Professional Documents

Culture Documents

M3 CJV Itp Ear00 Gen 000003

M3 CJV Itp Ear00 Gen 000003

Uploaded by

Ziaul Haq0 ratings0% found this document useful (0 votes)

36 views6 pagesOriginal Title

M3-CJV-ITP-EAR00-GEN-000003

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

36 views6 pagesM3 CJV Itp Ear00 Gen 000003

M3 CJV Itp Ear00 Gen 000003

Uploaded by

Ziaul HaqCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

(ely Ny ttt Riyadh Public Transport

wg fe

RIYADH METRO

Package 3 (Lines 4, 5 & 6)

at King Abdulaziz Project for >

a

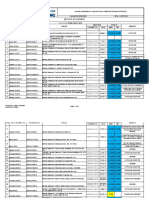

Inspection and Test Plan for Screed Application in Floors -

LINE 4

M3-CJV-ITP-EAR00-GEN-000003 AA

(Sub-Contractor Organization):

TS Author | Ghee [Ghee | Aneved

asian ovsiaion Destpaon Designation

bate & Sone Dale & Spine baie Sustee bai & Stare

GJV Organization: _ ee

Author Site Manager Line aalac Line Manager Project Manager

| Mohammad Ahmady Booun Hong Kiyeon Kwon Hoiyong Chung | Ignacio Gutierrez

cecomen | ote | aan | peste |fpetomn

MW bbed | biked) -

02-62. andy | \ 3-fab- (§ | aga ly 2

FAST Organization

[ Checked ei Reviewed Approved

Designation Designation Designation Designation

Date & Signature Date & Signature Date & Signature Date & Signature

Riyadh Metro Package 3 (Lies 4,58 6)

Inspection Test Plan for Applcaion of Coal Tar Epoxy Paint For Sanitary

‘Sewerage Manholes - Rev. AA

DOCUMENT CHANGE RECORD

| Date Change Description Author

AAI 01-02-2018 Creation ‘Mohammad Ahmady

AA 01-02-2018 First Submission to RAMPED ‘Mohammad Anmady

'MG-CJV-ITP-EAR00-GEN-000008 AA ‘01/02/2018 Page t oft

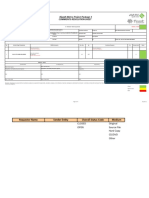

INSPECTION CHECKLIST [gt ils.

Solin

CONCRETE SCREED PLACEMENT

Name of Prose Contactor

RIVADH METRO PROJECT PACKAGE 3 FAST Cu

Item Description: ‘Area/Unit:

Rateroce Drawing Naz Rev. [TP Nor Tatvy No,

Now

Schetdled Inspection Date & Tine: | RAMPED Inspocton | Gorvactornapesfon Lovet IA No

tev

a ACCEPTANCE CRITERIA rerenence | accept | nevect | WA

1 Surtace Preparation Inaction

Examine substrates (Oampratng / Waterprooting or condlons

attoctngpoformance of sree, Pro Spee

“ sen aot,

Proceed with appletion only aferunsetistectorycondions have been | “asi A

corrected

Verify that base slabs meet finish and surface profile requirements in Pro}, Spec.

12 | jslon 8 Secion'Cashin Place Concrete” secon 544,

2 Material Recelving inspection

Concrete Seroed shall be accepted ihe temperature isbolow 620. | _ Pro). Spee

21 | Conctle Screed temperature ht exceeds $2 shallbo acta.” | Sedton OSs,

Actual creed Temperature *c. Max. 20) Pan 301.4

Concrete Setod Stump shal be accepted as per approved Mix

ap | Boson 20s046mm ony Ave

Actual Slump: _ mm. 7

3 instalation inspection

arande porto proceed placing of concrete sree:

1. Verify the IRs of Damproofing for non-wet areas (If Reqired)

na Watorpovtng lr wo! ares ony, ite aoopted

31 spproved by FAST AMPED. sor

2. Discipline clearance form shall be signed by Site Engr. to

ensure tat the embeded ern ere complete and at

requledinspecions havo been performed.

fap | Check nstaled Angle bars (Galvanized Polycarbonate andi =

bord instucing lock-out as er Approved Shop drawing

sag | Suey or conoree sored op elevations has been conducted and is

Reporte wae accepted by FaevRampod

Place screed continuously in a single layer, tamping and consolidating Proj. Spec.

3.4 | toachieve tight contact with bonding surface. Do not permit cold joints | Section 03544,

for seams to develop within pour stp peaea

| — Proj. Spec.

a8 | screed sutac witha salghtadg and sttko oo content elevations. | Section 09564,

Pat!

Pei Spo,

28 | stipe euanes utomly whe ieee, secon Sosa,

ranaaoe

te ACCEPTANCE CRITERIA rerenence | accept | nevect | NA

'M3-C)V-FOR-GQAO0-M50-014182 Rev. AA

Page 1of2

ae Fe

INSPECTION CHECKLIST

oo

eae

CONCRETE SCREED PLACEMENT

a7 | Bean iia foating wing bul oats to forma untorm and open- hth Sea

-7 | textured surtace plane tre of humps or hollows. len SE.

Finishing: Consolidate surlace with hand loat as soon as soreed.can | pao, Spec

4.7_| support equipment and operator. Re-saighion, cul down high spots, | scion dst,

And fil low spots. Repaat float passes and re-sraighioning until surface

is left with a uniform, smooth, granular texture. Petase

Hard Trowel Finish: Alte floating surace, apply ist trowel finish and

ag | consolidates scroedby power-driven trowel so na bisters develop, ee

Continuo trowoling passoo and ro-sraighton unl cufavo le amooth and | Selon O54

tuniform in texture.

Finish and measure surface so gap at ny point between soreed

tag | surlace and an unloveledtteestanding mong straightedge, resting | P'S,

an two high spots anc placed anywhore onthe surface, doos not aout:

exceed 6.4 mm,

Moisture Curing: Keap surfaces continuously moist for not lass than ee

aro | Seven days with water or absorptive cover, water saturated and kept | PL Spec.

Continuously wet. Cover sereed surfaces and edges with 200-mmlap | Seulon 09544,

over adjacent absorptive covers.

a Final Inspection

Comprossve Strength (28 Days) Tost Reports as peroquroment ot | pig, spo

a1 | ASTMC 109/C 109M. (C20, 10mm Aga.) ‘Section 63532

‘Actual Comp, Strength:___Mpa Pee

‘Compressive Strength (28 Days) Test Reports as per requiromont ot | pag, spec

42_| ASTMC 109/C 109M, (C20, 5mm Agg.) Sootion 03522

Actual Comp. Strength:, Mpa Peters

FEMARKS:

REFERENCE DOCUMENTS:

SUB-CONTRACTOR QA/QC/SITE RAMPED QA/ac

ACTORS FAST QAlac

NAME: NAME: NAME:

‘SIGNATURE SIGNATURE SIGNATURE:

DATE: DATE DATE:

M3-C]V-FOR-GQAO0-M50-014182 Rey. AA

Page 2012

ITP - Inspection and Test Plan for Screed Application in Floors -

Document No:

M3-CIV-ITP-EAROO-GEN-000003

ly . Revision: aa] AA

SS f2 et REF: Method Statement : M3-CIV-MST-EARSF-GEN-000001 Pages: 2

7 ir es M3-GEG-MST-EAROO-ELS-000002

Yoana ataee , Date: 2-Feb-18

REF: Check List : M3-CIV-FOR-GQA00-M50-014182

: ‘ 3 4 5 e 7 8 M

Activity Description of : {Qc Form Verifying Record ips eve

No | Actvity/inspection item | !sPection andTesting Method | Reference Documents Accoptance Criteria Ret: ee Breet Pr] | bere Peale Pe ear [ee

1._|GENERAL REQUIREMENTS (ie Mix Design Approval-Materials Approval, etc.)

a. Approved MAR

lb. Approved IFC Shop a. Riyodh Metro Station ané Buildings Ja. Approved Method Statement |a-Technical Manager

Drawings Specication Section 03544 part2-__fb.ThirdParty Test Reports |b,aavacengineer _|eriorto work

1. fa. Concrete Mix Design Approval Ja. approval of Mi 1

i sale prigee Walt concrete Delvery Receipt Products, Clause 2.1 Screed fc. Approved Checklist # M3-CWVe.third Party commencement eee | aie

a. Approved Method Materalso3532 For-canoo.ms0.014182 —_|Representative

Statement

.Approved Method

ee gaa Statement a Riyadh Metto Station and Buildings Ja. Approved Checks #: M3-CVa.Technical Manager Ipc to york

1.2 _|o. Approved Drawings epee Ib. Approved IFC Shop Speciation Section 03sad part1- _|ron-caaoomsoo1sis2 —_|b.aavac engineer : nf ]er

7 Drawings General, Clause 1.1 Related Documents eamecrren

a. Delivery Receipt Ja. Approved Shop Drawings 2. Riyadh Metro Station and Buildings Rae ae

1.4 |awire mesh (applicable) —_b.Review af Receipt Ib. Approved MAR specication Section 03544 Part 2- amin BNE tach delvery | 4 | w | w

esamping Jc. astm 185 Products, clause 2.1 Screed Materials Sins Fa,

Representative

a.visual Inspection/Documents _Ja.FASTHSE plan Heath and Safety conditions as per asite Wse :

5 |1H5€ requirement/safety eh a.Documents a:continueus

es es approved FASTHSE plan Pe Representative En Sele ink

2._ [Execution of Screed Appli Floors

a.Approved Method a.Approved Checklist &:3-clv-

surface Preperation eveing _|?™8H8 Inspections statement a. Riyadh Metro station and Buildings |FOR-GQAOOMSO.014182 Ja. surveyor _b.aw/ac

aa” | Seen b-Survey Levels b. Approved Drawings specication ection 03544 Part 3- _b.survey Report Engineer csite [Before Pouring nH] ow |w

MEP Clearances Execution Clause 3.1. and 3.1.b Engineer

Installation inspection ;

| Approved checklist #m3-Cv-

Embedded items Angles- ; lAporoved MS / ; ste engineer/ac

22 eed taneertreae, eer |Mstallnspection estes Approved Ms / Shop Drawings or-caxoo-msocisea [Pere Prior to placement aw] fw

Jc Mcp clearance

Boards & Block-out

Page 1 of 2

i ee b No: M3-CIV-ITP-EAROO-GEN-000003

ITP - Inspection and Test Plan for Screed Application in Floors - Line 4 ee

wy aoe ik

>» KS fa et REF; Method Statement ; M3-CJV-MST-EARSF-GEN-000001 Pages: 2

" 7 re ere M3-GEG-MST-EAROO-ELS-000002

YY rst et ata Date: 2-Feb-18

REF: Check List : M3-CJV-FOR-GQA00-IM50-014182

9

1 2 6

3 4 5 7 8 ion Level

Activity Description of ae ere ; QC Form/Verifying Record/ Inspeet

wi Aetiviy/inmecton tem | msPeetlon and Testing Method | Reference Documents Acceptance Criteria Ref: ens Responsible Person | inspection Frequeney. [TRAM ove

eo | (4

+Siump & Temperature

leach Delivery/Truck)

set of 3

la.witness- ‘Approved Mi fi

23 [recat rfenal ss esate " BS SACISOR \Specification Section 03544 Part 2 FOR-GQA00-M50.014182 aus M a ; H}| w lw] te

Prod le 1 Scree laterials fest Report Ie =) eee

IC. Approved MAR tS Canis he eee acta preet hespor Technician: Jeach subsequent 460 sq.

m, but not less than 6

samples for each

day's placement.

Ja.Witness-ASTM C 143 and ASTM |a.Approved Method ja. Riyadh Metro Station and Buildings |a.Approved Checklist #: M3-CIV-|a.QA/QC Engineer

24 Jeuring Jc 1064 statement Specification Section 03544 Part 2- | FOR-GCADO-Ms0-014182 [site Engineer specity as per Specs n}wls

fb, Aci 309n Products, Clause 2.1 Sereed Materials

a.a/aC Engineer

checking of screed level after a.Approved Checklist #: M3-CIV

la, Aproved SD a. Riyadh Metro Station and Bulldings bsite Engineer lon all carpet ane epoxy

A | dryness (only at carpet and epoxy}a. Visual Inspections w

2A |armness (only at carpet and enony|a.Visual Inspect b.Survey Report [Specification Section 03544 POR SSOADD MiE0-010182 [c.Site Supervisor floors WW H

foors)

jd.Surveyor

Ja.Approved ITP Ja. Riyadh Metro Station and Buildings —_|.Approved Checklist #: M3-CIV-|a.QA/QC Engineer

2.5. |Repair of Concrete Screed (itany) |a.Visual Inspections l>.Approved Materials for repairs [Specification Section 03544 Part 3- FoR-Gaaoo-ms0-014182 b.site Engineer [On all defective areas H] ow fw

Execution, Clause 3.6.A Repairs site Supervisor

Prepared By:

l= Hold point: Attendance required & signature on IR is @ must to proceed

following work Mohammad Ahmady - QA Engineer

IW = Witness point: Attendance expected & signature on IR is required, but

if the signatory is not present to sign at the time, follow on work may "

: Signature:

lproceed and the IR document(s) signed later. Revived By lapatires

Surveillance point: Random attendance, no signature is required on IR

lor its accompanying documentation. ohiannerad AWG OM Ene ear 9 VL e

IR = Review of record: It may be in addition to any of the other codes. CAA

[For any inspection level: | = Information/Report shall be provided by those Approved By: Signature:

|who are responsible for the Inspection.

“ Kiyeon Kwon —L4 QA/QC Manager

(*): To be specified case by case. E.g. Independent Laboratory

Page 2 of 2

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- 3) Method of StatementDocument10 pages3) Method of StatementZiaul HaqNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Template - QA QC Documents-UGS 04-Nov-2020 by GEGC (Final)Document103 pagesTemplate - QA QC Documents-UGS 04-Nov-2020 by GEGC (Final)Ziaul HaqNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Inspection Checklist: Concrete Screed PlacementDocument2 pagesInspection Checklist: Concrete Screed PlacementZiaul HaqNo ratings yet

- Ferco Doors-Fire Shutter Installation Insulated Manual Rev 01Document13 pagesFerco Doors-Fire Shutter Installation Insulated Manual Rev 01Ziaul HaqNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- FCC - Revised RFI LOG - 20-SEPT-2021Document1 pageFCC - Revised RFI LOG - 20-SEPT-2021Ziaul HaqNo ratings yet

- Template - QA QC Documents-UGS 04-Nov-2020 by GEGC (Final)Document45 pagesTemplate - QA QC Documents-UGS 04-Nov-2020 by GEGC (Final)Ziaul HaqNo ratings yet

- Zone - F2 & F3 Weekly Progress (Gegc) - 13-06-21Document4 pagesZone - F2 & F3 Weekly Progress (Gegc) - 13-06-21Ziaul HaqNo ratings yet

- Riyadh Metro Project Package 3 Comments Resolution Sheet: Overall Review Code Overall StatusDocument4 pagesRiyadh Metro Project Package 3 Comments Resolution Sheet: Overall Review Code Overall StatusZiaul HaqNo ratings yet

- Riyadh Metro Project Package 3 Comments Resolution Sheet: M3-GEG-MST-EAR00-ELS-000002Document5 pagesRiyadh Metro Project Package 3 Comments Resolution Sheet: M3-GEG-MST-EAR00-ELS-000002Ziaul HaqNo ratings yet

- 023-Ric-T-5493-15 - Mos-C-080 - Repairing of Cracks Reinforced Concrete Grade Slab at Taxi WayDocument8 pages023-Ric-T-5493-15 - Mos-C-080 - Repairing of Cracks Reinforced Concrete Grade Slab at Taxi WayZiaul HaqNo ratings yet