Professional Documents

Culture Documents

UL System CAJ1198

Uploaded by

vikaspisalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UL System CAJ1198

Uploaded by

vikaspisalCopyright:

Available Formats

Ì72CAJÇ+ÆÈADÇ+:(OÎ

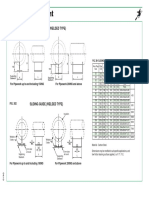

F Ratings - 2 and 3 Hr (See Items 2, 3D, 3E and 4B)

T Rating - 0 Hr

L Rating At Ambient - Less Than 1 CFM/Sq Ft

L Rating At 400F - Less Than 1 CFM/Sq Ft

W Rating - Class 1

1. Floor or Wall Assembly - Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400

kg/m3) concrete floor or min 5 in. (127 mm) thick reinforced lightweight or normal weight concrete wall. Wall may also be

constructed of any UL Classified Concrete Blocks*. Floor may also be constructed of any UL Classified hollow core Precast

Concrete Units*. Max diam of opening is 7 in. (178 mm) when floor is constructed of hollow-core precast concrete units.

Otherwise, max diam of opening is 26 in. (660 mm).

See Concrete Blocks (CAZT) and Precast Concrete Units (CFTV) categories in the Fire Resistance Directory for names of

manufacturers.

2. Steel Sleeve - (Optional, Not Shown) - Max 14 in. (356 mm) diam Schedule 10 (or heavier) steel pipe sleeve or max 14 in.

(356 mm) diam No. 26 ga (or heavier) sheet steel with square flange spot-welded to the sleeve near its midheight and sized to

be a min of 2 in. (51 mm) larger than the OD of the through penetrant. Sleeve cast or grouted into floor or wall flush with both

surfaces of floor or wall. When steel sleeve is used, F Rating of firestop system is 2 Hr.

3. Through Penetrant - One metallic pipe, conduit or tubing to be installed either concentrically or eccentrically within the firestop

system. The annular space between pipes, conduits or tubing and periphery of opening shall be min 0 in. ( 0 mm, point

contact) to max 2-1/4 in. (57 mm). Pipe, conduit or tubing to be rigidly supported on both sides of floor or wall assembly. The

following types and sizes of metallic pipes, conduits or tubing may be used:

A. Steel Pipe - Nom 24 in. (610 mm) diam (or smaller) Schedule 10 (or heavier) steel pipe. When steel sleeve is used, the

max pipe diam is 12 in. (305 mm).

B. Iron Pipe - Nom 24 in. (610 mm) diam (or smaller) cast or ductile iron pipe. When steel sleeve is used, the max pipe

diam is 12 in. (305 mm).

C. Conduit - Nom 4 in. (102 mm) diam (or smaller) steel electrical metallic tubing, nom 6 in. diam (or smaller) rigid steel

conduit or nom 1 in. diam (or smaller) flexible steel conduit.

D. Copper Tubing - Nom 6 in. (152 mm) diam (or smaller) Type L (or heavier) copper tubing. When max 6 in. (152 mm)

diam copper tubing is used, F Rating is 2 hr. When max 4 in. (102 mm) diam copper tubing is used, F Rating is 3 hr.

When steel sleeve is used, the max copper tubing diam is 4 in. (102 mm).

E. Copper Pipe - Nom 6 in. (152 mm) diam (or smaller) Regular (or heavier) copper pipe. When max 6 in. (152 mm) diam

copper pipe is used, F Rating is 2 hr. When max 4 in. (102 mm) diam copper pipe is used, F Rating is 3 hr. When

steel sleeve is used, the max copper pipe diam is 4 in. (102 mm).

Reproduced courtesy of Underwriters Laboratories, Inc.

Created or Revised: November 26, 2008 R

C-AJ-1198

(800)992-1180 (908)526-8000 FAX (908)231-8415 E-Mail:techserv@stifirestop.com Website:www.stifirestop.com PAGE 1 OF 2

4. Firestop System - The firestop system shall consist of the following:

A. Packing Material - Min 4 in. (102 mm) thickness of min 4 pcf (64 kg/m3) mineral wool batt insulation firmly packed into

opening as a permanent form. Packing material to be recessed from top surface of floor or from both surfaces of wall to

accommodate the required thickness of fill material. When floor is constructed of hollow-core precast concrete units

the packing material is to be flush with the bottom surface of the floor and extend through the thickness of the

floor except for the recess required at the top surface of the floor to accommodate the fill material.

B. Fill, Void or Cavity Material* - Sealant - Fill material applied within the annulus, flush with top surface of floor or with both

surfaces of wall. At the point contact location between penetrating item and concrete, a min 3/8 in. (10 mm) diam bead of fill

material shall be applied at the concrete/penetrating item interface on the top surface of floor and on both surfaces of wall.

When steel sleeve is used in concrete floor, a thin film of fill material shall be applied to cover edge of sleeve and to lap a

min of 1/2 in. onto concrete. A min 1/4 in. (6 mm) thickness of sealant is required in the annulus for the 2 hr F Rating.

A min 1/2 in. (13 mm) thickness of sealant is required in the annulus for the 3 hr F Rating.

SPECIFIED TECHNOLOGIES INC - Pensil 300 Sealant or SpecSeal Series SIL300 Sealant for floors or walls and Pensil

300 S/L Sealant or SpecSeal Series SIL300SL Sealant for floors only.

* Indicates such products shall bear the UL or cUL Certification Mark for jurisdictions employing the UL or cUL Certification

(such as Canada), respectively.

Reproduced courtesy of Underwriters Laboratories, Inc.

Created or Revised: November 26, 2008 R

C-AJ-1198

(800)992-1180 (908)526-8000 FAX (908)231-8415 E-Mail:techserv@stifirestop.com Website:www.stifirestop.com PAGE 2 OF 2

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 06the City Guilds Textbook Level 2 NVQ Diploma in Plumbing and Heating PDFDocument27 pages06the City Guilds Textbook Level 2 NVQ Diploma in Plumbing and Heating PDFSz Josef100% (1)

- List of Companies in PerungudiDocument7 pagesList of Companies in Perungudinsicfsrma bk100% (1)

- Honeywell Hbs Metro DMRC Case StudyDocument4 pagesHoneywell Hbs Metro DMRC Case StudyvikaspisalNo ratings yet

- Technology Challenges in Mobile PaymentDocument28 pagesTechnology Challenges in Mobile PaymentvikaspisalNo ratings yet

- UL 1709 V ISO Hydrocarbon FireDocument5 pagesUL 1709 V ISO Hydrocarbon FirevikaspisalNo ratings yet

- Max 6inch Non Metallic Pipe With LCI Sealant & Wrap StripsDocument3 pagesMax 6inch Non Metallic Pipe With LCI Sealant & Wrap StripsvikaspisalNo ratings yet

- Max 24 Inch Dia Insulated Pipe UL System With LCI Sealant OnlyDocument2 pagesMax 24 Inch Dia Insulated Pipe UL System With LCI Sealant OnlyvikaspisalNo ratings yet

- UL Case StudyDocument4 pagesUL Case StudyvikaspisalNo ratings yet

- Technical Data Sheet: Rockinsul RB SlabDocument1 pageTechnical Data Sheet: Rockinsul RB SlabvikaspisalNo ratings yet

- Firestop System Code DevelopmentDocument11 pagesFirestop System Code DevelopmentvikaspisalNo ratings yet

- Fire Incident at AMRI Hospital Kolkata PDFDocument5 pagesFire Incident at AMRI Hospital Kolkata PDFvikaspisalNo ratings yet

- Strss Management IDocument37 pagesStrss Management IvikaspisalNo ratings yet

- Preamble: Consult Club Industry Profiling-PetroleumDocument5 pagesPreamble: Consult Club Industry Profiling-PetroleumvikaspisalNo ratings yet

- Pipe ShoesDocument8 pagesPipe ShoeschabibNo ratings yet

- Bunny Chloe and Kitten Mi A New Version-1Document16 pagesBunny Chloe and Kitten Mi A New Version-1Nataly Rubilar100% (1)

- BA 03-01 Application Sulfide - Mercaptan UOP 163Document7 pagesBA 03-01 Application Sulfide - Mercaptan UOP 163Mr GhostNo ratings yet

- Varco Pruden BulidingsDocument12 pagesVarco Pruden BulidingspyrographicsNo ratings yet

- Sec. 9.2 Straightening: 72 AWWA D100-11Document10 pagesSec. 9.2 Straightening: 72 AWWA D100-11Ali RasnNo ratings yet

- MasterSeal 7000CR Test Report PDFDocument12 pagesMasterSeal 7000CR Test Report PDFbeck.26No ratings yet

- Brochure UCL ENG 2018Document12 pagesBrochure UCL ENG 2018ashumishra007No ratings yet

- TIH ListDocument5 pagesTIH ListDavid KahnNo ratings yet

- Combined Footing Design Based On ACI 318-02: Input DataDocument44 pagesCombined Footing Design Based On ACI 318-02: Input DataAlekh KatuwalNo ratings yet

- Mood Boards: Studio Unit Lobby & Reception AtriumDocument6 pagesMood Boards: Studio Unit Lobby & Reception AtriumTiara OyardoNo ratings yet

- Thermal Insulation Design-L-101 - Rev.01 PDFDocument65 pagesThermal Insulation Design-L-101 - Rev.01 PDFzulfikar bamneNo ratings yet

- ChemDocument34 pagesChemAaghash A SNo ratings yet

- Step by Step Log House ConstructionDocument62 pagesStep by Step Log House ConstructionSteve Peachey100% (3)

- Insulating Gloves - RegeltexDocument8 pagesInsulating Gloves - RegeltexricabralNo ratings yet

- Cover: Economy Box En-000-3545 (Replace "000" With Material Type. See Chart Below.) 8/23/2010Document1 pageCover: Economy Box En-000-3545 (Replace "000" With Material Type. See Chart Below.) 8/23/2010Justice KNo ratings yet

- Nickel Based ElectrodeDocument1 pageNickel Based Electrodewalter091011No ratings yet

- First Aid For Accident With HFC/HCFCDocument2 pagesFirst Aid For Accident With HFC/HCFCSrini VasanNo ratings yet

- 2nd Year NotesDocument8 pages2nd Year NotesHibba IsrarNo ratings yet

- Topic 8 NotesDocument32 pagesTopic 8 NoteswaleedNo ratings yet

- DEC CFBC Boiler ManualDocument104 pagesDEC CFBC Boiler Manualace-winnie100% (5)

- Class Test # 07: Physical ChemistryDocument4 pagesClass Test # 07: Physical ChemistryAryan AgarwalNo ratings yet

- FormworkDocument12 pagesFormworkalomartaylorNo ratings yet

- Becca SpecsDocument11 pagesBecca SpecsAlyanna Panganiban100% (1)

- Crochet Pattern: Leo - The Little DollDocument7 pagesCrochet Pattern: Leo - The Little DollMay Kyi100% (1)

- Deret TribolistrikDocument3 pagesDeret TribolistrikdaryekokuNo ratings yet

- Lecture 14 PDFDocument4 pagesLecture 14 PDFVikas Verma V. KumarNo ratings yet

- Production of Liquid Fuel From Plastic Waste Using Integrated Pyrolysis Method With Refinery Distillation Bubble Cap Plate Column-1Document9 pagesProduction of Liquid Fuel From Plastic Waste Using Integrated Pyrolysis Method With Refinery Distillation Bubble Cap Plate Column-1Bambang Sardi SardiNo ratings yet

- Electronegativity and Bond TriangleDocument9 pagesElectronegativity and Bond TrianglePedro BarónNo ratings yet