Professional Documents

Culture Documents

Fujiaire Ducted

Uploaded by

budikarya1181Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fujiaire Ducted

Uploaded by

budikarya1181Copyright:

Available Formats

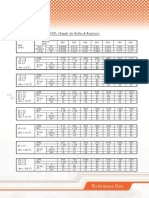

FUJIAIRE DUCTED TYPE AIR-CONDITIONER (R-22 COOLING)

Model

Indoor Unit

Outdoor Unit

Total Cooling Capacity

FULL COMPLIANCE SCROLL COMPRESSOR

FRESH COOL AIR TO EVERY CORNER

Fujiaires range of High Static Ducted Blower Split System offers a total range of applications (4hp to 75hp) to meet your cooling

demands. Delivering fresh air consistently to each and every corner, creating for a healthier and more comfortable living. With the use

of a Full Compliance Scroll Compressor, greater durability and reliability is promised, as well as minimising the demands on natural

resources with efficient performance.

Casing

HIGH EFFICIENCY

Possesses a high Energy Efficiency Ratio, delivering exceptional

performance with a reduction in energy consumption.

Dimension

Net Weight

Sound Power Level

Evaporator Coil

Type

Tube

During operation, vibration of the unit is minimised with a

low-pulse discharge and without-valve design.

Fujiaires unique system provides the adaptability of installation and flexibility of use within these areas.

Fin

GREAT RELIABILITY

EXTERNAL STATIC PRESSURE SELECTION

INCREASED DURABILITY

EXCELLENT AIR DISTRIBUTION

Long Duct Design the system offers the capability of long ducting installation and distribute the strong cool air through its high

external static pressure, hence increase the level of comfort for occupants;

Fresh Air Intakes Capable of introducing the fresh air into the building to improve the Indoor Air Quality (IAQ);

Silent Operation the ducted design allows for silent air distribution into the room without the intrusion of motor noise.

Material

Finishing

Insulation

Height (H)

Width (W)

Depth (D)

Material

Wall Thickness

Outer Diameter

Material

Thickness

Rows

Fins per Inch

The scroll compressor has 70% fewer moving parts than other

reciprocating compressor, translating into better durability and

decreased maintenance cost.

SILENT OPERATION

With less moving parts the scroll compressor functions with less

noise, never disrupting the consumer with quiet operation sound.

CONTROLLED SETTING

WIRED CONTROLLER (OPTIONAL)

Manage the entire system through a single wired controller with

LED display, providing convenience, immediate adjustability and

better control of the atmosphere.

Net Weight

Sound Power Level

Condenser Coil

Type

Tube

A SELECTION FROM OUR FULL RANGE

Fin

OUTDOOR UNITS

FLA 040 / 050CC

FLEXIBILITY IN INSTALLATION

The indoor unit FDB 40B - FDB 200B2 models come with

standard horizontal air discharge whereas FDB 250B2 - FDB

750B5 models come with standard vertical air discharge.

However, the model range from FDB 125B - FDB 750B5 are

convertible and designed to cater for either horizontal or vertical

air discharge applications.

FLA 060CC

FDA 040 / 050CC

FLA 080 / 100 / 125CB

FLA 150CC

INDOOR UNITS

Return Air

FDA 06CC-A11N FDA 080CC-A11N

FLA 060CC-E11N FLA 080CC-E11N

60,000

80,000

17.58

23.45

Horizontal Blow

Material

Wall Thickness

Outer Diameter

Material

Thickness

Number x Rows

Fins per Inch

Fan Motor

Fan Type / Drive

Fan Blade Material

Fan Blade Diameter

Fan Blade Quantity

Air Flow

Motor Type

Motor Quantity

Power Supply

Number x Rated Running Current

Number x Rated Power Input

Number x Rated Power Output

Motor Speed

Motor Poles

Compressor

Type

Power Supply

Rated Running Current

Rated Power Input

Maximum Starting Current

Compressor Speed

Protection Devices

Stage of Capacity Control

Starter Type

REFRIGERANT

Type

Type of Gas Precharged

564 (22.2)

858 (33.8)

764 (30.1)

50 (110)

62

564 (22.2)

858 (33.8)

764 (30.1)

55 (120)

62

564 (22.2)

1,493 (58.8)

764 (30.1)

85 (187)

65

FDA 060 / 080 / 100CC

FDA 125 / 150 CC

FDA 200CB

FDA 250 / 300 / 350 /

400 / 450 / 500CB

FDA 100CC-A11N FDA 125CC-E11N

FLA 100CB-E11N FLA 125CB-E11N

100,000

125,000

29.31

36.64

FDA 150CC-E11N

FLA 150CB-E11N

150,000

43.96

FDA 600 / 750CB

564 (22.2)

1,493 (58.8)

764 (30.1)

100 (220)

71

784 (30.9)

1,629 (64.1)

1,035 (40.8)

140 (308)

77

784 (30.9)

1,629 (64.1)

1,035 (40.8)

145 (319)

79

4

12

100-0

0.56 (6.03)

162 (531)

3

14

100-0

0.74 (8.00)

161 (525)

4

12

100-0

0.82 (8.83)

159 (521)

Cross Finned Tubes

Seamless Copper

0.33 (0.013)

9.5 (3/8)

Aluminium

0.11 (0.004)

mm (in)

3

12

100-0

0.27 (2.87)

131 (430)

4

12

100-0

0.27 (2.87)

168 (552)

3

12

100-0

0.50 (5.38)

113 (372)

1

283 (11.1)

203 (8.0)

35.4 (1,250)

100 (0.4)

-

1

283 (11.1)

203 (8.0)

45.4 (1,600)

100 (0.4)

-

2

283 (11.1)

203 (8.0)

56.7 (2,000)

100 (0.4)

-

1 x 1.84

1 x 404

1 x 182

780

6

220-240 / 1 / 50

1 x 3.36

1 x 776

1 x 326

840

4

2 x 1.84

2 x 404

2 x 182

780

6

3

14

100-0

0.50 (5.38)

142 (465)

3

14

100-0

0.50 (5.38)

142 (465)

Centrifugal / Direct

Centrifugal / Belt Driven

Zinc Coated Steel

2

2

283 (11.1)

283 (11.1)

203 (8.0)

203 (8.0)

70.9 (2,500)

70.9 (2,500)

100 (0.4)

100 (0.4)

-

2

283 (11.1)

203 (8.0)

90.7 (3,200)

100 (0.4)

-

Permanent Split Capacitor

220-240 / 1 / 50

2 x 1.84

2 x 1.84

2 x 404

2 x 404

2 x 182

2 x 182

780

780

6

6

Direct On Line (DOL)

2 x 3.36

2 x 776

2 x 326

840

4

1

395 (15.6)

381 (15.0)

119.0 (4,200)

150 (0.6)

B1 x 203 (8)

B1 x 102 (4)

B1 - SPZ

B-940 (37)

1

395 (15.6)

381 (15.0)

130.4 (4,600)

150 (0.6)

B1 x 178 (7)

B1 x 102 (4)

B1 - SPZ

B-914 (36)

Squirrel Cage Induction

380-415 / 3 / 50

3.4

3.4

1,100

1,630

1,500

1,500

1,400

1,400

4

4

R22

Nitrogen Holding

Capillary Tube

Flared

9.5 (3/8)

19.1 (3/4)

9.5 (3/8)

19.1 (3/4)

9.5 (3/8)

19.1 (3/4)

12.7 (1/2)

25.4 (1)

12.7 (1/2)

25.4 (1)

Thermostatic Expansion Valve

Brazed

15.9 (5/8)

15.9 (5/8)

28.6 (1 1/8)

34.9 (1 3/8)

15.9 (5/8)

34.9 (1 3/8)

25.4 (1)

709 x 470 (28 x 16)

12.7 (1/2)

1

709 x 470 (28 x 16)

12.7 (1/2)

1

448 x 470 (18 x 16)

12.7 (1/2)

3

1,000 (39.4)

1,000 (39.4)

350 (13.8)

1,000 (39.4)

1,000 (39.4)

350 (13.8)

1,230 (48.4)

970 (38.2)

350 (13.8)

89 (196)

65

89 (196)

65

116 (255)

65

mm (in)

mm (in)

mm (in)

1x1

16

m (ft)

m/min (FPM)

1x1

14

0.86 (9.25)

1x2

14

1.14 (12.27)

79 (258)

Washable Viledon (AAF R29)

448 x 470 (18 x 16)

448 x 470 (18 x 16)

12.7 (1/2)

12.7 (1/2)

3

3

Electro Galvanized Mild Steel

Epoxy Polyester Power Coating

946 (37.2)

977 (38.5)

1,300 (51.2)

1,184 (46.1)

500 (19.7)

950 (37.4)

448 x 470 (18 x 16) 493 x 690 (19.5 x 27) 493 x 690 (19.5 x 27)

12.7 (1/2)

50.8 (2)

50.8 (2)

3

3

3

977 (38.5)

1,184 (46.1)

950 (37.4)

977 (38.5)

1,184 (46.1)

950 (37.4)

1,072 (42.2)

1,188 (46.8)

995 (39.2)

153 (337)

77

180 (396)

78

224 (493)

80

258 (568)

84

Cross Finned Tubes

Seamless Copper

0.33 (0.013)

9.5 (3/8)

Aluminium

0.11 (0.004)

1x2

2x1

14

16

1.23 (13.2)

1.74 (18.7)

147 (485)

104 (342)

2x2

12

1.74 (18.7)

104 (342)

2x2

16

1.74 (18.7)

104 (342)

2x2

14

2.45 (26.4)

130 (424)

163 (359)

70

Propeller / Direct

ABS

mm (in)

CMM (CFM)

V / Ph / Hz

A

W

W

RPM

V / Ph / Hz

A

kW

A

RPM

556 (22)

1

141.6 (5,000)

170.0 (6,000)

Induction

1

220-240 / 1 / 50

1.51

439

200

860

840

6

6.3

3.60

48

2,880

7.5

4.40

53

2,870

460 (18)

2

212.5 (7,500)

660 (26)

1

181.4 (6,400)

660 (26)

1

181.4 (6,400)

1

380-415 / 3 / 50

1.5

680

468

920

6

1

380-415 / 3 / 50

1.5

680

468

920

6

2 x 0.71

2 x 124

2 x 60

840

Aluminium

660 (26)

660 (26)

1

1

181.4 (6,400)

181.4 (6,400)

Induction

1

1

380-415 / 3 / 50 380-415 / 3 / 50

1.5

1.5

680

680

468

468

920

920

6

6

Scroll

380-415 / 3 / 50

9.3

13.6

13.6

16.4

5.43

6.81

6.81

8.96

57

95

95

125

2,880

2,900

2,900

2,900

Overload Protection And Auto Reset High / Low Pressure Switch

On / Off

Auto-Trans (A/T)

R22

R22

Conditions:

1. Nominal cooling capacities are based on the following conditions: indoor 26.7CDB, 19.4CWB, outdoor 35CDB.

2. All specifications are subjected to change by manufacturer without prior notice.

FLA 080CC

FDA 080CC-A11N

FLA 080CB-E11N

80,000

23.45

Galvanized Mild Steel

Plain Gavanized

Polyethylene Foam

564 (22.2)

564 (22.2)

1,493 (58.8)

1,493 (58.8)

764 (30.1)

764 (30.1)

96 (211)

96 (211)

66

66

mm (in)

mm (in)

kg (lb)

dBA

Face Area

Face Velocity

Vertical Blow

mm (in)

mm (in)

mm (in)

kg (lb)

dBA

Capacity Steps

%

Face Area

m (ft)

Face Velocity

m/min (FPM)

Blower

Type / Drive

Blower Material

Quantity

Blower Diameter

mm (in)

Blower Length

mm (in)

Air Flow

CMM (CFM)

External Static Pressure

Pa (in wg)

Blower Pulley Diameter

mm (in)

Motor Pulley Diameter

mm (in)

Pulley

Type

V-Belt Type - Length

mm (in)

Fan Motor

Type

Power Supply

V / Ph / Hz

Number x Rated Running Current

A

Number x Rated Power Input

W

Number x Rated Power Output

W

Motor Speed

RPM

Motor Poles

Starter Type

Refrigerant & Pipe Size

Type

Type of Gas Precharged

Capacity Control

Pipe Connection Method

Pipe Size

Liquid

mm (in)

Gas

mm (in)

Drain Pipe Size

mm (in)

Air Filter

Type

Size

Length x Height

mm (in)

Depth

mm (in)

Quantity

OUTDOOR UNIT

Casing

Material

Finishing

Dimension

Height (H)

mm (in)

Width (W)

mm (in)

Depth (D)

mm (in)

Scroll members are able to separate in the presence of liquid

refrigerants or debris, eliminating high stress in members, in

turn improving the reliability of the compressor.

The system has the flexibility to select the external static

pressure depending upon your specific requirements.

FDA 050CC-A11N

FLA 050CC-E11N

50,000

14.65

INDOOR UNIT

SMOOTH OPERATION

FLEXIBILITY

Btu/h

kW

FDA 040CC-A11N

FLA 040CC-E11N

40,000

11.72

Nitrogen Holding

17.9

10.20

110

2,900

762 (30)

1

317.5 (11,200)

1

380-415 / 3 / 50

4.35

3,200

1,250

700

6

24.2

13.62

198

2,900

FUJIAIRE DUCTED TYPE AIR-CONDITIONER (R-22 COOLING)

Model

Indoor Unit

Outdoor Unit

Total Cooling Capacity

FULL COMPLIANCE SCROLL COMPRESSOR

FRESH COOL AIR TO EVERY CORNER

Fujiaires range of High Static Ducted Blower Split System offers a total range of applications (4hp to 75hp) to meet your cooling

demands. Delivering fresh air consistently to each and every corner, creating for a healthier and more comfortable living. With the use

of a Full Compliance Scroll Compressor, greater durability and reliability is promised, as well as minimising the demands on natural

resources with efficient performance.

Casing

HIGH EFFICIENCY

Possesses a high Energy Efficiency Ratio, delivering exceptional

performance with a reduction in energy consumption.

Dimension

Net Weight

Sound Power Level

Evaporator Coil

Type

Tube

During operation, vibration of the unit is minimised with a

low-pulse discharge and without-valve design.

Fujiaires unique system provides the adaptability of installation and flexibility of use within these areas.

Fin

GREAT RELIABILITY

EXTERNAL STATIC PRESSURE SELECTION

INCREASED DURABILITY

EXCELLENT AIR DISTRIBUTION

Long Duct Design the system offers the capability of long ducting installation and distribute the strong cool air through its high

external static pressure, hence increase the level of comfort for occupants;

Fresh Air Intakes Capable of introducing the fresh air into the building to improve the Indoor Air Quality (IAQ);

Silent Operation the ducted design allows for silent air distribution into the room without the intrusion of motor noise.

Material

Finishing

Insulation

Height (H)

Width (W)

Depth (D)

Material

Wall Thickness

Outer Diameter

Material

Thickness

Rows

Fins per Inch

The scroll compressor has 70% fewer moving parts than other

reciprocating compressor, translating into better durability and

decreased maintenance cost.

SILENT OPERATION

With less moving parts the scroll compressor functions with less

noise, never disrupting the consumer with quiet operation sound.

CONTROLLED SETTING

WIRED CONTROLLER (OPTIONAL)

Manage the entire system through a single wired controller with

LED display, providing convenience, immediate adjustability and

better control of the atmosphere.

Net Weight

Sound Power Level

Condenser Coil

Type

Tube

A SELECTION FROM OUR FULL RANGE

Fin

OUTDOOR UNITS

FLA 040 / 050 CC

FLEXIBILITY IN INSTALLATION

The indoor unit FDB 40B - FDB 200B2 models come with

standard horizontal air discharge whereas FDB 250B2 - FDB

750B5 models come with standard vertical air discharge.

However, the model range from FDB 125B - FDB 750B5 are

convertible and designed to cater for either horizontal or vertical

air discharge applications.

FLA 060 CC

FLA 080 CC

FLA 080 / 100 / 125 CB

FLA 150 CC

INDOOR UNITS

Return Air

FDA 06CC-A11N FDA 080CC-A11N

FLA 060CC-E11N FLA 080CC-E11N

60,000

80,000

17.58

23.45

Horizontal Blow

Material

Wall Thickness

Outer Diameter

Material

Thickness

Number x Rows

Fins per Inch

Fan Motor

Fan Type / Drive

Fan Blade Material

Fan Blade Diameter

Fan Blade Quantity

Air Flow

Motor Type

Motor Quantity

Power Supply

Number x Rated Running Current

Number x Rated Power Input

Number x Rated Power Output

Motor Speed

Motor Poles

Compressor

Type

Power Supply

Rated Running Current

Rated Power Input

Maximum Starting Current

Compressor Speed

Protection Devices

Stage of Capacity Control

Starter Type

REFRIGERANT

Type

Type of Gas Precharged

500 (19.7)

858 (33.8)

764 (30.1)

44 (97)

62

500 (19.7)

858 (33.8)

764 (30.1)

48 (106)

62

500 (19.7)

1,493 (58.8)

764 (30.1)

73 (161)

65

FDA 060 / 080 / 100 CC

FDA 125 / 150 CC

FDA 200 CB

FDA 250 / 300 / 350 /

400 / 450 / 500 CB

FDA 100CC-A11N FDA 125CC-E11N

FLA 100CB-E11N FLA 125CB-E11N

100,000

125,000

29.31

36.64

FDA 150CC-E11N

FLA 150CB-E11N

150,000

43.96

FDA 600 / 750 CB

500 (19.7)

1,493 (58.8)

764 (30.1)

88 (194)

71

679 (26.7)

1,644 (64.7)

1,189 (46.8)

128 (282)

77

679 (26.7)

1,644 (64.7)

1,189 (46.8)

132 (290)

79

4

12

100-0

0.56 (6.03)

162 (531)

3

14

100-0

0.74 (8.00)

161 (525)

4

12

100-0

0.82 (8.83)

159 (521)

Cross Finned Tubes

Seamless Copper

0.33 (0.013)

9.5 (3/8)

Aluminium

0.11 (0.004)

mm (in)

3

12

100-0

0.27 (2.87)

131 (436)

4

12

100-0

0.27 (2.87)

168 (557)

3

12

100-0

0.50 (5.38)

113 (372)

1

283 (11.1)

203 (8.0)

35.4 (1,250)

100 (0.4)

-

1

283 (11.1)

203 (8.0)

45.4 (1,600)

100 (0.4)

-

2

283 (11.1)

203 (8.0)

56.7 (2,000)

100 (0.4)

-

1 x 1.84

1 x 404

1 x 182

780

6

220-240 / 1 / 50

1 x 3.36

1 x 776

1 x 326

840

4

2 x 1.84

2 x 404

2 x 182

780

6

3

14

100-0

0.50 (5.38)

142 (465)

3

14

100-0

0.50 (5.38)

142 (465)

Centrifugal / Direct

Centrifugal / Belt Driven

Zinc Coated Steel

2

2

283 (11.1)

283 (11.1)

203 (8.0)

203 (8.0)

70.9 (2,500)

70.9 (2,500)

100 (0.4)

100 (0.4)

-

2

283 (11.1)

203 (8.0)

90.7 (3,200)

100 (0.4)

-

Permanent Split Capacitor

220-240 / 1 / 50

2 x 1.84

2 x 1.84

2 x 404

2 x 404

2 x 182

2 x 182

780

780

6

6

Direct On Line (DOL)

2 x 3.36

2 x 776

2 x 326

840

4

1

395 (15.6)

381 (15.0)

119.0 (4,200)

150 (0.6)

B1 x 203 (8)

B1 x 102 (4)

B1 - SPZ

B-940 (37)

1

395 (15.6)

381 (15.0)

130.4 (4,600)

150 (0.6)

B1 x 178 (7)

B1 x 102 (4)

B1 - SPZ

B-914 (36)

Squirrel Cage Induction

380-415 / 3 / 50

3.4

3.4

1,100

1,630

1,500

1,500

1,400

1,400

4

4

R22

Nitrogen Holding

Capillary Tube

Flared

9.5 (3/8)

19.1 (3/4)

9.5 (3/8)

19.1 (3/4)

9.5 (3/8)

19.1 (3/4)

12.7 (1/2)

25.4 (1)

12.7 (1/2)

25.4 (1)

Thermostatic Expansion Valve

Brazed

15.9 (5/8)

15.9 (5/8)

28.6 (1 1/8)

34.9 (1 3/8)

15.9 (5/8)

34.9 (1 3/8)

25.4 (1)

705 x 425 (28 x 17)

12.7 (1/2)

1

705 x 425 (28 x 17)

12.7 (1/2)

1

448 x 425 (18 x 17)

12.7 (1/2)

3

1,000 (39.4)

1,000 (39.4)

350 (13.8)

1,000 (39.4)

1,000 (39.4)

350 (13.8)

1,230 (48.4)

970 (38.2)

350 (13.8)

89 (196)

65

89 (196)

65

116 (255)

65

mm (in)

mm (in)

mm (in)

1x1

16

m (ft)

m/min (FPM)

1x1

14

0.86 (9.25)

1x2

14

1.14 (12.27)

79 (258)

Washable Viledon (AAF R29)

448 x 425 (18 x 17) 448 x 425 (18 x 17)

12.7 (1/2)

12.7 (1/2)

3

3

Electro Galvanized Mild Steel

Epoxy Polyester Power Coating

946 (37.2)

977 (38.5)

1,300 (51.2)

1,184 (46.6)

500 (19.7)

950 (37.4)

448 x 425 (18 x 17) 695 x 540 (27 x 21)

12.7 (1/2)

50.8 (2)

3

2

695 x 540 (27 x 21)

50.8 (2)

2

977 (38.5)

1,184 (46.6)

950 (37.4)

977 (38.5)

1,184 (46.6)

950 (37.4)

1,072 (42.2)

1,188 (46.8)

995 (39.2)

153 (337)

77

180 (396)

78

224 (493)

80

258 (568)

84

Cross Finned Tubes

Seamless Copper

0.33 (0.013)

9.5 (3/8)

Aluminium

0.11 (0.004)

1x2

2x1

14

16

1.23 (13.2)

1.74 (18.7)

147 (485)

104 (342)

2x2

12

1.74 (18.7)

104 (342)

2x2

16

1.74 (18.7)

104 (342)

2x2

14

2.45 (26.4)

130 (424)

163 (359)

70

Propeller / Direct

ABS

mm (in)

CMM (CFM)

V / Ph / Hz

A

W

W

RPM

V / Ph / Hz

A

kW

A

RPM

556 (22)

1

141.6 (5,000)

170.0 (6,000)

Induction

1

220-240 / 1 / 50

1.51

439

200

860

840

6

6.3

3.60

48

2,880

7.5

4.40

53

2,870

460 (18)

2

212.5 (7,500)

660 (26)

1

181.4 (6,400)

660 (26)

1

181.4 (6,400)

1

380-415 / 3 / 50

1.5

680

468

920

6

1

380-415 / 3 / 50

1.5

680

468

920

6

2 x 0.71

2 x 124

2 x 60

840

Aluminium

660 (26)

660 (26)

1

1

181.4 (6,400)

181.4 (6,400)

Induction

1

1

380-415 / 3 / 50 380-415 / 3 / 50

1.5

1.5

680

680

468

468

920

920

6

6

Scroll

380-415 / 3 / 50

9.3

13.6

13.6

16.4

5.43

6.81

6.81

8.96

57

95

95

125

2,880

2,900

2,900

2,900

Overload Protection And Auto Reset High / Low Pressure Switch

On / Off

Auto-Trans (A/T)

R22

R22

Conditions:

1. Nominal cooling capacities are based on the following conditions: indoor 26.7CDB, 19.4CWB, outdoor 35CDB.

2. All specifications are subjected to change by manufacturer without prior notice.

FDA 040 / 050 CC

FDA 080CC-A11N

FLA 080CB-E11N

80,000

23.45

Galvanized Mild Steel

Plain Gavanized

Polyethylene Foam

500 (19.7)

500 (19.7)

1,493 (58.8)

1,493 (58.8)

764 (30.1)

764 (30.1)

84 (185)

84 (185)

66

66

mm (in)

mm (in)

kg (lb)

dBA

Face Area

Face Velocity

Vertical Blow

mm (in)

mm (in)

mm (in)

kg (lb)

dBA

Capacity Steps

%

Face Area

m (ft)

Face Velocity

m/min (FPM)

Blower

Type / Drive

Blower Material

Quantity

Blower Diameter

mm (in)

Blower Length

mm (in)

Air Flow

CMM (CFM)

External Static Pressure

Pa (in wg)

Blower Pulley Diameter

mm (in)

Motor Pulley Diameter

mm (in)

Pulley

Type

V-Belt Type - Length

mm (in)

Fan Motor

Type

Power Supply

V / Ph / Hz

Number x Rated Running Current

A

Number x Rated Power Input

W

Number x Rated Power Output

W

Motor Speed

RPM

Motor Poles

Starter Type

Refrigerant & Pipe Size

Type

Type of Gas Precharged

Capacity Control

Pipe Connection Method

Pipe Size

Liquid

mm (in)

Gas

mm (in)

Drain Pipe Size

mm (in)

Air Filter

Type

Size

Length x Height

mm (in)

Depth

mm (in)

Quantity

OUTDOOR UNIT

Casing

Material

Finishing

Dimension

Height (H)

mm (in)

Width (W)

mm (in)

Depth (D)

mm (in)

Scroll members are able to separate in the presence of liquid

refrigerants or debris, eliminating high stress in members, in

turn improving the reliability of the compressor.

The system has the flexibility to select the external static

pressure depending upon your specific requirements.

FDA 050CC-A11N

FLA 050CC-E11N

50,000

14.65

INDOOR UNIT

SMOOTH OPERATION

FLEXIBILITY

Btu/h

kW

FDA 040CC-A11N

FLA 040CC-E11N

40,000

11.72

Nitrogen Holding

17.9

10.20

110

2,900

762 (30)

1

317.5 (11,200)

1

380-415 / 3 / 50

4.35

3,200

1,250

700

6

24.2

13.62

198

2,900

FUJIAIRE DUCTED TYPE AIR-CONDITIONER (R-22 COOLING)

Model

Indoor Unit

Outdoor Unit

Total Cooling Capacity

FULL COMPLIANCE SCROLL COMPRESSOR

FRESH COOL AIR TO EVERY CORNER

Fujiaires range of High Static Ducted Blower Split System offers a total range of applications (4hp to 75hp) to meet your cooling

demands. Delivering fresh air consistently to each and every corner, creating for a healthier and more comfortable living. With the use

of a Full Compliance Scroll Compressor, greater durability and reliability is promised, as well as minimising the demands on natural

resources with efficient performance.

Casing

HIGH EFFICIENCY

Possesses a high Energy Efficiency Ratio, delivering exceptional

performance with a reduction in energy consumption.

Dimension

Net Weight

Sound Power Level

Evaporator Coil

Type

Tube

During operation, vibration of the unit is minimised with a

low-pulse discharge and without-valve design.

Fujiaires unique system provides the adaptability of installation and flexibility of use within these areas.

Fin

GREAT RELIABILITY

EXTERNAL STATIC PRESSURE SELECTION

INCREASED DURABILITY

EXCELLENT AIR DISTRIBUTION

Long Duct Design the system offers the capability of long ducting installation and distribute the strong cool air through its high

external static pressure, hence increase the level of comfort for occupants;

Fresh Air Intakes Capable of introducing the fresh air into the building to improve the Indoor Air Quality (IAQ);

Silent Operation the ducted design allows for silent air distribution into the room without the intrusion of motor noise.

Material

Finishing

Insulation

Height (H)

Width (W)

Depth (D)

Material

Wall Thickness

Outer Diameter

Material

Thickness

Rows

Fins per Inch

The scroll compressor has 70% fewer moving parts than other

reciprocating compressor, translating into better durability and

decreased maintenance cost.

SILENT OPERATION

With less moving parts the scroll compressor functions with less

noise, never disrupting the consumer with quiet operation sound.

CONTROLLED SETTING

WIRED CONTROLLER (OPTIONAL)

Manage the entire system through a single wired controller with

LED display, providing convenience, immediate adjustability and

better control of the atmosphere.

Net Weight

Sound Power Level

Condenser Coil

Type

Tube

A SELECTION FROM OUR FULL RANGE

Fin

OUTDOOR UNITS

FLA 040 / 050 CC

FLEXIBILITY IN INSTALLATION

The indoor unit FDB 40B - FDB 200B2 models come with

standard horizontal air discharge whereas FDB 250B2 - FDB

750B5 models come with standard vertical air discharge.

However, the model range from FDB 125B - FDB 750B5 are

convertible and designed to cater for either horizontal or vertical

air discharge applications.

FLA 060 CC

FLA 080 CC

FLA 080 / 100 / 125 CB

FLA 150 CC

INDOOR UNITS

Return Air

FDA 060CC-A11N FDA 080CC-A11N

FLA 060CC-E11N FLA 080CC-E11N

60,000

80,000

17.58

23.45

Horizontal Blow

Material

Wall Thickness

Outer Diameter

Material

Thickness

Number x Rows

Fins per Inch

Fan Motor

Fan Type / Drive

Fan Blade Material

Fan Blade Diameter

Fan Blade Quantity

Air Flow

Motor Type

Motor Quantity

Power Supply

Number x Rated Running Current

Number x Rated Power Input

Number x Rated Power Output

Motor Speed

Motor Poles

Compressor

Type

Power Supply

Rated Running Current

Rated Power Input

Maximum Starting Current

Compressor Speed

Protection Devices

Stage of Capacity Control

Starter Type

REFRIGERANT

Type

Type of Gas Precharged

500 (19.7)

858 (33.8)

764 (30.1)

44 (97)

62

500 (19.7)

858 (33.8)

764 (30.1)

48 (106)

62

500 (19.7)

1,493 (58.8)

764 (30.1)

73 (161)

65

FDA 060 / 080 / 100 CC

FDA 125 / 150 CC

FDA 200 CB

FDA 250 / 300 / 350 /

400 / 450 / 500 CB

FDA 100CC-A11N FDA 125CC-E11N

FLA 100CB-E11N FLA 125CB-E11N

100,000

125,000

29.31

36.64

FDA 150CC-E11N

FLA 150CB-E11N

150,000

43.96

FDA 600 / 750 CB

500 (19.7)

1,493 (58.8)

764 (30.1)

88 (194)

71

679 (26.7)

1,644 (64.7)

1,189 (46.8)

128 (282)

77

679 (26.7)

1,644 (64.7)

1,189 (46.8)

132 (290)

79

4

12

100-0

0.56 (6.03)

162 (531)

3

14

100-0

0.74 (8.00)

161 (525)

4

12

100-0

0.82 (8.83)

159 (521)

Cross Finned Tubes

Seamless Copper

0.33 (0.013)

9.5 (3/8)

Aluminium

0.11 (0.004)

mm (in)

3

12

100-0

0.27 (2.87)

131 (436)

4

12

100-0

0.27 (2.87)

168 (557)

3

12

100-0

0.50 (5.38)

113 (372)

1

283 (11.1)

203 (8.0)

35.4 (1,250)

100 (0.4)

-

1

283 (11.1)

203 (8.0)

45.4 (1,600)

100 (0.4)

-

2

283 (11.1)

203 (8.0)

56.7 (2,000)

100 (0.4)

-

1 x 1.84

1 x 404

1 x 182

780

6

220-240 / 1 / 50

1 x 3.36

1 x 776

1 x 326

840

4

2 x 1.84

2 x 404

2 x 182

780

6

3

14

100-0

0.50 (5.38)

142 (465)

3

14

100-0

0.50 (5.38)

142 (465)

Centrifugal / Direct

Centrifugal / Belt Driven

Zinc Coated Steel

2

2

283 (11.1)

283 (11.1)

203 (8.0)

203 (8.0)

70.9 (2,500)

70.9 (2,500)

100 (0.4)

100 (0.4)

-

2

283 (11.1)

203 (8.0)

90.7 (3,200)

100 (0.4)

-

Permanent Split Capacitor

220-240 / 1 / 50

2 x 1.84

2 x 1.84

2 x 404

2 x 404

2 x 182

2 x 182

780

780

6

6

Direct On Line (DOL)

2 x 3.36

2 x 776

2 x 326

840

4

1

395 (15.6)

381 (15.0)

119.0 (4,200)

150 (0.6)

B1 x 203 (8)

B1 x 102 (4)

B1 - SPZ

B-940 (37)

1

395 (15.6)

381 (15.0)

130.4 (4,600)

150 (0.6)

B1 x 178 (7)

B1 x 102 (4)

B1 - SPZ

B-914 (36)

Squirrel Cage Induction

380-415 / 3 / 50

3.4

3.4

1,100

1,630

1,500

1,500

1,400

1,400

4

4

R22

Nitrogen Holding

Capillary Tube

Flared

9.5 (3/8)

19.1 (3/4)

9.5 (3/8)

19.1 (3/4)

9.5 (3/8)

19.1 (3/4)

12.7 (1/2)

25.4 (1)

12.7 (1/2)

25.4 (1)

Thermostatic Expansion Valve

Brazed

15.9 (5/8)

15.9 (5/8)

28.6 (1-1/8)

34.9 (1-3/8)

15.9 (5/8)

34.9 (1-3/8)

25.4 (1)

705 x 425 (28 x 17)

12.7 (1/2)

1

705 x 425 (28 x 17)

12.7 (1/2)

1

448 x 425 (18 x 17)

12.7 (1/2)

3

1,000 (39.4)

1,000 (39.4)

350 (13.8)

1,000 (39.4)

1,000 (39.4)

350 (13.8)

1,230 (48.4)

970 (38.2)

350 (13.8)

89 (196)

65

89 (196)

65

116 (255)

65

mm (in)

mm (in)

mm (in)

1x1

16

m (ft)

m/min (FPM)

1x1

14

0.86 (9.25)

1x2

14

1.14 (12.27)

79 (258)

Washable Viledon (AAF R29)

448 x 425 (18 x 17) 448 x 425 (18 x 17)

12.7 (1/2)

12.7 (1/2)

3

3

448 x 425 (18 x 17)

12.7 (1/2)

3

695 x 540 (27 x 21)

50.8 (2)

2

695 x 540 (27 x 21)

50.8 (2)

2

977 (38.5)

1,184 (46.6)

950 (37.4)

977 (38.5)

1,184 (46.6)

950 (37.4)

1,072 (42.2)

1,188 (46.8)

995 (39.2)

153 (337)

77

180 (396)

78

224 (493)

80

258 (568)

84

Cross Finned Tubes

Seamless Copper

0.33 (0.013)

9.5 (3/8)

Aluminium

0.11 (0.004)

1x2

2x1

14

16

1.23 (13.2)

1.74 (18.7)

147 (485)

104 (342)

2x2

12

1.74 (18.7)

104 (342)

2x2

16

1.74 (18.7)

104 (342)

2x2

14

2.45 (26.4)

130 (424)

Electro Galvanized Mild Steel

Epoxy Polyester Power Coating

946 (37.2)

977 (38.5)

1,300 (51.2)

1,184 (46.6)

500 (19.7)

950 (37.4)

163 (359)

70

Propeller / Direct

ABS

mm (in)

CMM (CFM)

V / Ph / Hz

A

W

W

RPM

V / Ph / Hz

A

kW

A

RPM

556 (22)

1

141.6 (5,000)

170.0 (6,000)

Induction

1

220-240 / 1 / 50

1.51

439

200

860

840

6

6.3

3.60

48

2,880

7.5

4.40

53

2,870

460 (18)

2

212.5 (7,500)

660 (26)

1

181.4 (6,400)

660 (26)

1

181.4 (6,400)

1

380-415 / 3 / 50

1.5

680

468

920

6

1

380-415 / 3 / 50

1.5

680

468

920

6

2 x 0.71

2 x 124

2 x 60

840

Aluminium

660 (26)

660 (26)

1

1

181.4 (6,400)

181.4 (6,400)

Induction

1

1

380-415 / 3 / 50 380-415 / 3 / 50

1.5

1.5

680

680

468

468

920

920

6

6

Scroll

380-415 / 3 / 50

9.3

13.6

13.6

16.4

5.43

6.81

6.81

8.96

57

95

95

125

2,880

2,900

2,900

2,900

Overload Protection And Auto Reset High / Low Pressure Switch

On / Off

Auto-Trans (A/T)

R22

R22

Conditions:

1. Nominal cooling capacities are based on the following conditions: indoor 26.7CDB, 19.4CWB, outdoor 35CDB.

2. All specifications are subjected to change by manufacturer without prior notice.

FDA 040 / 050 CC

FDA 080CC-A11N

FLA 080CB-E11N

80,000

23.45

Galvanized Mild Steel

Plain Gavanized

Polyethylene Foam

500 (19.7)

500 (19.7)

1,493 (58.8)

1,493 (58.8)

764 (30.1)

764 (30.1)

84 (185)

84 (185)

66

66

mm (in)

mm (in)

kg (lb)

dBA

Face Area

Face Velocity

Vertical Blow

mm (in)

mm (in)

mm (in)

kg (lb)

dBA

Capacity Steps

%

Face Area

m (ft)

Face Velocity

m/min (FPM)

Blower

Type / Drive

Blower Material

Quantity

Blower Diameter

mm (in)

Blower Length

mm (in)

Air Flow

CMM (CFM)

External Static Pressure

Pa (in wg)

Blower Pulley Diameter

mm (in)

Motor Pulley Diameter

mm (in)

Pulley

Type

V-Belt Type - Length

mm (in)

Fan Motor

Type

Power Supply

V / Ph / Hz

Number x Rated Running Current

A

Number x Rated Power Input

W

Number x Rated Power Output

W

Motor Speed

RPM

Motor Poles

Starter Type

Refrigerant & Pipe Size

Type

Type of Gas Precharged

Capacity Control

Pipe Connection Method

Pipe Size

Liquid

mm (in)

Gas

mm (in)

Drain Pipe Size

mm (in)

Air Filter

Type

Size

Length x Height

mm (in)

Depth

mm (in)

Quantity

OUTDOOR UNIT

Casing

Material

Finishing

Dimension

Height (H)

mm (in)

Width (W)

mm (in)

Depth (D)

mm (in)

Scroll members are able to separate in the presence of liquid

refrigerants or debris, eliminating high stress in members, in

turn improving the reliability of the compressor.

The system has the flexibility to select the external static

pressure depending upon your specific requirements.

FDA 050CC-A11N

FLA 050CC-E11N

50,000

14.65

INDOOR UNIT

SMOOTH OPERATION

FLEXIBILITY

Btu/hr

kW

FDA 040CC-A11N

FLA 040CC-E11N

40,000

11.72

Nitrogen Holding

17.9

10.20

110

2,900

762 (30)

1

317.5 (11,200)

1

380-415 / 3 / 50

4.35

3,200

1,250

700

6

24.2

13.62

198

2,900

FUJIAIRE DUCTED TYPE AIR-CONDITIONER (R-22 COOLING)

Model

Indoor Unit

Outdoor Unit

Total Cooling Capacity

Btu/hr

kW

FUJIAIRE DUCTED TYPE AIR-CONDITIONER (R-22 COOLING)

FDA 150CC2-E11N FDA 200CB2-E11N FDA 250CB2-E11N FDA 300CB2-E11N FDA 300CB3-E11N

FDA 350CB3-E11N

FLA 080CB-E11N x 2 FLA 100CB-E11N x 2 FLA 125CB-E11N x 2 FLA 150CC-E11N x 2 FLA 100CB-E11N x 3 FLA 100CB-E11N x 1 FLA 125CB-E11N x 2

150,000

200,000

250,000

300,000

300,000

350,000

43.96

58.62

73.27

87.92

87.92

102.58

Dimension

Material

Finishing

Insulation

Height (H)

Width (W)

Depth (D)

Net Weight

Sound Power Level

Evaporator Coil

Type

Tube

Fin

Indoor Unit

Outdoor Unit

Total Cooling Capacity

Btu/hr

kW

FDA 400CB4-E11N

FLA 100CB-E11N x 4

400,000

117.23

FDA 450CB3-E11N

FLA 150CC-E11N x 3

450,000

131.89

FDA 500CB4-E11N

FLA 125CB-E11N x 4

500,000

146.54

FDA 600CB4-E11N

FLA 150CC-E11N x 4

600,000

175.85

FDA 750CB5-E11N

FLA 150CC-E11N x 5

750,000

219.81

1,550 (61.0)

2,321 (91.4)

1,480 (58.3)

339 (746)

93

Electro Galvanized Mild Steel

Plain Galvanized

Polyethylene Foam

1,550 (61.0)

2,321 (91.4)

1,480 (58.3)

350 (770)

96

1,975 (77.8)

2,321 (91.4)

1,830 (72.0)

999 (2,198)

89

2,250 (88.6)

2,321 (91.4)

1,830 (72.0)

1,084 (2,385)

93

4

14

100-67-33-0

2.58 (27.78)

148 (486)

Cross Finned Tubes

Seamless Copper

0.33 (0.013)

9.5 (3/8)

Aluminium

0.11 (0.004)

5

12

100-75-50-25-0

2.58 (27.78)

165 (540)

6

12

100-75-50-25-0

3.37 (36.26)

151 (496)

6

12

100-80-60-40-20-0

3.90 (41.96)

164 (536)

1

592 (23.3)

564 (22.2)

340.1 (12,000)

200 (0.8)

B3 x 330 (13)

B3 x 127 (5)

B3 - SPZ

B-1524 (60)

1

592 (23.3)

564 (22.2)

382.7 (13,500)

250 (1.0)

B3 x 330 (13)

B3 x 140 (5.5)

B3 - SPZ

B-1550 (61)

Centrifugal / Belt Driven

Zinc Coated Steel

1

592 (23.3)

564 (22.2)

425.2 (15,000)

250 (1.0)

B3 x 305 (12)

B3 x 140 (5.5)

B3 - SPZ

B-1499 (59)

1

785 (30.9)

706 (27.8)

510.2 (18,000)

300 (1.2)

B3 x 381 (15)

B3 x 152 (6)

B3 - SPZ

B-1702 (67)

1

785 (30.9)

706 (27.8)

637.8 (22,500)

350 (1.4)

B3 x 356 (14)

B3 x 140 (5.5)

B3 - SPZ

B-1651 (65)

10.9

4.84

5.5

1,440

4

Star-Delta (S/D)

14.4

6.30

7.5

1,440

4

Star-Delta (S/D)

Squirrel Cage Induction

380-415 / 3 / 50

20.7

8.04

11.0

1,460

4

Star-Delta (S/D)

20.7

9.20

11.0

1,460

4

Star-Delta (S/D)

28.1

11.68

15.0

1,460

4

Star-Delta (S/D)

4 x 15.9 (5/8)

4 x 34.9 (1-3/8)

5 x 15.9 (5/8)

5 x 34.9 (1-3/8)

Indoor Unit

Indoor Unit

Casing

Model

Material

Wall Thickness

Outer Diameter

Material

Thickness

Rows

Fins Per Inch

mm (in)

mm (in)

mm (in)

kg (lb)

dBA

679 (26.7)

1,644 (64.7)

1,189 (46.8)

132 (290)

79

869 (34.2)

1,877 (73.9)

1,039 (40.9)

180 (396)

85

1,300 (51.2)

1,913 (75.3)

1,175 (46.3)

250 (550)

87

Galvanized Mild Steel

Plain Galvanized

Polyethylene Foam

1,300 (51.2)

1,913 (75.3)

1,175 (46.3)

270 (594)

89

5

12

100-67-33-0

1.62 (17.43)

157 (516)

4

12

100-71-36-0

2.35 (25.29)

127 (415)

1

470 (18.5)

460 (18.1)

255.1 (9,000)

200 (0.8)

B2 x 305 (12)

B2 x 165 (6.5)

B2 - SPZ

B - 1,880 (74)

1

470 (18.5)

460 (18.1)

297.6 (10,500)

200 (0.8)

B2 x 305 (12)

B2 x 152 (6)

B2 - SPZ

B - 1,880 (74)

Squirrel Cage Induction

380 - 415 / 3 / 50

8.0

8.0

4.00

4.00

4.0

4.0

1,440

1,440

4

4

Star-Delta (S/T)

Star-Delta (S/T)

10.9

4.51

5.5

1,440

4

Star-Delta (S/T)

4

12

100-50-0

0.82 (8.83)

159 (521)

4

12

100-50-0

1.10 (11.86)

165 (540)

4

14

100-50-0

1.46 (15.71)

155 (509)

Cross Finned Tubes

Seamless Copper

0.33 (0.013)

9.5 (3/8)

Aluminium

0.11 (0.004)

5

12

100-50-0

1.62 (17.43)

157 (516)

1

395 (15.6)

381 (15.0)

130.4 (4,600)

150 (0.6)

B1 x 178 (7)

B1 x 102 (4)

B1 - SPZ

B - 914 (36)

1

395 (15.6)

381 (15.0)

181.40 (6,400)

150 (0.6)

B1 x 178 (7)

B1 x 114 (4.5)

B1 - SPZ

B - 940 (37)

1

470 (18.5)

460 (18.1)

226.8 (8,000)

200 (0.8)

B2 x 305 (12)

B2 x 165 (6.5)

B2 - SPZ

B - 1,880 (74)

Belt Driven

Zinc Coated Steel

1

470 (18.5)

460 (18.1)

255.1 (9,000)

200 (0.8)

B2 x 305 (12)

B2 x 165 (6.5)

B2 - SPZ

B - 1,880 (74)

3.4

1.63

1.5

1,400

4

Direct On Line (DOL)

6.2

2.73

3.0

1,420

4

Star-Delta (S/T)

8.0

3.37

4.0

1,440

4

Star-Delta (S/T)

mm (in)

mm (in)

mm (in)

Capacity Steps

%

Face Area

m (ft)

Face Velocity

m/min (FPM)

Blower

Type/Drive

Blower Material

Quantity

Blower Diameter

mm (in)

Blower Length

mm (in)

Air Flow

CMM (CFM)

External Static Pressure

Pa (in wg)

Blower Pulley Diameter

mm (in)

Motor Pulley Diameter

mm (in)

Pulley

Type

V-Belt Type - Length

mm (in)

Fan Motor

Type

Power Supply

V/Ph/Hz

Number x Rated Running Current

A

Number x Rated Power Input

kW

Number x Rated Power Output

kW

Motor Speed

RPM

Motor Poles

Starter Type

Refrigerant & Pipe Size

Type

Type of Gas Precharged

Capacity Control

Pipe Connection Method

Liquid

mm (in)

Pipe Size

Gas

mm (in)

Drain Pipe Size

mm (in)

Air Filter

Type

Length x Height

mm (in)

Size

Depth

mm (in)

Quantity

Outdoor Unit

Material

Casing

Finishing

Height (H)

mm (in)

Dimension (Each) Width (W)

mm (in)

Depth (D)

mm (in)

Net Weight (Each)

kg (lb)

Sound Power Level

dBA

CONDENSER COIL

Type

Material

Wall Thickness

mm (in)

Tube

Outer Diameter

mm (in)

Material

Thickness

mm

(in)

Fin

Number x Rows (Each)

Fins Per Inch (Each)

Face Area (Each)

m (ft)

Face Velocity (Each)

m/min (FPM)

Fan Motor

Fan Type/Drive

Fan Blade Material

Fan Blade Diameter (Each)

mm (in)

Fan Blade Quantity (Each)

Air Flow (Each)

CMM (CFM)

Motor Type

Motor Quantity (Each)

Power Supply

V / Ph / Hz

Number x Rated Running Current (Each)

A

Number x Rated Power Input (Each)

W

Number x Rated Power Output (Each)

W

Motor Speed (Each)

RPM

Motor Poles

Compressor

Type

Power Supply

V / Ph / Hz

Rated Running Current (Each)

A

Rated Power Input (Each)

kW

Maximum Starting Current (Each)

A

Compressor Speed (Each)

RPM

Protection Devices

Stage of Capacity Control

Starter Type

REFRIGERANT

Type

Type of Gas Precharged

2 x 12.7 (1/2)

2 x 25.4 (1)

2 x 15.9 (5/8)

2 x 28.6 (1-1/8)

Casing

1,300 (51.2)

1,913 (75.3)

1,175 (46.3)

270 (594)

89

1,550 (61.0)

2,169 (85.4)

1,175 (46.3)

320 (704)

92

2x1

16

1.74 (18.7)

104 (342)

R22

Nitrogen Holding

Thermostatic Expansion Valve

Brazed

2 x 15.9 (5/8)

2 x 15.9 (5/8)

3 x 15.9 (5/8)

2 x 34.9 (1-3/8)

2 x 34.9 (1-3/8)

3 x 28.6 (1-1/8)

25.4 (1)

977 (38.5)

1,184 (46.6)

950 (37.4)

180 (396)

78

Electro Galvanized Mild Steel

Epoxy Polyester Powder Coating

977 (38.5)

1,072 (42.2)

977 (38.5)

1,184 (46.6)

1,188 (46.8)

1,184 (46.6)

950 (37.4)

995 (39.2)

950 (37.4)

224 (493)

258 (568)

180 (396)

80

84

78

2x2

12

1.74 (18.7)

104 (342)

Cross Finned Tubes

Seamless Copper

0.33 (0.013)

9.5 (3/8)

Aluminium

0.11 (0.004)

2x2

14

2.45 (26.4)

130 (424)

2x2

16

1.74 (18.7)

104 (342)

660 (26)

1

181.4 (6,400)

660 (26)

1

181.4 (6,400)

660 (26)

1

181.4 (6,400)

1.5

680

468

920

6

1.5

680

468

920

6

1.5

680

468

920

6

13.6

6.81

95

2,900

16.4

8.96

125

2,900

Propeller / Direct

Aluminium

762 (30)

1

317.5 (11,200)

Induction

1

380 - 415 / 3 / 50

4.4

3,200

1,250

700

6

1 x 15.9 (5/8)

1 x 28.6 (1-1/8)

2x2

12

1.74 (18.7)

104 (342)

Fin

2 x 15.9 (5/8)

2 x 34.9 (1-3/8)

657 x 450 (26 x 18)

50.8 (2)

9

977 (38.5)

1,184 (46.6)

950 (37.4)

180 (396)

78

2x2

12

1.74 (18.7)

104 (342)

977 (38.5)

1,184 (46.6)

950 (37.4)

224 (493)

80

2x2

16

1.74 (18.7)

104 (342)

660 (26)

1

181.4 (6,400)

660 (26)

1

181.4 (6,400)

660 (26)

1

181.4 (6,400)

1.5

680

468

920

6

1.5

680

468

920

6

1.5

680

468

920

6

Scroll

380-415 / 3 / 50

17.9

24.2

16.4

10.20

13.62

8.96

110

198

125

2,900

2,900

2,900

Overload Protection And Auto Reset High / Low Pressure Switch

On / Off

Auto-Trans (A/T)

R22

Nitrogen Holding

Net Weight

Sound Power Level

Evaporator Coil

Type

Tube

Washable Viledon (AAF R29)

695 x 540 (27 x 21) 690 x 493 (27 x 19.5) 571 x 560 (22.5 x 22) 571 x 560 (22.5 x 22) 571 x 560 (22.5 x 22)

50.8 (2)

50.8 (2)

50.8 (2)

50.8 (2)

50.8 (2)

2

4

6

6

6

977 (38.5)

1,184 (46.6)

950 (37.4)

153 (337)

77

Dimension

16.4

8.96

125

2,900

Material

Finishing

Insulation

Height (H)

Width (W)

Depth (D)

17.9

10.20

110

2,900

Material

Wall Thickness

Outer Diameter

Material

Thickness

Rows

Fin Per Inch

mm (in)

mm (in)

mm (in)

kg (lb)

dBA

1,550 (61.0)

2,321 (91.4)

1,480 (58.3)

330 (726)

90

mm (in)

mm (in)

mm (in)

Capacity Steps

%

Face Area

m (ft)

Face Velocity

m/min (FPM)

Blower

Type/Drive

Blower Material

Quantity

Blower Diameter

mm (in)

Blower Length

mm (in)

Air Flow

CMM (CFM)

External Static Pressure

Pa (in wg)

Blower Pulley Diameter

mm (in)

Motor Pulley Diameter

mm (in)

Pulley

Type

V-Belt Type - Length

mm (in)

Fan Motor

Type

Power Supply

V / Ph / Hz

Number x Rated Running Current

A

Number x Rated Power Input

kW

Number x Rated Power Output

kW

Motor Speed

RPM

Motor Poles

Starter Type

Refrigerant & Pipe Size

Type

Type of Gas Precharged

Capacity Control

Pipe Connection Method

Liquid

mm (in)

Pipe Size

Gas

mm (in)

Drain Pipe Size

mm (in)

Air Filter

Type

Length x Height

mm

Size

Depth

mm (in)

Quantity

Outdoor Unit

Material

Casing

Finishing

Height (H)

mm (in)

Dimension (Each)

Width (W)

mm (in)

Depth (D)

mm (in)

Net Weight (Each)

kg (lb)

Sound Power Level

dBA

Condenser Coil

Type

Material

Tube

Wall Thickness

mm (in)

Outer Diameter

mm (in)

Material

Thickness

mm (in)

Fin

Number x Rows (Each)

Fin per Inch (Each)

Face Area (Each)

m (ft)

Face Velocity (Each)

m/min (FPM)

Fan Motor

Fan Type / Drive

Fan Blade Material

Fan Blade Diameter (Each)

mm (in)

Fan Blade Quantity (Each)

Air Flow (Each)

CMM (CFM)

Motor Type

Motor Quantity (Each)

Power Supply

V / Ph / Hz

Number x Rated Running Current (Each)

A

Number x Rated Power Input (Each)

W

Number x Rated Power Output (Each)

W

Motor Speed (Each)

RPM

Motor Poles (Each)

Compressor

Type

Power Supply

V / Ph / Hz

Rated Running Current (Each)

A

Rated Power Input (Each)

kW

Maximum Starting Current (Each)

A

Compressor Speed (Each)

RPM

Protection Devices

Stage of Capacity Control

Starter Type

REFRIGERANT

Type

Type of Gas Precharged

Conditions:

1. Nominal cooling capacities are based on the following conditions: indoor 26.7CDB, 19.4CWB, outdoor 35CDB.

2. All specifications are subjected to change by manufacturer without prior notice.

4

14

100-75-50-25-0

2.35 (25.29)

145 (474)

R22

Nitrogen Holding

Thermostatic Expansion Valve

Brazed

4 x 15.9 (5/8)

4 x 34.9 (1-3/8)

25.4 (1)

4 x 15.9 (5/8)

4 x 28.6 (1-1/8)

3 x 15.9 (5/8)

3 x 34.9 (1-3/8)

530 x 450 (21 x 18)

50.8 (2)

12

530 x 450 (21 x 18)

50.8 (2)

12

Washable Viledon (AAF R29)

530 x 450 (21 x 18)

50.8 (2)

12

530 x 440 (21 x 17.5)

50.8 (2)

16

530 x 508 (21 x 20)

50.8 (2)

16

977 (38.5)

1,184 (46.1)

950 (37.4)

180 (396)

78

1,072 (42.2)

1,188 (46.8)

995 (39.2)

258 (568)

84

Electro Galvanized Mild Steel

Epoxy Polyester Powder Coating

977 (38.5)

1,184 (46.1)

950 (37.4)

224 (493)

80

1,072 (42.2)

1,188 (46.8)

995 (39.2)

258 (568)

84

1,072 (42.2)

1,188 (46.8)

995 (39.2)

258 (568)

84

2x2

14

2.45 (26.4)

130 (424)

Cross Finned Tubes

Seamless Copper

0.33 (0.013)

9.5 (3/8)

Aluminium

0.11 (0.004)

2x2

16

1.74 (18.7)

104 (342)

2x2

14

2.45 (26.4)

130 (424)

2x2

14

2.45 (26.4)

130 (424)

762 (30)

1

317.5 (11,200)

762 (30)

1

317.5 (11,200)

1

380-415 / 3 / 50

4.4

3,200

1,250

700

6

1

380-415 / 3 / 50

4.4

3,200

1,250

700

6

2x2

12

1.74 (18.7)

104 (342)

660 (26)

1

181.4 (6,400)

762 (30)

1

317.5 (11,200)

1

380-415 / 3 / 50

1.5

680

468

920

6

1

380-415 / 3 / 50

4.4

3,200

1,250

700

6

16.4

8.96

125

2,900

Propeller / Direct

Aluminium

660 (26)

1

181.4 (6,400)

Induction

1

380-415 / 3 / 50

1.5

680

468

920

6

Scroll

380-415 / 3 / 50

24.2

17.9

13.62

10.20

198

110

2,900

2,900

Overload Protection And Auto Reset High / Low Pressure

On / Off

Auto-Trans (A/T)

24.2

13.62

198

2,900

Switch

24.2

13.62

198

2,900

R22

Nitrogen Holding

Conditions:

1. Nominal cooling capacities are based on the following conditions: indoor 26.7CDB, 19.4CWB, outdoor 35CDB.

2. All specifications are subjected to change by manufacturer without prior notice.

FUJIAIRE (M) SDN. BHD. (184159-M)

Unit C3, Lot 4, Jalan Perusahaan 1, Batu Caves Industrial Estate, 68100 Batu Caves, Selangor D.E., Malaysia. Tel: 603-6186 0491 Fax: 603-6186 0492

Website: http://www.fujiaire.com.my Email: enquiry@fujiaire.com.my

HIGH STATIC DUCTED BLOWER SPLIT SYSTEM

FUJIAIRE DUCTED TYPE AIR-CONDITIONER (R-22 COOLING)

Model

Indoor Unit

Outdoor Unit

Total Cooling Capacity

Btu/hr

kW

FUJIAIRE DUCTED TYPE AIR-CONDITIONER (R-22 COOLING)

FDA 150CC2-E11N FDA 200CB2-E11N FDA 250CB2-E11N FDA 300CB2-E11N FDA 300CB3-E11N

FDA 350CB3-E11N

FLA 080CB-E11N x 2 FLA 100CB-E11N x 2 FLA 125CB-E11N x 2 FLA 150CC-E11N x 2 FLA 100CB-E11N x 3 FLA 100CB-E11N x 1 FLA 125CB-E11N x 2

150,000

200,000

250,000

300,000

300,000

350,000

43.96

58.62

73.27

87.92

87.92

102.58

Dimension

Material

Finishing

Insulation

Height (H)

Width (W)

Depth (D)

Net Weight

Sound Power Level

Evaporator Coil

Type

Tube

Fin

Indoor Unit

Outdoor Unit

Total Cooling Capacity

Btu/hr

kW

FDA 400CB4-E11N

FLA 100CB-E11N x 4

400,000

117.23

FDA 450CB3-E11N

FLA 150CC-E11N x 3

450,000

131.89

FDA 500CB4-E11N

FLA 125CB-E11N x 4

500,000

146.54

FDA 600CB4-E11N

FLA 150CC-E11N x 4

600,000

175.85

FDA 750CB5-E11N

FLA 150CC-E11N x 5

750,000

219.81

1,550 (61.0)

2,321 (91.4)

1,480 (58.3)

339 (746)

93

Electro Galvanized Mild Steel

Plain Galvanized

Polyethylene Foam

1,550 (61.0)

2,321 (91.4)

1,480 (58.3)

350 (770)

96

1,975 (77.8)

2,321 (91.4)

1,830 (72.0)

999 (2,198)

89

2,250 (88.6)

2,321 (91.4)

1,830 (72.0)

1,084 (2,385)

93

4

14

100-67-33-0

2.58 (27.78)

148 (486)

Cross Finned Tubes

Seamless Copper

0.33 (0.013)

9.5 (3/8)

Aluminium

0.11 (0.004)

5

12

100-75-50-25-0

2.58 (27.78)

165 (540)

6

12

100-75-50-25-0

3.37 (36.26)

151 (496)

6

12

100-80-60-40-20-0

3.90 (41.96)

164 (536)

1

592 (23.3)

564 (22.2)

340.1 (12,000)

200 (0.8)

B3 x 330 (13)

B3 x 127 (5)

B3 - SPZ

B-1524 (60)

1

592 (23.3)

564 (22.2)

382.7 (13,500)

250 (1.0)

B3 x 330 (13)

B3 x 140 (5.5)

B3 - SPZ

B-1550 (61)

Centrifugal / Belt Driven

Zinc Coated Steel

1

592 (23.3)

564 (22.2)

425.2 (15,000)

250 (1.0)

B3 x 305 (12)

B3 x 140 (5.5)

B3 - SPZ

B-1499 (59)

1

785 (30.9)

706 (27.8)

510.2 (18,000)

300 (1.2)

B3 x 381 (15)

B3 x 152 (6)

B3 - SPZ

B-1702 (67)

1

785 (30.9)

706 (27.8)

637.8 (22,500)

350 (1.4)

B3 x 356 (14)

B3 x 140 (5.5)

B3 - SPZ

B-1651 (65)

10.9

4.84

5.5

1,440

4

Star-Delta (S/D)

14.4

6.30

7.5

1,440

4

Star-Delta (S/D)

Squirrel Cage Induction

380-415 / 3 / 50

20.7

8.04

11.0

1,460

4

Star-Delta (S/D)

20.7

9.20

11.0

1,460

4

Star-Delta (S/D)

28.1

11.68

15.0

1,460

4

Star-Delta (S/D)

4 x 15.9 (5/8)

4 x 34.9 (1-3/8)

5 x 15.9 (5/8)

5 x 34.9 (1-3/8)

Indoor Unit

Indoor Unit

Casing

Model

Material

Wall Thickness

Outer Diameter

Material

Thickness

Rows

Fins Per Inch

mm (in)

mm (in)

mm (in)

kg (lb)

dBA

679 (26.7)

1,644 (64.7)

1,189 (46.8)

132 (290)

79

869 (34.2)

1,877 (73.9)

1,039 (40.9)

180 (396)

85

1,300 (51.2)

1,913 (75.3)

1,175 (46.3)

250 (550)

87

Galvanized Mild Steel

Plain Galvanized

Polyethylene Foam

1,300 (51.2)

1,913 (75.3)

1,175 (46.3)

270 (594)

89

5

12

100-67-33-0

1.62 (17.43)

157 (516)

4

12

100-71-36-0

2.35 (25.29)

127 (415)

1

470 (18.5)

460 (18.1)

255.1 (9,000)

200 (0.8)

B2 x 305 (12)

B2 x 165 (6.5)

B2 - SPZ

B - 1,880 (74)

1

470 (18.5)

460 (18.1)

297.6 (10,500)

200 (0.8)

B2 x 305 (12)

B2 x 152 (6)

B2 - SPZ

B - 1,880 (74)

Squirrel Cage Induction

380 - 415 / 3 / 50

8.0

8.0

4.00

4.00

4.0

4.0

1,440

1,440

4

4

Star-Delta (S/T)

Star-Delta (S/T)

10.9

4.51

5.5

1,440

4

Star-Delta (S/T)

4

12

100-50-0

0.82 (8.83)

159 (521)

4

12

100-50-0

1.10 (11.86)

165 (540)

4

14

100-50-0

1.46 (15.71)

155 (509)

Cross Finned Tubes

Seamless Copper

0.33 (0.013)

9.5 (3/8)

Aluminium

0.11 (0.004)

5

12

100-50-0

1.62 (17.43)

157 (516)

1

395 (15.6)

381 (15.0)

130.4 (4,600)

150 (0.6)

B1 x 178 (7)

B1 x 102 (4)

B1 - SPZ

B - 914 (36)

1

395 (15.6)

381 (15.0)

181.40 (6,400)

150 (0.6)

B1 x 178 (7)

B1 x 114 (4.5)

B1 - SPZ

B - 940 (37)

1

470 (18.5)

460 (18.1)

226.8 (8,000)

200 (0.8)

B2 x 305 (12)

B2 x 165 (6.5)

B2 - SPZ

B - 1,880 (74)

Belt Driven

Zinc Coated Steel

1

470 (18.5)

460 (18.1)

255.1 (9,000)

200 (0.8)

B2 x 305 (12)

B2 x 165 (6.5)

B2 - SPZ

B - 1,880 (74)

3.4

1.63

1.5

1,400

4

Direct On Line (DOL)

6.2

2.73

3.0

1,420

4

Star-Delta (S/T)

8.0

3.37

4.0

1,440

4

Star-Delta (S/T)

mm (in)

mm (in)

mm (in)

Capacity Steps

%

Face Area

m (ft)

Face Velocity

m/min (FPM)

Blower

Type/Drive

Blower Material

Quantity

Blower Diameter

mm (in)

Blower Length

mm (in)

Air Flow

CMM (CFM)

External Static Pressure

Pa (in wg)

Blower Pulley Diameter

mm (in)

Motor Pulley Diameter

mm (in)

Pulley

Type

V-Belt Type - Length

mm (in)

Fan Motor

Type

Power Supply

V/Ph/Hz

Number x Rated Running Current

A

Number x Rated Power Input

kW

Number x Rated Power Output

kW

Motor Speed

RPM

Motor Poles

Starter Type

Refrigerant & Pipe Size

Type

Type of Gas Precharged

Capacity Control

Pipe Connection Method

Liquid

mm (in)

Pipe Size

Gas

mm (in)

Drain Pipe Size

mm (in)

Air Filter

Type

Length x Height

mm (in)

Size

Depth

mm (in)

Quantity

Outdoor Unit

Material

Casing

Finishing

Height (H)

mm (in)

Dimension (Each) Width (W)

mm (in)

Depth (D)

mm (in)

Net Weight (Each)

kg (lb)

Sound Power Level

dBA

CONDENSER COIL

Type

Material

Wall Thickness

mm (in)

Tube

Outer Diameter

mm (in)

Material

Thickness

mm

(in)

Fin

Number x Rows (Each)

Fins Per Inch (Each)

Face Area (Each)

m (ft)

Face Velocity (Each)

m/min (FPM)

Fan Motor

Fan Type/Drive

Fan Blade Material

Fan Blade Diameter (Each)

mm (in)

Fan Blade Quantity (Each)

Air Flow (Each)

CMM (CFM)

Motor Type

Motor Quantity (Each)

Power Supply

V / Ph / Hz

Number x Rated Running Current (Each)

A

Number x Rated Power Input (Each)

W

Number x Rated Power Output (Each)

W

Motor Speed (Each)

RPM

Motor Poles

Compressor

Type

Power Supply

V / Ph / Hz

Rated Running Current (Each)

A

Rated Power Input (Each)

kW

Maximum Starting Current (Each)

A

Compressor Speed (Each)

RPM

Protection Devices

Stage of Capacity Control

Starter Type

REFRIGERANT

Type

Type of Gas Precharged

2 x 12.7 (1/2)

2 x 25.4 (1)

2 x 15.9 (5/8)

2 x 28.6 (1-1/8)

Casing

1,300 (51.2)

1,913 (75.3)

1,175 (46.3)

270 (594)

89

1,550 (61.0)

2,169 (85.4)

1,175 (46.3)

320 (704)

92

2x1

16

1.74 (18.7)

104 (342)

R22

Nitrogen Holding

Thermostatic Expansion Valve

Brazed

2 x 15.9 (5/8)

2 x 15.9 (5/8)

3 x 15.9 (5/8)

2 x 34.9 (1-3/8)

2 x 34.9 (1-3/8)

3 x 28.6 (1-1/8)

25.4 (1)

977 (38.5)

1,184 (46.6)

950 (37.4)

180 (396)

78

Electro Galvanized Mild Steel

Epoxy Polyester Powder Coating

977 (38.5)

1,072 (42.2)

977 (38.5)

1,184 (46.6)

1,188 (46.8)

1,184 (46.6)

950 (37.4)

995 (39.2)

950 (37.4)

224 (493)

258 (568)

180 (396)

80

84

78

2x2

12

1.74 (18.7)

104 (342)

Cross Finned Tubes

Seamless Copper

0.33 (0.013)

9.5 (3/8)

Aluminium

0.11 (0.004)

2x2

14

2.45 (26.4)

130 (424)

2x2

16

1.74 (18.7)

104 (342)

660 (26)

1

181.4 (6,400)

660 (26)

1

181.4 (6,400)

660 (26)

1

181.4 (6,400)

1.5

680

468

920

6

1.5

680

468

920

6

1.5

680

468

920

6

13.6

6.81

95

2,900

16.4

8.96

125

2,900

Propeller / Direct

Aluminium

762 (30)

1

317.5 (11,200)

Induction

1

380 - 415 / 3 / 50

4.4

3,200

1,250

700

6

1 x 15.9 (5/8)

1 x 28.6 (1-1/8)

2x2

12

1.74 (18.7)

104 (342)

Fin

2 x 15.9 (5/8)

2 x 34.9 (1-3/8)

657 x 450 (26 x 18)

50.8 (2)

9

977 (38.5)

1,184 (46.6)

950 (37.4)

180 (396)

78

2x2

12

1.74 (18.7)

104 (342)

977 (38.5)

1,184 (46.6)

950 (37.4)

224 (493)

80

2x2

16

1.74 (18.7)

104 (342)

660 (26)

1

181.4 (6,400)

660 (26)

1

181.4 (6,400)

660 (26)

1

181.4 (6,400)

1.5

680

468

920

6

1.5

680

468

920

6

1.5

680

468

920

6

Scroll

380-415 / 3 / 50

17.9

24.2

16.4

10.20

13.62

8.96

110

198

125

2,900

2,900

2,900

Overload Protection And Auto Reset High / Low Pressure Switch

On / Off

Auto-Trans (A/T)

R22

Nitrogen Holding

Net Weight

Sound Power Level

Evaporator Coil

Type

Tube

Washable Viledon (AAF R29)

695 x 540 (27 x 21) 690 x 493 (27 x 19.5) 571 x 560 (22.5 x 22) 571 x 560 (22.5 x 22) 571 x 560 (22.5 x 22)

50.8 (2)

50.8 (2)

50.8 (2)

50.8 (2)

50.8 (2)

2

4

6

6

6

977 (38.5)

1,184 (46.6)

950 (37.4)

153 (337)

77

Dimension

16.4

8.96

125

2,900

Material

Finishing

Insulation

Height (H)

Width (W)

Depth (D)

17.9

10.20

110

2,900

Material

Wall Thickness

Outer Diameter

Material

Thickness

Rows

Fin Per Inch

mm (in)

mm (in)

mm (in)

kg (lb)

dBA

1,550 (61.0)

2,321 (91.4)

1,480 (58.3)

330 (726)

90

mm (in)

mm (in)

mm (in)

Capacity Steps

%

Face Area

m (ft)

Face Velocity

m/min (FPM)

Blower

Type/Drive

Blower Material

Quantity

Blower Diameter

mm (in)

Blower Length

mm (in)

Air Flow

CMM (CFM)

External Static Pressure

Pa (in wg)

Blower Pulley Diameter

mm (in)

Motor Pulley Diameter

mm (in)

Pulley

Type

V-Belt Type - Length

mm (in)

Fan Motor

Type

Power Supply

V / Ph / Hz

Number x Rated Running Current

A

Number x Rated Power Input

kW

Number x Rated Power Output

kW

Motor Speed

RPM

Motor Poles

Starter Type

Refrigerant & Pipe Size

Type

Type of Gas Precharged

Capacity Control

Pipe Connection Method

Liquid

mm (in)

Pipe Size

Gas

mm (in)

Drain Pipe Size

mm (in)

Air Filter

Type

Length x Height

mm

Size

Depth

mm (in)

Quantity

Outdoor Unit

Material

Casing

Finishing

Height (H)

mm (in)

Dimension (Each)

Width (W)

mm (in)

Depth (D)

mm (in)

Net Weight (Each)

kg (lb)

Sound Power Level

dBA

Condenser Coil

Type

Material

Tube

Wall Thickness

mm (in)

Outer Diameter

mm (in)

Material

Thickness

mm (in)

Fin

Number x Rows (Each)

Fin per Inch (Each)

Face Area (Each)

m (ft)

Face Velocity (Each)

m/min (FPM)

Fan Motor

Fan Type / Drive

Fan Blade Material

Fan Blade Diameter (Each)

mm (in)

Fan Blade Quantity (Each)

Air Flow (Each)

CMM (CFM)

Motor Type

Motor Quantity (Each)

Power Supply

V / Ph / Hz

Number x Rated Running Current (Each)

A

Number x Rated Power Input (Each)

W

Number x Rated Power Output (Each)

W

Motor Speed (Each)

RPM

Motor Poles (Each)

Compressor

Type

Power Supply

V / Ph / Hz

Rated Running Current (Each)

A

Rated Power Input (Each)

kW

Maximum Starting Current (Each)

A

Compressor Speed (Each)

RPM

Protection Devices

Stage of Capacity Control

Starter Type

REFRIGERANT

Type

Type of Gas Precharged

Conditions:

1. Nominal cooling capacities are based on the following conditions: indoor 26.7CDB, 19.4CWB, outdoor 35CDB.

2. All specifications are subjected to change by manufacturer without prior notice.

4

14

100-75-50-25-0

2.35 (25.29)

145 (474)

R22

Nitrogen Holding

Thermostatic Expansion Valve

Brazed

4 x 15.9 (5/8)

4 x 34.9 (1-3/8)

25.4 (1)

4 x 15.9 (5/8)

4 x 28.6 (1-1/8)

3 x 15.9 (5/8)

3 x 34.9 (1-3/8)

530 x 450 (21 x 18)

50.8 (2)

12

530 x 450 (21 x 18)

50.8 (2)

12

Washable Viledon (AAF R29)

530 x 450 (21 x 18)

50.8 (2)

12

530 x 440 (21 x 17.5)

50.8 (2)

16

530 x 508 (21 x 20)

50.8 (2)

16

977 (38.5)

1,184 (46.1)

950 (37.4)

180 (396)

78

1,072 (42.2)

1,188 (46.8)

995 (39.2)

258 (568)

84

Electro Galvanized Mild Steel

Epoxy Polyester Powder Coating

977 (38.5)

1,184 (46.1)

950 (37.4)

224 (493)

80

1,072 (42.2)

1,188 (46.8)

995 (39.2)

258 (568)

84

1,072 (42.2)

1,188 (46.8)

995 (39.2)

258 (568)

84

2x2

14

2.45 (26.4)

130 (424)

Cross Finned Tubes

Seamless Copper

0.33 (0.013)

9.5 (3/8)

Aluminium

0.11 (0.004)

2x2

16

1.74 (18.7)

104 (342)

2x2

14

2.45 (26.4)

130 (424)

2x2

14

2.45 (26.4)

130 (424)

762 (30)

1

317.5 (11,200)

762 (30)

1

317.5 (11,200)

1

380-415 / 3 / 50

4.4

3,200

1,250

700

6

1

380-415 / 3 / 50

4.4

3,200

1,250

700

6

2x2

12

1.74 (18.7)

104 (342)

660 (26)

1

181.4 (6,400)

762 (30)

1

317.5 (11,200)

1

380-415 / 3 / 50

1.5

680

468

920

6

1

380-415 / 3 / 50

4.4

3,200

1,250

700

6

16.4

8.96

125

2,900

Propeller / Direct

Aluminium

660 (26)

1

181.4 (6,400)

Induction

1

380-415 / 3 / 50

1.5

680

468

920

6

Scroll

380-415 / 3 / 50

24.2

17.9

13.62

10.20

198

110

2,900

2,900

Overload Protection And Auto Reset High / Low Pressure

On / Off

Auto-Trans (A/T)

24.2

13.62

198

2,900

Switch

24.2

13.62

198

2,900

R22

Nitrogen Holding

Conditions:

1. Nominal cooling capacities are based on the following conditions: indoor 26.7CDB, 19.4CWB, outdoor 35CDB.

2. All specifications are subjected to change by manufacturer without prior notice.

FUJIAIRE (M) SDN. BHD. (184159-M)

Unit C3, Lot 4, Jalan Perusahaan 1, Batu Caves Industrial Estate, 68100 Batu Caves, Selangor D.E., Malaysia. Tel: 603-6186 0491 Fax: 603-6186 0492

Website: http://www.fujiaire.com.my Email: enquiry@fujiaire.com.my

HIGH STATIC DUCTED BLOWER SPLIT SYSTEM

You might also like

- 40LX040 060 (Malaysia)Document8 pages40LX040 060 (Malaysia)Leed ENNo ratings yet

- Dasco 19-26Document8 pagesDasco 19-26Ahmed AzadNo ratings yet

- FDB 400-750 407Document1 pageFDB 400-750 407yadi_baeNo ratings yet

- RCCN Wiring Duct VDRFDocument9 pagesRCCN Wiring Duct VDRFRCCNNo ratings yet

- 8015-0151-SC02-51-510-CI-DS-00001 - 01 - Layouts - Office ContainerDocument1 page8015-0151-SC02-51-510-CI-DS-00001 - 01 - Layouts - Office ContainerSi Chini100% (1)