Professional Documents

Culture Documents

Wireless Data Communication ViaGPRS - 2

Uploaded by

Java DiamondOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wireless Data Communication ViaGPRS - 2

Uploaded by

Java DiamondCopyright:

Available Formats

1 Automation Task

1 Automation Task

1.1 Application environment

In this configuration example the functions and features are explained using the

application example of a waste water treatment plant.

A continuous filling level measurement takes place in the inspection shaft.

Furthermore, the status of pump P1 installed in the inspection shaft is detected.

This information shall be sent in defined time intervals (send cycle) and be

visualized in the central station. The central station must be a decentralized PC

connected to the INTERNET.

Apart from visualization an option of archiving with date and time stamp must be

realized.

The state of pump P1 and the send cycle of the remote station shall be controlled

via the user interface of the central station.

Figure 1-1

Inspection Shaft

Remote Station 256

Remote Station 2

Copyright ¤ Siemens AG 2011 All rights reserved

GPR

Remote Station 1

GP

S

RS

P1

GPRS

Central Station

WinCC

flexible *1

*1

*2

*2 CSV SINAU

file Micro T

SC

Real-time stamp Value 1 Wert 2

22.02.2010 15:10:00 123 456 DSL

22.02.2010 15:09:00 789 193

... ... ... *1) Actual value visualization

*2) Archiving

The following requirements apply for archiving the filling level or pump status in a

csv.-file in the central station.

Table 1-1

No. Function

1. The system time of the remote station must be synchronized using the central

station, where the central station gives the system time.

2. In normal mode (GPRS connection active) the process values with the local

system time of the remote station shall be acquired and sent to the central

station. These system times must be adopted in the archive file.

3. In buffer mode (GPRS connection cancelled) the process values with the local

system time shall be filed non-volatile in the controller. After restoring the GPRS

connection, the process values + historic system time stamps shall be sent to

the central station in correct sequence.

S7-1200 and GPRS

6 V1.1, Entry ID: 39863979

1 Automation Task

1.2 Product-related environment

Remote Station

A GSM/GPRS modem SINAUT MD720-3 (4) shall be coupled with a SIMATIC S7-

1200 controller (3) using a RS232 communication module (2). A SINAUT ST7

connecting cable (7) is used for the connection.

In SINAUT MD720-3 a SIM card (6) has been inserted and a quadband antennae

ANT 794-4MR (5) is used for signal reception.

The power supply of all components is provided via a SIMATIC PM1207 Power

module (1).

Figure 1-2

Line protection switch

L1

N

PE

DC24V+

DC24V-

5

Copyright ¤ Siemens AG 2011 All rights reserved

1 2 3 4 6

7

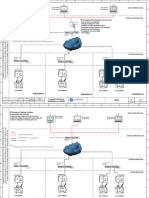

Central station

The central station consists of a SIMATIC MicroBox 427B (2). The software

components SINAUT Micro SC (3) and the visualization system WCC flexible (4)

have been installed on the MicroBox.

The power supply is provided via a SIMATIC PM1207 Power module (1).

The MicroBox is connected to the internet via a router (5).

Figure 1-3

Line protection switch

L1

N

PE

DC24V+

DC24V-

WinCC

flexible 4

SINAU

Micro T

SC 3

1 2

S7-1200 and GPRS

V1.1, Entry ID: 39863979 7

2 Automation Solution

2 Automation Solution

Please also note the documents listed in Table 6-1.

2.1 Transferring process values between the stations

Functions implemented in the application example

x Cyclic process data transfer from remote station to central station (2.1.1)

x Central station updates date through manual trigger (2.1.3)

2.1.1 Remote station sends process data to central station, trigger: S7-1200

controller

The remote station actively sends process data to the central station. The trigger

for this action occurs event-controlled or cyclical through the user program.

Figure 2-1

Central Station

OPC-Server OPC-Client

SINAUT MICRO SC WinCC

oder

WinCC flexible

Copyright ¤ Siemens AG 2011 All rights reserved

Remote Station

send

Trigger

2.1.2 The central station fetches data from the remote station, trigger:

SINAUT Micro SC

The central station actively fetches process data from the remote station using the

SINAUT Micro SC software. This action is triggered cyclically.

Figure 2-2

Central Station

OPC Server OPC Client

SINAUT MICRO SC WinCC

Properties – RS001

or

RS001 WinCC flexible

1

fetch modem1

secret1

Remote Station

15 Minutes

Kommentare

Trigger

In the example on hand all tags created in the OPC client are updated every 15

minutes. At the same time the connection status of S7-1200 controller and MD720-

3 modem is reevaluated.

This mechanism works since the OPC server SINAUT Micro SC automatically

creates an OPC item for each tag created in the OPC client. Therefore the current

tag management is always known to SINAUT Micro SC and the tag update can be

performed.

S7-1200 and GPRS

8 V1.1, Entry ID: 39863979

2 Automation Solution

2.1.3 Central station fetches data from the remote station, trigger: OPC

client

The central station actively fetches process data from the remote station using the

OPC client. The trigger of this action is the operator of the visualization software or

a script. The script or the operator (using a configured interface) set a system-

generated BOOL-type tag. Process data are fetched from the remote station

analog to the process described in chapter 2.1.2.

Figure 2-3

Central Station

OPC Server OPC Client

SINAUT MICRO SC WinCC

or

WinCC flexible

fetch MSC:[RS001]GPRSConnected

MSC:[RS001]PLCConnected

Remote Station MSC:[RS001]BytesReceived

MSC:[RS001]BytesTransmitted

MSC:[RS001]RefreshValues

.

.

.

.

Trigger

Copyright ¤ Siemens AG 2011 All rights reserved

2.1.4 Remote station sends data to remote station, trigger: S7-1200

The remote station actively sends process data to another remote station. The

trigger for this action occurs event-controlled or cyclical through the user program.

The sent frames are first transferred to the central station and there forwarded to

the respective remote station. There is no tag update in the OPC client.

Figure 2-4

Remote Station 1 Central Station

OPC Server OPC Client

fetch SINAUT MICRO SC WinCC

or

WinCC flexible

Trigger

Remote Station n

Note This functionality has not been realized in the example on hand.

S7-1200 and GPRS

V1.1, Entry ID: 39863979 9

2 Automation Solution

2.1.5 Remote station fetches data from a remote station, trigger: S7-1200

The remote station actively fetches process data from another remote station. The

trigger for this action occurs event-controlled or cyclical through the user program.

The sent frames are first transferred to the central station and there they are

forwarded to the respective remote station. The response frame with the process

data is returned to the remote station in the same way. There is no tag update in

the OPC client.

Figure 2-5

Remote Station 1 Central Station

OPC Server OPC Client

SINAUT MICRO SC WinCC

or

WinCC flexible

fetch

Trigger

Remote Station n

Copyright ¤ Siemens AG 2011 All rights reserved

Note This functionality has not been realized in the example on hand.

2.1.6 Comparison of trigger mechanisms

Table 2-1

No. Trigger Pros/cons and application cases

1. S7-1200 x Various send cycles can be implemented

controller x Prioritized sending of frames (e.g. for alarm messages)

x Buffering of process data

x Sending of subsets possible

x Full flexibility

x Highest workload compared with other trigger mechanisms

2. SINAUT x Most simple implementation of all trigger mechanisms

Micro SC x No programming necessary

x Updating of subsets of the configured process values is not

possible (everything will always be updated)

3. OPC x Manual trigger for value update (for configured button in the

client visualization software)

x Script-based update (as far as the visualization software supports

script languages)

x Value update upon request through higher-level process

connection

x Updating of subsets of the configured process values is not

possible (everything will always be updated)

S7-1200 and GPRS

10 V1.1, Entry ID: 39863979

You might also like

- Wireless Data Communication Vias71200 - 002Document6 pagesWireless Data Communication Vias71200 - 002Java DiamondNo ratings yet

- Training CourseDocument376 pagesTraining CourseHuynh DuongNo ratings yet

- 1 - SSDACPart E GGTronicsDocument16 pages1 - SSDACPart E GGTronicsaditya_vyas_13No ratings yet

- Analog Output Option: IQ Plus 355 Digital Weight IndicatorDocument6 pagesAnalog Output Option: IQ Plus 355 Digital Weight IndicatorJairo Gabriel Ramón RomeroNo ratings yet

- Wireless Data Communication Vias71200 - 003Document7 pagesWireless Data Communication Vias71200 - 003Java DiamondNo ratings yet

- Wireless Data Communication ViaS71200 - 3Document5 pagesWireless Data Communication ViaS71200 - 3Java DiamondNo ratings yet

- Configuration Overview: Simatic Pcs 7Document8 pagesConfiguration Overview: Simatic Pcs 7Phét Hay PhétNo ratings yet

- SM GP 90 PDFDocument32 pagesSM GP 90 PDFyoppiNo ratings yet

- 57-61 SA056 - 72dpiDocument5 pages57-61 SA056 - 72dpiWellington MendonçaNo ratings yet

- 1.1 Switch Status (Transmitted) : Auxiliary Input / Output Status 1Document4 pages1.1 Switch Status (Transmitted) : Auxiliary Input / Output Status 1ass manNo ratings yet

- HP Compal La-4732p Uma - Rev 1.0Document46 pagesHP Compal La-4732p Uma - Rev 1.0Nanang FathurrohimNo ratings yet

- La-6121p Ncl50 Uma Rev1.0Document46 pagesLa-6121p Ncl50 Uma Rev1.0yeneider barlizaNo ratings yet

- BA Frequency Inverters 9300 Vector v3-1 enDocument185 pagesBA Frequency Inverters 9300 Vector v3-1 enKS LaiNo ratings yet

- CSCS System-Config EDC HQ Tony 20190613Document6 pagesCSCS System-Config EDC HQ Tony 20190613Łukasz KrzesińskiNo ratings yet

- Sisteme Informatice În Energetică: Ș.L.DR - Ing. Nicoleta Arghira Prof - Dr.ing. Sergiu Stelian IliescuDocument31 pagesSisteme Informatice În Energetică: Ș.L.DR - Ing. Nicoleta Arghira Prof - Dr.ing. Sergiu Stelian Iliescudoctornegrila100% (1)

- GLS Platform OverviewDocument27 pagesGLS Platform OverviewkentmultanNo ratings yet

- Vsat DesignDocument1 pageVsat DesignpamplaNo ratings yet

- LTE System InterfacesDocument66 pagesLTE System Interfaceskoreta fouatsaNo ratings yet

- DrotekDoc - 0891B08A - DP0601 GNSS RTK (F9P) PDFDocument15 pagesDrotekDoc - 0891B08A - DP0601 GNSS RTK (F9P) PDFMihai TudoseNo ratings yet

- IPASOLINK VR10 SpecificationsDocument32 pagesIPASOLINK VR10 SpecificationsWisam Hassan100% (1)

- Trans-Auto Eng Short v15Document28 pagesTrans-Auto Eng Short v15asif MehmoodNo ratings yet

- Ipaso vr4 06 GGS-000396-09E specifications-SS1901Document32 pagesIpaso vr4 06 GGS-000396-09E specifications-SS1901jvidalcmx-1No ratings yet

- Approach Warning To Midsection Interlocked LC GatesDocument2 pagesApproach Warning To Midsection Interlocked LC GatesShashankRaghavNo ratings yet

- TCAN Evaluation Module (Rev. A)Document16 pagesTCAN Evaluation Module (Rev. A)Ecus ElectronicsNo ratings yet

- Gs50a01a11-01en 002Document9 pagesGs50a01a11-01en 002Dhirender DagarNo ratings yet

- LTE Basics Day1Document14 pagesLTE Basics Day1samuel omoworareNo ratings yet

- Universal Temperature Converter KFD2-UT2-2: FunctionDocument4 pagesUniversal Temperature Converter KFD2-UT2-2: FunctionAlamsyah SyamsuddinNo ratings yet

- LTE IP TroubleshootingDocument35 pagesLTE IP TroubleshootingbobphotographyNo ratings yet

- Introduction MME FNS: Dieter SchneiderDocument5 pagesIntroduction MME FNS: Dieter SchneiderponadamajhiNo ratings yet

- LA-5811P Dell AlienwareDocument59 pagesLA-5811P Dell AlienwaregkyankielNo ratings yet

- Lso Lan PDFDocument1 pageLso Lan PDFLê HiếuNo ratings yet

- Comunicación RIODocument6 pagesComunicación RIOmaniatico25No ratings yet

- NR Architecture & Protocol: June, 2020Document39 pagesNR Architecture & Protocol: June, 2020raj1978enatorNo ratings yet

- DWWebinar Session2Document20 pagesDWWebinar Session2Getachew MekonnenNo ratings yet

- Authorized Licensed Use Limited To: IEEE Xplore. Downloaded On October 23,2023 at 15:25:49 UTC From IEEE Xplore. Restrictions ApplyDocument9 pagesAuthorized Licensed Use Limited To: IEEE Xplore. Downloaded On October 23,2023 at 15:25:49 UTC From IEEE Xplore. Restrictions ApplyAsmir JahićNo ratings yet

- TPItL10 ARDETEM EN PDFDocument37 pagesTPItL10 ARDETEM EN PDFJose Yamid Jojoa GomezNo ratings yet

- Tosvert Vf-S15 Parameter ListDocument47 pagesTosvert Vf-S15 Parameter ListΑντώνης ΣπυρόπουλοςNo ratings yet

- CAP581 enDocument424 pagesCAP581 enBata ZivanovicNo ratings yet

- SMPInstallation ListsDocument80 pagesSMPInstallation ListsvaldoNo ratings yet

- 03 - PLC Manual v1 - 2 - Siemens - enDocument15 pages03 - PLC Manual v1 - 2 - Siemens - enQuốc ViệtNo ratings yet

- DP Event 02.22Document12 pagesDP Event 02.22GabrielNo ratings yet

- Merging Unit and Process Bus Solution: Unrestricted © Siemens 2020Document51 pagesMerging Unit and Process Bus Solution: Unrestricted © Siemens 2020Oscar Pulido SuarezNo ratings yet

- Topology: Created by NRU Untuk Pelanggan Merapi Utama PharmaDocument10 pagesTopology: Created by NRU Untuk Pelanggan Merapi Utama PharmaArham Sofyan PLINo ratings yet

- TPS A9pDocument16 pagesTPS A9pMaxwell MateyoNo ratings yet

- Public 1541807902 Chapter-14b-Io-LinkDocument19 pagesPublic 1541807902 Chapter-14b-Io-LinkFoaad HawarNo ratings yet

- D117/D118 Point To Point Diagram: Controller BoardDocument9 pagesD117/D118 Point To Point Diagram: Controller BoardOcean PrintNo ratings yet

- Hoja de Especificacion de Liebert SiteLink 12Document5 pagesHoja de Especificacion de Liebert SiteLink 12slifer250987No ratings yet

- DGA900 Architecture HEDNODocument2 pagesDGA900 Architecture HEDNOsafafgsgNo ratings yet

- Section 2: 2-1 General Description PE/TRD/CN/0303 12.02/EN March, 2000Document6 pagesSection 2: 2-1 General Description PE/TRD/CN/0303 12.02/EN March, 2000hungpm2013No ratings yet

- FSP 150CC-825 Quick Start Guide R2Document30 pagesFSP 150CC-825 Quick Start Guide R2pbartlett1977No ratings yet

- LTE Fundamentals: Mihir Kumar Dash Ericsson 2020-09-09Document31 pagesLTE Fundamentals: Mihir Kumar Dash Ericsson 2020-09-09Mihir DashNo ratings yet

- 2103 X Band 10kw DiagramDocument1 page2103 X Band 10kw DiagramZafar YabNo ratings yet

- Trinamic Tmc4361a LaDocument230 pagesTrinamic Tmc4361a LaLeoWangNo ratings yet

- ePACII - Quick Start ManualDocument10 pagesePACII - Quick Start ManualSergey ZaytsevNo ratings yet

- 2-Hw Descr OMSN R4.3-5Document100 pages2-Hw Descr OMSN R4.3-5znesroNo ratings yet

- S01M07ed2 Monitoring FunctionsDocument16 pagesS01M07ed2 Monitoring FunctionsOtto KampbeltNo ratings yet

- ENGEL CC100 Technical 40t PDFDocument219 pagesENGEL CC100 Technical 40t PDFAdr100% (2)

- 11.4.6 Packet Tracer - Implement A Local SPANDocument3 pages11.4.6 Packet Tracer - Implement A Local SPANManuel SeclenNo ratings yet

- SCADA ConfigurationDocument1 pageSCADA ConfigurationDhammikeNo ratings yet

- Wireless Data Communication Vias71200 - 005Document9 pagesWireless Data Communication Vias71200 - 005Java DiamondNo ratings yet

- Wireless Data Communication ViaS71200 - 1Document5 pagesWireless Data Communication ViaS71200 - 1Java DiamondNo ratings yet

- Wireless Data Communication ViaS71200 - 3Document5 pagesWireless Data Communication ViaS71200 - 3Java DiamondNo ratings yet

- Wireless Data Communication ViaGPRS - 5Document8 pagesWireless Data Communication ViaGPRS - 5Java DiamondNo ratings yet

- Wireless Data Communication ViaGPRS - 1Document5 pagesWireless Data Communication ViaGPRS - 1Java DiamondNo ratings yet

- Wireless Data Communication ViaGPRS - 01Document5 pagesWireless Data Communication ViaGPRS - 01Java DiamondNo ratings yet

- Assessment Submission Sheet: Australian Ideal CollegeDocument18 pagesAssessment Submission Sheet: Australian Ideal CollegeBishal GaneshNo ratings yet

- Introducing - A - Rasch-Type - Anthropomorphism - Scale RujitenDocument3 pagesIntroducing - A - Rasch-Type - Anthropomorphism - Scale RujitenНемања КиџинNo ratings yet

- Present Scenario of Social Media and Its Implication On StudentsDocument5 pagesPresent Scenario of Social Media and Its Implication On Studentsvinay kumarNo ratings yet

- HRM-380-2-final Data Analysis report-Group-ADocument40 pagesHRM-380-2-final Data Analysis report-Group-ATabassum Mostazir 1811750630No ratings yet

- L3H CAS - PresoDocument140 pagesL3H CAS - PresoPablo RestrepoNo ratings yet

- SC Unit IIDocument64 pagesSC Unit IIpawarpravin06No ratings yet

- 19ECS448P Secure Software Engineering - Lab ManualDocument26 pages19ECS448P Secure Software Engineering - Lab ManualGowthamiNo ratings yet

- Napa 1069 Oil FilterDocument1 pageNapa 1069 Oil Filterkman548No ratings yet

- Battery Thermal Runaway Testing MethodsDocument15 pagesBattery Thermal Runaway Testing Methodsodemircioglu2No ratings yet

- DCC ProgrammingDocument238 pagesDCC ProgrammingEmad MulqiNo ratings yet

- B1 Module 1 Lesson 2Document6 pagesB1 Module 1 Lesson 2Dionis DagumanNo ratings yet

- AgreementDocument7 pagesAgreementVOJE DIFNo ratings yet

- Spesifikasi: UOM Kekerapan / Unit Ukuran Bil. Unit Ukuran Sehari Bil. Unit Ukuran Sebulan KuantitiDocument4 pagesSpesifikasi: UOM Kekerapan / Unit Ukuran Bil. Unit Ukuran Sehari Bil. Unit Ukuran Sebulan Kuantitifarracie frederickNo ratings yet

- GeneratorDocument17 pagesGeneratorsanjay sharmaNo ratings yet

- Sdc-415 Series: Instruction ManualDocument21 pagesSdc-415 Series: Instruction ManualBruno OliveiraNo ratings yet

- Number and Operations in Base Ten: Place Value, Greater Than, Less Than, Equal To, Compare, RoundDocument26 pagesNumber and Operations in Base Ten: Place Value, Greater Than, Less Than, Equal To, Compare, RoundMultivirtual Call CentersNo ratings yet

- Curriculum SAP GRC Risk Management - Consultant TrainingDocument2 pagesCurriculum SAP GRC Risk Management - Consultant TraininglawalNo ratings yet

- BATCH 36 4th Week SCHEDULE (9702)Document1 pageBATCH 36 4th Week SCHEDULE (9702)TOSHIKA SONINo ratings yet

- L-Series Position Controller Rohs Compliant: Product Manual 35154 (Revision - , 07/2019)Document74 pagesL-Series Position Controller Rohs Compliant: Product Manual 35154 (Revision - , 07/2019)CH MUBASHER MAQSOOD ALAMNo ratings yet

- ATB Series Integral Throttle Body Actuators: NomenclatureDocument5 pagesATB Series Integral Throttle Body Actuators: NomenclatureMaxiSanchezNo ratings yet

- Electrical Bushing Adapter - Product Picture From Yueqing Yingdete Electric Co., LTDDocument2 pagesElectrical Bushing Adapter - Product Picture From Yueqing Yingdete Electric Co., LTDĐoàn Ngọc ĐạiNo ratings yet

- Prospectus of Black Fragrance SchoolDocument17 pagesProspectus of Black Fragrance SchoolEmmakapoNo ratings yet

- Coa SyllabusDocument11 pagesCoa SyllabusSaravana VelNo ratings yet

- Note Analyzer User GuideDocument26 pagesNote Analyzer User GuideVictor AdrianNo ratings yet

- FPGA Workshop User Manual Ver2Document78 pagesFPGA Workshop User Manual Ver2jack_zia5073No ratings yet

- 1oracle SCM Cloud (Purchasing, Order Management)Document340 pages1oracle SCM Cloud (Purchasing, Order Management)AhmedNo ratings yet

- Honeywell VisionPro 8000 Install InstructionsDocument12 pagesHoneywell VisionPro 8000 Install InstructionskoolermanNo ratings yet

- 23-24 AP PC Q3 # 2 PSET STUDENT Due Mar 7,8Document14 pages23-24 AP PC Q3 # 2 PSET STUDENT Due Mar 7,8reemfallaha08No ratings yet

- ENM232-6VIA - With Encore Electronics 5.1 Channel PCI Sound CardDocument2 pagesENM232-6VIA - With Encore Electronics 5.1 Channel PCI Sound CardmarcojaoNo ratings yet

- JAP234 Handout 2Document4 pagesJAP234 Handout 2studentNo ratings yet