Professional Documents

Culture Documents

Catalog 2019-2020

Catalog 2019-2020

Uploaded by

Michail Armitage0 ratings0% found this document useful (0 votes)

23 views12 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views12 pagesCatalog 2019-2020

Catalog 2019-2020

Uploaded by

Michail ArmitageCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

Ig A i

WHD

EE Wi sPinDLe MoToR a

—

More Value for Your Machine

Co

Ww a 3 .

Changzhou Troy Machinery& Electric Co., Ltd.

Company Profile

‘Changzhou Troy Machinery & Electric Co, Li, was founded in 1998, which

is ahigh-ech enterprise specializing in research & development, production &

sales of High Speed Spindle Motor for over 20 years.

‘We actively introduce advanced production equipment and first-class test

machines to Improve the qual of products. With advanced technology and

reliable qualiy.we have received popuiar recognition from our clients home

and abroad. More and more people are accepting our brand "WHO".

‘Our products mainly have five series, Including STZ, STF, STM, STL, STX

which are widely used for CNC. machines, Engraving. machines Oring

machines Edge banging machines and so on. Furthermore, we can design and

manufacture special spindle motors according to requirements of our custom

{fs nsistng onthe enterprise spin of "Customer Fist, More Vale to your

Machine" we have exported out products o USA, Russia, Europe, India, Bazi,

Iran et, all over the wor

Tank you for choosing us, and we will goon supplying you higher quality

and beter servi.

Lau

[ATC Air Cooling Spindle o

[ATC Water Cooling Spin oe

Ar Cooling Spindle with Square Body 03

‘Air Cooling Spindle with Squara8Flange Body 05

Ai Cooling Spindle wth Independent Elect Fan 08

Air Cooling Spindle with Round Body 10

Woater Cooling Spindle for WoodiPlastic 1"

Water Cooing Spindle for Metal “

Spindle for Edge Banding Machine 8

Spindle Customized wv

woRksHoP 19

Tips Before Using For All Spindles 20

tig Engrave Deng akin of CNC Rou machine

wm Characteristics

1. Wi highprecion Adopt ER si coe i asthe unique characteris of

ron cri ea hh

‘1 ap sat racket rade feared rin iene proecton eas ot

‘crisis ob P50 ar protects nara pars fom he est fa

OMA

noveine Ola

st¥80.10360

2 NS

1m Applicatio

lig Engraving Dring in al kinds of CNC Router machine.

Characteristics

1. Savo costs and me —Wit anges, customers can have fewer meuring

pistes ana are more convenient

iin ighprocisen ~~ Adopt ER series colt ru, has the unique character.

istics ot high precision

1's grade anguar contact bearings or ceramic bal bearings are used With

Suen bearings. he svength and stftess of eectne specs ae greatly

improved andthe RPM can reach 24000r/min. ten provge song suppor for

high effceney ard igh precision processing of CNC:

{1 ign presizon dame lane tering conducted onal ote parts

sien the tolerance vive of ess han GO.

5 The argh sft racket made of exruded aluminum rales the protection

Class of elect spndos tobe PSO and protects intemal pars from the rest

ordust

LL I *:

vera

mits

vx

=

LL

1m Application

lig Engraving Dring in kinds of CNC Router machine.

Characteristics

1, Low ncizo—With independent letroric fan ts mere human and comfort

abe.

2 Wit high precision —- Adopt ER series colt ut has the unique characters-

test righ precision

5a grade angular contact bearings ar ceramic ball earings are use. With such

beanie the strength and stffneseof sac sandos are great enoved and

the RM can rech 240001/min. can provi strong support for high efficency

and high pecsion processing of CNC.

4. }egh precion dynamic baancig testing is conducted on al rotable parts with

the tlrance vale of fse than GO

The aright shaft bracket made of extruded suminum raises the protection

{lass of electric pines to be P50 and protects itera parts from tne treat of

=~ i

1m Applicatio

ating, Engraving, Dring nal kinds of CNC Rout machine. Especial stable

Tor woodwarking machine.

Characteristics

1 Low noise—Witnwatercooting system. The noise i vor ow.

2. ttn igh precision Adopt ER series colt rut Ras the unique characters-

‘ies of igh precision

5's grado angular contact bearings or ceramic ball earings are used. Wth such

ibeange the strength and stneze of sacra sendes are greaty wmgoved Sod

‘he RM can reach 24000. ean provi strong suppor Tar gh etisency

na high peecsion processing of CNC.

5 Fagh precision dynomie baancing testing is condita on all rotabe parts, with

the tolerance vale of tse than GO.

BTho aright shaft bracket mace of extruded aluminum raises the protection

{lass of elec pines to be PO and protects terol parts fem he treat of

OMA

srze02a

verzz009

eran

‘wa

8.

Ga

‘Application

‘Trimming, Miling, Engravi

machine and CNE machine

Characteristics

1. Small body— It's more human and comfortable.

2. The strength and stiffness of electric spindles are good. It can

provide strong support for high efficiency and high precision pro-

cessing of edge bending machine and CNC.

3.The airtight shaft bracket made of extruded aluminum raises

the protection class of electric spindles to be IP5Q and protects

internal parts from the threat of dust,

3. Driling in all kinds of edge banding

ag

srrass.sa.0374

ot

TY

strEas69.0750

‘m Application

aig, Engraving, Dring in al knds of CNC machine.

m Characteristics

1. Spindle Motor Customized-—WHD con suply Spindle Motors Customized 3

Tigh precion processing of

'3Figh precision dyeamic balancing testing tx conducted on al otable pats, with

the tolerance vate of ass than COA.

“The setght shaft Erscket made of extrued aluminum raises the protection

{tase of eecvie spins to be P50 and protects itorna parts rom th treat of

Gost

= Ot

OMA

sr160.12055.432

=

someone

srxiz002

WORKSHOP

Tips Before Using For All Spindles

1. Tho olctic spindle andthe equoncy invertor shall be suitable wih each

cer. The specications and parametor stings of to invertor sll match

the nominal parameters ofthe spinal, and it will burn the spinle if the

stings are not coro

2. During storage and transport of the spindle, the status of high-speed

‘970930 sie the bearing wil change. The user shalirun at alow speed rst

by stating fom the lowest speed ofthe spindle for 30 minutes and then 20

minutes for every 3000 rounds; otherwise there wil have abnormal sound,

noise, heat and other phenomena, which wil affect the bearing Ife ifthe

spindle is stated directly at @ high speed. During long term storage, the

spindle shal run (at ow spoed) fr 15-30 minutes once a week at least,

3. Cale. nut and inner taper hola shall be washed clean when insaling

blades onthe spindle in order to avoid any impact onthe procsion. The blade

handle shale inertd into he cot more than 15mm,

4. For éaly machining the since shal be warmed up, run or 15-20 minutes

when the machining speed reached and ten performs precise machining.

Its better to stop the spine or two hours every day inorder to recover Its

‘mechanical fatigue and prolong its He time

5. No knocking the end cover ofthe spindle. No hammering the cllet and

blade head when removing blades. No shocking or coliing during transport,

storage and using, especialy the end ofthe spine

6. The spine shi unin designated direction,

7 Tha spindle eal be installed and fxad according tothe relevant crawings

& &

Constant ‘Your Spine

sStorance ‘cer

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Брашура (Оптимз)Document11 pagesБрашура (Оптимз)Michail ArmitageNo ratings yet

- HR A10vDocument8 pagesHR A10vMichail ArmitageNo ratings yet

- HR A4vso250hs4Document11 pagesHR A4vso250hs4Michail ArmitageNo ratings yet

- HR DBWDocument10 pagesHR DBWMichail ArmitageNo ratings yet

- HR 20vlo190le2dDocument7 pagesHR 20vlo190le2dMichail ArmitageNo ratings yet

- HR 4wrzeDocument23 pagesHR 4wrzeMichail ArmitageNo ratings yet

- 06 Насос Harlex a4vso180dr30r-Fpb13n00Document75 pages06 Насос Harlex a4vso180dr30r-Fpb13n00Michail ArmitageNo ratings yet

- HR A6ve250hzDocument5 pagesHR A6ve250hzMichail ArmitageNo ratings yet

- 01 А20VLO190LE2D10R-NZD24K01Document16 pages01 А20VLO190LE2D10R-NZD24K01Michail ArmitageNo ratings yet

- 3/2 and 4/2 Directional Poppet Valve, With Solenoid Operation, For Water Emulsions and WaterDocument16 pages3/2 and 4/2 Directional Poppet Valve, With Solenoid Operation, For Water Emulsions and WaterMichail ArmitageNo ratings yet

- 05 Гидромотор Harlex a6vm107ha1000004c65awv0d4xx200-sDocument80 pages05 Гидромотор Harlex a6vm107ha1000004c65awv0d4xx200-sMichail ArmitageNo ratings yet

- Technical Catalog HR-PAVC SeriesDocument9 pagesTechnical Catalog HR-PAVC SeriesMichail ArmitageNo ratings yet

- 02 А6VE250HZ63W2-VZM088B-SO172Document35 pages02 А6VE250HZ63W2-VZM088B-SO172Michail ArmitageNo ratings yet

- 02 Аксиально-поршневой Регулируемый Насос a10vo Серия 52 и 53Document64 pages02 Аксиально-поршневой Регулируемый Насос a10vo Серия 52 и 53Michail ArmitageNo ratings yet

- Fixed Plug-In Motor A2Fe: Series 6Document24 pagesFixed Plug-In Motor A2Fe: Series 6Michail ArmitageNo ratings yet

- Proportional Pressure Reducing Valve, Pilot Operated: FeaturesDocument13 pagesProportional Pressure Reducing Valve, Pilot Operated: FeaturesMichail ArmitageNo ratings yet

- Ordering Data 4Wrl E 4X: A1 24 M V 16 120 MDocument2 pagesOrdering Data 4Wrl E 4X: A1 24 M V 16 120 MMichail ArmitageNo ratings yet

- DB/DBW: DB/DBW 30/5X Series Pilot Operated Pressure Relief ValvesDocument4 pagesDB/DBW: DB/DBW 30/5X Series Pilot Operated Pressure Relief ValvesMichail ArmitageNo ratings yet

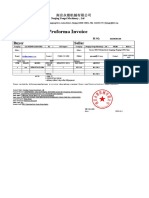

- Pi 20220803Document1 pagePi 20220803Michail ArmitageNo ratings yet

- A10vec RD91710 1997-03Document12 pagesA10vec RD91710 1997-03Michail ArmitageNo ratings yet

- Fixed Displacement Motor A2FM: Open and Closed CircuitsDocument9 pagesFixed Displacement Motor A2FM: Open and Closed CircuitsMichail ArmitageNo ratings yet

- Technical Catalog Hr-Pgh4: FeaturesDocument12 pagesTechnical Catalog Hr-Pgh4: FeaturesMichail ArmitageNo ratings yet

- High-Performance External Gear Pump Azpb: FeaturesDocument4 pagesHigh-Performance External Gear Pump Azpb: FeaturesMichail ArmitageNo ratings yet

- 2244Document2 pages2244Michail ArmitageNo ratings yet

- Technical Catalog HRA10VSO100DFR/31R: FeaturesDocument13 pagesTechnical Catalog HRA10VSO100DFR/31R: FeaturesMichail ArmitageNo ratings yet

- Servo Solenoid Valves With On-Board Electronics: Type HR4WRPE ..EA.Document15 pagesServo Solenoid Valves With On-Board Electronics: Type HR4WRPE ..EA.Michail ArmitageNo ratings yet

- Technical Catalog HRA6VM107HD1/63W: FeaturesDocument18 pagesTechnical Catalog HRA6VM107HD1/63W: FeaturesMichail ArmitageNo ratings yet

- A4VSODocument72 pagesA4VSOMichail Armitage100% (1)

- Axial Piston Variable Pump A4VSO Series 1x and 3x: RE 92050/10.2018, Bosch Rexroth AGDocument76 pagesAxial Piston Variable Pump A4VSO Series 1x and 3x: RE 92050/10.2018, Bosch Rexroth AGMichail ArmitageNo ratings yet

- Axial Piston Variable Pump A10VSO Series 32: RE 92714/08.2015, Bosch Rexroth AGDocument48 pagesAxial Piston Variable Pump A10VSO Series 32: RE 92714/08.2015, Bosch Rexroth AGMichail ArmitageNo ratings yet