Professional Documents

Culture Documents

Table J.2.1 Filler Strengths Table J.2.2 Tensile Strengths For 5183, 5356, and 5556 Studs

Uploaded by

Abdullah NajjarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Table J.2.1 Filler Strengths Table J.2.2 Tensile Strengths For 5183, 5356, and 5556 Studs

Uploaded by

Abdullah NajjarCopyright:

Available Formats

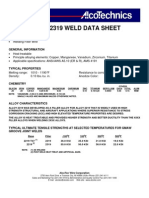

Table J.2.1 Table J.2.

2

FILLER STRENGTHS TENSILE STRENGTHS FOR 5183, 5356,

Tensile Ultimate Shear Ultimate

AND 5556 STUDS

Filler Strength (ksi) Strength (ksi) Capacitor

1100 11 7.5 Stud Size Arc (lb) Discharge (lb)

2319 35 16 6–32 – 375

4043 24 11.5 8–32 – 635

4047 – 13 10–24 770 770

4643 – 13.5 ¼–20 1360 1360

5183 40 21 5

⁄16–18 2300 2300

5356 35 17 3

⁄8–16 3250 –

5554 31 17 7 ⁄16–14 4400 –

5556 42 20 ½–13 5950 –

5654 30 12

Table J.2.2M

Table J.2.1M TENSILE STRENGTHS FOR 5183, 5356,

FILLER STRENGTHS AND 5556 STUDS

Tensile Ultimate Shear Ultimate Capacitor

Filler Strength (MPa) Strength (MPa) Stud Size Arc (kN) Discharge (kN)

1100 75 50 6–32 – 1.67

2319 240 110 8–32 – 2.82

4043 165 80 10–24 3.42 3.42

4047 – 90 ¼–20 6.05 6.05

4643 – 95 5

⁄16–18 10.2 10.2

5183 275 145 3 ⁄8–16 14.5 –

5356 240 115 7 ⁄16–14 19.6 –

5554 215 115 ½–13 26.5 –

5556 290 140

5654 205 85

stresses of the base metal within 1.0 in. (25 mm) of the

weld shall be 85% of the values for unwelded 6005-T5.

For 6063 lighting poles through 0.375 in. (10 mm) thick

J.2.4 Stud Welds welded in the T4 temper with 4043 ller and arti cially

aged to the T6 temper after welding:

The nominal tensile strength Rn of a stud weld is:

a) The design and allowable stresses of the base metal

Rn = Tuw (J.2-5) within 1.0 in. (25 mm) of the weld shall be 85% of the

values for unwelded 6063-T6.

where b) The design stress is 12.5 ksi (85 MPa) and the allowable

stress is 8 ksi (55 MPa) for welds in socket type bases.

Tuw = tensile strength of the stud in Table J.2.2 or c) The design stress is 9 ksi (60 MPa) and the allowable

Table J.2.2M stress is 5.9 ksi (41 MPa) for welds in other than socket

The base metal thickness for arc stud welding shall type bases.

not be less than 50% of the stud diameter. The base metal

thickness for capacitor discharge stud welding shall not be J.3 Bolts

less than 25% of the stud diameter. J.3.1 Bolt Material

J.2.5 Post-Weld Heat Treating Bolt material shall be:

For 6005 lighting poles through 0.250 in. (6 mm) thick a) Aluminum: Bolts shall meet ASTM F 468 and be 2024-

welded in the T1 temper with 4043 ller and arti cially T4, 6061-T6, or 7075-T73. When 2024 bolts will be

aged to the T5 temper after welding, design and allowable exposed to contact with liquid water or humidity near

I-56 January 2010

You might also like

- 2nd Edition 2016 Design Guide 11 - Floor Vibrations Due To Human Activity PDFDocument138 pages2nd Edition 2016 Design Guide 11 - Floor Vibrations Due To Human Activity PDFSigfridoLoges100% (5)

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Designers Guide To Eurocode 6 Design of Masonry Structures EN 1996 1 1 PDFDocument144 pagesDesigners Guide To Eurocode 6 Design of Masonry Structures EN 1996 1 1 PDFAtiq R RafiNo ratings yet

- NF P 18 710 UhpcDocument136 pagesNF P 18 710 UhpcKashif Naukhez100% (2)

- Fire Safety of Composites in Prefabricated Building (FRP)Document12 pagesFire Safety of Composites in Prefabricated Building (FRP)hafiz zain saeedNo ratings yet

- ASM ExtrusionDocument605 pagesASM ExtrusionGokhan Celikdag100% (2)

- The Technology of Cement IndustriesDocument42 pagesThe Technology of Cement Industriestesfayregs gebretsadik0% (1)

- Substation Design DataDocument23 pagesSubstation Design DataHugh cab100% (1)

- Alloy 6013 Tech Sheet 1Document4 pagesAlloy 6013 Tech Sheet 1IlyasNo ratings yet

- ALUMINIUM ALLOYS FOR EXTRUDED PROFILESDocument19 pagesALUMINIUM ALLOYS FOR EXTRUDED PROFILESDon JonesNo ratings yet

- DECADES OF DEDICATION TO THE NATIONDocument4 pagesDECADES OF DEDICATION TO THE NATIONTarun BhatiaNo ratings yet

- Physical and Piezoelectric Properties of APC Materials ChartDocument2 pagesPhysical and Piezoelectric Properties of APC Materials ChartTrương Anh DuyNo ratings yet

- Plasma HPR130Document4 pagesPlasma HPR130Imre VarnjuNo ratings yet

- Safe Reliable Powerful: Molded Case Circuit Breaker NZM - 1000 VACDocument6 pagesSafe Reliable Powerful: Molded Case Circuit Breaker NZM - 1000 VACAndy FarleyNo ratings yet

- Zetty Catalogue 121Document1 pageZetty Catalogue 121ramukolakiNo ratings yet

- Alloy 2319 welding data sheetDocument2 pagesAlloy 2319 welding data sheetSyam NathNo ratings yet

- Technical Information APP. 5 Field of Application:: 6 Bar/10 Bar /16 BarDocument2 pagesTechnical Information APP. 5 Field of Application:: 6 Bar/10 Bar /16 BarVignesh BharathiNo ratings yet

- Esab, Ok 309L (29.12.16)Document1 pageEsab, Ok 309L (29.12.16)RodrigoNo ratings yet

- Propiedades ZamakDocument5 pagesPropiedades ZamakMNNo ratings yet

- S690Document2 pagesS690corsini999No ratings yet

- Alloy 4047 Weld Data SheetDocument2 pagesAlloy 4047 Weld Data SheetMarcoAntonioNo ratings yet

- Technical Losses of Distribution Line (1.8.23)Document4 pagesTechnical Losses of Distribution Line (1.8.23)ASIF KHANNo ratings yet

- HSFG Bolts For Rdso DrawingsDocument5 pagesHSFG Bolts For Rdso DrawingschepurthiNo ratings yet

- Detroit Diesel 92 Service ManualDocument167 pagesDetroit Diesel 92 Service ManualVer Ghom100% (1)

- Technical Data For All PilgersDocument4 pagesTechnical Data For All PilgersTushar PachlangiaNo ratings yet

- Enerji Katalog enDocument406 pagesEnerji Katalog enllruNo ratings yet

- Technical Losses of Distribution Line (1.1.19)Document3 pagesTechnical Losses of Distribution Line (1.1.19)jiguparmar1516No ratings yet

- Technical Losses of Distribution Line (1.1.17)Document4 pagesTechnical Losses of Distribution Line (1.1.17)Vikas VikasNo ratings yet

- Features: Water WaterDocument1 pageFeatures: Water WaterajsdlkasjdklNo ratings yet

- Contactors and Contactor AssembliesDocument18 pagesContactors and Contactor AssemblieschochoroyNo ratings yet

- Anchor Bolt: S. No. Bolt Description Qty. AB Dia. (D) Verticle Length (H) Thread (T)Document31 pagesAnchor Bolt: S. No. Bolt Description Qty. AB Dia. (D) Verticle Length (H) Thread (T)Sudhanshu PalNo ratings yet

- TorqueDocument2 pagesTorquestaedtlerpNo ratings yet

- Models Indoor Unit Outdoor Unit Arg14Rlb Aog14RgaDocument18 pagesModels Indoor Unit Outdoor Unit Arg14Rlb Aog14Rgabigor2No ratings yet

- Material List 18.07.2017Document2 pagesMaterial List 18.07.2017virai hemanNo ratings yet

- Technical Information APP. 5 Field of Application:: 6 Bar/10 Bar /16 BarDocument2 pagesTechnical Information APP. 5 Field of Application:: 6 Bar/10 Bar /16 BarAshok SureshNo ratings yet

- Product Catalog AluminiuDocument32 pagesProduct Catalog AluminiusnoofsnoofNo ratings yet

- Fatigue Test (Project Report)Document15 pagesFatigue Test (Project Report)Ahmad Fraz0% (1)

- Three Phase Squirrel Cage Induction Motors: Maa Series 63 - 160 SIZESDocument6 pagesThree Phase Squirrel Cage Induction Motors: Maa Series 63 - 160 SIZESsugirinNo ratings yet

- Enclosed Switch CatalogueDocument28 pagesEnclosed Switch CatalogueSteveMateNo ratings yet

- Technical Losses of Distribution Line (1.1.17)Document3 pagesTechnical Losses of Distribution Line (1.1.17)ulul khanNo ratings yet

- Hot Rolled Sheets: LARSSEN (U) SectionsDocument1 pageHot Rolled Sheets: LARSSEN (U) SectionsdikhwanaNo ratings yet

- Strengths: Mixers - AeratorsDocument2 pagesStrengths: Mixers - AeratorsKashif MasudNo ratings yet

- TTM CatalogueDocument26 pagesTTM CatalogueMaksim100% (1)

- DESIGN OPTIMIZATIONDocument35 pagesDESIGN OPTIMIZATIONdasun1988No ratings yet

- Spheroidal GraphiteDocument1 pageSpheroidal GraphiteS.Mohana sundaramNo ratings yet

- Tunnel-13 Steel DetailsDocument10 pagesTunnel-13 Steel DetailsDeepak Lal DasNo ratings yet

- Gas Well Casing and Tubing Data PDFDocument2 pagesGas Well Casing and Tubing Data PDFAlexandru AndreiNo ratings yet

- Series 1060: Zetco Bronze Ball Valve F&F Lever HandleDocument2 pagesSeries 1060: Zetco Bronze Ball Valve F&F Lever HandleguslohNo ratings yet

- ISO 9001, ISO 14001: LG Low Voltage Air Circuit BreakersDocument24 pagesISO 9001, ISO 14001: LG Low Voltage Air Circuit BreakersDong BachNo ratings yet

- GeneralDocument39 pagesGeneralDeerendra KaranthNo ratings yet

- Dasco HvacDocument35 pagesDasco HvacrafaelNo ratings yet

- TurnbucklesDocument4 pagesTurnbucklesFunda TuranNo ratings yet

- Low-loss Power Splitters for Indoor and Outdoor UseDocument1 pageLow-loss Power Splitters for Indoor and Outdoor UseVíctor Romeu100% (1)

- Air GougingDocument4 pagesAir GougingJose Marie Rmgrocks BatoNo ratings yet

- A Study of The Grouped Arrangements of Stud Connectors On Shear StrengthDocument15 pagesA Study of The Grouped Arrangements of Stud Connectors On Shear Strengthfs jiNo ratings yet

- Bs 7835 11Kv LSZH Single Core Screened CableDocument2 pagesBs 7835 11Kv LSZH Single Core Screened CablefoaadahmadNo ratings yet

- Installation Manual for Midea Air Conditioner Models KFR-26GW/BP2DN1Y-PA402(A3), KFR-32GW/BP2DN1Y-PA402(A3), and KFR-35GW/BP2DN1Y-PA402(A3Document40 pagesInstallation Manual for Midea Air Conditioner Models KFR-26GW/BP2DN1Y-PA402(A3), KFR-32GW/BP2DN1Y-PA402(A3), and KFR-35GW/BP2DN1Y-PA402(A3mr.aikidoNo ratings yet

- SD II PDF - OCRDocument18 pagesSD II PDF - OCRSuraj KumarNo ratings yet

- IEI Mechanical Property Matrix For New WebsiteDocument4 pagesIEI Mechanical Property Matrix For New Websitejuan rodriguezNo ratings yet

- Katalog SCV A FC En06Document16 pagesKatalog SCV A FC En06twet wegwNo ratings yet

- WeldingDocument1 pageWeldingNNo ratings yet

- Original Spear Parts FMCDocument2 pagesOriginal Spear Parts FMCSardar PerdawoodNo ratings yet

- Welded Connections GuideDocument29 pagesWelded Connections GuideShaira CalderonNo ratings yet

- Technical - Spec SkirtDocument25 pagesTechnical - Spec SkirtStructures ProductionNo ratings yet

- Cosmos Alminium-Technical - Specifications PDFDocument2 pagesCosmos Alminium-Technical - Specifications PDFmindsopenNo ratings yet

- Type ESR: FeaturesDocument4 pagesType ESR: FeaturesHari Sita RukminiNo ratings yet

- 20230301-Gate CanopyDocument3 pages20230301-Gate CanopyAbdullah NajjarNo ratings yet

- Eurocode 2: Design of Concrete Structures: @seismicisolationDocument72 pagesEurocode 2: Design of Concrete Structures: @seismicisolationAbdullah NajjarNo ratings yet

- Foyer: Mezzanine Floor Ground FloorDocument1 pageFoyer: Mezzanine Floor Ground FloorAbdullah NajjarNo ratings yet

- BemoDocument17 pagesBemoAbdullah NajjarNo ratings yet

- 035 - C - SK - 024 Stair Details 01Document1 page035 - C - SK - 024 Stair Details 01Abdullah NajjarNo ratings yet

- Eurocode 2 Part 1,6 - DDENV 1992-1-6-1994Document24 pagesEurocode 2 Part 1,6 - DDENV 1992-1-6-1994Abdullah NajjarNo ratings yet

- Spider FaçadeDocument2 pagesSpider FaçadeAbdullah NajjarNo ratings yet

- DumlllJ Unlt-Lolld Method EumplesDocument1 pageDumlllJ Unlt-Lolld Method EumplesAbdullah NajjarNo ratings yet

- 5t Yk CraneDocument1 page5t Yk CraneAbdullah NajjarNo ratings yet

- VIBDocument2 pagesVIBAbdullah NajjarNo ratings yet

- IITK-GSDMA Wind Codes Project ReportDocument106 pagesIITK-GSDMA Wind Codes Project ReportFung MakNo ratings yet

- Hree-Mornant Equation For CBDocument1 pageHree-Mornant Equation For CBAbdullah NajjarNo ratings yet

- Statically Indeterminate Portal Frame by Force MethodDocument1 pageStatically Indeterminate Portal Frame by Force MethodAbdullah NajjarNo ratings yet

- Support Rotation& in A Simply Supported BeamDocument1 pageSupport Rotation& in A Simply Supported BeamAbdullah NajjarNo ratings yet

- Hole Diameters For Type C, D, F, and T ScrewsDocument1 pageHole Diameters For Type C, D, F, and T ScrewsAbdullah NajjarNo ratings yet

- Weld Fillers For Cast AlloysDocument1 pageWeld Fillers For Cast AlloysAbdullah NajjarNo ratings yet

- Appendix 4 Design For Fire ConditionsDocument1 pageAppendix 4 Design For Fire ConditionsAbdullah NajjarNo ratings yet

- Constants For S-N CurvesDocument1 pageConstants For S-N CurvesAbdullah NajjarNo ratings yet

- Stress Category Details for Fatigue DesignDocument1 pageStress Category Details for Fatigue DesignAbdullah NajjarNo ratings yet

- Hole Diameters For TypeDocument1 pageHole Diameters For TypeAbdullah NajjarNo ratings yet

- Appendix 1 Testing: 1.1 General ProvisionsDocument1 pageAppendix 1 Testing: 1.1 General ProvisionsAbdullah NajjarNo ratings yet

- Standard Specifications for Aluminum Alloys and Mechanical TestingDocument1 pageStandard Specifications for Aluminum Alloys and Mechanical TestingAbdullah NajjarNo ratings yet

- Appendix 3 Design For FatigueDocument1 pageAppendix 3 Design For FatigueAbdullah NajjarNo ratings yet

- ELASTIC BUCKLING STRESS Fe OF ELEMENTSDocument1 pageELASTIC BUCKLING STRESS Fe OF ELEMENTSAbdullah NajjarNo ratings yet

- TENSION COEFFICIENT KTDocument1 pageTENSION COEFFICIENT KTAbdullah NajjarNo ratings yet

- Design requirements for structural components subjected to fatigue and repeated loadingDocument1 pageDesign requirements for structural components subjected to fatigue and repeated loadingAbdullah NajjarNo ratings yet

- Excellent barrier and gloss properties of PTM polyester filmDocument1 pageExcellent barrier and gloss properties of PTM polyester filmHamdy AkkadNo ratings yet

- Amran Et Al. 2022 - 3D-Printable Alkali-Activated Concretes For Building Applications-A Critical ReviewDocument24 pagesAmran Et Al. 2022 - 3D-Printable Alkali-Activated Concretes For Building Applications-A Critical Review孟嫣然No ratings yet

- 09-Thai Cooling TowerDocument27 pages09-Thai Cooling TowerEnergy4You100% (1)

- Tekaflex Pu 40 For Use in ConstructionDocument2 pagesTekaflex Pu 40 For Use in ConstructionEzeval GráficaNo ratings yet

- Poly (Vinyl Chloride) Jacket For Wire and CableDocument2 pagesPoly (Vinyl Chloride) Jacket For Wire and Cableمحمد مقلدNo ratings yet

- Wonderwall: Technical LeafletDocument3 pagesWonderwall: Technical LeafletmegaNo ratings yet

- Bubble Cap Tray CatalogDocument12 pagesBubble Cap Tray Cataloghaonamtran2222002No ratings yet

- Cogon Fiber in Earth Brick As A Sustainable Building Material - ReportDocument74 pagesCogon Fiber in Earth Brick As A Sustainable Building Material - ReportLEKI DORJINo ratings yet

- Technical Data Sheet: Easicoat Professional Refinish SystemDocument24 pagesTechnical Data Sheet: Easicoat Professional Refinish System'Jeiami Verano CaramayNo ratings yet

- R-TEK Conveyor Belt Brochure: Heat, Flame, Oil Resistant Belting SolutionsDocument22 pagesR-TEK Conveyor Belt Brochure: Heat, Flame, Oil Resistant Belting Solutionsmilos dzinoNo ratings yet

- Au-Sn Lead Free Solders in ElectronicDocument12 pagesAu-Sn Lead Free Solders in ElectronicPanji PanjiNo ratings yet

- FlowcableDocument4 pagesFlowcableFrancois-No ratings yet

- Vehicle Tribology: Concept of WearDocument21 pagesVehicle Tribology: Concept of Wearjamesv52_743942786No ratings yet

- Crushed EPS in Light Weight ConcreteDocument4 pagesCrushed EPS in Light Weight ConcreteIdrus zlnNo ratings yet

- W3 - L8 - MRCS - Concrete Deterioration - 3 PDFDocument42 pagesW3 - L8 - MRCS - Concrete Deterioration - 3 PDFsrinivasanNo ratings yet

- Conplast SP440 SuperplasticizerDocument2 pagesConplast SP440 SuperplasticizerRanganath NagargojeNo ratings yet

- Fiber Consumption in Nonwovens1Document12 pagesFiber Consumption in Nonwovens1gowrikathirNo ratings yet

- Sunguard Climaguard AME Processing Guidelines 0922Document49 pagesSunguard Climaguard AME Processing Guidelines 0922MiroslavNo ratings yet

- BMSE D 22 02382 ReviewerDocument28 pagesBMSE D 22 02382 ReviewerHEMANTH KUMAR CNo ratings yet

- ASTM D 3105 99 Testing Elastomeric and Plastomeric Roofing and Waterproofing MaterialsDocument3 pagesASTM D 3105 99 Testing Elastomeric and Plastomeric Roofing and Waterproofing Materialsmario3312No ratings yet

- Modular Balcony Connectors Provide Thermal Break SolutionDocument2 pagesModular Balcony Connectors Provide Thermal Break SolutionCarolina CordeiroNo ratings yet

- Ean Arie Jibaou: Arielle Lapp - Ellen Pierce - Porsche JacksonDocument1 pageEan Arie Jibaou: Arielle Lapp - Ellen Pierce - Porsche JacksonPriyanka NNo ratings yet

- DDW Compact Air Handling Unit: Panduan InstallasiDocument23 pagesDDW Compact Air Handling Unit: Panduan InstallasiRidwan baritoNo ratings yet

- Pipe CalculationDocument10 pagesPipe CalculationTrishul Nath PallayNo ratings yet

- Bs6088-Aiipl 202203011546377064Document4 pagesBs6088-Aiipl 202203011546377064Vijendra KumarNo ratings yet

- Schedule of Minimum Test Requirements for Earthworks and Pavement ConstructionDocument23 pagesSchedule of Minimum Test Requirements for Earthworks and Pavement ConstructionApple CurimatmatNo ratings yet

- Prevent Grinding Burn DamageDocument55 pagesPrevent Grinding Burn DamagesubbuNo ratings yet