Professional Documents

Culture Documents

الرص في التربة

Uploaded by

Jomana JomanaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

الرص في التربة

Uploaded by

Jomana JomanaCopyright:

Available Formats

Soil Compaction Soil Mechanics-3rd class

Y. M. Civil Engineering Department/ Mustansiriyah University 1/8

Soil Compaction Soil Mechanics-3rd class

Soil Compaction

1. Introduction

Compaction is the densification of soils by the application of mechanical energy. In which control specifications

for the compaction of cohesive soils were developed by Procter (1933); thus, the standard laboratory

compaction test is commonly called the proctor test. The compaction effort (CE) is a measure of the mechanical

energy applied to the soil mass.

Wh * H h * Nr.Layers * Nr.blows / layer

CE

volume

Where: Wh = Weight of hammer; Hh = hight of fall.

Compaction is commonly practiced in engineering projects in which main components of the structure are

made of soil (e.g., highway embankments, earth dams, landfill clay liners). Generally, compaction reduces

permeability, compressibility (settlements), and shrinkage, and it increases the soil strength and bearing

capacity because of the reduction in the void ratio. In the laboratory, the compaction effort may be determined

by impact or dynamic (most common) kneading or static methods.

The compaction curve (Figure 1) usually represents the relationship between the moulding water content (w)

of the soil and its dry unit weight or dry density (d). Figure (1) shows the results of soil that tested, which is

classified as CL in the USCS. The two important keys of compaction curve are: the maximum dry density (dmax)

and the corresponding optimum water content, OWC (or optimum moisture content, OMC). The portion of the

curve that has water content lower than the OWC is labelled dry of optimum (DOP), and the region with water

content greater than the OWC is wet of optimum (WOP).

For a given type of soil, as the compaction effort increases, the maximum dry density increases and the

optimum water content decreases. The points of maximum dry density and optimum water content for the

various compaction efforts tend to fall along a line named line of optimum (LOO).

Y. M. Civil Engineering Department/ Mustansiriyah University 2/8

Soil Compaction Soil Mechanics-3rd class

2. Advantages of compaction

1. Decrease in void ratio, e

2. Increase in degree of saturation, Sr

3. Increase in dry unit weight, dry

4. Increase in shear strength.

5. Decrease in permeability.

6. Decrease in compressibility.

7. Water content during the compaction

remains constant.

Figure 1 Compaction curves for Standard compaction effort (Lambe & Whitman, 1969)

Y. M. Civil Engineering Department/ Mustansiriyah University 3/8

Soil Compaction Soil Mechanics-3rd class

3. Factors Affecting on compaction process

1. Water content.

2. Compaction Effort, CE.

3. Soil type.

Figure 2 Compaction curves (Dynamic) for silty clay with

different CE (Lambe & Whitman, 1969).

Y. M. Civil Engineering Department/ Mustansiriyah University 4/8

Soil Compaction Soil Mechanics-3rd class

4. Type of compaction

4.1 By Energy

1- Standard Proctor test

2- Modified Proctor test

In SI units, the CE is in kJ.m/m3 (which is equal to kN/m2 for static compaction), e.g., CE =

594.8 KJ/m3 for Standard Proctor and 2694 KJ.m/m3 for Modified Proctor). In FPS units, 1 Ibft/ft3 = 0.04796

kJ.m/m3. Table (1) presents the size of the hammer, height of the drop, number of the drops, number of the

layers of soil, and volume of the mold.

Table (1) The size of the hammer, height of the drop, number of the drops, number of the layers of soil,

and volume of the mold.

Standard Modified

SI Units FPS Units SI Units FPS Units

Weight of hammer 24.5 (N) 5.5 (Ib) 44.5 (N) 10( Ib)

Height of fall 0.305 (m) 12 (in) 0.457 (m) 18 (in)

Number of layers 3 3 5 5

Blows per layer 25 25 25 25

Mold volume(105-mm-diameter) 0.0009422 (m2) 1130 (ft3) 0.0009422 (m2) 1130 (ft3)

Size of soil used (-)No.4 sieve (-)No.4 sieve (-)No.4 sieve (-)No.4 sieve

Compaction effort or energy 594.8 (kJ.m/m3) 12400 (ft.Ib/ft3) 2698 (kJ.m/m3) 56255 ( ft.Ib/ft3)

Y. M. Civil Engineering Department/ Mustansiriyah University 5/8

Soil Compaction Soil Mechanics-3rd class

4.2 By type of applied stress (Static & Dynamic)

Standard & Modified compaction tests are dynamic.

4.3 By Equipment

1. smooth or Steel-wheel rollers

2. sheep foot rollers

3. Rubber-tired roller

4. Hand tampers

5. Others

Compaction equipment and soil compaction application

Y. M. Civil Engineering Department/ Mustansiriyah University 6/8

Soil Compaction Soil Mechanics-3rd class

5. Effect of compaction on soil structure

For a given compaction effort and dry unit weight, the soil structure tends to be more flocculated for compaction

on the dry side of optimum as compared to the dispersed soil compacted on the wet side of optimum. In dry of

optimum, the particles or particle groups general alignment in horizontal planes, because the hammer (dynamic

compaction) does not penetrate the soil as in case of the piston (static compaction), (Mitchell, 1993). However,

when fine-grained soil is sufficiently wet of optimum, the compaction rammer penetrates the soil surface as a

result of a bearing capacity failure under the rammer face; alignment of particles along the failure surface

develops as a result of successive rammer blows.

Figure 3 Effect of compaction on soil

structure (Lambe & Whitman, 1969)

Y. M. Civil Engineering Department/ Mustansiriyah University 7/8

Soil Compaction Soil Mechanics-3rd class

6. Relative compaction (RC)

For a given

dry field

RC * 100% 95%

drylab

7. Equations of compaction

Compaction curve

wet

Wwet wet

dry

V 1 w

Zero air voids line (ZAV)

A = 0 & Sr = 1

Gs

dry w

1 w.Gs

Degree of saturations lines

For A = 5%, 10%, 20% or For Sr = 95%, 90%, 80%

Gs (1 A)

dry w

1 w.Gs

Y. M. Civil Engineering Department/ Mustansiriyah University 8/8

You might also like

- Intro & Subgrade CompactionDocument27 pagesIntro & Subgrade CompactionCarlos Ramos GuerraNo ratings yet

- Drahmedsoil Mechanicsnoteschapter 6Document54 pagesDrahmedsoil Mechanicsnoteschapter 6Burak YeşilNo ratings yet

- DYNAMIC SSI PPT Final11Document81 pagesDYNAMIC SSI PPT Final11Shwetha JNo ratings yet

- 10 - Ground MovementsDocument48 pages10 - Ground MovementsanarNo ratings yet

- 2 - Thusyanthan - ICGGE 2004 PDFDocument6 pages2 - Thusyanthan - ICGGE 2004 PDFDr I ThusyanthanNo ratings yet

- 17 - Article Text (File - Docx With No Author Information) - 25-1-10-20191128Document12 pages17 - Article Text (File - Docx With No Author Information) - 25-1-10-20191128Frimini Mng'anyaNo ratings yet

- Effect of Earthquake Induced Lateral Soil Movement On Piles in A Sloping GroundDocument4 pagesEffect of Earthquake Induced Lateral Soil Movement On Piles in A Sloping GroundrkNo ratings yet

- 17 PDFDocument8 pages17 PDFamirNo ratings yet

- University of Mauritius Faculty of EngineeringDocument6 pagesUniversity of Mauritius Faculty of EngineeringAvinaash VeeramahNo ratings yet

- Tunnelling and Deep Excavations: Ground Movements and Their EffectsDocument32 pagesTunnelling and Deep Excavations: Ground Movements and Their EffectsAnonymous D5s00DdU100% (1)

- Assessment of Geotextile Reinforced Embankment On Soft Clay SoilDocument6 pagesAssessment of Geotextile Reinforced Embankment On Soft Clay SoilEric ChanNo ratings yet

- Compressive Strength of Compressed Earth Block Masonry. Transactions On The Built EnvironmentDocument10 pagesCompressive Strength of Compressed Earth Block Masonry. Transactions On The Built EnvironmentRossemary Enciso CastroNo ratings yet

- Assessment of Load-Carrying Capacity of Bored Pile in Clay Soil Using Different MethodsDocument11 pagesAssessment of Load-Carrying Capacity of Bored Pile in Clay Soil Using Different Methodsbtcong93No ratings yet

- Module 8 of GeotechDocument39 pagesModule 8 of GeotechAnore, Raecel John V.No ratings yet

- Schneider Muntau Bathaeian2018 Article SimulationOfSettlementAndBeariDocument17 pagesSchneider Muntau Bathaeian2018 Article SimulationOfSettlementAndBeariAbderrahmane AbdelahelhirtsiNo ratings yet

- Notes 1 - Soil CompactionDocument50 pagesNotes 1 - Soil CompactionTang Ching Pang100% (1)

- 27e072d131ba774 Ek PDFDocument8 pages27e072d131ba774 Ek PDFzerlopezNo ratings yet

- Foundation EngineeringDocument2 pagesFoundation Engineeringsagar kumarNo ratings yet

- DR Ahmed Soil Mechanics Notes Chapter 6Document54 pagesDR Ahmed Soil Mechanics Notes Chapter 6COMEDY NEPALNo ratings yet

- 6 - Thusyanthan - Geofrontiers 2005Document13 pages6 - Thusyanthan - Geofrontiers 2005Dr I ThusyanthanNo ratings yet

- Soil-Structure Interaction Analysis of 300M Tall Reinforced Concrete Chimney With Piled Raft and Annular Raft Under Along Wind LoadDocument21 pagesSoil-Structure Interaction Analysis of 300M Tall Reinforced Concrete Chimney With Piled Raft and Annular Raft Under Along Wind LoadFrancisco Javier Torres AlvaradoNo ratings yet

- Keller-Liquefaction Potential Around Pile FoundationsDocument24 pagesKeller-Liquefaction Potential Around Pile FoundationsnumspyNo ratings yet

- FE Lecture-3Document7 pagesFE Lecture-3Joey LarozaNo ratings yet

- JAET - Volume 38 - Issue 2 - Pages 81-96Document16 pagesJAET - Volume 38 - Issue 2 - Pages 81-96fatima ezzahraa latifiNo ratings yet

- SSI Introduction PDFDocument29 pagesSSI Introduction PDFdesigner STRNo ratings yet

- CE504Document4 pagesCE504Mohasin KamalNo ratings yet

- Effect of Soil Constitutive Models On Determination of Deformations Caused by Deep-ExcavationsDocument19 pagesEffect of Soil Constitutive Models On Determination of Deformations Caused by Deep-ExcavationsFoolad Gharb100% (1)

- Chapter Two: Soil CompressionDocument30 pagesChapter Two: Soil CompressionOso OsoNo ratings yet

- CE - 303 - GE - End Sem-1Document3 pagesCE - 303 - GE - End Sem-1Anudeep KumarNo ratings yet

- Laterite Soil Shear Strength Characteristics From The Use of The Standard Proctor and Compression MachineDocument13 pagesLaterite Soil Shear Strength Characteristics From The Use of The Standard Proctor and Compression MachineAZOJETENo ratings yet

- Determination of Shear Modulus of Soil From Static and Seismic Penetration TestingDocument19 pagesDetermination of Shear Modulus of Soil From Static and Seismic Penetration TestingHüseyin EkiciNo ratings yet

- Assessment of Changes in Shear Strength Parameters For Soils Below Circular Machine FoundationDocument9 pagesAssessment of Changes in Shear Strength Parameters For Soils Below Circular Machine Foundationm.sc.abdilmoezelgarfNo ratings yet

- Subject: Geotechnics I (BFC 21702) Tutorial: CHAPTER 6 (Shear Strength)Document2 pagesSubject: Geotechnics I (BFC 21702) Tutorial: CHAPTER 6 (Shear Strength)muhd nizamNo ratings yet

- Rutting Behaviour in Geosynthetic - Reinforced PavementsDocument5 pagesRutting Behaviour in Geosynthetic - Reinforced PavementsAmaro24No ratings yet

- Cyclic Behavior of Laterally Loaded Concrete Piles Embedded Into Cohesive SoilDocument15 pagesCyclic Behavior of Laterally Loaded Concrete Piles Embedded Into Cohesive SoilAhmed ArafaNo ratings yet

- Application of Ultrasonic Method in Asphalt Concrete Testing For Fatigue Life EstimationDocument6 pagesApplication of Ultrasonic Method in Asphalt Concrete Testing For Fatigue Life EstimationFelipe ArceNo ratings yet

- Compaction: Prof. (DR) K.S. WaghDocument60 pagesCompaction: Prof. (DR) K.S. WaghAshish KondalwadeNo ratings yet

- Our Official Android App - REJINPAUL NETWORK FromDocument2 pagesOur Official Android App - REJINPAUL NETWORK FromKarthickNo ratings yet

- V Compaction: Courtesy of U.S. WICK DRAIN, INCDocument74 pagesV Compaction: Courtesy of U.S. WICK DRAIN, INCramlanNo ratings yet

- Modeling Failure Mechanisms in Sands Under Extreme Loads Using COMSOLDocument4 pagesModeling Failure Mechanisms in Sands Under Extreme Loads Using COMSOLMohamed TabetNo ratings yet

- Notes 1 - Shear StrengthDocument57 pagesNotes 1 - Shear StrengthMohamedAjmuzshanNo ratings yet

- FGE II AssignmentDocument2 pagesFGE II Assignmenttamratdugo9No ratings yet

- Final Geotech & Foundation Fall 2020Document3 pagesFinal Geotech & Foundation Fall 2020Saroosh ul Musatafa CheemaNo ratings yet

- Geotechnical Engineering-Ii: 5 BSC Civil Engineering - SemesterDocument8 pagesGeotechnical Engineering-Ii: 5 BSC Civil Engineering - SemesterFadli PunyeNo ratings yet

- GEO11 Paper 185Document6 pagesGEO11 Paper 185Safak BooksNo ratings yet

- Undrained Triaxial Test: DescriptionDocument12 pagesUndrained Triaxial Test: Descriptionkirti pawarNo ratings yet

- Report Highway 4Document16 pagesReport Highway 4Philimond SegieNo ratings yet

- Evaluation of Liquefaction Potential ofDocument5 pagesEvaluation of Liquefaction Potential ofEcstacy EphurioNo ratings yet

- Dynamic Analysis of Two Adjacent TunnelsDocument8 pagesDynamic Analysis of Two Adjacent TunnelsAniruddha BhaduriNo ratings yet

- Lecture 4 Design of Shallow FoundationDocument43 pagesLecture 4 Design of Shallow FoundationNadia Alentajan Abduka IINo ratings yet

- 2013 Asem13 Geotubes FemDocument11 pages2013 Asem13 Geotubes FemJose Leo MissionNo ratings yet

- Year II Soil Mechanics Lecture NotesDocument14 pagesYear II Soil Mechanics Lecture NotesRobert WalusimbiNo ratings yet

- Dynamic Fe Analysis For Stability of Embankment On Silty Clay During EarthquakesDocument7 pagesDynamic Fe Analysis For Stability of Embankment On Silty Clay During EarthquakesNguyen Chau LanNo ratings yet

- Operational Devices For Compaction Optimization and Quality ControlDocument10 pagesOperational Devices For Compaction Optimization and Quality ControlcannonlicaNo ratings yet

- Bored Tunnels in Soft SoilsDocument7 pagesBored Tunnels in Soft SoilsDEBASISNo ratings yet

- Mod 6Document51 pagesMod 6Dipankar nathNo ratings yet

- Fault Zone Dynamic Processes: Evolution of Fault Properties During Seismic RuptureFrom EverandFault Zone Dynamic Processes: Evolution of Fault Properties During Seismic RuptureMarion Y. ThomasNo ratings yet

- تصميم السدود المائيةDocument17 pagesتصميم السدود المائيةJomana JomanaNo ratings yet

- Highway Capacity and Performance L1+2Document8 pagesHighway Capacity and Performance L1+2Jomana JomanaNo ratings yet

- AutoCAD DiplomaDocument183 pagesAutoCAD DiplomaAzmi BazazouNo ratings yet

- اكثر من 300صورة بعنوان معلومة في الصورة للمهندس عبد الغني الجند PDFDocument88 pagesاكثر من 300صورة بعنوان معلومة في الصورة للمهندس عبد الغني الجند PDFصهيبNo ratings yet

- Highway Capacity and Performance L3+4Document15 pagesHighway Capacity and Performance L3+4Jomana JomanaNo ratings yet

- Universal 1-Component Polyurethane Joint Sealant: DescriptionDocument2 pagesUniversal 1-Component Polyurethane Joint Sealant: DescriptionAkram ShaikhNo ratings yet

- Extron H.264 Media Processors and Encoders Streaming To Third Parties Using RTMPDocument9 pagesExtron H.264 Media Processors and Encoders Streaming To Third Parties Using RTMPJomana JomanaNo ratings yet

- PDFDocument216 pagesPDFJomana JomanaNo ratings yet

- Huawei-4G-Router-3-Prime-B818-263 Datasheet: Quick SpecDocument3 pagesHuawei-4G-Router-3-Prime-B818-263 Datasheet: Quick SpecJomana JomanaNo ratings yet

- ChatLog B31 Lect - Skin Infections - DR Jaheersha 2021-04-17 08 - 46Document1 pageChatLog B31 Lect - Skin Infections - DR Jaheersha 2021-04-17 08 - 46Jomana JomanaNo ratings yet

- Materials: Optimization of Actuation Load and Shape Recovery Speed of Polyester-Based/Fe O Composite FoamsDocument13 pagesMaterials: Optimization of Actuation Load and Shape Recovery Speed of Polyester-Based/Fe O Composite FoamsJomana JomanaNo ratings yet

- ChatLog B31 Psy Lect - Psychiatry of Substance Abuse - DR Mazin Awad 2021-02-18 07 - 57Document1 pageChatLog B31 Psy Lect - Psychiatry of Substance Abuse - DR Mazin Awad 2021-02-18 07 - 57Jomana JomanaNo ratings yet

- Khaled Emad Alrutroot CVDocument1 pageKhaled Emad Alrutroot CVJomana JomanaNo ratings yet

- ChatLog Ebtisam Faraj - S Meeting 2021 - 02 - 18 09 - 22Document1 pageChatLog Ebtisam Faraj - S Meeting 2021 - 02 - 18 09 - 22Jomana JomanaNo ratings yet

- Ce2356 Environmental Engineering Laboratory L T P C0 0 3 2: V+ TeamDocument40 pagesCe2356 Environmental Engineering Laboratory L T P C0 0 3 2: V+ TeamJomana JomanaNo ratings yet

- ChatLog B31 Lect - Basic Dermatology - Skin in Systemic Disease - DR Jaheersha 2021-04-24 09 - 38Document1 pageChatLog B31 Lect - Basic Dermatology - Skin in Systemic Disease - DR Jaheersha 2021-04-24 09 - 38Jomana JomanaNo ratings yet

- The Project.2-5Document4 pagesThe Project.2-5Jomana JomanaNo ratings yet

- Sem6 Labmanual Ee Lab Manual-413Document18 pagesSem6 Labmanual Ee Lab Manual-413mremcivilNo ratings yet

- Department of Civil & Environmental Engineering: Research Student / Staff: Laboratory Release FormDocument1 pageDepartment of Civil & Environmental Engineering: Research Student / Staff: Laboratory Release FormJomana JomanaNo ratings yet

- King Abdul Aziz University: IE 255 Engineering EconomyDocument11 pagesKing Abdul Aziz University: IE 255 Engineering EconomyJomana JomanaNo ratings yet

- Sem6 Labmanual Ee Lab Manual-413Document18 pagesSem6 Labmanual Ee Lab Manual-413mremcivilNo ratings yet

- ACFrOgCv MHFi3sSLgYHQsdrBQeUhmnukqf DNAVlFJuFobhDAJobc7sgkmUW1CgvqSGFLfiMdROkGpmoC mj7JD2AviFn3Yz2C031u1m93aOCwKohIgLdlaDzX1NwXVwDocument58 pagesACFrOgCv MHFi3sSLgYHQsdrBQeUhmnukqf DNAVlFJuFobhDAJobc7sgkmUW1CgvqSGFLfiMdROkGpmoC mj7JD2AviFn3Yz2C031u1m93aOCwKohIgLdlaDzX1NwXVwJomana JomanaNo ratings yet

- Lab-Handout ENV PDFDocument35 pagesLab-Handout ENV PDFMd KhalekNo ratings yet

- King Faisal University College of Engineering Department Of: Civil and Environmental EngineeringDocument5 pagesKing Faisal University College of Engineering Department Of: Civil and Environmental EngineeringJomana JomanaNo ratings yet

- Exp12 PDFDocument13 pagesExp12 PDFSarang BondeNo ratings yet

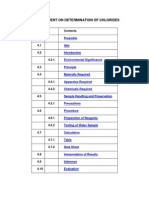

- Determination of Chlorides Exp4 - PDFDocument12 pagesDetermination of Chlorides Exp4 - PDFSusheel Talreja100% (1)

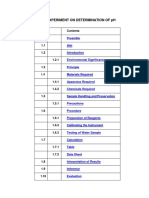

- 1.0 Experiment On Determination of PH: Sl. NoDocument12 pages1.0 Experiment On Determination of PH: Sl. NoJomana JomanaNo ratings yet

- Sem6 Labmanual Ee Lab Manual-413Document18 pagesSem6 Labmanual Ee Lab Manual-413mremcivilNo ratings yet

- Determination of Conductivity Exp3 - PDFDocument12 pagesDetermination of Conductivity Exp3 - PDFSusheel TalrejaNo ratings yet

- Failure of A Gasket During A Hydrostatic TestDocument7 pagesFailure of A Gasket During A Hydrostatic TesthazopmanNo ratings yet

- Troubleshooting For Rb750Glr4: Poe Does Not WorkDocument7 pagesTroubleshooting For Rb750Glr4: Poe Does Not Workjocimar1000No ratings yet

- Tekla Structures ToturialsDocument35 pagesTekla Structures ToturialsvfmgNo ratings yet

- WPGPipingIndex Form 167 PDFDocument201 pagesWPGPipingIndex Form 167 PDFRaj AryanNo ratings yet

- Rhino HammerDocument4 pagesRhino HammerMichael BNo ratings yet

- Reverse Osmosis ProcessDocument10 pagesReverse Osmosis ProcessHeshamNo ratings yet

- Marshall Baillieu: Ian Marshall Baillieu (Born 6 June 1937) Is A Former AustralianDocument3 pagesMarshall Baillieu: Ian Marshall Baillieu (Born 6 June 1937) Is A Former AustralianValenVidelaNo ratings yet

- Mathematics 2 First Quarter - Module 5 "Recognizing Money and Counting The Value of Money"Document6 pagesMathematics 2 First Quarter - Module 5 "Recognizing Money and Counting The Value of Money"Kenneth NuñezNo ratings yet

- Electric Arc Furnace STEEL MAKINGDocument28 pagesElectric Arc Furnace STEEL MAKINGAMMASI A SHARAN100% (3)

- Eclipsecon MQTT Dashboard SessionDocument82 pagesEclipsecon MQTT Dashboard Sessionoscar.diciomma8446No ratings yet

- Aisc Research On Structural Steel To Resist Blast and Progressive CollapseDocument20 pagesAisc Research On Structural Steel To Resist Blast and Progressive CollapseFourHorsemenNo ratings yet

- Saic-M-2012 Rev 7 StructureDocument6 pagesSaic-M-2012 Rev 7 StructuremohamedqcNo ratings yet

- Fast Binary Counters and Compressors Generated by Sorting NetworkDocument11 pagesFast Binary Counters and Compressors Generated by Sorting Networkpsathishkumar1232544No ratings yet

- Payment Plan 3-C-3Document2 pagesPayment Plan 3-C-3Zeeshan RasoolNo ratings yet

- QuestionDocument7 pagesQuestionNgọc LuânNo ratings yet

- Study of Means End Value Chain ModelDocument19 pagesStudy of Means End Value Chain ModelPiyush Padgil100% (1)

- BSL-3 Training-1Document22 pagesBSL-3 Training-1Dayanandhi ElangovanNo ratings yet

- List of Light Commercial LED CodesDocument8 pagesList of Light Commercial LED CodesRenan GonzalezNo ratings yet

- Drug Study TemplateDocument2 pagesDrug Study TemplateKistlerzane CABALLERONo ratings yet

- Moparm Action - December 2014 USADocument100 pagesMoparm Action - December 2014 USAenricoioNo ratings yet

- Part A Plan: Simple Calculater Using Switch CaseDocument7 pagesPart A Plan: Simple Calculater Using Switch CaseRahul B. FereNo ratings yet

- Mentorship ICT at A GlanceDocument5 pagesMentorship ICT at A GlanceTeachers Without Borders0% (1)

- U2 - Week1 PDFDocument7 pagesU2 - Week1 PDFJUANITO MARINONo ratings yet

- ACC403 Week 10 Assignment Rebecca MillerDocument7 pagesACC403 Week 10 Assignment Rebecca MillerRebecca Miller HorneNo ratings yet

- Business-Model Casual Cleaning ServiceDocument1 pageBusiness-Model Casual Cleaning ServiceRudiny FarabyNo ratings yet

- A Varactor Tuned Indoor Loop AntennaDocument12 pagesA Varactor Tuned Indoor Loop Antennabayman66No ratings yet

- Key Features of A Company 1. Artificial PersonDocument19 pagesKey Features of A Company 1. Artificial PersonVijayaragavan MNo ratings yet

- MNO Manuale Centrifughe IngleseDocument52 pagesMNO Manuale Centrifughe IngleseChrist Rodney MAKANANo ratings yet

- 3.1 Radiation in Class Exercises IIDocument2 pages3.1 Radiation in Class Exercises IIPabloNo ratings yet

- Frito Lay AssignmentDocument14 pagesFrito Lay AssignmentSamarth Anand100% (1)