Professional Documents

Culture Documents

Fuel System: Section

Uploaded by

Abu MaryamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fuel System: Section

Uploaded by

Abu MaryamCopyright:

Available Formats

FUEL SYSTEM

B ENGINE

SECTION

FUEL SYSTEM

FL FL

E

CONTENTS

PREPARATION ........................................................... 2 INSPECTION AFTER INSTALLATION .................. 8 F

Commercial Service Tools ........................................ 2 Disassembly and Assembly ...................................... 8

FUEL SYSTEM ........................................................... 3 DISASSEMBLY ..................................................... 9

Checking Fuel Lines ................................................. 3 ASSEMBLY ......................................................... 10 G

General Precautions ................................................ 3 FUEL TANK .............................................................. 11

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND Removal and Installation ........................................ 11

FUEL PUMP ASSEMBLY ........................................... 4 REMOVAL ........................................................... 11

H

Removal and Installation .......................................... 4 INSTALLATION ................................................... 12

REMOVAL ............................................................. 4 INSPECTION AFTER INSTALLATION ................ 13

INSPECTION AFTER REMOVAL ......................... 7 SERVICE DATA AND SPECIFICATIONS (SDS) ...... 14

INSTALLATION ..................................................... 7 Standard and Limit .................................................. 14 I

FUEL TANK ......................................................... 14

Revision: 2005 July FL-1 2006 X-Trail

PREPARATION

PREPARATION PFP:00002

Commercial Service Tools ABS00D0K

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

(Kent-Moore No.)

Description

Tool name

(J-38879-A) Removing and installing fuel tank lock ring

Fuel tank lock ring wrench

ZZA0122D

Revision: 2005 July FL-2 2006 X-Trail

FUEL SYSTEM

FUEL SYSTEM PFP:17503

A

Checking Fuel Lines ABS00D0L

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loose connections, chafing or deterio- FL

ration.

If necessary, repair or replace damaged parts.

C

SMA803A

E

General Precautions ABS00D0M

WARNING:

When replacing fuel line parts, be sure to observe the following.

F

● Put a “CAUTION: INFLAMMABLE” sign in the workshop.

● Be sure to work in a well ventilated area and furnish workshop with a CO2 fire extinguisher.

● Do not smoke while servicing fuel system. Keep open flames and sparks away from the work area. G

● Put drained fuel in an explosion-proof container and put the lid on securely. Keep the container in

safe area.

CAUTION: H

● Use gasoline required by the regulations for octane number. Refer to GI-5, "Precautions for Fuel

(Unleaded Regular Gasoline Recommended)" .

● Before removing fuel line parts, perform the following procedures: I

– Release fuel pressure from the fuel lines. Refer to EC-80, "FUEL PRESSURE RELEASE" .

– Disconnect battery cable at negative terminal.

● Always replace clamps with new ones. J

● Do not kink or twist tubes when they are being installed.

● Perform work on level place.

● Do not tighten hose clamps excessively to avoid damaging hoses. K

● After connecting fuel tube quick connectors, make sure

quick connectors are secure.

Ensure that connector and resin tube do not contact any L

adjacent parts.

● After installing tubes, check if there are no fuel leakage at

connections in the following steps. M

– Apply fuel pressure to fuel lines with turning ignition switch

“ON” (with engine stopped). Then check for fuel leaks at

connections.

– Start engine and rev it up and check for fuel leaks at con-

nections.

● For servicing “Evaporative Emission System” parts, refer to

EC-30, "EVAPORATIVE EMISSION SYSTEM" .

● For servicing “On Board Refueling Vapor Recovery (ORVR)

System” parts, refer to EC-37, "ON BOARD REFUELING

VAPOR RECOVERY (ORVR)" .

SBIA0504E

Revision: 2005 July FL-3 2006 X-Trail

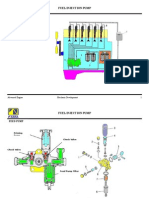

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY PFP:17042

Removal and Installation ABS00D0N

PBIC2257E

Main fuel level sensor unit, fuel filter Jet pump, fuel hose and jet pump

1. Lock ring 2. 3.

and fuel pump assembly inlet assembly

4. Chamber 5. Seal packing 6. Sub fuel level sensor unit

REMOVAL

WARNING:

Be sure to read “General Precautions” when working on the fuel system. Refer to FL-3, "General Pre-

cautions" .

1. Check fuel level on fuel gauge. If fuel gauge indicates more than

the level as shown in the figure (full or almost full), drain fuel

from fuel tank until fuel gauge indicates level as shown in the fig-

ure or below.

NOTE:

Fuel will be spilled when removing main and sub fuel level sen-

sor units for the top of the fuel is above the main and sub fuel

level sensor units installation surface.

● As a guide, fuel level becomes the position as shown in the

figure or below when approximately 15 (4 US gal, 3-1/4 Imp

gal) of fuel are drained from fuel tank. FEL0403D

● In a case that fuel pump does not operate, perform the follow-

ing procedure.

a. Insert hose of less than 20 mm (0.79 in) in diameter into fuel filler tube through fuel filler opening to draw

fuel from fuel filler tube.

b. Disconnect fuel filler hose from fuel filler tube. Refer to FL-11, "FUEL TANK" .

c. Insert hose into fuel tank through fuel filler hose to draw fuel from fuel tank.

2. Release the fuel pressure from the fuel lines. Refer to EC-80, "FUEL PRESSURE RELEASE" .

3. Open fuel filler lid.

4. Open fuel filler cap and release the pressure inside fuel tank.

5. Lift to hold rear seat cushion up. Refer to SE-24, "REAR SEAT" .

Revision: 2005 July FL-4 2006 X-Trail

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

6. Remove inspection hole cover for main and sub fuel level sen-

sor units. A

● Remove cover by pushing it, then by turning clips clockwise

by 90 degrees and by matching both cover hole and clip

shape. FL

PBIC2258E

D

7. Disconnect harness connector and quick connector.

G

KBIA0280E

● Disconnect quick connector as follows: H

– Hold the sides of connector, push in tabs and pull out fuel feed

hose.

– If quick connector sticks to tube of fuel level sensor unit, push I

and pull quick connector several times until it starts to move.

Then disconnect quick connector by pulling.

J

SFE562A K

Revision: 2005 July FL-5 2006 X-Trail

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

CAUTION:

● Quick connector can be disconnected when the tabs

are completely depressed. Do not twist it more than

necessary.

● Do not use any tools to disconnect quick connector.

● Keep resin tube away from heat. Be especially careful

when welding near the resin tube.

● Prevent acid liquid such as battery electrolyte, etc.

from getting on resin tube.

● Do not bend or twist resin tube during installation and

disconnection.

● Do not remove the remaining retainer on hard tube (or

the equivalent) except when resin tube or retainer is

replaced.

● When resin tube or hard tube (or the equivalent) is

replaced, also replace retainer with a new one.

● Replace same color retainer as before replacing.

Retainer color: Green

SBIA0504E

● To keep the connecting portion clean and to avoid

damage and foreign materials, cover them completely

with plastic bags or something similar.

PBIC0163E

8. Using fuel tank lock ring wrench (commercial service tool: J-

38879-A), remove lock ring.

PBIC0240E

9. Remove main fuel level sensor unit, fuel filter and fuel pump assembly, and sub fuel level sensor unit as

follows.

CAUTION:

● Do not bend float arm during removal.

● Avoid polluting the inside by residue fuel. Draw out with avoiding inclination by supporting with

a cloth.

● Avoid impacts such as falling when handling components.

Revision: 2005 July FL-6 2006 X-Trail

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

a. Removal of main fuel level sensor unit, fuel filter and fuel pump

assembly: A

i. Raise main fuel level sensor unit, fuel filter and fuel pump

assembly, and disconnect jet pump.

ii. Leave jet pump on fuel tank with fuel hose. FL

CAUTION:

Do not separate jet pump and fuel hose.

iii. If necessary, remove chamber from the bottom of fuel tank by C

sliding toward the rear of the vehicle.

PBIC2733E

D

b. Removal of sub fuel level sensor unit:

i. Raise and release sub fuel level sensor unit to remove.

ii. If necessary, remove jet pump inlet with fuel hose from the bottom of fuel tank by pinching tabs. E

CAUTION:

Do not separate jet pump inlet and fuel hose.

INSPECTION AFTER REMOVAL F

Make sure that fuel pump strainer is free from foreign materials. If any are found, remove them.

INSTALLATION G

Note the following, and install in the reverse order of removal.

Chamber and Jet Pump

H

When installing chamber and jet pump, insert them fully until a click

sound of full stopper engagement is heard (Ditto for jet pump inlet).

K

KBIA0302E

Main and Sub Fuel Level Sensor Unit

1. Install seal packing to fuel tank without any twist. L

2. Face fuel level sensor unit, fuel filter and fuel pump assembly as

shown in the figure, and install it to fuel tank. (Figure shows left

side of fuel tank.)

M

CAUTION:

Do not bend float arm during installing.

NOTE:

On right side of fuel tank, there are three carved lines on fuel

tank. Set mating mark between two outer carved lines.

KBIA0282E

3. Tighten rock ring with rock ring wrench (commercial service tool: J-38879-A).

CAUTION:

Install rock ring horizontally.

Revision: 2005 July FL-7 2006 X-Trail

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

Quick Connector

Connect quick connector of fuel feed hose as follows:

1. Check the connection for damage and foreign materials.

2. Align the connector with the tube, then insert the connector straight into the tube until a click sound is

heard.

3. After connecting, make sure that the connection is secure by following method.

● Visually confirm that the two tabs are connected to the connector.

● Pull the tube and the connector to make sure they are

securely connected.

PBIC1653E

Inspection Hole Cover

1. Install inspection hole covers with the front mark (arrow) facing front of the vehicle.

2. Lock clips by turning counterclockwise by 90 degrees.

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leaks.

1. Turn ignition switch “ON” (with engine stopped), then check connections for leaks by applying fuel pres-

sure to fuel piping.

2. Start engine and rev it up and make sure there are no fuel leaks at the fuel system connections.

Disassembly and Assembly ABS00D0O

PBIC2734E

1. Main fuel level sensor unit 2. Bracket 3. Rubber

4. Fuel pump 5. Packing 6. Fuel filter

7. O-ring 8. Pressure regulator 9. Clip

10. O-ring

CAUTION:

Sub fuel level sensor unit cannot be disassembled and should be replaced as a unit.

Revision: 2005 July FL-8 2006 X-Trail

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

DISASSEMBLY

1. Separate fuel pump and bracket from fuel filter as follows: A

a. Using flat-bladed screwdriver, separate the snap fit portion of

bracket in the order of (1), (2), (3) and (4) as shown in the figure.

FL

D

PBIC2735E

b. Pull out fuel pump, and disconnect harness connector. E

PBIC2736E H

2. Separate fuel filter and main fuel level sensor unit as follows:

a. Fit a used O-ring into space between fuel level sensor unit and I

fuel filter. Undo catches and separate main fuel level sensor and

fuel filter.

● For reference when reassembling, put a mating mark on outer

J

edges of main fuel level sensor unit and fuel filter with some

means which cannot be erased by fuel.

b. Insert flat-bladed screwdriver to the gap between fuel filter and

main fuel level sensor unit to separate them. K

CAUTION: PBIC2737E

● Put cloth or similar one on the edge of screwdriver not to

damage the inserted portion. L

● Separate main fuel level sensor unit by pulling it straight. If lateral force is applied, inner resin

tube (between main fuel level sensor unit and fuel filter) may break.

3. Remove pressure regulator from fuel filter as follows: M

a. Open and remove the clip.

b. Pull pressure regulator straight out during removal.

CAUTION:

● Handle fuel tube carefully and avoid damaging it.

● Avoid impacts such as falling during removal.

● Do not disassemble or adjust.

Revision: 2005 July FL-9 2006 X-Trail

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

ASSEMBLY

Note the following, and assemble in the reverse order of disassembly.

Fuel Filter and Fuel Pump

● Install fuel filter and fuel pump with the tabs aligned, make sure a click sound of secure engagement is

heard.

● Securely connect harness connector of fuel pump.

Pressure Regulator

Install pressure regulator as follows:

1. Install O-ring.

CAUTION:

● Do not reuse O-ring. Replace it with a new one.

● Handle O-ring with bare hands. Do not wear gloves.

● Visually check O-ring, mounting parts and mating parts for foreign materials and flaws.

● Before installing, lubricate new engine oil.

● To avoid damage, do not apply an excessive force (pulling or stretching).

2. Insert the clip to the groove of pressure regulator.

PBIC2494E

3. With the clip installed, insert pressure regulator straight by matching the fuel filter lug and the clip notch.

4. Make sure that the fuel filter lug and clip notch are securely engaged.

Revision: 2005 July FL-10 2006 X-Trail

FUEL TANK

FUEL TANK PFP:17202

A

Removal and Installation ABS00D0P

FL

PBIC2738E

K

1. Fuel filler cap 2. Grommet 3. Fuel filler tube

4. Clip 5. Fuel filler tube protector 6. Vent hose

7. Vent tube 8. Vent hose 9. Recirculation hose L

10. Fuel tank 11. Fuel filler hose 12. Recirculation hose

13. Signal hose 14. Vent hose 15. Refueling EVAP vapor cut valve

Refueling EVAP vapor cut valve M

16. 17. Cover 18. Fuel tank protector

bracket

19. Fuel tank band 20. Fuel tank band

REMOVAL

WARNING:

Be sure to read “General Precautions” when working on the fuel system. Refer to FL-3, "General Pre-

cautions" .

1. Perform the steps 1 to 7 of “REMOVAL” in “ FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL

PUMP ASSEMBLY”. Refer to FL-4, "REMOVAL" .

● Drain fuel from fuel tank if necessary. Refer to FL-4, "REMOVAL" .

CAUTION:

Because fuel tank forwardly inclines and is not firmly affixed when installing/removing, fuel

should be drained if there is any remaining quantity.

● Perform work on level place.

2. Remove exhaust center tube and insulator. Refer to EX-2, "EXHAUST SYSTEM" .

3. Remove propeller shaft. (AWD models) Refer to PR-3, "REAR PROPELLER SHAFT" .

Revision: 2005 July FL-11 2006 X-Trail

FUEL TANK

4. Using a transmission jack, support the bottom of final drive

assembly (AWD models) or rear suspension member (2WD

models).

5. Remove mounting nuts on rear suspension member, and lower

the transmission jack carefully until just before rear suspension

member is removed from stud bolts on the vehicle. Refer to

RSU-5, "REAR SUSPENSION ASSEMBLY" .

KBIA0285E

6. Remove fuel tank protector.

7. Disconnect fuel filler hose, EVAP hose, recirculation hose and

vent hose at fuel tank side.

● For disconnection procedure of quick connector on EVAP

hose, refer to FL-4, "FUEL LEVEL SENSOR UNIT, FUEL FIL-

TER AND FUEL PUMP ASSEMBLY" .

PBIC2739E

8. Remove fuel tank band mounting bolts while supporting fuel

tank.

CAUTION:

Sustain the bottom of fuel tank by using plate or anything

same.

9. Remove fuel tank.

● After lifting down the front portion of fuel tank, remove fuel

tank by pulling it from the upper front of final drive assembly,

so that fuel tank can move forwardly. (AWD models)

CAUTION: KBIA0290E

Pay attention not to drop fuel tank because it forwardly

inclines and is not firmly affixed.

NOTE:

It is desirable that more than two technicians work together.

10. Remove fuel filler tube with the following procedure if necessary.

a. Remove fuel filler tube protector.

b. Remove bolts and nuts between strut and rear axle assembly. Refer to RSU-7, "Component" .

c. Remove fuel filler tube.

INSTALLATION

Note the following, and install in the reverse order of removal.

● Surely clamp fuel hoses and insert hose to the length below.

Fuel filler hose : 35mm (1.38 in)

The other hoses : 25mm (0.98 in)

● Be sure hose clamp is not placed on swelled area of fuel tube.

● Tighten fuel hose clamp so that the remaining length of screw thread becomes to the following.

Fuel tank side : 2 - 6 mm (0.08 - 0.24 in)

Fuel filler tube side : 7 - 11 mm (0.28 - 0.43 in)

● Fit fuel tank band pin to the vehicle side securely.

Revision: 2005 July FL-12 2006 X-Trail

FUEL TANK

● Before fixing fuel tank, temporarily install fuel filler tube if removed.

CAUTION: A

Use genuine fuel filler tube mounting bolts or equivalent. Make sure to tighten them to the speci-

fied torque.

● To connect quick connector, refer to FL-8, "Quick Connector" . FL

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leaks.

C

1. Turn ignition switch “ON” (with engine stopped), and check connections for leaks by applying fuel pres-

sure to fuel piping.

2. Start engine and rev it up and make sure there are no fuel leaks at the fuel system tube and hose connec-

D

tions.

Revision: 2005 July FL-13 2006 X-Trail

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS) PFP:00030

Standard and Limit ABS00D0Q

FUEL TANK

Fuel tank capacity Approx. 60 (15-7/8 US gal, 13-1/4 Imp gal)

Fuel recommendation Refer to GI-5

Revision: 2005 July FL-14 2006 X-Trail

You might also like

- Nissan Armada 2004 SCDocument16 pagesNissan Armada 2004 SCHendrick CepedaNo ratings yet

- Fuel System: SectionDocument14 pagesFuel System: SectionDaniel CopaNo ratings yet

- Fuel System: SectionDocument14 pagesFuel System: SectionJamar OliverNo ratings yet

- Fuel System: SectionDocument16 pagesFuel System: SectionJBNo ratings yet

- 2007 Nissan Xterra 16Document18 pages2007 Nissan Xterra 16Roma Roma100% (1)

- 2007 Nissan Quest 43998Document14 pages2007 Nissan Quest 43998israelNo ratings yet

- 2002-Nissan-Altima-Fuel SystemDocument10 pages2002-Nissan-Altima-Fuel SystemSergio Robles CastroNo ratings yet

- Fuel System: SectionDocument18 pagesFuel System: SectionChew LayNo ratings yet

- FL PDFDocument10 pagesFL PDFAldo ApazzaNo ratings yet

- Fuel System: SectionDocument16 pagesFuel System: SectionVolkan AKNo ratings yet

- Fuel System: SectionDocument12 pagesFuel System: Sectiondavid94navarroNo ratings yet

- Fuel System: SectionDocument12 pagesFuel System: SectionskpppNo ratings yet

- Fuel System: SectionDocument10 pagesFuel System: Sectionkarlitos4000No ratings yet

- Fuel System: SectionDocument12 pagesFuel System: SectionErickson GarciaNo ratings yet

- Fuel SystemDocument14 pagesFuel Systemshortbus22No ratings yet

- Fuel System: SectionDocument16 pagesFuel System: SectionSilvio ServinNo ratings yet

- Fuel System: SectionDocument16 pagesFuel System: SectioncesarNo ratings yet

- FL PDFDocument8 pagesFL PDFROSILENE PASSOSNo ratings yet

- Fuel System: SectionDocument14 pagesFuel System: SectionEdni OropezaNo ratings yet

- 2005 Nissan X Trail 27Document26 pages2005 Nissan X Trail 27Roberto RizzaNo ratings yet

- Fuel System: SectionDocument16 pagesFuel System: SectionBrian BobbNo ratings yet

- Fuel System: SectionDocument8 pagesFuel System: SectionKatya FirsenkoNo ratings yet

- Fuel System: SectionDocument12 pagesFuel System: Sectionmacau apNo ratings yet

- Fuel System: SectionDocument13 pagesFuel System: SectionDaniel Oliveira de ChavesNo ratings yet

- FL PDFDocument8 pagesFL PDFAnonymous 64HDY7IiN0No ratings yet

- 2008 Nissan Versa 22Document14 pages2008 Nissan Versa 22Daryl TimothyNo ratings yet

- Fuel System: SectionDocument14 pagesFuel System: Sectionfearimus1No ratings yet

- FFD 220930 003943Document33 pagesFFD 220930 003943Andres RodriguezNo ratings yet

- FL PDFDocument26 pagesFL PDFAlexanderNo ratings yet

- Fuel System: SectionDocument24 pagesFuel System: SectionAldo LlerenaNo ratings yet

- Parking Brake System: SectionDocument10 pagesParking Brake System: SectionSilvio ServinNo ratings yet

- FL Navara DDocument20 pagesFL Navara DJean MoralesNo ratings yet

- Propeller Shaft: SectionDocument10 pagesPropeller Shaft: Sectiondavid94navarroNo ratings yet

- FL PDFDocument15 pagesFL PDFCarlos Tito AmésquitaNo ratings yet

- Fuel System: SectionDocument17 pagesFuel System: SectionederengNo ratings yet

- Fuel System: SectionDocument24 pagesFuel System: SectionedgarNo ratings yet

- Parking Brake System: SectionDocument8 pagesParking Brake System: SectionLupita MorenoNo ratings yet

- Fuel System: SectionDocument14 pagesFuel System: SectionHarol CastilloNo ratings yet

- Rear Suspension: SectionDocument14 pagesRear Suspension: SectionSilvio ServinNo ratings yet

- Parking Brake System: SectionDocument10 pagesParking Brake System: SectionJBNo ratings yet

- Fuel System: SectionDocument18 pagesFuel System: SectionZona Educación Especial ZacapaoaxtlaNo ratings yet

- Ps - Power Steering SystemDocument6 pagesPs - Power Steering SystemBRILLIANCE AUTO LIFENo ratings yet

- Rear Suspension: SectionDocument12 pagesRear Suspension: SectionABBAS ALINo ratings yet

- Fuel System Service Manual On A 2008 Infiniti G37sDocument15 pagesFuel System Service Manual On A 2008 Infiniti G37sAdel HomsiNo ratings yet

- Pathfinder 2005 - Parking BrakeDocument10 pagesPathfinder 2005 - Parking BrakePaper-FaceNo ratings yet

- Instrument Panel: SectionDocument16 pagesInstrument Panel: SectionSilvio ServinNo ratings yet

- Sistema de Combustible Nissan 370 Z 2009Document15 pagesSistema de Combustible Nissan 370 Z 2009Hendrick CepedaNo ratings yet

- Exhaust SystemDocument4 pagesExhaust Systemshortbus22No ratings yet

- Instrument Panel: SectionDocument14 pagesInstrument Panel: Sectionfearimus1No ratings yet

- Rear Axle: SectionDocument12 pagesRear Axle: SectionJBNo ratings yet

- Nissan Sentra 2009 Service Manual Nissan Sentra 2009 Service ManualFUEL SYSTEM PDFDocument13 pagesNissan Sentra 2009 Service Manual Nissan Sentra 2009 Service ManualFUEL SYSTEM PDFDavid BNo ratings yet

- Exhaust System: SectionDocument4 pagesExhaust System: SectionKelvin CarrionNo ratings yet

- Fuel System: SectionDocument15 pagesFuel System: SectionDiego496No ratings yet

- Accelerator Control SystemDocument4 pagesAccelerator Control SystemPaolo MadambaNo ratings yet

- Clutch: SectionDocument18 pagesClutch: SectionSteven AmadorNo ratings yet

- MT - Manual TransaxleDocument14 pagesMT - Manual TransaxleBRILLIANCE AUTO LIFENo ratings yet

- Acc PDFDocument8 pagesAcc PDFCarlos Eduardo ZelidonNo ratings yet

- FL PDFDocument27 pagesFL PDFMontasir AlkinaniNo ratings yet

- RF PDFDocument10 pagesRF PDFROSILENE PASSOSNo ratings yet

- Rear Suspension: SectionDocument14 pagesRear Suspension: SectionAbu MaryamNo ratings yet

- Front Suspension: SectionDocument14 pagesFront Suspension: SectionAbu MaryamNo ratings yet

- A B C D E F G H I J K L M: Quick Reference IndexDocument2 pagesA B C D E F G H I J K L M: Quick Reference IndexAbu MaryamNo ratings yet

- Body Control System: SectionDocument8 pagesBody Control System: SectionAbu MaryamNo ratings yet

- CO2 ReductionDocument6 pagesCO2 ReductionMarc LabataNo ratings yet

- Energy Efficient Roadway Lighting Opportunities and BenefitsDocument15 pagesEnergy Efficient Roadway Lighting Opportunities and BenefitsHesham AlzarooniNo ratings yet

- Manuel Manto 785C InglesDocument104 pagesManuel Manto 785C Inglesciprian quispe challco100% (1)

- Eye EssayDocument6 pagesEye Essayppggihnbf100% (2)

- Lab 5 - Wireless Power Transfer PDFDocument2 pagesLab 5 - Wireless Power Transfer PDFRuben CollinsNo ratings yet

- 4fuel Injection PumpDocument9 pages4fuel Injection PumpJoko Sukariono100% (2)

- Hazardous Areas Stanwell Power StationDocument19 pagesHazardous Areas Stanwell Power Stationghostamir100% (1)

- DTK-120HW, DTK-MRJ11, DTK-2LVLP: Surge ProtectorsDocument1 pageDTK-120HW, DTK-MRJ11, DTK-2LVLP: Surge Protectorsethan8888No ratings yet

- Data Sheet - AST r01Document3 pagesData Sheet - AST r01elvis linaresNo ratings yet

- May Monthly Report GasperDocument14 pagesMay Monthly Report GasperOWTCNo ratings yet

- Free Energy SurpriseDocument21 pagesFree Energy SurpriseJeanJones100% (3)

- Magnalock Models M32, M62 and M82B Installation InstructionsDocument1 pageMagnalock Models M32, M62 and M82B Installation InstructionsMilos StoisavljevicNo ratings yet

- C4 BMobile RobotsDocument114 pagesC4 BMobile RobotsMichael DavisNo ratings yet

- Introduction To The CompanyDocument3 pagesIntroduction To The Companymansi sainiNo ratings yet

- Diamer Basha DamDocument6 pagesDiamer Basha DamKashif Ali Hasnain0% (1)

- Hs35a 2011Document11 pagesHs35a 2011Ross Mathew0% (1)

- Laporan Praktik Mesin ListrikDocument4 pagesLaporan Praktik Mesin ListrikFatimah azzahraNo ratings yet

- Steam Drum, Water Wall & Evaporator - VWHA054Document36 pagesSteam Drum, Water Wall & Evaporator - VWHA054Mani SunNo ratings yet

- R ChidambaramDocument2 pagesR Chidambaramshridhar sutarNo ratings yet

- Pressure - Enthalpy Diagram For The Refrigerant R-22: Li Q U IdDocument1 pagePressure - Enthalpy Diagram For The Refrigerant R-22: Li Q U IdRifki AuliaNo ratings yet

- Component Maintenance Manual With Illustrated Parts ListDocument62 pagesComponent Maintenance Manual With Illustrated Parts ListRaymond Zamora100% (7)

- Hyster H80XM K005Document646 pagesHyster H80XM K005André Targino75% (4)

- Sealing For Hydropower EquipmentDocument28 pagesSealing For Hydropower EquipmentJenny Cecilia Ureña ZuriNo ratings yet

- Technical Capabilities PDI 2019 09Document10 pagesTechnical Capabilities PDI 2019 09carlosNo ratings yet

- Dr. Sadaf Siddiq 08F UET PHD ME 47Document206 pagesDr. Sadaf Siddiq 08F UET PHD ME 47hassanNo ratings yet

- Compression Springs: Dimensions According To DIN 2098Document9 pagesCompression Springs: Dimensions According To DIN 2098Андрей МеренковNo ratings yet

- Chapter 1 MCQ'SDocument2 pagesChapter 1 MCQ'SNaveed MughalNo ratings yet

- Basic Tuning 101: Air Fuel RatioDocument14 pagesBasic Tuning 101: Air Fuel RatioBronwynne OctoberNo ratings yet

- Earthing RequirementDocument7 pagesEarthing RequirementSandy ChoudhariNo ratings yet

- PWHTDocument118 pagesPWHTSumedh Singh100% (19)