Professional Documents

Culture Documents

STPS2L40: 40 V, 2 A Low Drop Power Schottky Rectifier

Uploaded by

Nirmal NepalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

STPS2L40: 40 V, 2 A Low Drop Power Schottky Rectifier

Uploaded by

Nirmal NepalCopyright:

Available Formats

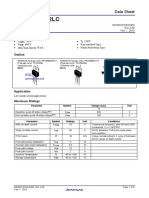

STPS2L40

Datasheet

40 V, 2 A low drop power Schottky rectifier

Features

• Very small conduction losses

• Negligible switching losses

• Low forward voltage drop

• Surface mount miniature package

• Avalanche rated

• ECOPACK2 component

Applications

• Telecom power supply

• Set-top box power supply

• TV power supply

• Battery charger

Description

Single chip Schottky rectifiers designed for high frequency miniature switched mode

power supplies such as adaptors and on board DC/DC converters.

Packaged in SMB, SMA Flat, SMA Flat Notch and SMB Flat, the STPS2L40 is ideal

for surface mounting and used in low voltage, high frequency inverters, free wheeling

and polarity protection applications.

Product status

STPS2L40

Product summary

Symbol Value

IF(AV) 2A

VRRM 40 V

T j(max.) 150 °C

VF(typ.) 0.31 V

DS2146 - Rev 6 - September 2019 www.st.com

For further information contact your local STMicroelectronics sales office.

STPS2L40

Characteristics

1 Characteristics

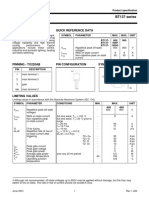

Table 1. Absolute ratings (limiting values at 25 °C, unless otherwise specified)

Symbol Parameter Value Unit

VRRM Repetitive peak reverse voltage 40 V

SMB TL = 130 °C

Average forward current, δ = 0.5, square

IF(AV) SMB Flat TL = 140 °C 2 A

wave

SMA Flat, SMA Flat Notch TL = 130 °C

IFSM Surge non repetitive forward current tp = 10 ms sinusoidal 75 A

PARM Repetitive peak avalanche power tp = 10 µs, Tj = 125 °C 158 W

Tstg Storage temperature range -65 to +150 °C

Tj Maximum operating junction temperature(1) +150 °C

1. (dPtot/dTj) < (1/Rth(j-a)) condition to avoid thermal runaway for a diode on its own heatsink.

Table 2. Thermal resistance parameter

Symbol Parameter Max. value Unit

SMB 20

SMB Flat 10

Rth(j-l) Junction to lead °C/W

SMA Flat 20

SMA Flat Notch 20

For more information, please refer to the following application note :

• AN5088 : Rectifiers thermal management, handling and mounting recommendations

Table 3. Static electrical characteristics

Symbol Parameter Test conditions Min. Typ. Max. Unit

Tj = 25 °C - 220 µA

IR(1) Reverse leakage current Tj = 100 °C VR = 40 V - 20 mA

Tj = 125 °C - 38 80 mA

Tj = 25 °C - 0.39

IF = 1 A

Tj = 125 °C - 0.25 0.28

Tj = 25 °C - 0.43

VF(1) Forward voltage drop IF = 2 A V

Tj = 125 °C - 0.31 0.34

Tj = 25 °C - 0.50

IF = 4 A

Tj = 125 °C - 0.39 0.45

1. Pulse test: tp = 380 µs, δ < 2%

To evaluate the conduction losses, use the following equation:

P = 0.22 x IF(AV) + 0.06 x IF2(RMS)

DS2146 - Rev 6 page 2/17

STPS2L40

Characteristics

For more information, please refer to the following application notes related to the power losses :

• AN604: Calculation of conduction losses in a power rectifier

• AN4021: Calculation of reverse losses on a power diode

DS2146 - Rev 6 page 3/17

STPS2L40

Characteristics (curves)

1.1 Characteristics (curves)

Figure 1. Average forward power dissipation versus Figure 2. Average forward current versus ambient

average forward current temperature (δ = 0.5) SMB

PF(AV)(W) IF(AV)(A)

1.2 2.2

Rth(j-a)=Rth(j-l)

SMB

δ = 0.1 δ = 0.2 2.0

δ = 0.5

1.0 δ = 0.05 1.8

1.6 Rth(j-a)=100°C/W

0.8 δ=1 1.4

1.2

0.6 1.0

0.8

0.4

0.6

T T

0.4

0.2

0.2

IF(AV)(A) δ=tp/T tp δ=tp/T tp Tamb (°C)

0.0

0.0

0 25 50 75 100 125 150

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2 2.4 2.6 2.8

Figure 3. Average forward current versus ambient Figure 4. Average forward current versus ambient

temperature (δ = 0.5, SMB Flat) temperature (δ = 0.5, SMA Flat, SMA Flat Notch)

IF(AV)(A) IF(AV)(A)

2.2 2.2

SMA Flat

Rth(j-a)=Rth(j-l) SMB Flat Rth(j-a)=Rth(j-l) SMA Flat Notch

2.0 2.0

1.8 1.8

1.6 Rth(j-a)=100°C/W 1.6 Rth(j-a)=200°C/W

1.4 1.4

1.2 1.2

1.0 1.0

0.8

0.8

0.6

0.6 T T

0.4

0.4

0.2

0.2 δ=tp/T tp Tamb (°C) δ=tp/T tp Tamb (°C)

0.0

0.0

0 25 50 75 100 125 150

0 25 50 75 100 125 150

DS2146 - Rev 6 page 4/17

STPS2L40

Characteristics (curves)

Figure 5. Normalized avalanche power derating versus

pulse duration (Tj = 125 °C) Figure 6. Relative variation of thermal impedance junction

to ambient versus pulse duration (SMB)

PARM (t p )

PARM (10 µs) Zth(j-a)/ Rth(j-a)

1 1.0

SMB

0.9

0.8

0.7

0.1 0.6

0.5

0.4

0.3

0.01

0.2

Single pulse

0.1

t p (s)

t p(µs) 0.0

0.001 1.E-02 1.E-01 1.E+00 1.E+01 1.E+02 1.E+03

1 10 100 1000

Figure 7. Relative variation of thermal impedance junction Figure 8. Relative variation of thermal impedance junction

to lead versus pulse duration (SMB flat) to ambient versus pulse duration (SMA Flat)

Zth(j-l) / Rth(j-l) Zth(j-a)/ Rth(j-a)

1.0 1.0

SMB Flat

0.9 0.9

SMA Flat / SMA Flat Notch

0.8 0.8

0.7 0.7

0.6 0.6

0.5 0.5

0.4 0.4

0.3 0.3

Single pulse

0.2 0.2

Single pulse

0.1 0.1

t p (s) t p (s)

0.0 0.0

1.E-04 1.E-03 1.E-02 1.E-01 1.E+00 1.E+01 1.E-02 1.E-01 1.E+00 1.E+01 1.E+02 1.E+03

Figure 9. Reverse leakage current versus reverse voltage Figure 10. Junction capacitance versus reverse voltage

applied (typical values) applied (typical values)

IR(mA) C(pF)

1.E+02 1000

Tj = 125 °C F=1MHz

VOSC=30mVRMS

Tj=25°C

1.E+01

1.E+00

100

1.E-01

Tj = 25 °C

1.E-02

VR(V) V R (V)

10

1.E-03

1 10 100

0 5 10 15 20 25 30 35 40

DS2146 - Rev 6 page 5/17

STPS2L40

Characteristics (curves)

Figure 11. Forward voltage drop versus forward current Figure 12. Forward voltage drop versus forward current

(high level) (low level)

IF(A) IF(A)

10.0 3.0

Tj=125°C

Tj=125°C 2.5 (maximum values)

(Maximum

(maximum values)

(Maximum

Tj=25°C

(maximum values) 2.0

Tj=125°C Tj=125°C

(typical values) (typical values)

1.0 1.5

Tj=25°C

(maximum values)

1.0

0.5

VF(V) VF(V)

0.1 0.0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.0 0.1 0.2 0.3 0.4 0.5 0.6

Figure 13. Thermal resistance junction to ambient versus Figure 14. Thermal resistance junction to ambient versus

copper surface under each lead (SMB) copper surface under each lead (SMB flat)

Rth(j-a) (°C/W)

Rth(j-a) (°C/W)

200 200

Epoxy printed circuit board FR4, eCu = 35 µm SMB flat

Epoxy p ri nted ci rcui t board FR4, coppe r t hi ckness: 35 µm SMB

150 150

100 100

50 50

S(Cu)(cm²) SCu (cm²)

0 0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Figure 15. Thermal resistance junction to ambient versus copper surface under each lead (SMA Flat, SMA

Flat Notch)

Rth(j-a) (°C/W)

200

Epoxy printed circuit board FR4, copper thickness: 35 µm

SMA Flat

SMA Flat Notch

150

100

50

S(Cu)(cm²)

0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

DS2146 - Rev 6 page 6/17

STPS2L40

Package information

2 Package information

In order to meet environmental requirements, ST offers these devices in different grades of ECOPACK packages,

depending on their level of environmental compliance. ECOPACK specifications, grade definitions and product

status are available at: www.st.com. ECOPACK is an ST trademark.

2.1 SMB package information

• Epoxy meets UL94, V0

• Lead-free package

Figure 16. SMB package outline

E1

A1

C A2

L b

DS2146 - Rev 6 page 7/17

STPS2L40

SMB package information

Table 4. SMB package mechanical data

Dimensions

Ref. Millimeters Inches (for reference only)

Min. Max. Min. Max.

A1 1.90 2.45 0.074 0.097

A2 0.05 0.20 0.001 0.008

b 1.95 2.20 0.076 0.087

c 0.15 0.40 0.005 0.016

D 3.30 3.95 0.129 0.156

E 5.10 5.60 0.200 0.221

E1 4.05 4.60 0.159 0.182

L 0.75 1.50 0.029 0.060

Figure 17. SMB recommended footprint

1.62 2.60 1.62

(0.064) (0.102) (0.064)

2.18

(0.086)

5.84

(0.230)

DS2146 - Rev 6 page 8/17

STPS2L40

SMB Flat package information

2.2 SMB Flat package information

• Epoxy meets UL94, V0

• Lead-free package

Figure 18. SMB Flat package outline

A

c

D

L 2x

L1 2 x

E E1

L2 2 x

Table 5. SMB Flat mechanical data

Dimensions

Ref. Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

A 0.90 1.10 0.035 0.044

b 1.95 2.20 0.076 0.087

c 0.15 0.40 0.005 0.016

D 3.30 3.95 0.129 0.156

E 5.10 5.60 0.200 0.221

E1 4.05 4.60 0.159 0.182

L 0.75 1.50 0.029 0.060

L1 0.40 0.016

L2 0.60 0.024

DS2146 - Rev 6 page 9/17

STPS2L40

SMB Flat package information

Figure 19. Footprint recommendations, dimensions in mm (inches)

1.20 3.44 1.20

(0.047) (0.136) (0.047)

2.07

(0.082)

5.84

(0.230)

millimeters

(inches)

DS2146 - Rev 6 page 10/17

STPS2L40

SMA Flat package information

2.3 SMA Flat package information

• Epoxy meets UL94, V0

• Lead-free package

Figure 20. SMA Flat package outline

A

c

D

L 2x

L1 2 x

E E1

L

L2 2 x

b 2x

Table 6. SMA Flat package mechanical data

Dimensions

Ref. Millimeters Inches (for reference only)

Min. Typ. Max. Min. Typ. Max.

A 0.90 1.10 0.035 0.044

b 1.25 1.65 0.049 0.065

c 0.15 0.40 0.005 0.016

D 2.25 2.95 0.088 0.117

E 4.80 5.60 0.188 0.221

E1 3.95 4.60 0.155 0.182

L 0.75 1.50 0.029 0.060

L1 0.50 0.020

L2 0.50 0.020

DS2146 - Rev 6 page 11/17

STPS2L40

SMA Flat package information

Figure 21. SMA Flat recommended footprint in mm (inches)

5.52

(0.217)

1.52

(0.060)

1.20 3.12 1.20

(0.047) (0.123) (0.047)

millimeter s

(inches)

DS2146 - Rev 6 page 12/17

STPS2L40

SMA Flat Notch package information

2.4 SMA Flat Notch package information

• Epoxy meets UL94, V0

• Cooling method: by conduction (C)

• Band indicates cathode

Figure 22. SMA Flat Notch package outline

Table 7. SMA Flat Notch package mechanical data

Dimensions

Ref. Millimeters Inches (for reference only)

Min. Typ. Max. Min. Typ. Max.

A1 0.90 1.10 0.035 0.044

A1 0.05 0.002

b 1.25 1.65 0.049 0.065

C 0.15 0.40 0.005 0.016

D 2.25 2.90 0.088 0.115

E 5.00 5.35 0.196 0.211

E1 3.95 4.60 0.155 0.182

G 2.00 0.079

G1 0.85 0.033

L 0.75 1.20 0.029

L1 0.45 0.018

L2 0.45 0.018

L3 0.05 0.002

V 8° 8°

V1 8° 8°

DS2146 - Rev 6 page 13/17

STPS2L40

SMA Flat Notch package information

Figure 23. SMA Flat Notch recommended footprint in mm (inches)

1.20 3.12 1.20

(0.047) (0.123) (0.047)

1.52

(0.060)

5.52

(0.217)

DS2146 - Rev 6 page 14/17

STPS2L40

Ordering Information

3 Ordering information

Table 8. Ordering information

Order code Marking Package Weight Base qty. Delivery mode

STPS2L40U GD4 SMB 0.107 g 2500 Tape and reel

STPS2L40UF FGD4 SMB Flat 0.050 g 5000 Tape and reel

STPS2L40AF F2L4 SMA Flat 0.035 g 10 000 Tape and reel

STPS2L40AFN A24 SMA Flat Notch 0.039 g 10 000 Tape and reel

DS2146 - Rev 6 page 15/17

STPS2L40

Revision history

Table 9. Document revision history

Date Version Changes

Jul-2003 2A Last update.

31-Jan-2007 3 Reformatted to current standard. Added ECOPACK statement. Added SMBflat package.

18-Sep-2008 4 Reformatted to current standard. Updated ECOPACK statement. Added SMAflat package.

Updated Table 1. Absolute ratings (limiting values at 25 °C, unless otherwise specified) and

04-Dec-2018 5

Figure 5. Normalized avalanche power derating versus pulse duration (Tj = 125 °C).

27-Sep-2019 6 Added Section 2.4 SMA Flat Notch package information.

DS2146 - Rev 6 page 16/17

STPS2L40

IMPORTANT NOTICE – PLEASE READ CAREFULLY

STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, enhancements, modifications, and improvements to ST

products and/or to this document at any time without notice. Purchasers should obtain the latest relevant information on ST products before placing orders. ST

products are sold pursuant to ST’s terms and conditions of sale in place at the time of order acknowledgement.

Purchasers are solely responsible for the choice, selection, and use of ST products and ST assumes no liability for application assistance or the design of

Purchasers’ products.

No license, express or implied, to any intellectual property right is granted by ST herein.

Resale of ST products with provisions different from the information set forth herein shall void any warranty granted by ST for such product.

ST and the ST logo are trademarks of ST. For additional information about ST trademarks, please refer to www.st.com/trademarks. All other product or service

names are the property of their respective owners.

Information in this document supersedes and replaces information previously supplied in any prior versions of this document.

© 2019 STMicroelectronics – All rights reserved

DS2146 - Rev 6 page 17/17

You might also like

- STPS3150 STMicroelectronicsDocument16 pagesSTPS3150 STMicroelectronicssegundo zapataNo ratings yet

- Stps 2 H 100Document19 pagesStps 2 H 100WAN MOZESNo ratings yet

- Stps 340Document19 pagesStps 340Mariusz KaźmierczakNo ratings yet

- STTH212: DescriptionDocument11 pagesSTTH212: DescriptionPablo Gonzalez RivielloNo ratings yet

- STTH1R02 200V 1.5A U-FastDocument15 pagesSTTH1R02 200V 1.5A U-Fastrara221122raraNo ratings yet

- STTH1R02: 200 V - 1.5 A Ultrafast Recovery DiodeDocument15 pagesSTTH1R02: 200 V - 1.5 A Ultrafast Recovery DiodeAlex Nicole SanchezNo ratings yet

- 20N60M2EP Mark STP20N60M2-EP 600V 13A FETDocument14 pages20N60M2EP Mark STP20N60M2-EP 600V 13A FETRuslanNo ratings yet

- Stps 30100 STDocument9 pagesStps 30100 STDerkis MarcanoNo ratings yet

- Features: Transil™Document10 pagesFeatures: Transil™Tirwanda EdhoNo ratings yet

- Sensitive Gate SCR: 800 V 12 Amp 200 ADocument7 pagesSensitive Gate SCR: 800 V 12 Amp 200 AfrancoNo ratings yet

- Media 3323329Document6 pagesMedia 3323329Daniel MesiNo ratings yet

- Features: Transil™Document9 pagesFeatures: Transil™m.furqan.q.tsNo ratings yet

- STTH 102Document12 pagesSTTH 102Abel GaunaNo ratings yet

- BT137 PhiDocument6 pagesBT137 PhiJavierJBVNo ratings yet

- Stps 10120 CDocument9 pagesStps 10120 CLEWIS RODRIGUEZNo ratings yet

- Triacs BT139 Series: General Description Quick Reference DataDocument6 pagesTriacs BT139 Series: General Description Quick Reference DataJose Luis SabinoNo ratings yet

- Bt136 SeriesDocument6 pagesBt136 SeriesRudy GunawanNo ratings yet

- D Data Sheet: BT131W SeriesDocument9 pagesD Data Sheet: BT131W Seriesuser_scribd54635No ratings yet

- Bta 12 6008 Impressora SansungDocument6 pagesBta 12 6008 Impressora SansungLuciano Francisco Dos SantosNo ratings yet

- D Data Sheet: BT300S SeriesDocument8 pagesD Data Sheet: BT300S SeriesFabio LastraNo ratings yet

- Fagor FT0109MN00RB DatasheetDocument6 pagesFagor FT0109MN00RB DatasheetJose BenavidesNo ratings yet

- Acst2 8SBDocument13 pagesAcst2 8SBoguiaNo ratings yet

- REN R07ds1031ej0300 bcr16cm12lc DST 20190201Document9 pagesREN R07ds1031ej0300 bcr16cm12lc DST 20190201Purwanto B012No ratings yet

- TN6050-12PI: 60 A, 1200 V Standard SCRDocument11 pagesTN6050-12PI: 60 A, 1200 V Standard SCRluis lopezNo ratings yet

- Bta06 600BDocument7 pagesBta06 600BMikhaelA.RodriguezNo ratings yet

- BT138 SeriesDocument8 pagesBT138 SeriesYogi RuliemNo ratings yet

- STPS30H100C: 100 V Power Schottky RectifierDocument12 pagesSTPS30H100C: 100 V Power Schottky RectifierPablo AllosiaNo ratings yet

- BT131 Series: General Description Quick Reference DataDocument5 pagesBT131 Series: General Description Quick Reference DataDabro FabioNo ratings yet

- BT169 01Document7 pagesBT169 01Rizky SyahNo ratings yet

- D ft1208dj ft1208mj ft1204mj ft1204dj ft1208bj ft1208nj ft1204bj TDocument6 pagesD ft1208dj ft1208mj ft1204mj ft1204dj ft1208bj ft1208nj ft1204bj TMindSet MarcosNo ratings yet

- Diodo Tarjeta Logica Del 1 Disco Duro Wester Digital de 500gb Modelo WD5000AAKX - 083CA1 Del DVR WesrDocument10 pagesDiodo Tarjeta Logica Del 1 Disco Duro Wester Digital de 500gb Modelo WD5000AAKX - 083CA1 Del DVR WesrHernan Vallenilla Rumildo MixNo ratings yet

- ACS110-7SN/SB2: Ac Line Switch Asd™ AC Switch FamilyDocument10 pagesACS110-7SN/SB2: Ac Line Switch Asd™ AC Switch FamilySamerNo ratings yet

- STPS80170C: 170 V Power Schottky RectifierDocument9 pagesSTPS80170C: 170 V Power Schottky Rectifiern tanevarNo ratings yet

- STPS80H100CY Schottky RectifierDocument10 pagesSTPS80H100CY Schottky RectifierAnonymous oyUAtpKNo ratings yet

- stps20s100cfp SCHOTTKY DIODEDocument7 pagesstps20s100cfp SCHOTTKY DIODEANDREASBOULNo ratings yet

- str-x6768n Ds en PDFDocument9 pagesstr-x6768n Ds en PDFCarlNo ratings yet

- Datasheet Acs 120 PDFDocument11 pagesDatasheet Acs 120 PDFyudi heriyantoNo ratings yet

- DatasheetDocument2 pagesDatasheetMario Alberto Saavedra MeridaNo ratings yet

- Data Sheet: BYV42E, BYV42EB SeriesDocument9 pagesData Sheet: BYV42E, BYV42EB SeriesSaurabh ManavNo ratings yet

- Bta08 600CDocument5 pagesBta08 600CBrayan ZaragozaNo ratings yet

- TRIACS CatálogoDocument8 pagesTRIACS CatálogoJacy FigueNo ratings yet

- STF 13 NM 60 NDDocument12 pagesSTF 13 NM 60 NDlejojoel321No ratings yet

- STPS40L45C: Low Drop Power Schottky RectifierDocument11 pagesSTPS40L45C: Low Drop Power Schottky Rectifiersasan hatamiNo ratings yet

- BT137Document7 pagesBT137Gabriel RacovskyNo ratings yet

- stth60rq06 M2yDocument12 pagesstth60rq06 M2yRahul SinghNo ratings yet

- Thyristors BT169 Series Logic Level: General Description Quick Reference DataDocument6 pagesThyristors BT169 Series Logic Level: General Description Quick Reference Datawasantha bandaraNo ratings yet

- STPS3045CT/CG/CR/CP/CPI/CW/CFP: Power Schottky RectifierDocument9 pagesSTPS3045CT/CG/CR/CP/CPI/CW/CFP: Power Schottky Rectifierигорь федотовNo ratings yet

- BT136BDocument6 pagesBT136BsaumyakanthaNo ratings yet

- Str-x6759n Ds enDocument9 pagesStr-x6759n Ds enCleiton SilvaNo ratings yet

- BT152 PhilipsSemiconductorsDocument8 pagesBT152 PhilipsSemiconductorsDiego RicardoNo ratings yet

- Datasheet 2Document8 pagesDatasheet 2YELZAX C.ANo ratings yet

- Bat 41Document11 pagesBat 41Tanko SuleNo ratings yet

- 2P4M ThinkiSemiconductorDocument3 pages2P4M ThinkiSemiconductorbasheer almetwakelNo ratings yet

- BT169D L DatasheetDocument12 pagesBT169D L DatasheetFadila LazimNo ratings yet

- Stps 20 S 100 CDocument12 pagesStps 20 S 100 CEnrico RotaNo ratings yet

- Bta16 600B PDFDocument5 pagesBta16 600B PDFŽaba Od ŽadaNo ratings yet

- tn4050hp 12gy tr-2935903Document11 pagestn4050hp 12gy tr-2935903chawkigenieNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Ice Machines UK LTD: Service Manual CP 30Sc E CP 30 E CP 45 E CP 70 E CP 120 EDocument21 pagesIce Machines UK LTD: Service Manual CP 30Sc E CP 30 E CP 45 E CP 70 E CP 120 ENirmal NepalNo ratings yet

- LNK364PNDocument16 pagesLNK364PNウイレイヘル メロネNo ratings yet

- Triacs BT 12 600v PDFDocument7 pagesTriacs BT 12 600v PDFgolg1de1994No ratings yet

- 1. 材料:80G双胶纸,正反面印刷; 2. 印刷为黑白色单色印刷; 3. 所有印刷内容正确、清晰,不得有漏印、误印,无印刷缺陷; 4. 幅面:(210±3)X(145±3)(单位:Mm); 5.未注公差按照Gb1800 (现行) .It15; 6.颜色及整体效果必须经过研发部确认后方能生产,产品检验以封样件为准; 7.符合Rohs现行标准要求和Reach指令。Document14 pages1. 材料:80G双胶纸,正反面印刷; 2. 印刷为黑白色单色印刷; 3. 所有印刷内容正确、清晰,不得有漏印、误印,无印刷缺陷; 4. 幅面:(210±3)X(145±3)(单位:Mm); 5.未注公差按照Gb1800 (现行) .It15; 6.颜色及整体效果必须经过研发部确认后方能生产,产品检验以封样件为准; 7.符合Rohs现行标准要求和Reach指令。Nirmal NepalNo ratings yet

- Ic PWMDocument26 pagesIc PWMhsrairNo ratings yet

- My Lfe RootDocument1 pageMy Lfe RootNirmal NepalNo ratings yet

- My Lfe RootDocument1 pageMy Lfe RootNirmal NepalNo ratings yet

- Essential & Practical Circuit Analysis Part 1 - DC CircuitsDocument33 pagesEssential & Practical Circuit Analysis Part 1 - DC CircuitsFlorin FinaruNo ratings yet

- Wa11d3 PCB ControlDocument1 pageWa11d3 PCB ControlNirmal NepalNo ratings yet

- Washing Machine Controller With A New Programming PDFDocument5 pagesWashing Machine Controller With A New Programming PDFNirmal NepalNo ratings yet

- Wa11d3 PCB ControlDocument1 pageWa11d3 PCB ControlNirmal NepalNo ratings yet

- Solder Desolder PCB Repair GuideDocument186 pagesSolder Desolder PCB Repair Guideasi555No ratings yet

- Essential & Practical Circuit Analysis Part 1 - DC CircuitsDocument33 pagesEssential & Practical Circuit Analysis Part 1 - DC CircuitsFlorin FinaruNo ratings yet

- Renesas Discrete General CatalogDocument43 pagesRenesas Discrete General CatalogKevin TateNo ratings yet

- Acjt2 JiejieDocument7 pagesAcjt2 JiejieNirmal NepalNo ratings yet

- TOP247YNDocument52 pagesTOP247YNLaércio MatosNo ratings yet

- Acjt2 JiejieDocument7 pagesAcjt2 JiejieNirmal NepalNo ratings yet

- Washing Machine Controller With A New Programming PDFDocument5 pagesWashing Machine Controller With A New Programming PDFNirmal NepalNo ratings yet

- IEEE Device Numbers and Functions For Switchgear ApparatusDocument12 pagesIEEE Device Numbers and Functions For Switchgear ApparatusSarah FrazierNo ratings yet

- Npcil QuestionsDocument9 pagesNpcil Questionsjp mishraNo ratings yet

- Galaxy PW Muti Module Technical SpecsDocument30 pagesGalaxy PW Muti Module Technical SpecsRUBEN LOZANONo ratings yet

- BDT Gleichrichter EDocument2 pagesBDT Gleichrichter EM Kashif JunaidNo ratings yet

- Met 2Document225 pagesMet 2Pranav kant100% (1)

- Tle Ratio 2Document145 pagesTle Ratio 2Cybill Astrids Rey RectoNo ratings yet

- Pspice Pe ManualDocument41 pagesPspice Pe Manualfylobedo99No ratings yet

- Examen Dr. AliDocument2 pagesExamen Dr. AliLuis Miguel SaldañaNo ratings yet

- Product Description: 400 Amp Ferroresonant Rectifier at - 48VDCDocument2 pagesProduct Description: 400 Amp Ferroresonant Rectifier at - 48VDCxray123zzzNo ratings yet

- Jntu Online Examinations (Mid 2 - Eca)Document22 pagesJntu Online Examinations (Mid 2 - Eca)venkat gautam100% (2)

- Datasheet 579314 (59-8010-A0) en 220V 50HzDocument53 pagesDatasheet 579314 (59-8010-A0) en 220V 50HzBlue PntNo ratings yet

- Design and Simulation of 80 KHZ High Frequency Converter Using CD 4047IC CMOSDocument6 pagesDesign and Simulation of 80 KHZ High Frequency Converter Using CD 4047IC CMOSEditor IJTSRD100% (1)

- Megadrive Lci 1Document28 pagesMegadrive Lci 1lollollol1515615df4gNo ratings yet

- Service Manual Service Manual Service Manual Service Manual: Epson GT-10000Document83 pagesService Manual Service Manual Service Manual Service Manual: Epson GT-10000chamaidisvNo ratings yet

- Liebert Intellislot 485: Modbus Reference GuideDocument52 pagesLiebert Intellislot 485: Modbus Reference GuideLuis Felipe MoyanoNo ratings yet

- Real Time Emg Signal ProcessingDocument17 pagesReal Time Emg Signal ProcessingKutay ÖzenNo ratings yet

- Applied ElectronicsDocument40 pagesApplied ElectronicsGuruKPO75% (4)

- A PROJECT REPORT ON Electronic Voting MachineDocument97 pagesA PROJECT REPORT ON Electronic Voting Machinereddu143No ratings yet

- 10 MicrowaveDocument14 pages10 Microwaverdc02271No ratings yet

- MCQs of EC Electrical N ElectronicsDocument22 pagesMCQs of EC Electrical N ElectronicsSatish Bojjawar100% (2)

- 362-RCm2 FuellessEngineM2 Plans Part3 PDFDocument15 pages362-RCm2 FuellessEngineM2 Plans Part3 PDFLeonardo Eladio Vergara100% (1)

- BE8161-Basic Electrical Electronics and Instrumentation Engineering Lab ManualDocument162 pagesBE8161-Basic Electrical Electronics and Instrumentation Engineering Lab ManualAntonio LeonNo ratings yet

- Simple DC Power SupplyDocument24 pagesSimple DC Power Supplyapi-411100163No ratings yet

- 71584B SymptomsDocument26 pages71584B SymptomsDhrubajyoti BoraNo ratings yet

- 01 - Elementary-Electronics-1963Document164 pages01 - Elementary-Electronics-1963Jones Damas PeixotoNo ratings yet

- Clinical ThermometerDocument33 pagesClinical ThermometerDevraj MandalNo ratings yet

- 74276-Study On EseDocument109 pages74276-Study On Esestanjack99No ratings yet

- Unisonic Technologies Co., LTD: Ultrafast, Low Switching Loss Rectifier DiodeDocument3 pagesUnisonic Technologies Co., LTD: Ultrafast, Low Switching Loss Rectifier Diodealexjcc10No ratings yet

- Sinus Premium LED Series User Manual v2Document35 pagesSinus Premium LED Series User Manual v2Florin Apopei100% (1)

- Power Electronics: DR - Arkan A.Hussein Power Electronics Fourth ClassDocument13 pagesPower Electronics: DR - Arkan A.Hussein Power Electronics Fourth Classmohammed aliNo ratings yet