Professional Documents

Culture Documents

WLX526-modular Belt

Uploaded by

Dinos ArhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WLX526-modular Belt

Uploaded by

Dinos ArhCopyright:

Available Formats

Modular belt conveyor WL526X

Modular plastic belt conveyor WL526X

Contents

System information...........................................................123 Drive units – configuration strings ....................................132

Conveyor sections.............................................................124 End drive units ..................................................................133

Modular Belts - Introduction .............................................125 Idler end units – introduction ............................................134

Modular belts ....................................................................126 Idler units ..........................................................................134

Conveyor Beams - Introduction.........................................127 Plain Bends - Introduction.................................................135

Conveyor frame components ............................................129 Support System Modules - Introduction ...........................137

Slide rail ............................................................................130

End Drive Units - Introduction...........................................131

System information

PO

XLX

X85X

X180X

X300X

WL

222X

WL

System overview Technical specifications 273X

FlexLink's newly developed stainless steel conveyor is WL

designed to fit into demanding primary and secondary Maximum speed: 40 m/min 374X

packaging applications. It addresses important aspects Maximum conveyor length: 20 m

of today's packing processes, such as being easy to

Max single item weight: up to 30 kg WL

clean, smooth handling of products, safe for operators, 526X

robust design, long life, and easy to maintain with a low Total load on a conveyor: 300 kg

cost of ownership. Max product weight per

WL

The modularized and standardized design ensures fast belt pitch: 1,5 kg/slide rail 678X

set up, and facilitates rapid future extensions and Max permissible pull force

changes. (with bends): 1000 N CSX

Max permissible pull force

(without bends): 1200 N GRX

FSTX

TR

APX

IDX

© FlexLink 2017 System information 123

Conveyor sections

3 5

6

4

1 2

7

1. Idler end units 2. Conveyor beams 3. Plain bends

4. Support modules 5. Vertical bends 6. Modular belts

7. End drive units

The modular plastic belt conveyor in five widths – 222, 273, 374, 526 and 678 mm – can be built as straight sections

or in S, U or L-shape with 30, 45, 60, 90° (180° only for 222 and 273) horizontal bend, or combinations thereof.

Vertical bends are available in 5° (3° only for 222 and 273) positive or negative.

Kit for conveyor beam end,

always included in:

- End drive units

- Idler end units

- Plain bends

- Vertical bends

x4

x4

124 Conveyor sections © FlexLink 2017

Modular Belts - Introduction

Outer slide rail Belt

Slide rail

Upper cross bar

Belt guide

Lower cross bar

Modular belt, Radius flush grid, curve-running

The belt consists of plastic hinged links connected by

plastic rods. The wide belts are woven together by links

that are 102 mm, 124 mm, and 180 mm wide. The Technical characteristics

assembled belt forms a wide, flat, and tight conveyor sur- Belt width 456 mm

face. Five standard widths of belt can be delivered: 152

Modular belt weight (Acetal)

mm, 203 mm, 304 mm, 456 mm, and 608 mm. Radius flush grid (R2.2) 3,43 kg/m

Radius flush grid (R1.7) 3,85 kg/m

Standard belt color is white but blue belts can also be Flat top belt 3,22 kg/m

ordered. Modular belt height

Radius flush grid 13 mm

Belts with polyamide pins are available for dry or semi- Flat top belt 10 mm

wet applications. In constant wet applications, belts with PO

Belt pitch 25,4 mm

acetal pins must be used. This is due to the fact that pol-

Max. permissible belt tension without bends 1200N

yamide pins will absorb water and swell in wet applica- Max. permissible belt tension through a bend 1000N/750N* XLX

tions, and acetal pins will squeak in dry environments.

*belt R.17 (WLTP 1A304S, WLTP 1A304 BS, WLTP 1A304WS,

WLTP 1A304 WBS) X85X

Flat top belt, straight running Temperature range (Acetal) 1 °C to +40 °C

For other temper-

atures request for X180X

The belt has a minimal number of seams and has open quotation

hinges that are easy to clean. The belt is white and is

available with acetal pins for wet applications X300X

Travel direction of the belts: Tools and accessories WL

The belt should be pretensioned with a return slack of 222X

about 25 mm. Too much belt slack is a safety risk as the

belt can hang below the side of the conveyor beam. A belt WL

tensioner tool (5118803) is available in order to facilitate 273X

installation of the belt and minimize the amount of slack

in the return belt. WL

374X

Ordering information

WL

Radius flush grid Flat top belt The belt is delivered in assembled 1 m lengths. To calcu- 526X

late the total length required, remember to add for belt

consumed by the idler and drive units. WL

678X

CSX

GRX

FSTX

TR

APX

IDX

© FlexLink 2017 Modular Belts - Introduction 125

Modular belts

Radius flush grid belt (R2.2), Dry Flat top belt

Plain belt

Belt material Acetal (POM)

Pin material Polyamide (PA), Flat top belt

brown Belt material Acetal (POM)

Length 1 m Pin material Acetal (POM), white

456 mm wide, White WLTP 1A456 Length 1 m

456 mm wide, Blue WLTP 1A456 B 456 mm wide WLTP 1B456 W

Radius flush grid belt (R2.2), Wet Radius flush grid belt (R1.7), Dry

Plain belt Plain belt

Belt material Acetal (POM) Belt material Acetal (POM)

Pin material Acetal (POM), Pin material Polyamide (PA),

white brown

Length 1 m Length 1 m

456 mm wide, White WLTP 1A456 W 456 mm wide, White WLTP 1A456 S

456 mm wide, Blue WLTP 1A456 WB 456 mm wide, Blue WLTP 1A456 BS

Belt tensioner tool for radius flush grid

Belt tensioner tool 5118803

126 Modular belts © FlexLink 2017

Radius flush grid belt (R1.7), Wet

Plain belt

Belt material Acetal (POM)

Pin material Acetal (POM),

white

Length 1 m

456 mm wide, White WLTP 1A456 WS

456 mm wide, Blue WLTP 1A456 WBS

PO

XLX

X85X

X180X

X300X

WL

222X

WL

273X

WL

374X

WL

526X

WL

678X

CSX

GRX

FSTX

TR

APX

IDX

© FlexLink 2017 Modular belts 127

Conveyor Beams - Introduction

Components such as plain bends, etc., cannot be

placed too close to an End drive unit. Therefore, the min-

imum permissible length for conveyor beam sections

when connecting to an End drive unit is 844 mm. This

ensures a sufficient amount of return belt tension directly

after the drive sprocket to avoid slack close to the

sprocket wheel. The return belt hanging between the first

two belt guides provides this belt tension (called back

tension). For more information see WLX Engineering

guidelines.

Connecting brackets have to be ordered separately

when joining End drives, idler ends, conveyor beams, etc.

When joining two conveyor beams, a beam spacer kit

must be ordered separately.

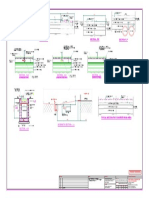

Conveyor frame structure

Conveyor dimensions

Frame profiles and cross bars

In order to facilitate cleaning, the top belt can be lifted up A

40

and the outer slide rails can be folded back. B

For hygiene reasons, the WLX system is based on an Top

easy-to-clean, free hanging return belt. of

belt

Elongation of the belt due to load is normally evenly

distributed on the return side and along the whole con-

veyor, and placement of the belt guides for the return belt

is critically important for proper conveyor system perfor-

mance. Conveyor beams can be ordered from 142 mm

up to 3000 mm and are always pre-engineered and con-

figured according to the rules that must be followed.

Conveyor beams are normally not symmetrical, which

is why they have an upstream and downstream end. An

arrow label on the conveyor beam side indicates the WL526X

appropriate top belt travel direction to ensure correct Conveyor width A 526 mm

assembly. Usable belt width B 456 mm

Top of belt:

WLTP 1A 52 mm

WLTP 1B 49 mm

128 Conveyor Beams - Introduction © FlexLink 2017

Technical specifications

Minimum permissible conveyor beam length to be con-

nected:

PO

XLX

X85X

In order to simplify the cleaning process FlexLink can X180X

offer belt lift arms for straight conveyors. Contact FlexLink

for more information. X300X

WLCBX 3A WL

Standard length 3000 mm 222X

6 mm space, easy to clean

47 85

WL

273X

25 25

WL

472 472

500 500 500 500 500 500 374X

3000

WL

526X

6 mm space, easy to clean

WL

678X

WLCBX LA

L = 1700 mm CSX

6 mm space, easy to clean Example

200

Top belt travel direction

GRX

FSTX

25 25

472

500 500 500 TR

(L - 6 = 1694)

L = 1700 APX

IDX

© FlexLink 2017 Conveyor Beams - Introduction 129

Conveyor frame components

Conveyor beam, Easy Clean Beam spacer Kit for WL526

x8 x4

Conveyor beam, WL526X

Length 3 m (3000 ±1,2 mm) WLCBX 3A526

Length to order (142- 2999 mm) WLCBX LA526

* Use online configurator when

ordering

Effective track length: 2,1 m

Weight, incl belt: 21 kg/m

Connecting bracket kit

Beam spacer kit WLCEX A526

56

Ø 10 mm

Recommended Torx tool for fasten spacer

85

Size T30

Torx Spacer

Connecting Bracket

For beam WLCJX 10X56

Including 4 pcs M10 screws

Beam support brackets

56

Ø 10 mm

85

85

Ø 10 mm

M10 x 2

85

85

A B C

Beam support bracket (A) WLCSX 10X56

Including 6 pcs M10 screws

Beam support bracket (B)

Including 2 pcs M10 screws and

2 pcs spacer WLRDX M10X25 WLCSX 10

Beam support bracket (C) WLCSX

Adjustable ±40° 10X56V40

130 Conveyor frame components © FlexLink 2017

Slide rail

Slide rail

A B

Slide rail, length 3 m

Slide rail (A) WLCRX 3

Outer slide rail (B) WLCRX 3 B

Connecting Strip

x4

x4

Connecting strip kit WLAHX 100

Must be ordered in multiples of 10 PO

XLX

Drill fixture for connecting strip

X85X

X180X

X300X

WL

222X

Contains drill fixtures for both 5118922

WLCRX 3 and WLCRX 3B WL

273X

WL

374X

WL

526X

WL

678X

CSX

GRX

FSTX

TR

APX

IDX

© FlexLink 2017 Slide rail 131

End Drive Units - Introduction

Technical specifications

Maximal speed................................... 40 m/min

Number of teeth on sprocket wheel ... 16

Belt tensioner unit

A belt tensioner unit should always be placed near the

End drive unit and its use is recommended:

- for long conveyors >20 meters

- for long conveyors >15 m and a speed of >30 m/min

- for conveyors with frequent starts/stops, especially if the

End drive unit load is high

- if an End drive unit needs to be placed close to a plain

End drive units bend

- if an End drive unit needs to be placed on the lower part

Size Direct drive, no slip next to a conveyor slope section

clutch

- for short conveyors where the belt slack length is insuf-

ficient to lift the belt for cleaning

Drive unit F, V

types

Drive unit types

A soft motor start is recommended for use with high-

speed and long conveyors. This is because these types

of modular belts are quite heavy, and the free hanging

return belt can begin to oscillate momentarily during

startup.

A grease nipple is included in all flange bearings. The

bearings are initially filled with FDA-approved, food-

grade grease (NSF H1).

Ordering information

End drive units including SEW motors IP 65, can be Drive units with motors must be specified using the web-

ordered with food-grade oil and stainless steel hollow based configurator. The configurator provides detailed

shafts in the web-based configurator. information and step-by-step guidance in the specifica-

tion process. A product code string is generated, contain-

Motor specifications ing the specification details. See next page for examples

of code strings.

Motors are available for 230/400 V, 50 Hz and 230/460 V

or 330/575 V, 60 Hz. All motors can be connected for Drive units without motors can be ordered using the des-

delta or star configuration by means of jumpers. ignations in the catalogue.

Variable speed motors are SEW Movimot, 380–500 V. • Connecting brackets have to be ordered separately.

Note that variable speed motors include a control box

that adds 93 mm to the width of the motor. • Slide rail must be ordered separately.

Dimension drawings in catalogue

Note that dimensions relating to drive unit motors depend

on the motor specified during the configuration. In most

cases, the motors shown in the catalogue drawings rep-

resent the largest size. If variable speed motors are used,

some dimensions may increase, indicated by dimension

values xxx (V: yyy). V represents the max dimension

using variable speed motor.

132 End Drive Units - Introduction © FlexLink 2017

Drive units – configuration strings

Below are two examples of text strings obtained from the

configurator with explanations.

Drive unit with fixed speed motor

Item no A B D E G H I

HNP - L - V4 - SA37 - 50/230 - 0,18kW - TF

Drive unit with variable speed motor

Item no A B D E F G J K

HPV - L - V6-15 SA37 - MM03 - 50/380-500 - C - P

Item no - Drive type I – Thermal protection

WLEBX: End drive No: No thermal protection

TF: Thermal protection type TF

TH: Thermal protection type TH

A – 0-Unit (position is omitted for variable speed motors)

HNP: Direct drive, no slip clutch

....V: Variable speed J – Hybrid cable

No: No hybrid cable

B – Motor position C: Hybrid cable included in SEW Movimot PO

L: Left (position is omitted for fixed speed motors)

XLX

R: Right

K – Fieldbus

X85X

D – Speed No: No fieldbus

V...: Fixed speed... m/min P: Profibus fieldbus, maintenance switch X180X

V... -...: Variable speed range...-... m/min D: DeviceNet fieldbus, maintenance switch

(position is omitted for fixed speed motors)

X300X

E – Gearbox

WL

SA37: SEW motor type SA37 222X

F – Movimot size WL

273X

MM03: SEW Movimot type, 0,37 kW

MM05: SEW Movimot type, 0,55 kW

MM07: SEW Movimot type, 0,75 kW WL

(position is omitted for fixed speed motors) 374X

WL

G – Electrical environment 526X

50/230: 50 Hz, 230 V

50/400: 50 Hz, 400 V WL

60/230: 60 Hz, 230 V 678X

60/460: 60 Hz, 460 V

60/575: 60 Hz, 575 V CSX

50/380-500: SEW Movimot variable speed motor

60/380-500: SEW Movimot variable speed motor GRX

H – Motor power FSTX

... kW: Motor power, kW

(position is omitted for variable speed motors TR

see position F)

APX

IDX

© FlexLink 2017 Drive units – configuration strings 133

End drive units

End drive unit Easy Clean, Radius flush grid 526 End drive unit S, Radius flush grid 526

212

347

71

804

End drive unit End drive unit

Fixed/variable speed* WLEBX A526 Fixed/variable speed* WLEBX A526 S

Without motor: Without motor:

Transmission on left side WLEBX0A526NLP Transmission on left side WLEBX0A526NLP S

Transmission on right side WLEBX0A526NRP Transmission on right side WLEBX0A526NRP S

* Use online configurator when ordering * Use online configurator when ordering

Effective track length: 0,8 m Effective track length: 0,75 m

Weight, incl belt: 20 kg Weight, incl belt: 19,2 kg

End drive unit Easy Clean, Flat top 526 End drive unit J, Radius flush grid 526

212

347

71

804

End drive unit

End drive unit Fixed/variable speed* WLEBX A526 J

Fixed/variable speed* WLEBX B526 Without motor:

Without motor: Transmission on left side WLEBX0A526NLPJ

Transmission on left side WLEBX0B526NLP Transmission on right side WLEBX0A526NRPJ

Transmission on right side WLEBX0B526NRP

* Use online configurator when ordering * Use online configurator when ordering

Effective track length: 0,80 m Effective track length: 0,75 m

Weight, incl belt: 20 kg Weight, incl belt: 33,0 kg

134 End drive units © FlexLink 2017

Belt tensioner unit

542

TOB

510

295

Belt tensioner for:

WL526X 5118890

Required extra belt length 0,55 m PO

Weight, incl belt: 19 kg

XLX

X85X

X180X

X300X

WL

222X

WL

273X

WL

374X

WL

526X

WL

678X

CSX

GRX

FSTX

TR

APX

IDX

© FlexLink 2017 End drive units 135

Idler end units – Introduction

Chain guidance at end of conveyor

The idler end unit is used to guide the chain from the

return side of the conveyor up to the top side with a min-

imum of friction. The chain is guided by two or more idler

wheels on a common, rotating shaft supported by ball

bearings.

Ordering information

• Connecting strips are included with the idler end

units.

• Slide rail must be ordered separately.

Idler end unit (generic picture)

Idler units

Idler end unit, WL526 Idler end unit, WL526 S

Idler end unit (For conveyors Idler end unit WLEJX 300A526 S

with plain bends) WLEJX 300A526

* Use online configurator when ordering

Idler en unit (Only for straight Effective track length: 0,75 m

conveyors) Weight, incl belt: 15,4 kg

WLEJX 300B526

* Use online configurator when ordering

Effective track length: 0,80 m

Weight, incl belt: 18 kg

136 Idler end units – Introduction © FlexLink 2017

Plain Bends - Introduction

When using radius flush grid belts in plain bends, the belt Plain bend, Easy Clean 45°

pull force will be concentrated on the outer part of the

belt. A certain straight section is needed before and after

the bend in order to transfer the load between the outer 450

belt section and evenly distribute it to the straight belt

section. This is critical before entering another plain

bend, end drive unit, etc. This required straight section is

always integrated in the plain bend itself (300 mm for

WL374X, 450 mm for WL526X, and 600 mm for

WL678X).

Plain bend placement, as for all other Flexlink conveyors,

should always be considered. A plain bend placed too far

downstream on a conveyor generates unnecessary belt

pull. Also, placement of a plain bend too close to an end

drive unit can lead to an unnecessary slack increase and R 1240

a separate slack unit must be added. Always use the

Flexlink calculation tool (FLCT) to calculate the resulting 45°

pull forces.

450

Plain bend, 45°±1°

R=1240±10 mm PO

WLBPX 45A526

* Use online configurator when XLX

ordering

Effective track length: 4,2 m

Weight, incl belt: 54 kg X85X

X180X

Plain bend, Easy Clean 30° Plain bend, Easy Clean 60°

X300X

450

450 WL

222X

WL

273X

WL

374X

R 1240

WL

R 1240 526X

30° 60°

WL

678X

450

450 CSX

GRX

Plain bend, 30°±1° Plain bend, 60°±1° FSTX

R=1240±10 mm WLBPX 30A526 R=1240±10 mm WLBPX 60A526

* Use online configurator when * Use online configurator when TR

ordering ordering

Effective track length: 3,4 m Effective track length: 4,9 m APX

Weight, incl belt: 46 kg Weight, incl belt: 64 kg

IDX

© FlexLink 2017 Plain Bends - Introduction 137

Plain Bends (continued)

Plain bend, Easy Clean 45° R1,7

Plain bend, Easy Clean 90°

450

R 1240

90°

450

Plain bend, 45°±1°

Plain bend, 90°±1°

R=1006±10 mm WLBPX 45A526 S

R=1240±10 mm WLBPX 90A526 * Use online configurator when ordering

* Use online configurator when ordering Effective track length: 3,38 m

Effective track length: 6,5 m Weight, incl belt: 49,3 kg

Weight, incl belt: 79 kg

Plain bend, Easy Clean 60° R1,7

Plain bend, Easy Clean 30° R1,7

Plain bend, 60°±1°

Plain bend, 30°±1°

R=1006±10 mm WLBPX 60A526 S

R=1006±10 mm WLBPX 30A526 S * Use online configurator when ordering

* Use online configurator when ordering Effective track length: 3,91 m

Effective track length: 2,85 m Weight, incl belt: 53,5 kg

Weight, incl belt: 45,1 kg

138 Plain Bends - Introduction © FlexLink 2017

Plain bend, Easy Clean 90° R1,7 Vertical bends

Vertical bend, Easy Clean, 5° (neg.)

5°

493 493

1065

Vertical bend 5°, neg WLBVX 5A526N

* Use online configurator

when ordering

Effective track length: 2,1 m

Weight, incl belt: 32 kg

Vertical bend, Easy Clean, 5° (pos.)

1080

Plain bend, 90°±1°

R=1006±10 mm WLBPX 90A526 S

* Use online configurator when ordering PO

5°

Effective track length: 4,96 m

Weight, incl belt: 67 kg XLX

541

Plain bend, Easy Clean 180° R1,7 541

X85X

Vertical bend 5°, pos WLBVX 5A526P

X180X

* Use online configurator

when ordering X300X

Effective track length: 2,1 m

Weight, incl belt: 32 kg WL

222X

WL

273X

WL

374X

WL

526X

WL

678X

CSX

Plain bend, 180°±2°

GRX

R=1006±10 mm WLBPX 180A526 S

* Use online configurator when ordering FSTX

Effective track length: 8,12 m

Weight, incl belt: 102,2 kg

TR

APX

IDX

© FlexLink 2017 Plain Bends - Introduction 139

Support System Modules - Introduction

Conveyor supports

Support modules must be specified using the web-based configurator. There, a product code string is generated that

contains the specification details (E.g., WLUFX S01-WL374X-900).

Support module, single leg Support module, type H

Connecting brackets

Top of belt

660 - 1500

Adjustable foot

± 33

Support module type H WLUFX S01

Support module type H, WLUFX S01

Parameter Option

Platform WL222X

Support module, single leg WLUFX S04 WL273X

WL374X

Support module, single leg WLUFX S04 WL526X

WL678X

Parameter Option

Top of belt: 660-1500 mm

Top of belt: 660-1500 mm

Foot type: XCFSX 16x80 H

Foot type: XCFSX 16x80 H

XCFSX 16x80 HA

XCFSX 16x80 HA

XCFSX 16x80

XCFSX 16x80

XCFSX 16x80 A

XCFSX 16x80 A

Bracket type: WLCSX 10X56

Bracket type: WLCSX 10X56

WLCSX 10

WLCSX 10

WLCSX 10X56V40

Foot holder for adjustable foot

Adjustable foot

46

M10 (x2) M16

37

Max

66

243 Min

85

Ø 15 mm

Ø 80

31

M16

Depth 100

Adjustable foot

M16 XCFSX 16x80

Foot holder M16, Anchoring XCFSX 16x80 A

XCFCX 16x100 M16, EHEDG/3A

Including 2 pcs M10 screws XCFSX 16x80 H

M16, EHEDG/3A, Anchoring XCFSX 16x80 HA

140 Support System Modules - Introduction © FlexLink 2017

PO

XLX

X85X

X180X

X300X

WL

222X

WL

273X

WL

374X

WL

526X

WL

678X

CSX

GRX

FSTX

TR

APX

IDX

© FlexLink 2017 Support System Modules - Introduction 141

142 Support System Modules - Introduction © FlexLink 2017

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- JLG 40 HA Partes PDFDocument318 pagesJLG 40 HA Partes PDFFranco Lichardi100% (1)

- Roland Service Manual Vs540iDocument296 pagesRoland Service Manual Vs540iJohn Swanson100% (1)

- Machine Design and Shop Practice Pre BoardDocument7 pagesMachine Design and Shop Practice Pre BoardFrankie NovelaNo ratings yet

- Compresor Ceccato CSC 50 ES3000 PDFDocument8 pagesCompresor Ceccato CSC 50 ES3000 PDFRenato García Espinosa67% (9)

- Stanley Number 5 and Up Plane Tote C 06 eDocument3 pagesStanley Number 5 and Up Plane Tote C 06 eArturo Isaak Gonzalez Palazuelos0% (1)

- Catalogo de Parte COP 2550 UX +Document112 pagesCatalogo de Parte COP 2550 UX +Alvaro Varas100% (2)

- 1232E Datasheet enDocument6 pages1232E Datasheet enASIFNo ratings yet

- 1232E Datasheet enDocument6 pages1232E Datasheet enASIFNo ratings yet

- Omron CJ1W-1189767 PDFDocument39 pagesOmron CJ1W-1189767 PDFJose Alvaro G.HNo ratings yet

- Dceff700Document80 pagesDceff700Dinos ArhNo ratings yet

- FP0R PLC Katalog PDFDocument20 pagesFP0R PLC Katalog PDFSantoso IbnutoroNo ratings yet

- Omron CJ1W-1189767 PDFDocument39 pagesOmron CJ1W-1189767 PDFJose Alvaro G.HNo ratings yet

- 201-Eng 1 1 26Document12 pages201-Eng 1 1 26Dinos ArhNo ratings yet

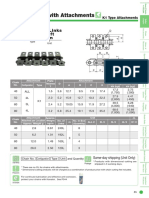

- Roller Chains With Attachments: 40-2L K1 240 Links 10ft 3mDocument1 pageRoller Chains With Attachments: 40-2L K1 240 Links 10ft 3mDinos ArhNo ratings yet

- WLX526-modular BeltDocument20 pagesWLX526-modular BeltDinos ArhNo ratings yet

- FP0R PLC Katalog PDFDocument20 pagesFP0R PLC Katalog PDFSantoso IbnutoroNo ratings yet

- FP0R PLC Katalog PDFDocument20 pagesFP0R PLC Katalog PDFSantoso IbnutoroNo ratings yet

- ST Series Servo Motor: Beijing KND CNC Technique Co.,Ltd. 01.2012Document21 pagesST Series Servo Motor: Beijing KND CNC Technique Co.,Ltd. 01.2012Dinos ArhNo ratings yet

- Compact 30mm air cylinder with internal threadDocument1 pageCompact 30mm air cylinder with internal threadDinos ArhNo ratings yet

- Roller Chains With Attachments: 40-2L K1 240 Links 10ft 3mDocument1 pageRoller Chains With Attachments: 40-2L K1 240 Links 10ft 3mDinos ArhNo ratings yet

- Roller Chains With Attachments: 40-2L A1 240 Links 10ft 3mDocument1 pageRoller Chains With Attachments: 40-2L A1 240 Links 10ft 3mDinos ArhNo ratings yet

- cpm1 Programming Manual PDFDocument541 pagescpm1 Programming Manual PDFDinos ArhNo ratings yet

- Roller Chains With Attachments: 40-2L A1 240 Links 10ft 3mDocument1 pageRoller Chains With Attachments: 40-2L A1 240 Links 10ft 3mDinos ArhNo ratings yet

- Roller Chains With Attachments: 40-2L K1 240 Links 10ft 3mDocument1 pageRoller Chains With Attachments: 40-2L K1 240 Links 10ft 3mDinos ArhNo ratings yet

- Roller Chains With Attachments: 40-2L K1 240 Links 10ft 3mDocument1 pageRoller Chains With Attachments: 40-2L K1 240 Links 10ft 3mDinos ArhNo ratings yet

- Roller Chains With Attachments: 40-2L A1 240 Links 10ft 3mDocument1 pageRoller Chains With Attachments: 40-2L A1 240 Links 10ft 3mDinos ArhNo ratings yet

- 8 Chapter 8 Fasteners, GasketsDocument16 pages8 Chapter 8 Fasteners, GasketsBo GyiNo ratings yet

- WP Presentation GB 301Document28 pagesWP Presentation GB 301김동옥No ratings yet

- Oxygen Manifold Validation and Verification DocumentDocument6 pagesOxygen Manifold Validation and Verification DocumentFlame StNo ratings yet

- New PL-TCM in Vietnam Optimized for Strip ProductionDocument10 pagesNew PL-TCM in Vietnam Optimized for Strip ProductionSANTOSH TIWARINo ratings yet

- ATR FCOM 1-16 Power PlantDocument44 pagesATR FCOM 1-16 Power PlantoscarNo ratings yet

- Afs Ball Valve Product CatalogDocument8 pagesAfs Ball Valve Product Catalogherysyam1980No ratings yet

- Instruction and Lubrication Manual For Dodge Chain CouplingsDocument2 pagesInstruction and Lubrication Manual For Dodge Chain Couplingsdave chaudhuryNo ratings yet

- Overhead Crane Pre Shift InspectionDocument1 pageOverhead Crane Pre Shift InspectionRafflesia GroupNo ratings yet

- Sma-2600-Ten-Sd-07a (R0) Layout With Finish Road Top Level & Pile Detail 10.05.2021Document1 pageSma-2600-Ten-Sd-07a (R0) Layout With Finish Road Top Level & Pile Detail 10.05.2021DIGITAL SIRNo ratings yet

- BalancingmanDocument9 pagesBalancingmanapi-697931486No ratings yet

- 2022.10.28 3 Phase Decanter CentrifugeDocument14 pages2022.10.28 3 Phase Decanter CentrifugeGeorgeNo ratings yet

- Installation and Operation Instruction: Flowcon Green 15-40 MM (1/2"-1 1/2")Document2 pagesInstallation and Operation Instruction: Flowcon Green 15-40 MM (1/2"-1 1/2")Gabriel Arriagada UsachNo ratings yet

- Francis Urbines Litostroj Power Product SheetDocument2 pagesFrancis Urbines Litostroj Power Product SheetНенад АритоновиќNo ratings yet

- Table 24 AH Flanged Tees (Clauses 9.1 and 11.1) All 1s 1538: 1993Document1 pageTable 24 AH Flanged Tees (Clauses 9.1 and 11.1) All 1s 1538: 1993Akshat JainNo ratings yet

- Chart Torques WGDocument2 pagesChart Torques WGebastien2No ratings yet

- Spring SpecificationDocument1 pageSpring SpecificationAbhijeetNo ratings yet

- HWO-Halliburton - Rig Up Procedure - 13.04.2023Document57 pagesHWO-Halliburton - Rig Up Procedure - 13.04.2023Mohamad Faizul KhoruddinNo ratings yet

- HpsebDocument25 pagesHpsebVimal SinghNo ratings yet

- en SMDocument102 pagesen SMhoangphuc28497No ratings yet

- Manual Controlli MVB56Document2 pagesManual Controlli MVB56dwNo ratings yet

- Goulds 3316 BulletinDocument12 pagesGoulds 3316 BulletinJesús DeveraNo ratings yet

- Model B, C, CHD Tubing Spider Cut SheetDocument2 pagesModel B, C, CHD Tubing Spider Cut SheetEdgar Moreira Fernandez100% (1)

- Nust Institute of Civil Engineering (Nice) Sector H-12, IslamabadDocument10 pagesNust Institute of Civil Engineering (Nice) Sector H-12, IslamabadAbdullah ShamshadNo ratings yet

- Eggbeater 1 Exploded View JAN22CDocument1 pageEggbeater 1 Exploded View JAN22CAlejandroz GonzalezNo ratings yet

- TheMastersCarpetorMasonryandBaalWorshipIdentical 10011492Document415 pagesTheMastersCarpetorMasonryandBaalWorshipIdentical 10011492Mustafa DedovićNo ratings yet