Professional Documents

Culture Documents

Cu/Pvc: PT KMI Wire and Cable TBK

Cu/Pvc: PT KMI Wire and Cable TBK

Uploaded by

HarryOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cu/Pvc: PT KMI Wire and Cable TBK

Cu/Pvc: PT KMI Wire and Cable TBK

Uploaded by

HarryCopyright:

Available Formats

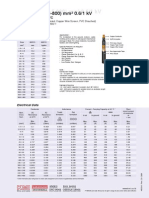

CU/PVC

NYAF

Flexible Copper Conductor, PVC Insulated

Applications:

• Power cord or internal wiring with low mechanical stress for electrical

equipments, machineries, distribution panels, luminaires and other electrical

used in dry indoor premises, substitutes NYA.

• Permanent instalation in conduit, inherently flame retardant in compliance

with IEC 60332-1.

Rated Voltage : 300/500 V

Standard Specification : SNI 04-6629.3 : 2006 (IEC 06)

Cable Size Conductor DC Resistance at Current Short Standard

(No. of core Make-up Carrying Circuit Packing

x Conductor (No.of wire 20˚C 70˚C Capacity in Current Insulation/ Overall Cable Length

Area) x Diameter) Conductor Insulation air 30˚C 1 Sec. Thickness Diameter Weight *

nom. nom. max. min. max. max. nom. approx. approx. (meter/

(mm2) (mm) (ohm/km) (Mohm.km) (A) (A) (mm) (mm) (kg/km) packing)

0.5 16 x 0.20 39. 0 0.013 6 58 0.6 2.2 9 100/c

0.75 24 x 0.20 26. 0 0.011 10 86 0.6 2.3 12 100/c

1.00 32 x 0.20 19. 5 0.010 16 115 0.6 2.6 16 100/c

Test Voltage : 2,000 VAC/5 minutes

Rated Voltage : 450/750 V

Standard Specification : SNI 04-6629.3 : 2006 (IEC 02)

Cable Size Conductor DC Resistance at Current Short Standard

(No. of core Make-up Carrying Circuit Packing

x Conductor (No.of wire 20˚C 70˚C Capacity in Current Insulation/ Overall Cable Length

Area) x Diameter) Conductor Insulation air 30˚C 1 Sec. Thickness Diameter Weight *

nom. nom. max. min. max. max. nom. approx. approx. (meter/

(mm2) (mm) (ohm/km) (Mohm.km) (A) (A) (mm) (mm) (kg/km) packing)

1.5 30 x 0.25 13. 3 0.010 24 173 0.7 3.2 22 100/c

2.5 50 x 0.25 7. 98 0.009 32 288 0.8 3.9 35 100/c

4 56 x 0.30 4. 95 0.007 41 460 0.8 4.4 52 100/c

6 84 x 0.30 3. 30 0.006 53 690 0.8 5.0 73 100/c

10 80 x 0.40 1. 91 0.0056 72 1,150 1.0 6.4 122 100/c

16 126 x 0.40 1. 21 0.0046 97 1,840 1.0 7.4 180 100/c

25 196 x 0.40 0. 78 0.0044 128 2,875 1.2 9.3 275 1,000/d

35 276 x 0.40 0. 554 0.0038 156 4,025 1.2 10.5 347 1,000/d

50 396 x 0.40 0. 386 0.0037 195 5,750 1.4 12.4 531 1,000/d

70 360 x 0.50 0. 272 0.0032 243 8,050 1.4 14.2 735 1,000/d

95 475 x 0.50 0. 206 0.0032 287 10,925 1.6 16.5 969 1,000/d

120 608 x 0.50 0. 161 0.0029 342 13,801 1.6 18.5 1,279 1,000/d

150 756 x 0.50 0. 129 0.0029 386 17,251 1.8 20.3 1,559 1,000/d

185 925 x 0.50 0. 106 0.0029 441 21,276 2.0 22.6 1,899 500/d

240 1221 x 0.50 0. 0801 0.0028 520 27,601 2.2 25.7 2,479 500/d

Test Voltage : 2,500 VAC/5 minutes

Rev. 4.0/22-09-2015

* c = coil d = drum PT KMI Wire and Cable Tbk reserves the right to change the data content without prior notification

PT KMI Wire and Cable Tbk

Jl. Raya Bekasi Km. 23,1 - Cakung, Jakarta 13910, INDONESIA

PO BOX 2468, Jakarta 10001, Phone +62-21-4601733, Fax +62-21-4601738

rhema

E-mail: domesticmarketing@kmi.co.id, overseasmarketing@kmi.co.id

Website: www.kmi.co.id

You might also like

- Power Technologies ATS Low Voltage Transfer SwitchesDocument20 pagesPower Technologies ATS Low Voltage Transfer SwitchesGalih Aji100% (1)

- 2017 DrakaDocument40 pages2017 Drakaapisha1233100% (1)

- SLD For CCTVDocument1 pageSLD For CCTVLorenz Adriano RoblesNo ratings yet

- Electronic Load Controller (ELC) : For Small Hydro Power ApplicationDocument11 pagesElectronic Load Controller (ELC) : For Small Hydro Power ApplicationAri PamungkasNo ratings yet

- Pak Hendra Cipinang 1.5-ModelDocument1 pagePak Hendra Cipinang 1.5-ModelFaidulNo ratings yet

- Na2Xsekfgby 3 X (25-300) MM 3.6/6 KVDocument5 pagesNa2Xsekfgby 3 X (25-300) MM 3.6/6 KVRinda_RaynaNo ratings yet

- NA2XYDocument5 pagesNA2XYAndri ProdjodiprodjoNo ratings yet

- NA2XSEBY KabelDocument5 pagesNA2XSEBY KabelSemar AngNo ratings yet

- Data Sheet Kabel NA2XSEYDocument5 pagesData Sheet Kabel NA2XSEYGansar KharismawanNo ratings yet

- N2 XSEKFGb YDocument5 pagesN2 XSEKFGb YRinda_RaynaNo ratings yet

- N2XYDocument4 pagesN2XYuyab1989No ratings yet

- N2XBYDocument5 pagesN2XBYcyuenkNo ratings yet

- N2XSEBYDocument5 pagesN2XSEBYRinda_RaynaNo ratings yet

- NYSYDocument5 pagesNYSYRinda_RaynaNo ratings yet

- N2XKB (AL) Y 1 X (16-800) MM 0.6/1 KVDocument5 pagesN2XKB (AL) Y 1 X (16-800) MM 0.6/1 KVmuhammad wafiNo ratings yet

- Legrand Niloe Stop Kontak SaklarDocument24 pagesLegrand Niloe Stop Kontak SaklarAlfiansyah Dharma Setia DjaketraNo ratings yet

- BUSBARDocument8 pagesBUSBARRachit KhannaNo ratings yet

- N2 XFGB YDocument4 pagesN2 XFGB YRinda_RaynaNo ratings yet

- Brosur Voksel Hv-70kvDocument2 pagesBrosur Voksel Hv-70kvSyahrul MakkuassangNo ratings yet

- Standarisasi KabelDocument44 pagesStandarisasi Kabeladzan isaacNo ratings yet

- Fujiaire DuctedDocument6 pagesFujiaire Ductedbudikarya11810% (1)

- Mit 185UD5Document2 pagesMit 185UD5Pakito ChocolateroNo ratings yet

- Nfa2xsy TDocument2 pagesNfa2xsy Terni.ainy93No ratings yet

- FM-02 Consumable Material Feb 16 Stock RecordDocument6 pagesFM-02 Consumable Material Feb 16 Stock RecordyogoNo ratings yet

- Kabel Metal Nyy, Nym, Nya, NyfgbyDocument14 pagesKabel Metal Nyy, Nym, Nya, NyfgbyMitha Wahyu PangestiNo ratings yet

- N2xsy Sni IecDocument5 pagesN2xsy Sni IecMario SitorusNo ratings yet

- Jembo KableDocument10 pagesJembo KableBambang Sigit PriyantoNo ratings yet

- Buku Standarisasi Spek Mtu PLN - SK Dir 216 (Bus VT)Document1 pageBuku Standarisasi Spek Mtu PLN - SK Dir 216 (Bus VT)PontasNo ratings yet

- Design and Implementation of A Bidirectional DC-DC Converter For Stand-Alone Photovoltaic SystemsDocument12 pagesDesign and Implementation of A Bidirectional DC-DC Converter For Stand-Alone Photovoltaic SystemsIfan Seven SeasNo ratings yet

- 43 Calculate Cable Tray Size 1.1.15Document4 pages43 Calculate Cable Tray Size 1.1.15vjvijay88No ratings yet

- Water Leak DetektorDocument8 pagesWater Leak DetektorKonk HolicNo ratings yet

- PV DatasheetDocument5 pagesPV DatasheetRafdi Dzulfikar RNo ratings yet

- Reynaldo ZoroDocument9 pagesReynaldo ZoroRully Himawan NstNo ratings yet

- Katalog Industrial - Sep 2020Document123 pagesKatalog Industrial - Sep 2020chaling3No ratings yet

- N2XCYDocument5 pagesN2XCYRinda_RaynaNo ratings yet

- Brosur Katalog Fire Alarm HOOSEKIDocument6 pagesBrosur Katalog Fire Alarm HOOSEKIAris SucahyoNo ratings yet

- BOQ UGC Semanggi Barat - Mampang Dan Rekonduktoring Semanggi Barat - Karet 1 X 1000Document12 pagesBOQ UGC Semanggi Barat - Mampang Dan Rekonduktoring Semanggi Barat - Karet 1 X 1000Reinhard Jesaya SimbolonNo ratings yet

- Nyy PDFDocument5 pagesNyy PDFDen WhNo ratings yet

- Harga BCDocument2 pagesHarga BCAde YD SaputraNo ratings yet

- Petir Dan Metode Rolling Sphere Method - Bryan - ShareDocument64 pagesPetir Dan Metode Rolling Sphere Method - Bryan - ShareJumhanter hutagaolNo ratings yet

- Elektronika Daya Kuliah Ke 2Document39 pagesElektronika Daya Kuliah Ke 2Hafizh Al KhawarizmiNo ratings yet

- Perhitungan Titik Lampu Pada MasjidDocument2 pagesPerhitungan Titik Lampu Pada MasjidFerdiNo ratings yet

- Company Profile PT PLN Persero Up2D MakassarDocument11 pagesCompany Profile PT PLN Persero Up2D MakassarDCC SelatanNo ratings yet

- Ecoluxon Spec Dan Harga 20190501 (Lentera)Document37 pagesEcoluxon Spec Dan Harga 20190501 (Lentera)Don MintaprajaNo ratings yet

- NA2XSEBY 3 X (25-300) MM 3.6/6 KVDocument5 pagesNA2XSEBY 3 X (25-300) MM 3.6/6 KVMario SitorusNo ratings yet

- THERA TMEX503 ES Modbus GatewayDocument1 pageTHERA TMEX503 ES Modbus GatewayAbdul Reza RahmanNo ratings yet

- Product Data Sheet: Motor-Mechanism - MT250 - 110..130 V DCDocument1 pageProduct Data Sheet: Motor-Mechanism - MT250 - 110..130 V DCRicardo Calmon100% (1)

- Yahagi Siren S-283Document1 pageYahagi Siren S-283WidyaNo ratings yet

- STD PT - Amarta KaryaDocument16 pagesSTD PT - Amarta Karyaarif makharimNo ratings yet

- Manual Book UV AQUAFIDESDocument48 pagesManual Book UV AQUAFIDESMartha WidjayaNo ratings yet

- Katalog GensetDocument2 pagesKatalog GensetRevi Alvin RazaqiNo ratings yet

- Soil Thermal Resistivity FactsDocument4 pagesSoil Thermal Resistivity FactspvpavanNo ratings yet

- Bus Bar SizeDocument4 pagesBus Bar SizeMartono Abu HanifNo ratings yet

- RKS Fire AlarmDocument10 pagesRKS Fire AlarmAlex Sandro OktavianNo ratings yet

- Technical Spec NA2XSEYBY 3x300mm2Document2 pagesTechnical Spec NA2XSEYBY 3x300mm2Suyanto Âñd Fámïly100% (1)

- Tacsr Jec 3406 PDFDocument1 pageTacsr Jec 3406 PDFomar_cohen_1No ratings yet

- NYSYDocument5 pagesNYSYsaturasatuNo ratings yet

- NYBYDocument5 pagesNYBYEnnoAjeyNo ratings yet

- High Voltage Power Cables 2XS (F) 2Y - A2XS (F) 2YDocument3 pagesHigh Voltage Power Cables 2XS (F) 2Y - A2XS (F) 2YNeven Ahmed HassanNo ratings yet

- CablesDocument9 pagesCablesMoch ArfiandiNo ratings yet