesPack-P Ar 1 1 0 0 - 3 5 0 0: Instructions BookletAbdulSattarNo ratings yet

- MA TER DR Rev.1Document13 pagesMA TER DR Rev.1AbdulSattarNo ratings yet

- 90281000T10Z001K000Document9 pages90281000T10Z001K000AbdulSattarNo ratings yet

- Installation, Operation & Maintenance ManualDocument93 pagesInstallation, Operation & Maintenance ManualAbdulSattarNo ratings yet

- Baelz 373-E07 Electric ActuatorDocument3 pagesBaelz 373-E07 Electric ActuatorAbdulSattarNo ratings yet

- 3-Phase Network Control Relay Product Data SheetDocument7 pages3-Phase Network Control Relay Product Data SheetAbdulSattarNo ratings yet

- 2008ect-113 R1Document16 pages2008ect-113 R1jake1000No ratings yet

- 3-Phase Network Control Relay Product Data SheetDocument7 pages3-Phase Network Control Relay Product Data SheetAbdulSattarNo ratings yet

- 4-Way Reversing ValvesDocument3 pages4-Way Reversing ValvesAbdulSattarNo ratings yet

- Pack-P Ar 1 1 0 0 - 3 5 0 0: Instructions BookletDocument16 pagesPack-P Ar 1 1 0 0 - 3 5 0 0: Instructions BookletAbdulSattarNo ratings yet

- Micromanometer: Ventilation TestingDocument19 pagesMicromanometer: Ventilation TestingAbdulSattarNo ratings yet

- 3-Phase Network Control Relay Product Data SheetDocument7 pages3-Phase Network Control Relay Product Data SheetAbdulSattarNo ratings yet

- Zelio Control RM4TG20Document6 pagesZelio Control RM4TG20AbdulSattarNo ratings yet

- Screw Chiller Parts ListDocument28 pagesScrew Chiller Parts Listeka prasetiaNo ratings yet

- Monarch-Nice 1000 Electric Drawing PDFDocument9 pagesMonarch-Nice 1000 Electric Drawing PDFGalang AntoNo ratings yet

- Me Lab 6Document9 pagesMe Lab 6BensoyNo ratings yet

- Steel SpecificationsDocument18 pagesSteel SpecificationssurenderbuddhaNo ratings yet

- Up-Aces Ce Quiz 2011Document8 pagesUp-Aces Ce Quiz 2011Claver G. MontesNo ratings yet

- Latest Progress in TGD: The Geometry of World of Classical Worlds and Emergence of Unitary S-MatrixDocument77 pagesLatest Progress in TGD: The Geometry of World of Classical Worlds and Emergence of Unitary S-MatrixLuciano FagundesNo ratings yet

- Puente Seccion CompuestaDocument158 pagesPuente Seccion CompuestaJulio César Cubas GuevaraNo ratings yet

- AKM 2G Servo Motor: Selection GuideDocument84 pagesAKM 2G Servo Motor: Selection GuideVahan KirakosyanNo ratings yet

- Ch02-Zealey PRE 4thppDocument67 pagesCh02-Zealey PRE 4thppMuhammad Kashif RashidNo ratings yet

- Is 8000 ManualDocument152 pagesIs 8000 ManualmartinxueloNo ratings yet

- MMPDS-11 Chapter 9 Guidelines for Presentation of DataDocument5 pagesMMPDS-11 Chapter 9 Guidelines for Presentation of Databananth1No ratings yet

- 3rt1034-1a Specs PDFDocument2 pages3rt1034-1a Specs PDFTGS ElectricalNo ratings yet

- Electrical Installation and Maintenance Grade 11: Learning CompetencyDocument15 pagesElectrical Installation and Maintenance Grade 11: Learning CompetencyCristal Gumalang100% (5)

- API 600 Trim No.Document19 pagesAPI 600 Trim No.SUBHASISH BHATTACHARYYANo ratings yet

- Direct VariationDocument44 pagesDirect VariationMary Ann Rasco100% (1)

- Verify Geometrically That c×a+b = c×a + c×b Using ParallelogramsDocument4 pagesVerify Geometrically That c×a+b = c×a + c×b Using ParallelogramsblehboNo ratings yet

- SPE 125581 Global Laboratory Experience of CO2-EOR Flooding: V D V A I 1Document15 pagesSPE 125581 Global Laboratory Experience of CO2-EOR Flooding: V D V A I 1shayanepmNo ratings yet

- Short Circuit and Overcurrent Protection of IGCT-based Three-Level NPC InvertersDocument7 pagesShort Circuit and Overcurrent Protection of IGCT-based Three-Level NPC InvertersReza GhasemiNo ratings yet

- Unit 16 ExplanationDocument12 pagesUnit 16 ExplanationAnh MaiNo ratings yet

- Effect of Temperature and Cooling Rates on the α+β Morphology of Ti-6Al-4V Alloy Effect of Temperature and Cooling Rates on the α+β Morphology of Ti-6Al-4V AlloyDocument8 pagesEffect of Temperature and Cooling Rates on the α+β Morphology of Ti-6Al-4V Alloy Effect of Temperature and Cooling Rates on the α+β Morphology of Ti-6Al-4V AlloysaltbathNo ratings yet

- Instructions for Combined Boiler CombustionDocument23 pagesInstructions for Combined Boiler CombustionMavio ViorelNo ratings yet

- Em 111-Calculus 1 (Differential Calculus) : Graph of A FunctionDocument3 pagesEm 111-Calculus 1 (Differential Calculus) : Graph of A FunctionJohn Philip NadalNo ratings yet

- Piping Design GuideDocument65 pagesPiping Design GuideShrey PatelNo ratings yet

- 3G3mx2-v2 Ds e 1 1 csm1126864Document54 pages3G3mx2-v2 Ds e 1 1 csm1126864Pertti HänninenNo ratings yet

- GRADE 7 SCIENCE ModuleDocument41 pagesGRADE 7 SCIENCE ModuleKristine Dela CruzNo ratings yet

- 4FE-28Y-40P With FHU+60Document17 pages4FE-28Y-40P With FHU+60tedychrNo ratings yet

- Aqa 83001H QP Jun19Document24 pagesAqa 83001H QP Jun19himakshee singhviNo ratings yet

- Golden Ratio Face AnalysisDocument3 pagesGolden Ratio Face AnalysisClairyssa Myn D CaballeroNo ratings yet

- 25 - Ray Optics and Optical Instruments - KeynotesDocument28 pages25 - Ray Optics and Optical Instruments - KeynotesthorNo ratings yet

- Bernoulli's Principle and Application: Ang SovannDocument45 pagesBernoulli's Principle and Application: Ang SovannKantilal MalwaniaNo ratings yet

- Packaged, Dry, Rapid-Hardening Cementitious Materials For Concrete RepairsDocument4 pagesPackaged, Dry, Rapid-Hardening Cementitious Materials For Concrete RepairsJesús Luis Arce GuillermoNo ratings yet