Professional Documents

Culture Documents

Chapter Four: Material Handling

Uploaded by

Bukti Negal0 ratings0% found this document useful (0 votes)

17 views7 pagesThe document provides an outline and overview of chapter 4 on material handling. It discusses the importance of material handling in ensuring the right materials are delivered at the right time and place. The objectives of an effective material handling system are to reduce costs, improve safety, quality and productivity. A material handling system should be designed when there are changes to products, layouts, equipment becomes obsolete or there are frequent accidents. The total cost of material handling per unit includes equipment costs, labor costs and maintenance costs.

Original Description:

Original Title

Chapter 4

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides an outline and overview of chapter 4 on material handling. It discusses the importance of material handling in ensuring the right materials are delivered at the right time and place. The objectives of an effective material handling system are to reduce costs, improve safety, quality and productivity. A material handling system should be designed when there are changes to products, layouts, equipment becomes obsolete or there are frequent accidents. The total cost of material handling per unit includes equipment costs, labor costs and maintenance costs.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views7 pagesChapter Four: Material Handling

Uploaded by

Bukti NegalThe document provides an outline and overview of chapter 4 on material handling. It discusses the importance of material handling in ensuring the right materials are delivered at the right time and place. The objectives of an effective material handling system are to reduce costs, improve safety, quality and productivity. A material handling system should be designed when there are changes to products, layouts, equipment becomes obsolete or there are frequent accidents. The total cost of material handling per unit includes equipment costs, labor costs and maintenance costs.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

CHAPTER FOUR

Material Handling

Outline

o Introduction and Importance

o Objectives of Material Handling

o When To Design A Material Handling System?

o Cost of Handling

Ms. Leena Shemsu

4.1 Introduction and Importance

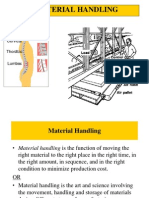

• Material handling means providing the right amount of the right

material, in the right condition, at the right place, at the right time, in the

right position and for the right cost, by using the right method.

• It is simply picking up, moving, and lying down of materials through

manufacture.

• The importance of material handling function is greater in industries where

the ratio of handling cost to the processing cost is large.

• Today material handling is rightly considered as one of the most potentially

lucrative areas for reduction of costs.

• A properly designed and integrated material handling system provides

tremendous cost saving opportunities and customer services

improvement potential.

4.2 Objectives of Material Handling

• The primary objective of a material handling system is to reduce the unit

cost of production. The other subordinate objectives are:

1. Reduce manufacturing cycle time

2. Reduce delays, and damage

3. Promote safety and improve working conditions

4. Promote productivity

i. Material should flow in a straight line

ii. Material should move as short distance as possible

iii. Use gravity

iv. Move more material at one time

v. Automate material handling

5. Maintain or improve product quality

6. Promote increased use of facilities

i. Promote the use of building cube

ii. Purchase versatile equipment

iii. Develop a preventive maintenance program

iv. Maximize the equipment utilization etc.

7. Reduce tare weight

8. Control inventory

4.3 When To Design A Material Handling System?

• The need to design a material handling system arises when:

A new product is being planned for manufacture

Change in the existing product design requiring a corresponding change

in the layout

Obsolescence of facilities

Frequent accidents

Adoption of new safety standards

4.4 Cost of Material Handling

• The total cost of material handling per unit must decrease. The total cost

per unit is the sum of the following:

1. Cost of material handling equipment – both fixed cost and operating cost

calculated as the cost of equipment divided by the number of units of

material handled over the working life of the equipment.

2. Cost of labor – both direct and indirect associated cost calculated in terms

of cost per unit of material handled.

3. Cost of maintenance of equipment, damages, lost orders and

expediting expenses, also calculated, in terms of cost per unit of material

handled.

End of Chapter 4

You might also like

- Petronas Technical Standards: Process Hazard Analysis (PHA)Document33 pagesPetronas Technical Standards: Process Hazard Analysis (PHA)heki100% (1)

- Contact Us: 6646 4941/3340 3359: Green International - UPDA Electrical Question & Answer - 5Document16 pagesContact Us: 6646 4941/3340 3359: Green International - UPDA Electrical Question & Answer - 5Kip ClayNo ratings yet

- Material Handling and Equipments: Chapter-OneDocument35 pagesMaterial Handling and Equipments: Chapter-Oneeba yohannesNo ratings yet

- MM ch6Document7 pagesMM ch6thebestofworld2014No ratings yet

- MH Lect Chapter 1Document19 pagesMH Lect Chapter 1Kuma AlexoNo ratings yet

- Chapter 9 MH Systems DesignDocument19 pagesChapter 9 MH Systems DesignKhánh Đoan Lê ĐìnhNo ratings yet

- Chepter 4 PoDocument7 pagesChepter 4 PoPriya dharshiniNo ratings yet

- Material HandlingDocument41 pagesMaterial HandlingmjbicaldoNo ratings yet

- Stores Management and Materials HandlingDocument21 pagesStores Management and Materials HandlingMr. Umang PanchalNo ratings yet

- Chapter 1 Introduction To MH - AregawiDocument32 pagesChapter 1 Introduction To MH - AregawiBeke derejeNo ratings yet

- Chapter 6 Material HandlingDocument18 pagesChapter 6 Material HandlingRamadan DestaNo ratings yet

- MH Chapter 1Document20 pagesMH Chapter 1nurhussen nureNo ratings yet

- Material HandlingDocument4 pagesMaterial HandlingVaidehiranaNo ratings yet

- Alkesh Dinesh Mody Institute For Financial & Managemnt StudiesDocument16 pagesAlkesh Dinesh Mody Institute For Financial & Managemnt Studiessonalic18No ratings yet

- Layout Chapter 5Document60 pagesLayout Chapter 5Tadi YosNo ratings yet

- Material Handling: Submitted byDocument19 pagesMaterial Handling: Submitted byprateek gandhiNo ratings yet

- Material Handling SystemsDocument15 pagesMaterial Handling SystemsShreyas JyothishNo ratings yet

- Definition of Material HandlingDocument12 pagesDefinition of Material HandlingAnkur MahteNo ratings yet

- MM CH 6Document7 pagesMM CH 6dawitsam7No ratings yet

- PLFD PrateekDocument19 pagesPLFD Prateekprateek gandhiNo ratings yet

- Material Handling LeturerDocument42 pagesMaterial Handling LeturerMohammad Anwar AliNo ratings yet

- Material Handling-POMDocument19 pagesMaterial Handling-POMLavkeshhNo ratings yet

- Material HANDLING PowerPoint PresentationDocument34 pagesMaterial HANDLING PowerPoint PresentationSamiul AlamNo ratings yet

- Chapter 1 Introduction To MHS - 22Document53 pagesChapter 1 Introduction To MHS - 22Kim TuyenNo ratings yet

- Material HandlingDocument17 pagesMaterial HandlingJessica SaballeroNo ratings yet

- Chp.7 Material HandlingDocument26 pagesChp.7 Material HandlinganfaalNo ratings yet

- Material HandlingDocument25 pagesMaterial HandlingAsmita JoshiNo ratings yet

- Material Handling EquipmentDocument52 pagesMaterial Handling EquipmentmichaelNo ratings yet

- Material Handling Flow PatternDocument20 pagesMaterial Handling Flow PatternAli WarsiNo ratings yet

- Method Study: Navanendra Singh Asst Prof. (Department of Fashion Technology) NIFT-PatnaDocument41 pagesMethod Study: Navanendra Singh Asst Prof. (Department of Fashion Technology) NIFT-PatnaMritunjay BhartiNo ratings yet

- Materials HandlingDocument18 pagesMaterials HandlingJessica SaballeroNo ratings yet

- Material HandlingDocument30 pagesMaterial HandlingGeeta Rani100% (1)

- 06W7 Ch05 Facilities MaterialHandlingDocument33 pages06W7 Ch05 Facilities MaterialHandlingNhi HuynhNo ratings yet

- Chapter 3 - MATERIAL HANDLING PDFDocument10 pagesChapter 3 - MATERIAL HANDLING PDFShiverrania 29080% (1)

- Outlines: Materials Handling EquipmentDocument17 pagesOutlines: Materials Handling EquipmentYonatan TaddeseNo ratings yet

- Chapter 2. Unit LoadDocument58 pagesChapter 2. Unit LoadKim TuyenNo ratings yet

- Group 1 MH FinalDocument40 pagesGroup 1 MH FinalRoli Jojy JohnNo ratings yet

- Food EngineeringDocument14 pagesFood EngineeringDomician BenardNo ratings yet

- Material Handling Unit 1Document42 pagesMaterial Handling Unit 1Shyamasis GhoshNo ratings yet

- Management Techniques and Medical MaterialsDocument72 pagesManagement Techniques and Medical MaterialsHari KrishnaNo ratings yet

- Module 2 Material Handling - Part 2 by ADFerrerDocument56 pagesModule 2 Material Handling - Part 2 by ADFerrerCzarina OpagueNo ratings yet

- 06 POM Materials HandlingDocument28 pages06 POM Materials HandlingHimanshu KumarNo ratings yet

- UNIT 1 - Introduction To Material Handling EquipmentsDocument20 pagesUNIT 1 - Introduction To Material Handling EquipmentsAdugna GosaNo ratings yet

- Module 4 (1) 5Document79 pagesModule 4 (1) 5The Killer SwitchNo ratings yet

- Material Handling HDFCDocument42 pagesMaterial Handling HDFCAjay ChauhanNo ratings yet

- Material HandelingDocument14 pagesMaterial HandelingAakanshaNo ratings yet

- MHE Chapter 4Document26 pagesMHE Chapter 4nurhussen nureNo ratings yet

- Material HandlingDocument12 pagesMaterial HandlingshahzanladiwalaNo ratings yet

- Material Handling 2009Document45 pagesMaterial Handling 2009FarhinNo ratings yet

- Oda Bisil Collega Ambo Branch Course Name:material Management Acadamic Year-2014 E.C 3RD Year First SemisterDocument32 pagesOda Bisil Collega Ambo Branch Course Name:material Management Acadamic Year-2014 E.C 3RD Year First SemisterGemechis GurmesaNo ratings yet

- Abe 214 Lecture NoteDocument46 pagesAbe 214 Lecture Noteemmanueladah147No ratings yet

- Materials ManagementDocument16 pagesMaterials ManagementJoseph George KonnullyNo ratings yet

- Introduction of Material HandlingDocument14 pagesIntroduction of Material HandlingsankasturkarNo ratings yet

- Mpe 411-Topic 3 NotesDocument17 pagesMpe 411-Topic 3 NoteskandeabigaelNo ratings yet

- III I Material Handling (OE)Document109 pagesIII I Material Handling (OE)RINKAL LOUNGANINo ratings yet

- Material Handling SummaryDocument4 pagesMaterial Handling SummaryBoyd Mearns100% (1)

- Inventory ControlDocument72 pagesInventory Controlvishal thapar100% (1)

- A Scientific Criteria For Determining A Good Plant LayoutDocument36 pagesA Scientific Criteria For Determining A Good Plant LayoutSenthilKumar SubramanianNo ratings yet

- Mcs Meaning and ObjectivesDocument6 pagesMcs Meaning and ObjectivesRatheesh KumarNo ratings yet

- Tutorial SolutionDocument8 pagesTutorial SolutionBukti NegalNo ratings yet

- Topic 4: Equilibrium Binding and Chemical KineticsDocument23 pagesTopic 4: Equilibrium Binding and Chemical KineticsBukti NegalNo ratings yet

- Addis Ababa University Addis Ababa Institute of TechnologyDocument3 pagesAddis Ababa University Addis Ababa Institute of TechnologyBukti NegalNo ratings yet

- PPC Mid Exam 04 Dec 2013Document3 pagesPPC Mid Exam 04 Dec 2013Bukti NegalNo ratings yet

- Decision Making (Chapter 9)Document55 pagesDecision Making (Chapter 9)Bukti NegalNo ratings yet

- AWS B5.17-2008 Specification For The Qualification Ofwelding FabricatorsDocument22 pagesAWS B5.17-2008 Specification For The Qualification Ofwelding FabricatorsKawan BartrasNo ratings yet

- Building Information Modeling (BIM) To Manage Design and Construction Phases of Peruvian Public ProjectsDocument12 pagesBuilding Information Modeling (BIM) To Manage Design and Construction Phases of Peruvian Public ProjectsbuildingandstructureNo ratings yet

- Cardinal Utility, Consumer Surplus and Producer SurplusDocument23 pagesCardinal Utility, Consumer Surplus and Producer SurplusJaiaaditya RaoNo ratings yet

- AAA Exam Kit NotesDocument21 pagesAAA Exam Kit NotesSheda AshrafNo ratings yet

- 1HGJDocument76 pages1HGJkingsley_psb100% (1)

- Principles of Marketing 16th Edition Kotler Test BankDocument26 pagesPrinciples of Marketing 16th Edition Kotler Test BankJerryMitchellkegq100% (33)

- TheUtilizationofTargetCostingintheTelecomIndustry Krstevski MancheskiDocument7 pagesTheUtilizationofTargetCostingintheTelecomIndustry Krstevski MancheskiNathem NasherNo ratings yet

- Draw Hands Clock Face Whole HoursDocument2 pagesDraw Hands Clock Face Whole Hoursazenith091685No ratings yet

- Factor Humano en La Productividad Competencias TransversalesDocument12 pagesFactor Humano en La Productividad Competencias Transversalesmayra ALEXANDRA JARA LAVERDENo ratings yet

- Why Do We Subtract Cash and Add Debt When Calculating The Enterprise Value of A Firm - QuoraDocument10 pagesWhy Do We Subtract Cash and Add Debt When Calculating The Enterprise Value of A Firm - QuoraLester OrtegaNo ratings yet

- (Project Title) : Earned Value Analysis ReportDocument4 pages(Project Title) : Earned Value Analysis ReportFarnas ApNo ratings yet

- Hard and Soft Information in Banks Ratings PDFDocument25 pagesHard and Soft Information in Banks Ratings PDFnoor ul hqNo ratings yet

- 03 1+referencesDocument42 pages03 1+referencesMukesh YadavNo ratings yet

- Grp-51 CRAIG MANUFACTURINGDocument8 pagesGrp-51 CRAIG MANUFACTURINGLaksh SinghalNo ratings yet

- (COSMOS Certi) 1,3-B.G - 21.12.31Document2 pages(COSMOS Certi) 1,3-B.G - 21.12.31Nindy Dellia PutriNo ratings yet

- Supply Chain Management MCQ Questions and Answers PDFDocument4 pagesSupply Chain Management MCQ Questions and Answers PDFMijanur RahmanNo ratings yet

- Systems Analysis and Design 5th Edition Roth Test BankDocument16 pagesSystems Analysis and Design 5th Edition Roth Test BankLey Esguerra80% (5)

- Tax PNL Report FY2022-2023 R205425Document40 pagesTax PNL Report FY2022-2023 R205425aroralokeshNo ratings yet

- Project ClosureDocument16 pagesProject Closuresohaib900009No ratings yet

- Qualifying Exams Reviewer Management Science (1 Sem) : Objective FunctionDocument14 pagesQualifying Exams Reviewer Management Science (1 Sem) : Objective FunctionCristina TayagNo ratings yet

- DocumentDocument2 pagesDocumentHibaNo ratings yet

- Jamo C 97 II Floorstanding Speakers PairDocument13 pagesJamo C 97 II Floorstanding Speakers PairAndre LisboaNo ratings yet

- Series of 2023: Office of The SecretaryDocument1 pageSeries of 2023: Office of The SecretaryJoshua BrentNo ratings yet

- MSC International Business Dissertation TopicsDocument8 pagesMSC International Business Dissertation TopicsBestCollegePaperWritingServiceSingapore100% (1)

- The ISO17025 Standard: Why? What? How?: July 2017Document36 pagesThe ISO17025 Standard: Why? What? How?: July 2017Lara GadžunNo ratings yet

- Aud339 Audit Planning Part 2Document26 pagesAud339 Audit Planning Part 2Nur IzzahNo ratings yet

- H1 Taipei Capital Markets Radar ColliersDocument8 pagesH1 Taipei Capital Markets Radar Colliersnhungoc3028No ratings yet

- Perpetual Vs Periodic Inventory SystemDocument9 pagesPerpetual Vs Periodic Inventory SystemKhrystyna Kos100% (1)