Professional Documents

Culture Documents

TEC Extended I/O Controller: Control Applications Product Description Product Numbers Accessories

Uploaded by

Erasmo Franco SOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TEC Extended I/O Controller: Control Applications Product Description Product Numbers Accessories

Uploaded by

Erasmo Franco SCopyright:

Available Formats

Installation Instructions

Document No. 540-1028

November 15, 2012

TEC Extended I/O Controller

Generic Controller I/O Layout. See Wiring Diagram for application specific details.

damage to the printed circuit board

Control Applications from electrostatic discharge.

2497

Accessories

Product Description

Low cost temporary temperature 540-658P25

These instructions explain how to field install or sensor, 10K thermistor with RJ11,

replace a Siemens TEC Extended I/O Controller. that enables space control if the

permanent room or duct sensor is

not installed (pack of 25).

Product Numbers Duct Temperature Sensor, NTC QAM1035.008P50

100K Type 2, 3" Probe for

Siemens TEC Extended I/O Controller 540-863JN Commissioning Only

Shipping carton includes a controller assembly, a Warning/Caution Notation

mounting rail, and two self-tapping/drilling screws.

WARNING

CAUTION

Personal injury/loss of life may

Keep the unit in its static-proof bag occur if you do not follow the

until installation. procedures as specified.

Otherwise you run the risk of

Item No. 540-1028. Rev. CA Page 1 of 4

Document No. 540-1028

Installation Instructions

November 15, 2012

CAUTION NOTE:

If the controller is being installed on a

Equipment damage or loss of data box with 1 or more stages of electric

may occur if you do not follow the heat, the 550-809 MOV with pre-

procedures as specified. terminated spade connectors must be

installed across the manufacturer-

supplied airflow switch. MOVs can be

Expected Installation Time installed at the time the controller is

factory mounted; coordinate with the

New controller installation 10 Minutes box manufacturer prior to order

placement. For field installation, see

Replacement (old controller has 6 Minutes Metal Oxide Varistor Kit Installation

removable terminal blocks) Instructions (540-986).

Replacement (old controller does not 16 Minutes

have removable terminal blocks)

Installation Instructions

NOTE:

NOTE:

All wiring must conform to national and

You may require additional time for

local codes and regulations (NEC, CE,

database work at the field panel.

etc.).

Required Tools and Materials 1. Secure the mounting rail in the controller’s

desired location.

Small flat-blade screwdriver (1/8-inch blade

width) 2. Place the ESD wrist strap on your wrist and

Cabling and connectors attach it to a good earth ground.

Cordless drill/driver set 3. Remove the controller from the static proof bag

and snap it into place on the mounting rail.

Prerequisites 4. Connect the FLN.

Wiring conforms to NEC and local codes and

regulations. For further information see the

Wiring Guidelines Manual.

Room temperature sensor installed (optional).

24 Vac Class 2 power available.

Supply power to the unit is OFF.

Any application specific hardware or devices

installed.

5. Connect the point wiring (see Wiring Diagrams).

6. Plug the room temperature sensor cable into the

RTS port.

Page 2 of 4 Siemens Industry, Inc.

Document No. 540-1028

Installation Instructions

November 15, 2012

7. Connect the power trunk. DO NOT apply power CAUTION

to the controller without first consulting the

The controller’s DOs control 24 Vac

specialist. loads only. The maximum rating is

12 VA for each DO. An external

interposing relay is required for any

of the following:

• VA requirements higher than the

maximum

• 110 or 220 Vac requirements

• DC power requirements

• Separate transformers used to

power the load.

(for example part number 540-147,

Terminal Equipment Controller

NOTE: Relay Module)

As a standard grounding procedure,

ensure that a ground wire is connected

directly from neutral of the 24Vac

secondary (the side that connects to

the "C" terminal of the TEC) to earth.

The installation is complete.

Wiring for AI with a 4 to 20mA Sensor.

NOTE:

If the voltage/current switch is set to

current and a 4 to 20mA sensor is

connected to an AI, then special wiring

requirements must be followed.

Wiring Diagram

Siemens Industry, Inc. Page 3 of 4

Document No. 540-1028

Installation Instructions

November 15, 2012

*A voltage/current switch for AI 3 is located under the

controller’s cover on the circuit board (behind AI 3). It must

be set either to voltage or current position according to

function.

Application 2497 – Extended I/O Controller.

Information in this document is based on specifications believed correct at the time of publication. The right is reserved to make changes as

design improvements are introduced. Product or company names mentioned herein may be the trademarks of their respective owners.

© 2012 Siemens Industry, Inc.

Siemens Industry, Inc. Your feedback is important to us. If you have Document No.540-1028

Building Technologies Division comments about this document, please send them Printed in the USA

1000 Deerfield Parkway to SBT_technical.editor.us.sbt@siemens.com. Page 4 of 4

Buffalo Grove, IL 60089-4513

USA

You might also like

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- AC650 Frame 1-3 HA464828U003 - ENDocument70 pagesAC650 Frame 1-3 HA464828U003 - ENMery Helen Barraza DelgadoNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Power Roof Ventilators: DescriptionDocument8 pagesPower Roof Ventilators: DescriptionEMRE GULERNo ratings yet

- Siemens APOGEE Wireless TEC Room Temperature Sensor (Mesh)Document3 pagesSiemens APOGEE Wireless TEC Room Temperature Sensor (Mesh)iulianbmNo ratings yet

- Bu4010 GB 0400Document26 pagesBu4010 GB 0400yoquins22No ratings yet

- Parker SSD Drives 690PB To PF Installation ManualDocument170 pagesParker SSD Drives 690PB To PF Installation ManualIGHORODJENo ratings yet

- HA502320U001Document138 pagesHA502320U001Diana Amaya NatividadNo ratings yet

- SSD 650 DriveDocument308 pagesSSD 650 DriveKamikase VilãoNo ratings yet

- AC10 Series - IP20 Product Manual - HA502320U001 Issue 5Document149 pagesAC10 Series - IP20 Product Manual - HA502320U001 Issue 5abrap_dNo ratings yet

- 650v AngDocument86 pages650v Angnabil alayoubiNo ratings yet

- Parker 631 Full Product Manual PDFDocument185 pagesParker 631 Full Product Manual PDFEverton LuisNo ratings yet

- Catalyst 2960-S Hardware InstallationDocument24 pagesCatalyst 2960-S Hardware InstallationFredys Alberto Villarreal RhenalsNo ratings yet

- Parker 590C - Full Product Manual - NoteDocument241 pagesParker 590C - Full Product Manual - Notepyae soneNo ratings yet

- 514C DC Controller: Product ManualDocument44 pages514C DC Controller: Product ManualRIGID TYRESNo ratings yet

- Quick Start Guide - Ecotower 2 370124.103 r1.1Document16 pagesQuick Start Guide - Ecotower 2 370124.103 r1.1Junior EspinalNo ratings yet

- Probe/Thermistor Interface Module: Installation GuideDocument10 pagesProbe/Thermistor Interface Module: Installation GuideShalvaTavdgiridzeNo ratings yet

- Installation Instruction: VWMB Wall-Mounted UnitsDocument17 pagesInstallation Instruction: VWMB Wall-Mounted UnitsJose GarzonNo ratings yet

- 690+ Series AC Drive: Software Product ManualDocument242 pages690+ Series AC Drive: Software Product ManualDanilo CarvalhoNo ratings yet

- Bu0280 GB 3709Document78 pagesBu0280 GB 3709Santos LpNo ratings yet

- Supplementary Documentation: Compact Instructions Explosion Proof RTD Assembly in Thermowell T13Document2 pagesSupplementary Documentation: Compact Instructions Explosion Proof RTD Assembly in Thermowell T13Antoni VallejoNo ratings yet

- User Manual JetWave 2212SDocument89 pagesUser Manual JetWave 2212SDurga Prasad SharmaNo ratings yet

- A6V10307387_enDocument7 pagesA6V10307387_enESNo ratings yet

- GEH-6421System Manual For Mark VIDocument342 pagesGEH-6421System Manual For Mark VIjorge lopezNo ratings yet

- Ha 465492Document170 pagesHa 465492Gabriel Leite Dos SantosNo ratings yet

- PCS-902S X Technical Manual en Overseas General X R1.30Document637 pagesPCS-902S X Technical Manual en Overseas General X R1.30Yd Kinan100% (1)

- User Manual: Installation Poe Injector Spider Giga 2Tx Poe EecDocument28 pagesUser Manual: Installation Poe Injector Spider Giga 2Tx Poe EecHygor ViegasNo ratings yet

- 506-507-508 ManualDocument31 pages506-507-508 Manualcs.makeNo ratings yet

- Drivecon XT Series Instruction ManualDocument120 pagesDrivecon XT Series Instruction ManualHochimidNo ratings yet

- 63 2697 SmartVFD BACnet ManualDocument40 pages63 2697 SmartVFD BACnet ManualglesterNo ratings yet

- Nord SK 500E DeviceNet ManualDocument48 pagesNord SK 500E DeviceNet ManualNabeel MohammedNo ratings yet

- 8902 LS (Parker)Document20 pages8902 LS (Parker)abdohalim248No ratings yet

- 650V 123 Installation Manual HA467649U002Document101 pages650V 123 Installation Manual HA467649U002vdalsheroqNo ratings yet

- 690+ Series: Frame G, H & JDocument149 pages690+ Series: Frame G, H & JDanilo CarvalhoNo ratings yet

- Modem Arris DG860 User GuideDocument47 pagesModem Arris DG860 User GuideshulistNo ratings yet

- PCS-931S X Technical Manual en Overseas General X R1.30Document659 pagesPCS-931S X Technical Manual en Overseas General X R1.30Chính Hà ThanhNo ratings yet

- Manual Bu 0500 GB: Intelligent Drivesystems, Worldwide ServicesDocument173 pagesManual Bu 0500 GB: Intelligent Drivesystems, Worldwide ServicesSamuel OdeiaddoNo ratings yet

- PCS-9611S - Electrified Railway - Technical Manual - EN - Overseas General - X - R1.00 - 1127Document227 pagesPCS-9611S - Electrified Railway - Technical Manual - EN - Overseas General - X - R1.00 - 1127Bader AhmedNo ratings yet

- Sec Electronics: G - Type Lift ControllerDocument56 pagesSec Electronics: G - Type Lift Controllermohammad ghassanNo ratings yet

- Switch Installation: Safety WarningsDocument30 pagesSwitch Installation: Safety WarningsaliNo ratings yet

- TV LCD Zenith L17V36DVDDocument24 pagesTV LCD Zenith L17V36DVDlewis gonzalezNo ratings yet

- 690+ Series AC Drive: Frame G, H & JDocument148 pages690+ Series AC Drive: Frame G, H & JDanilo CarvalhoNo ratings yet

- Variador 650vDocument146 pagesVariador 650valvaro velasquezNo ratings yet

- TV LCD Zenith L17V36Document24 pagesTV LCD Zenith L17V36lewis gonzalezNo ratings yet

- Idcgroupsliteraturedocumentsqs520 Qs001 en e PDFDocument38 pagesIdcgroupsliteraturedocumentsqs520 Qs001 en e PDFCody KeiferNo ratings yet

- 520-qs001 - En-E Configuracion Basica PDFDocument38 pages520-qs001 - En-E Configuracion Basica PDFluis.chuquimiaNo ratings yet

- TLX InstallationManual Engl.Document34 pagesTLX InstallationManual Engl.Nenad StankovićNo ratings yet

- Nordac SK 750E: Manual For Frequency InvertersDocument157 pagesNordac SK 750E: Manual For Frequency InvertersjorgeNo ratings yet

- Instructiuni de Operare LenzeDocument24 pagesInstructiuni de Operare Lenzelin2m3No ratings yet

- Westinghouse / Cutler Hammer "DS" Power BreakersDocument11 pagesWestinghouse / Cutler Hammer "DS" Power BreakersRonald H SantosNo ratings yet

- Mvaj 05 10 20 Manual GBDocument38 pagesMvaj 05 10 20 Manual GBsamlash100% (2)

- HA501333U001Document92 pagesHA501333U001Builder ĐiênNo ratings yet

- Manual Instalacion 900CRDocument16 pagesManual Instalacion 900CRgeovanyhazellopezsixtosNo ratings yet

- Installation Guide: VLT Ethernet/Ip Mca 121Document18 pagesInstallation Guide: VLT Ethernet/Ip Mca 121Fernando SierraNo ratings yet

- Power FlexDocument36 pagesPower FlexamiguitoNo ratings yet

- Ruskin TDP05K Install Manual AM PDFDocument24 pagesRuskin TDP05K Install Manual AM PDFAndrés Muñoz PeraltaNo ratings yet

- Service Manual: Product Type: LCD TV Chassis: ML-024A Manual Part #: 3828VD0131Y Product Year: 2003 Model SeriesDocument19 pagesService Manual: Product Type: LCD TV Chassis: ML-024A Manual Part #: 3828VD0131Y Product Year: 2003 Model SeriesGilbertoAdonayGutierrezNo ratings yet

- Lenze SMD Basic Io ManualDocument20 pagesLenze SMD Basic Io ManualDaneeNo ratings yet

- 3100R Instructions Read CarefullyDocument2 pages3100R Instructions Read CarefullySergio RecabarrenNo ratings yet

- Flexible RG316 Coax Cable Data SheetDocument4 pagesFlexible RG316 Coax Cable Data SheetМакс БелыйNo ratings yet

- Tea 5170Document9 pagesTea 5170Erasmo Franco SNo ratings yet

- 3.5A Switching Regulator: Multipower BCD TechnologyDocument23 pages3.5A Switching Regulator: Multipower BCD TechnologyErasmo Franco SNo ratings yet

- Quad Eia-422/3 Line Receiver With Three-State Outputs: Semiconductor Technical DataDocument4 pagesQuad Eia-422/3 Line Receiver With Three-State Outputs: Semiconductor Technical DataGabriel RacovskyNo ratings yet

- Machxo2™ Family Data Sheet: Ds1035 Version 3.3, March 2017Document116 pagesMachxo2™ Family Data Sheet: Ds1035 Version 3.3, March 2017Haider MalikNo ratings yet

- MC1488Document8 pagesMC1488Erasmo Franco SNo ratings yet

- Aluminum Electrolytic Capacitors: Capacitors With Screw TerminalsDocument30 pagesAluminum Electrolytic Capacitors: Capacitors With Screw TerminalsFernando BarbosaNo ratings yet

- D1user PDFDocument348 pagesD1user PDFGaby Uvidia RobalinoNo ratings yet

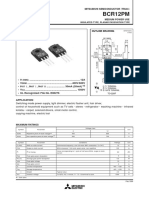

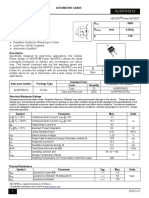

- Mitsubishi BCR12PM TriacDocument5 pagesMitsubishi BCR12PM TriacErasmo Franco SNo ratings yet

- SK25GD063: Semitop 3Document5 pagesSK25GD063: Semitop 3Erasmo Franco SNo ratings yet

- TVS Diodes Data SheetsDocument212 pagesTVS Diodes Data SheetsBenjamin Dover100% (1)

- 571470-2B Linear Encoders For Numerically Controlled Machine Tools PDFDocument60 pages571470-2B Linear Encoders For Numerically Controlled Machine Tools PDFbejo sudobolNo ratings yet

- VXXX J Tr34 Tech-Spec 01-15Document7 pagesVXXX J Tr34 Tech-Spec 01-15Erasmo Franco SNo ratings yet

- Miniature Relays: Contact DataDocument12 pagesMiniature Relays: Contact DataErasmo Franco SNo ratings yet

- Icl 7135Document13 pagesIcl 7135Branislav CelicNo ratings yet

- Power CommandDocument98 pagesPower CommandAngel Danubio Medina Perez100% (1)

- 900-0545 I3iWatch100Document87 pages900-0545 I3iWatch100thegr8t1No ratings yet

- Block Diagram of I.C. Timer (Such As 555) and Its WorkingDocument12 pagesBlock Diagram of I.C. Timer (Such As 555) and Its Workingkaran007_m100% (1)

- SI-8201L SankenelectricDocument6 pagesSI-8201L SankenelectricErasmo Franco SNo ratings yet

- RM84 / RM85 / RM87: Miniature Electromagnetic RelaysDocument2 pagesRM84 / RM85 / RM87: Miniature Electromagnetic RelaysErasmo Franco SNo ratings yet

- VOD205T, VOD206T, VOD207T, VOD211T, VOD213T, Optocoupler, Phototransistor Output, Dual Channel, SOIC-8 PackageDocument7 pagesVOD205T, VOD206T, VOD207T, VOD211T, VOD213T, Optocoupler, Phototransistor Output, Dual Channel, SOIC-8 PackageErasmo Franco SNo ratings yet

- MITSUBISHI DIGITAL/ANALOG INTERFACE SWITCHING REGULATORDocument28 pagesMITSUBISHI DIGITAL/ANALOG INTERFACE SWITCHING REGULATORnachcratchNo ratings yet

- Scale Prod HeidenhainDocument56 pagesScale Prod Heidenhainmoi301No ratings yet

- Datasheet - 2021-12-30T094724.807Document10 pagesDatasheet - 2021-12-30T094724.807Erasmo Franco SNo ratings yet

- MITSUBISHI DIGITAL/ANALOG INTERFACE SWITCHING REGULATORDocument28 pagesMITSUBISHI DIGITAL/ANALOG INTERFACE SWITCHING REGULATORnachcratchNo ratings yet

- Linear Encoders For Numerically Controlled Machine ToolsDocument52 pagesLinear Encoders For Numerically Controlled Machine ToolsFaulhaber AdrianNo ratings yet

- Lambda LQD Power Supply Repair and ModificationDocument1 pageLambda LQD Power Supply Repair and ModificationErasmo Franco SNo ratings yet

- Incremental Encoders: Hollow or End Shaft Max. Ø15 MM Resolution 5... 2048 PulsesDocument4 pagesIncremental Encoders: Hollow or End Shaft Max. Ø15 MM Resolution 5... 2048 PulsesErasmo Franco SNo ratings yet

- This Copy Was Printed On: Sep 19, 2003 08:33:37 COPY - Check Issue StatusDocument2 pagesThis Copy Was Printed On: Sep 19, 2003 08:33:37 COPY - Check Issue StatusErasmo Franco SNo ratings yet

- 0-100v 10aDocument3 pages0-100v 10aService ServexmotionNo ratings yet

- CPT111 - Chapter 2 (Programming Exercises)Document6 pagesCPT111 - Chapter 2 (Programming Exercises)Sam Chee HoeNo ratings yet

- Android Developing RESTful Android AppsDocument56 pagesAndroid Developing RESTful Android Appsmeetdhiraj81No ratings yet

- Pioneer DVR533HS Operating InstructionsDocument116 pagesPioneer DVR533HS Operating InstructionspschnobNo ratings yet

- Logo Design by TubikDocument46 pagesLogo Design by Tubikrandosm100% (1)

- OopsDocument3 pagesOopsVikas SaxenaNo ratings yet

- Taxonomy Matching Using Background KnowledgeDocument3 pagesTaxonomy Matching Using Background KnowledgeK.S. Bouthillette von Ostrowski100% (1)

- AIIMS appointment slip for orthopedics on 26 DecDocument2 pagesAIIMS appointment slip for orthopedics on 26 DecSatya NarayanNo ratings yet

- M.tech Electronics Communication EngineeringDocument72 pagesM.tech Electronics Communication EngineeringHemant IngaleNo ratings yet

- Erro CtreeDocument37 pagesErro Ctreemarcianovc1189No ratings yet

- Lee Seyeon - 8th Grade U2 - DJ - ArchitectureDocument46 pagesLee Seyeon - 8th Grade U2 - DJ - Architectureapi-481593484No ratings yet

- Ata Ide InterfaceDocument3 pagesAta Ide InterfaceDAFRANCARNo ratings yet

- Pratt Chapter 2Document41 pagesPratt Chapter 2sandeep bhardwajNo ratings yet

- EcoStruxure Building Operation - System Reference GuideDocument1,922 pagesEcoStruxure Building Operation - System Reference GuideWalter BarbaNo ratings yet

- Electronic Reservation Slip IRCTC E-Ticketing AgentDocument4 pagesElectronic Reservation Slip IRCTC E-Ticketing AgentSandeep JainNo ratings yet

- Gaming CosDocument2 pagesGaming CosVed Prakash GiriNo ratings yet

- IP Addresses: Classful AddressingDocument80 pagesIP Addresses: Classful AddressingHamza AwanNo ratings yet

- K8 Karakorum Light Attack and Multi Role Trainer AircraftDocument11 pagesK8 Karakorum Light Attack and Multi Role Trainer AircraftHtain Win100% (1)

- Curso Python y GISDocument205 pagesCurso Python y GISJuan david Gonzalez vasquezNo ratings yet

- Cyber Risks in IoT SystemsDocument27 pagesCyber Risks in IoT SystemsCorporacion H21No ratings yet

- Rfic & Mmic-0Document12 pagesRfic & Mmic-0PhilippeaNo ratings yet

- Elementary Linear Algebra: Anton & Rorres, 9 EditionDocument67 pagesElementary Linear Algebra: Anton & Rorres, 9 EditionShilingi FidelNo ratings yet

- Pws 005311 EmersonDocument4 pagesPws 005311 EmersonSiddharthJoshiNo ratings yet

- Electronics For You Magazine April 2018Document160 pagesElectronics For You Magazine April 2018Ganesh Raaja Natarajan75% (4)

- Cloudguard Cnapp Final - DesignedDocument36 pagesCloudguard Cnapp Final - DesignedGfact MailNo ratings yet

- Test Light Is A Pocket Size Tool Used To: Two Contact One Contact NeonDocument19 pagesTest Light Is A Pocket Size Tool Used To: Two Contact One Contact NeonJohn Lester M. Dela CruzNo ratings yet

- Riello. Презентация MultiPowerDocument49 pagesRiello. Презентация MultiPowerКонстантин КиселёвNo ratings yet

- Fairchild Logic Selection GuideDocument12 pagesFairchild Logic Selection Guidenapoleon_velasc3617No ratings yet

- STAAD Pro Advanced AnalysisDocument7 pagesSTAAD Pro Advanced AnalysisGuru Prasad67% (3)

- Analysis and design of animated film "THE STRUGGLEDocument16 pagesAnalysis and design of animated film "THE STRUGGLEAgus FROSTNo ratings yet

- Electronic Records Management System Adoption ReadDocument9 pagesElectronic Records Management System Adoption ReadAININA SYAZWINA ZAINUL AZMANNo ratings yet