Professional Documents

Culture Documents

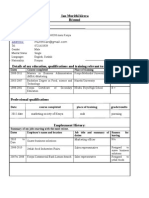

Automated Double Way Hacksaw Machine

Uploaded by

BADINEHALSANDEEPOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automated Double Way Hacksaw Machine

Uploaded by

BADINEHALSANDEEPCopyright:

Available Formats

International Journal of Advanced Research in Basic Engineering Sciences and Technology (IJARBEST)

AUTOMATED DOUBLE WAY HACKSAW

1

Sathyanathan.M, 2Chandru.S, 2Lingesh.K, 2Ragul.K, 2Vijay.S

1

Associate Professor, Department of Mechanical Engineering, Knowledge Institute of Technology, Tamil Nadu,

India.

2

UG Scholar, Department of Mechanical Engineering, Knowledge Institute of Technology, Tamil Nadu, India

Abstract— This project is the design and construction of an automatic power hacksaw machine for cutting of

metal to different size and length with the help of hacksaw. The objective of this project is to save man power

and time in cutting metals in order to achieve high productivity. Automation plays a dominant role in the world

economy these days and in daily application in industries. In automatic hacksaw machine the scotch yoke

mechanism is used in two pair and we arrange it with hacksaw. This hacksaw machine has two hacksaw blades

which is cut two work pieces with in one time and in accurate number of cycles. So, it will helpful to increase

productivity, it save time to stop it and run it again, also less human effort required.

Keywords: Hacksaw machine, scotch yoke mechanism.

1. INTRODUCTION from them is not satisfactory as it has low cutting

rate.

In present condition many electrically operated

power hacksaw machines of different companies with

different specifications are available for the use in 3. DESCRPTION OF COMPONENTS

shop floor. These machines are so precise that they

can cut metal bars with minimum time made up of 3.1 Frame Base

different materials but they have one and major

disadvantage that those are able to cut two piece of We take 75cm x 30cm square steel frame

bar at a time. For industries to achieve the mass base. We take 75 cm in base length because; we want

production, it is necessary to cut metal bars with high to give stability our prototype model of four way

rate. So it is impossible to depend upon conventional hacksaw machine not get lot of vibration the

single frame power hacksaw machines and need the machine in running condition.

improvement in technology and design of such

machines. With the help of this two-way power 3.2 DC Motor

hacksaw machine the two metal bars can be cut

The motor we have used is a wiper DC

simultaneously to get high speed cutting rate and to

motor of 60 rpm. A machine that converts DC

achieve mass production for maximum profit in

Electrical power into mechanical power is known as a

related companies. As this machine overcomes all the

D.C. motor. This operation is based on the principle

limitations and drawbacks of conventional hacksaw

that when a current carrying conductor is placed in a

machines, it is also helpful for small scale industries

magnetic field, the conductor experiences a

due to its simple working and operating conditions

mechanical force. The direction of this force is given

along with its compatibility, efficiency and affordable

by Fleming’s left hand rule and magnitude is given

price. This project is about cutting the wood, metal,

by; F = BI .There is no constructional difference

pipe, angle, channel, flat plates, rods and such other

between a D.C. motor and a D.C. generator. The

things.

same D.C. machine can be run as a generator or

motor.

2. PROBLEM IDENTIFICATION

Present scenario of industry focuses on the high

production rate with less consumption of resources.

To achieve this we need to minimize idle time and

machine time per unit. The two way hacksaw blade

machine improves those factors by reducing time per

Fig 3.1: DC motor

unit to increase the production.

In present situation electrical as well as

hydraulic operated machines are used but the output

ISSN (ONLINE):2456-5717 61 Vol.4, Issue.8, August 2018

International Journal of Advanced Research in Basic Engineering Sciences and Technology (IJARBEST)

4. DESIGN OF DOUBLE WAY

HACKSAW

3.3 Hollow Disc

We use the acrylics transparent disc in

circular shape (radius of 7.5 cm). On this disc all the

bearing is happen. It helps to convert the rotary

motion to linear movement.

Fig. 4.1: Double way Hacksaw

3.4 Hacksaw Blade

Hacksaw blade is made of Bi-metallic. In

hacksaw like most frame saws, the blade can be 5. WORKING PRINCIPLE

mounted with the teeth facing toward or away from A hacksaw machine is work on principle of

the handle, resulting in cutting. Action on either the SCOTCH YOKE MECHANISM in this rotary motion

push or pull stroke. In normal use, cutting vertically of shaft is to be convert into the reciprocating motion

downwards with work held in a bench vice, hacksaw of hacksaw frame. Working principle of hacksaw

blade should be set to be facing forwards. Some machine is very simple. First of all the hacksaw

frame saws, including fret saws and piercing saws, machine is put on ground and after that whatever

have their blades set to be facing the handle because metal, wood, pvc, is cut is fixed on vice at required

they are used to cut by being pulled down against a length, After that the electric motor is connect with

horizontal surface, by the help of scotch yoke electricity. Now start the electric motor due to that the

mechanism. The hacksaw blade is connected to the shaft of motor and hollow disc will be rotate and also

link bar by the help of linear bushing. rotate the eccentric Centre and link connect to it. Due

to rotation of links the hacksaw frame will be

reciprocate on the metal and cutting of metal is done.

6. APPLICATIONS

1. Hacksaw is most commonly used for cutting

hard materials. They are used extensively in

forestry, construction and demolition.

Fig 3.2: Hacksaw Blade

2. Some hacksaws are used as instruments to make

music.

3.5 Connecting Rods

A hole on at the end of this rod is made for joints and 3. Chainsaw carving is a flourishing modern at

form. Special saws have been developed for this

link connections. we have used two of these shaft for

two side hack saw. Together with the crank, it forms purpose.

a simple mechanism that converts reciprocating

4. In engineering industry.

motion into rotating motion. A connecting rod may

also convert rotating motion into reciprocating 5. In Workshop.

motion.

7. ADVANTAGES

1. Weight of the machine is less.

2. It reduces the work of labor.

3. Easy to make because of simple construction.

4. High production rate.

5. Cost is less.

6. Easy maintenance and maintenance cost is less.

Fig 3.3: Connecting rod 7. It withstand all atmospheric effects.

ISSN (ONLINE):2456-5717 62 Vol.4, Issue.8, August 2018

International Journal of Advanced Research in Basic Engineering Sciences and Technology (IJARBEST)

8. CONCULSION Development of Pedal Powered Hacksaw”,

International Journal of Emerging Trends in

To overcome problems in conventional Engineering and Development Issue 5, Vol. 3

hacksaw machines, due to high efficiency, easy to (April.-May. 2015).

operate and affordable price the proposed model of

two-way power hacksaw machine is helpful and

completes all the expectations needed in the mini

industries. It can withstand the vibrations, no hazards

from jerk, no special training required to operate it.

Other hacksaw machines can cut one part at a time

but this machine can cut two parts at a time. This

hacksaw machine has lighter weight compare to other

machine. The cost of machine is less and easy to

operate and affordable for all industries.

9. REFERENCES

[1] Build a power hacksaw with vise, Authors: -

Vincent Gingery.

[2] D.V. Sabarinanda, Siddhartha, B. Sushil

Krishnana, T. Mohanraj , “Design and

Fabrication Of Automated Hacksaw Machine”,

International Journal of Innovative Research in

Science, Engineering and Technology, ISSN

(Online): 2319-8753, volume 3, April 2014.

[3] R. Subhash, C.M. Meenakshi, K. Samuel

Jayakaran, C. Venkateswaran, R. Sasidharan,

Fabrication pedal powered hacksaw.

[4] Prof. Nitinchandra R. Patel, Mohammad A.

Vasanwala, Balkrushna B. Jani, Ravi Thakkar,

Miteshkumar D. Rathwa, Material selection and

testing of hacksaw blade based on mechanical

Properties”, International Journal of Innovative

Research in Science, Engineering and

Technology, ISSN: 2319-8753, volume 2, Issue

6, June 2013.

[5] Prof. K. Prashant R, Rathod Nayan, Rahate

Prashant , Halaye Prashant, “Theoretical

Analysis of Multi-Way Power Hacksaw

Machine”, International Journal of Research in

Advent Technology, Vol.3, No.4, April 2015 E-

ISSN: 2321-9637 .

[6] R.S.Khurmi, J.K.Guptal, (2012)”Theory of

machines”, Page no. 143-168.

[7] Matt Campbell Stephen s. Nestinger,

Department of mechanical and aeronautical

engineering university of California computer

davis, Aided Design and Analysis of the

whitworth quick return mechanism.

[8] Rishi Anand, Khomesh, Shrawan Kumar, Prof.

Alok Verma,” Theoretical Analysis Of Four

Way Hacksaw Blade Machine”, International

Journal of Advance Research and Innovative

Ideas in Education, ISSN(O)-2395-4396, Vol-2

,Issue-2 April2016.

[9] Vivek Kumar Chauhan, Faheem khan,

Chandresh Kumar Joshi, “Design and

ISSN (ONLINE):2456-5717 63 Vol.4, Issue.8, August 2018

You might also like

- Fabrication of Automated Four-Way Hack Saw Machine by Using Scotch Yoke MechanismDocument7 pagesFabrication of Automated Four-Way Hack Saw Machine by Using Scotch Yoke MechanismMikyas BelayNo ratings yet

- Designing and Fabrication of Double Acting Hacksaw MachineDocument6 pagesDesigning and Fabrication of Double Acting Hacksaw MachineVARSHAN HARIGANTHNo ratings yet

- Automated Double Hacksaw MachineDocument5 pagesAutomated Double Hacksaw MachineInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Fabrication of Solar Powered Wood and Metal Cutting Hacksaw MachineDocument3 pagesFabrication of Solar Powered Wood and Metal Cutting Hacksaw MachineRamsathayaNo ratings yet

- Multi Way Hack Saw Machine-A Review: Pratik Awati, Shubham Amrutkar, Satish Sable, Swapnil Wani, Ashwin DharmeDocument3 pagesMulti Way Hack Saw Machine-A Review: Pratik Awati, Shubham Amrutkar, Satish Sable, Swapnil Wani, Ashwin DharmeAjitNo ratings yet

- Four Way Hacksaw Machine Ijariie2053Document6 pagesFour Way Hacksaw Machine Ijariie2053ParvezRazaNo ratings yet

- High Speed 4-Way Hacksaw MachineDocument46 pagesHigh Speed 4-Way Hacksaw Machineindia cybercafeNo ratings yet

- Development of Heavy Duty Shredder: Nordin Othman & NG Cheah ChoonDocument6 pagesDevelopment of Heavy Duty Shredder: Nordin Othman & NG Cheah Choonjozsef laszloNo ratings yet

- SYNOPSIS Solar Powered Mechanical HacksawDocument10 pagesSYNOPSIS Solar Powered Mechanical HacksawEsteFan AjayNo ratings yet

- DC Powered Energy Based Hacksaw MachineDocument61 pagesDC Powered Energy Based Hacksaw Machinenaresh pendlyNo ratings yet

- Theoretical Analysis of Multi-Way Power Hacksaw MachineDocument4 pagesTheoretical Analysis of Multi-Way Power Hacksaw MachineJames AzurinNo ratings yet

- Automatic Power Four Way Hacksaw MachineDocument6 pagesAutomatic Power Four Way Hacksaw Machinebrian galangNo ratings yet

- ProjectDocument38 pagesProjectChowdariNo ratings yet

- 4 Way Hacksaw MachineDocument8 pages4 Way Hacksaw Machinepandi67% (3)

- Chapter-1 Inroduction: 4 Way Hacksaw MachineDocument47 pagesChapter-1 Inroduction: 4 Way Hacksaw MachinekarthikNo ratings yet

- Creating and Manufacturing A Pedal-Powered HacksawDocument4 pagesCreating and Manufacturing A Pedal-Powered HacksawInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design & Fabrication of Portable Table Saw For Small Wood Working Project & WorkshopDocument4 pagesDesign & Fabrication of Portable Table Saw For Small Wood Working Project & WorkshopVIVA-TECH IJRINo ratings yet

- Design and Fabrication of Motorized Hacksaw MachineDocument9 pagesDesign and Fabrication of Motorized Hacksaw MachineIJRASETPublicationsNo ratings yet

- Solar Powered Light Duty Flexible Drilling MechanismDocument4 pagesSolar Powered Light Duty Flexible Drilling MechanismOmkar SinghNo ratings yet

- ReportDocument4 pagesReportTanjid Al TajimNo ratings yet

- Design and Development of Four Way Hacksaw Machine: Umesh Nachan Rohit Singh Rutij PhaltankarDocument4 pagesDesign and Development of Four Way Hacksaw Machine: Umesh Nachan Rohit Singh Rutij PhaltankarPankaj GautamNo ratings yet

- Design and fabrication of a double-acting hacksaw machine for high-speed cuttingDocument8 pagesDesign and fabrication of a double-acting hacksaw machine for high-speed cuttingsankaramarayanan100% (1)

- Smart Solar Grass Cutter Robot For Grass Trimming Ijariie1954 PDFDocument6 pagesSmart Solar Grass Cutter Robot For Grass Trimming Ijariie1954 PDFBemn BayuNo ratings yet

- Design & Fabrication of 360° Flexible Drilling MachineDocument4 pagesDesign & Fabrication of 360° Flexible Drilling MachineSumit ShuklaNo ratings yet

- MPM Research PaperDocument5 pagesMPM Research PaperPratik TyagiNo ratings yet

- Development of An Economical Solar Powered Lawn MoverDocument7 pagesDevelopment of An Economical Solar Powered Lawn MoverIJRASETPublicationsNo ratings yet

- Fabrication of Special Purpose Machine: R Kumar, Hemanth Kumar J, Chethan KumarDocument4 pagesFabrication of Special Purpose Machine: R Kumar, Hemanth Kumar J, Chethan KumarMikyas BelayNo ratings yet

- High Speed 4 Way Hacksaw MachineDocument21 pagesHigh Speed 4 Way Hacksaw MachineSAURABH CHOUDHARYNo ratings yet

- Lovely Professional University PEDAL–POWERED HACKSAW METAL CUTTER AND WASHING MACHINEDocument13 pagesLovely Professional University PEDAL–POWERED HACKSAW METAL CUTTER AND WASHING MACHINEbalbir100% (1)

- Designing and Fabrication of a High-Speed Double Acting Hacksaw MachineDocument8 pagesDesigning and Fabrication of a High-Speed Double Acting Hacksaw MachineGrish PurbeyNo ratings yet

- CRANK SHAFT OPERATED MULTI BLADE HACKSAWDocument15 pagesCRANK SHAFT OPERATED MULTI BLADE HACKSAWTanvi Khurana100% (2)

- Fixture For Plasma Cutting Machine For Circular CutsDocument3 pagesFixture For Plasma Cutting Machine For Circular CutsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Pedal Operated HacksawDocument37 pagesPedal Operated HacksawChowdari100% (1)

- 360° Welding Cutting Rotary Turn Table Welding PositionerDocument4 pages360° Welding Cutting Rotary Turn Table Welding PositionerSanath KumarNo ratings yet

- Design and Fabrication of Automated Smart Solar Grass Cutter Using GPS TechnologyDocument6 pagesDesign and Fabrication of Automated Smart Solar Grass Cutter Using GPS TechnologyAV VNo ratings yet

- JETIRFP06013Document4 pagesJETIRFP06013Ropah ChihuriNo ratings yet

- Theoretical Analysis of Multi Way PowerDocument4 pagesTheoretical Analysis of Multi Way PowerTanjid Al TajimNo ratings yet

- Design and Fabrication of Multioperational MachineDocument4 pagesDesign and Fabrication of Multioperational MachineResearch Publish JournalsNo ratings yet

- Roever Engineering College Design and Fabrication of Double Acting Scotch Yoke Power HacksawDocument31 pagesRoever Engineering College Design and Fabrication of Double Acting Scotch Yoke Power HacksawSergio PugazhNo ratings yet

- Final Four WayDocument35 pagesFinal Four WayRohitsingh JadaunNo ratings yet

- Cbe-241rev Quad Processing MachineDocument12 pagesCbe-241rev Quad Processing MachineVigneshMurugesh ANo ratings yet

- Six-Axis WEDM for Micro End Mill FabricationDocument11 pagesSix-Axis WEDM for Micro End Mill FabricationmarkrichardmuradNo ratings yet

- Carbon Brush Performance On Slip RingsDocument6 pagesCarbon Brush Performance On Slip Ringstan.garcia.ramosNo ratings yet

- Fme6 Activity2 PDFDocument7 pagesFme6 Activity2 PDFFred BorjaNo ratings yet

- Motorised Hammer Project ReportDocument35 pagesMotorised Hammer Project ReportRaja ManeNo ratings yet

- Motorised Hammer Project ReportDocument35 pagesMotorised Hammer Project ReportRaja ManeNo ratings yet

- Using Ishikawa Method in Power Hacksaw MaintenanceDocument8 pagesUsing Ishikawa Method in Power Hacksaw MaintenanceInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Dual Side Shaper Machine Increases Productivity Under 39 CharactersDocument22 pagesDual Side Shaper Machine Increases Productivity Under 39 CharactersGopuNo ratings yet

- Irjet V3i1161 PDFDocument6 pagesIrjet V3i1161 PDFAkshay ThoraveNo ratings yet

- Design and Fabrication of Double Acting Hack Saw Machine Using Scotch Yoke MechanismDocument24 pagesDesign and Fabrication of Double Acting Hack Saw Machine Using Scotch Yoke MechanismManoj ManuNo ratings yet

- Nikhil btp-19-12-4,04Document21 pagesNikhil btp-19-12-4,04sahilNo ratings yet

- Fabrication of Waste Cable Stripping Machine For Recycling Copper MaterialDocument7 pagesFabrication of Waste Cable Stripping Machine For Recycling Copper MaterialIJRASETPublicationsNo ratings yet

- Design and Fabrication of Solar Grass CutterDocument4 pagesDesign and Fabrication of Solar Grass CutterSOUMIK DASNo ratings yet

- Design and Fabrication of Ploughing MachineDocument6 pagesDesign and Fabrication of Ploughing MachineARUN V100% (1)

- Power Operated HacksawDocument27 pagesPower Operated HacksawAnkit SinghNo ratings yet

- Sree Krishna College of Engineering Unai, Anaicut, Vellore - 632 101. Department of Mechanical EngineeringDocument22 pagesSree Krishna College of Engineering Unai, Anaicut, Vellore - 632 101. Department of Mechanical EngineeringManoj ManuNo ratings yet

- FABRICATION OF FOUR WAY HACKSAW BLADE MACHINE Ijariie2072 PDFDocument9 pagesFABRICATION OF FOUR WAY HACKSAW BLADE MACHINE Ijariie2072 PDFDinesh RathorNo ratings yet

- Small Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsFrom EverandSmall Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsNo ratings yet

- Nupurthesis PDFDocument64 pagesNupurthesis PDFSarada Sankar DasNo ratings yet

- Richland CNC Turning BasicsDocument34 pagesRichland CNC Turning BasicsBADINEHALSANDEEPNo ratings yet

- Types of CNC Machining EbookDocument17 pagesTypes of CNC Machining EbookMadjid YaalaouiNo ratings yet

- Siemens 828D PDFDocument32 pagesSiemens 828D PDFPalaniappan SolaiyanNo ratings yet

- PGSL 0313 en en-US PDFDocument590 pagesPGSL 0313 en en-US PDFR GanesanNo ratings yet

- Solar Hacksaw Project ReportDocument55 pagesSolar Hacksaw Project Reportramesh218482% (11)

- Quadri Shaik Shoaib Khavi Farooqui 78Document10 pagesQuadri Shaik Shoaib Khavi Farooqui 78KhAn A WaseemNo ratings yet

- Fabrication of Solar Operated Grinding MachineDocument2 pagesFabrication of Solar Operated Grinding MachineBADINEHALSANDEEPNo ratings yet

- ReportDocument3 pagesReportBADINEHALSANDEEPNo ratings yet

- "Solar Seed Sowing Machine": January 2016Document31 pages"Solar Seed Sowing Machine": January 2016Akshay GopalNo ratings yet

- Mechanical Engineering Books CollectionDocument737 pagesMechanical Engineering Books CollectionDiyar Nezar83% (18)

- Project Presentation 2ndDocument11 pagesProject Presentation 2ndBADINEHALSANDEEPNo ratings yet

- CNCSoftwareDocument17 pagesCNCSoftwarectaylor102No ratings yet

- Solar Powered Grinding MachineDocument8 pagesSolar Powered Grinding MachineBADINEHALSANDEEPNo ratings yet

- Saravanakumar 2018 IOP Conf. Ser. Mater. Sci. Eng. 402 012188Document14 pagesSaravanakumar 2018 IOP Conf. Ser. Mater. Sci. Eng. 402 012188Prakash Kumar GautamNo ratings yet

- Final Year Seminar Report UG-2019 Batch11-156 PDFDocument34 pagesFinal Year Seminar Report UG-2019 Batch11-156 PDFsaket3sanidhy0% (1)

- Mechanical Engineering Books CollectionDocument737 pagesMechanical Engineering Books CollectionDiyar Nezar83% (18)

- Power Plant Engg Lect Notes 6th SemDocument58 pagesPower Plant Engg Lect Notes 6th SemRobin AroraNo ratings yet

- Saravanakumar 2018 IOP Conf. Ser. Mater. Sci. Eng. 402 012188Document14 pagesSaravanakumar 2018 IOP Conf. Ser. Mater. Sci. Eng. 402 012188Prakash Kumar GautamNo ratings yet

- Solar Powered Grinding MachineDocument3 pagesSolar Powered Grinding MachineBADINEHALSANDEEPNo ratings yet

- Multi-Purpose Machine Performs Drilling, Cutting & GrindingDocument6 pagesMulti-Purpose Machine Performs Drilling, Cutting & GrindingAnonymous IK1nsqBqSNo ratings yet

- Presentation 9Document27 pagesPresentation 9BADINEHALSANDEEPNo ratings yet

- PPE Lecture NotesDocument118 pagesPPE Lecture NotesMITTA NARESH BABU100% (1)

- Project Title: 2 Wheel Drive Froklift For Industry WarehouseDocument1 pageProject Title: 2 Wheel Drive Froklift For Industry WarehouseBADINEHALSANDEEPNo ratings yet

- A Project Report Submitted in Partial Fulfilment of The Requirements For The Award of Degree of inDocument22 pagesA Project Report Submitted in Partial Fulfilment of The Requirements For The Award of Degree of inBADINEHALSANDEEPNo ratings yet

- Presentation 1Document3 pagesPresentation 1BADINEHALSANDEEPNo ratings yet

- Indian Energy ScenarioDocument12 pagesIndian Energy ScenarioBADINEHALSANDEEPNo ratings yet

- PPE Lecture NotesDocument118 pagesPPE Lecture NotesMITTA NARESH BABU100% (1)

- Power Plant Engg Lect Notes 6th SemDocument58 pagesPower Plant Engg Lect Notes 6th SemRobin AroraNo ratings yet

- Presentation 9Document27 pagesPresentation 9BADINEHALSANDEEPNo ratings yet

- MTPDF4 Exact and Non-Exact Differential EquationsDocument27 pagesMTPDF4 Exact and Non-Exact Differential Equationsnaughty dela cruzNo ratings yet

- Lesson No. 1 - Pipe Sizing HydraulicsDocument4 pagesLesson No. 1 - Pipe Sizing Hydraulicsusaid saifullahNo ratings yet

- 11 - Leo Vega Bolt Failure AnalysisDocument35 pages11 - Leo Vega Bolt Failure AnalysissymkimonNo ratings yet

- Four Golden RuleDocument6 pagesFour Golden RulerundyudaNo ratings yet

- KireraDocument3 pagesKireramurithiian6588No ratings yet

- AGWA Guide GlazingDocument96 pagesAGWA Guide GlazingMoren AlfonsoNo ratings yet

- Phy 111 - Eos Exam 2015Document7 pagesPhy 111 - Eos Exam 2015caphus mazengeraNo ratings yet

- Duobias M 200 TM Section02 Performance SpecificationDocument12 pagesDuobias M 200 TM Section02 Performance SpecificationtonytomsonNo ratings yet

- Costallocationvideolectureslides 000XADocument12 pagesCostallocationvideolectureslides 000XAWOw Wong100% (1)

- Teaching Speaking: Daily Activities Lesson PlanDocument3 pagesTeaching Speaking: Daily Activities Lesson PlanMARCELANo ratings yet

- D 4 Development of Beam Equations: M X V XDocument1 pageD 4 Development of Beam Equations: M X V XAHMED SHAKERNo ratings yet

- Clock 38 InstructionsDocument20 pagesClock 38 InstructionsCanNo ratings yet

- Awareness On Biomedical Waste Management Among Dental Students - A Cross Sectional Questionnaire SurveyDocument8 pagesAwareness On Biomedical Waste Management Among Dental Students - A Cross Sectional Questionnaire SurveyIJAR JOURNALNo ratings yet

- Power Electronics Lab 1 (07DEM19F1005)Document15 pagesPower Electronics Lab 1 (07DEM19F1005)Mohd Faizul Idham AhmadNo ratings yet

- PricelistDocument2,276 pagesPricelistadilcmsNo ratings yet

- SIGA Monitoring ToolDocument3 pagesSIGA Monitoring ToolMhalou Jocson EchanoNo ratings yet

- ZFDC 20 1HDocument1 pageZFDC 20 1Hkentier21No ratings yet

- Manual Reductora IVECO TM 265 - TM 265ADocument31 pagesManual Reductora IVECO TM 265 - TM 265ARomà ComaNo ratings yet

- Effect of In-Store Shelf Spacing On PurchaseDocument20 pagesEffect of In-Store Shelf Spacing On Purchasesiddeshsai54458No ratings yet

- Namatacan HS Report on Regional Diagnostic AssessmentDocument13 pagesNamatacan HS Report on Regional Diagnostic AssessmentDonnabelle MedinaNo ratings yet

- 722.6 Transmission Conductor Plate Replacement DIYDocument3 pages722.6 Transmission Conductor Plate Replacement DIYcamaro67427100% (1)

- Worksheet Mendel's LawsDocument3 pagesWorksheet Mendel's LawsAkito NikamuraNo ratings yet

- PTE - Template - Essay All TypesDocument8 pagesPTE - Template - Essay All TypeskajalNo ratings yet

- Xerox University Microfilms: 300 North Zeeb Road Ann Arbor, Michigan 48106Document427 pagesXerox University Microfilms: 300 North Zeeb Road Ann Arbor, Michigan 48106Muhammad Haris Khan KhattakNo ratings yet

- Using Sunspots To Measure Solar Rotation: Astronomy 104 Observing Laboratory Spring 2009Document6 pagesUsing Sunspots To Measure Solar Rotation: Astronomy 104 Observing Laboratory Spring 2009Jeko Betguen PalangiNo ratings yet

- POLE FOUNDATION ANALYSIS EXCEL TOOLDocument18 pagesPOLE FOUNDATION ANALYSIS EXCEL TOOLJosue HasbunNo ratings yet

- Methodology of Legal Research: Challenges and OpportunitiesDocument8 pagesMethodology of Legal Research: Challenges and OpportunitiesBhan WatiNo ratings yet

- Datasheet 1MBH 50D - 60Document5 pagesDatasheet 1MBH 50D - 60jtec08No ratings yet

- Unit 3 Digital Documentation: Multiple Choice QuestionsDocument7 pagesUnit 3 Digital Documentation: Multiple Choice Questions07tp27652% (21)

- A Guide For School LeadersDocument28 pagesA Guide For School LeadersIsam Al HassanNo ratings yet