Professional Documents

Culture Documents

Brushless Servomotor Guide

Uploaded by

Wesam Fh WfhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brushless Servomotor Guide

Uploaded by

Wesam Fh WfhCopyright:

Available Formats

Brushless Servomotor Product Guide

Guiding you towards the right solution.

More solutions from us equals more success for you.

At Torque Systems, we have always believed in giving you more choices. After all, your application is

unique, so the Brushless Servomotor you choose for it should be unique, too. While the competition stacks

their shelves with motors and hardware, we pack ours with engineered solutions. The truth is,

our shelf contains just about any type of solution you could require, from simple integration components

such as brakes, encoders and tachometers, to elaborate breakthrough designs.

In addition to our wide selection of clean operating, low maintenance brushless servomotors, we also

provide you with a range of standard integration and custom engineered options to round out your solution.

Our typical standard integration

options include:

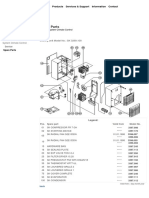

A) Custom Connectors C) Standard & Custom

A Connector Locations Shaft Configurations

Housings D) Multiple Gearhead

Options

E Cabling

E) Brakes

B) Multiple Standard Winding

Configurations F) Hall Sensors

Matched Windings Standard and Custom

Thermostats Encoders

Resolvers

Tachometers

F G) Standard Flange

B Mounting

NEMA Mounting

C

IEC Mounting

Multiple Standard

Winding Configurations

D

Our typical custom engineered

options include:

Being able to choose from an array of Brushless AC Servomotor

Extended Ambient Temperature Ratings

solutions is only the beginning. You will also be guided through

Custom Winding Configurations

the entire selection process by members of our highly trained

Special Electromagnetic Design Platforms sales force. They will work closely with you so they can gain

Specialized Military Coatings a thorough understanding of your particular application.

Corrosion Resistant Materials This enables them to determine how to create the best solution

Food Grade Materials for you. Once that judgment has been made, our application

development engineers step in to ensure that at the end of

Custom Bearings

the process you receive a reliable, high-quality working solution.

Witness Testing All this is possible because Torque Systems will design a

IP 65 and IP 67 Sealing product to fit your application — rather than altering your

application to fit our product.

To make the entire process as smooth as possible, we give

you the opportunity to size motors and select many standard

integration options using our convenient web site servomotor

platform configuration feature. To begin the process, simply

visit www.torquesystems.com.

Brushless Servomotor Platforms

Key: Continuous Duty Intermittent Duty

Standard Design Features: Rigid Application Development Process:

High Energy Neodymium Magnets Application Review

CE/UL Compliant Motion Profile Analysis

Multiple Winding Availability Magnetic FEA 3D Modeling & Computer Simulation

Sealed Bearings Prototype Design

Clean Operating, Low Maintenance Brushless Design Performance Verification

Platform 2000/2200 Max. Performance

Platform BMR 2000/2200 12 standard available windings

Platform Rated Power Cont. Stall Torque Peak Torque Rotor Inertia

Number W lb-in NM lb-in NM lb-in-sec2 Kg(10-4)-m2

2005 215 5 0.56 23 2.60 0.0004 0.4519

2010 350 10 1.13 45 5.08 0.0009 1.0169

2205 215 5 0.56 23 2.60 0.0004 0.4519

2210 350 10 1.13 45 5.08 0.0009 1.0169

Platform 2300 Max. Performance

Platform BNL 2300 12 Standard Windings Available

Platform Rated Power Cont. Stall Torque Peak Torque Rotor Inertia

Number W oz-in NM oz-in NM oz-in-sec2 Kg(10-4)-m2

2305 145 50 0.35 250 1.77 0.00159 0.1120

2310 260 100 0.71 500 3.53 0.00281 0.1981

2315 320 120 0.85 600 4.24 0.00380 0.2684

2320 330 140 0.99 700 4.94 0.00480 0.3388

Platform 3000/3300 Max. Performance

Platform BNR 3000/3300 12 Standard Windings Available

Platform Rated Power Cont. Stall Torque Peak Torque Rotor Inertia

Number W lb-in NM lb-in NM lb-in-sec2 Kg(10-4)-m2

3012 670 12 1.36 60 6.78 0.00080 0.9039

3024 1430 24 2.71 110 12.43 0.00150 0.1695

3034 1700 34 3.84 150 16.95 0.00196 0.2215

3312 670 12 1.36 60 6.78 0.00080 0.9039

3324 1430 24 2.71 110 12.43 0.00150 0.1695

3334 1700 34 3.84 150 16.95 0.00196 0.2215

Platform 4000/4400 Max. Performance

Platform BMR 4000/4400 12 Standard Windings Available

Platform Rated Power Cont. Stall Torque Peak Torque Rotor Inertia

Number W lb-in NM lb-in NM lb-in-sec2 Kg(10-4)-m2

4027 1560 27 3.1 115 13.0 0.00260 2.9376

4045 2440 45 5.1 200 22.6 0.00420 4.7454

4067 2930 67 7.6 300 33.9 0.00720 8.1349

4427 1560 27 3.1 115 13.0 0.00260 2.9376

4445 2440 45 5.1 200 22.6 0.00420 4.7454

4467 2930 67 7.6 300 33.9 0.00720 8.1349

BPS Direct Drive Sets 17 Total Platforms, 12 Windings Each* Key Benefits:

Max. Rated Power Cont. Stall Torque Peak Torque Rotor Inertia Easy integration into customer hardware

Performance Kw oz-in NM oz-in NM oz-in-sec2 Kg(10-4)-m2

No belts, gears or backlash

2320 0.5 160 1.130 700 4.944 0.00539 0.3807

Minimize size & weight, maximize rate

& position accuracy

Max. Rated Power Cont. Stall Torque Peak Torque Rotor Inertia

Performance Kw lb-in NM lb-in NM lb-in-sec2 Kg(10-4)-m2 Low electrical time constant for

fast response

3030 1.7 34 3.84 170 19.21 0.001609 1.8179

High pole count for smooth,

4030 2.0 55 6.2 315 35.59 0.003558 4.0200 low cogging operation

5050 6.2 200 22.6 900 101.7 0.016600 18.756

Custom motors available up to 7.5 in. (190 mm) diameter and 450 lb.– in. (41 NM)

*For a complete list of available platforms, please consult the BPS data sheet

Simply put: Torque Systems will

design a product to fit your application —

rather than altering your application to

fit our product.

Nominal Motor Dimensions

Platforms 2200, 3300 & 4400 Platforms 2000, 3000 & 4000

Notes:

Platform Frame Length Frame Diameter Encoder Addition D End Bell Connector D End Bell Connector Shaft Extension Shaft Diameter

Round or D End Bell E -in. (mm) C/L to Motor End Height to Motor C/L S -in. (mm) U -in. (mm)

M -in. (mm) L -in. (mm) H -in. (mm) Additions including

BMR 2000 2005 5.72 (145.3) 2.28 (57.9) 0 0 0.85 (21.6) 2.54 (2.54) 0.77 (19.6) 0.355 (9.02) brakes, resolvers, rear

shaft extensions, and

2010 7.22 (183.4) 2.28 (57.9) 0 0 0.85 (21.6) 2.54 (2.54) 0.77 (19.6) 0.355 (9.02) seals will increase

BMR 2200 2205 4.99 (126.7) 2.28 (57.9) 0.85 (21.6) N/A N/A N/A N/A 0.77 (19.6) 0.355 (9.02) overall length

2210 6.49 (164.8) 2.28 (57.9) 0.85 (21.6) N/A N/A N/A N/A 0.77 (19.6) 0.355 (9.02)

Shaft extension includes

BNL 2300 2305 2.47 (62.4) 2.25 (57.2) 0.85 (21.6) N/A N/A N/A N/A 0.81 (20.6) 0.25 (6.35) motor face pilot

2310 2.97 (75.4) 2.25 (57.2) 0.85 (21.6) N/A N/A N/A N/A 0.81 (20.6) 0.25 (6.35)

Connectors, connector

2315 3.47 (88.1) 2.25 (57.2) 0.85 (21.6) N/A N/A N/A N/A 0.81 (20.6) 0.25 (6.35) housings, and mounting

2320 3.97 (100.8) 2.25 (57.2) 0.85 (21.6) N/A N/A N/A N/A 0.81 (20.6) 0.25 (6.35) flanges may increase

overall diameter

BNR 3000 3012 6.40 (162.6) 3.38 (85.9) 0 0 1.37 (34.8) 3.35 (3.35) 1 (25.4) 0.5 (12.7)

3024 7.40 (188.0) 3.38 (85.9) 0 0 1.37 (34.8) 3.35 (3.35) 1 (25.4) 0.5 (12.7) Nema and IEC mounting

3034 8.40 (213.4) 3.38 (85.9) 0 0 1.37 (34.8) 3.35 (3.35) 1 (25.4) 0.5 (12.7) standards available

BNR 3300 3312 3.91 (99.3) 3.38 (85.9) 0.85 (21.6) N/A N/A N/A N/A 1 (25.4) 0.5 (12.7) Motor dimesions subject

3324 4.91 (124.7) 3.38 (85.9) 0.85 (21.6) N/A N/A N/A N/A 1 (25.4) 0.5 (12.7) to change

3334 5.98 (158.9) 3.38 (85.9) 0.85 (21.6) N/A N/A N/A N/A 1 (25.4) 0.5 (12.7)

BMR 4000 4027 8.5 (215.9) 4.21 (106.9) 0 0 1.82 (1.82) 3.35 (46.2) 2.04 (51.8) 0.625 (15.9)

4045 9.75 (247.7) 4.21 (106.9) 0 0 1.82 (1.82) 3.35 (46.2) 2.04 (51.8) 0.625 (15.9)

4067 11.75 (298.5) 4.21 (106.9) 0 0 1.82 (1.82) 3.35 (46.2) 2.04 (51.8) 0.75 (19.1)

BMR 4400 4427 6.00 (152.4) 4.21 (106.9) 0.85 (21.6) N/A N/A N/A N/A 2.04 (51.8) 0.625 (15.9)

4445 7.25 (184.2) 4.21 (106.9) 0.85 (21.6) N/A N/A N/A N/A 2.04 (51.8) 0.625 (15.9)

4467 9.25 (234.0) 4.21 (106.9) 0.85 (21.6) N/A N/A N/A N/A 2.04 (51.8) 0.75 (19.1)

Ask about our other motion controls solutions & capabilities:

DC Brush Servomotors

Expert application development engineering

Complete repair and refurbishing services

Brush & Brushless Motors

MTI-Torque Systems MTI-Torque Systems

6 Enterprise Road

8201 109th St. Suite 500

Unique Solutions for Unique Customers. Billerica, MA 01821-3954

U.S.A.

Pleasant Prairie, WI 53158

Ph: 800.669.5112 www.torquesystems.com

978.667.5100

Fx: 978.0600.0280

Sales: customer@slmti.com

www.torquesystems.com

©2016 MTI Torque Systems. All rights

reserved PGBLM-2/16

You might also like

- CMC Brush Servo Motor 2011 CatalogDocument4 pagesCMC Brush Servo Motor 2011 CatalogElectromateNo ratings yet

- CMC Brush Servo Motor 2011 CatalogDocument4 pagesCMC Brush Servo Motor 2011 CatalogServo2GoNo ratings yet

- Servo Motor J - SeriesDocument15 pagesServo Motor J - SeriesNkiti RichNo ratings yet

- Keppel OTD Mooring SolutionsDocument16 pagesKeppel OTD Mooring Solutionsjeremytoh89No ratings yet

- About Durago: Wheel Hub Repair KitsDocument4 pagesAbout Durago: Wheel Hub Repair KitsphillipdiazNo ratings yet

- Specifications: Accudrive - Precision Motion Control SolutionsDocument2 pagesSpecifications: Accudrive - Precision Motion Control SolutionsLeroy AraoNo ratings yet

- BMW Diagnostic Kit Allows Coding, BMW ISTA Download Diagnostics and Fault Code ResetDocument1 pageBMW Diagnostic Kit Allows Coding, BMW ISTA Download Diagnostics and Fault Code Resetport23No ratings yet

- SMS - 2003 For Web PDFDocument96 pagesSMS - 2003 For Web PDFbatatahcNo ratings yet

- Fixturlaser ECO Wind BrochureDocument4 pagesFixturlaser ECO Wind BrochureCleydson Vieira GomesNo ratings yet

- Cyber Kit Motors enDocument8 pagesCyber Kit Motors enmakkihassanNo ratings yet

- SFT Company ProfileDocument8 pagesSFT Company ProfileAndy BayuNo ratings yet

- Kisssoft Brochure en PDFDocument11 pagesKisssoft Brochure en PDFWojciechNo ratings yet

- CSK FormspragDocument7 pagesCSK FormspragdenisNo ratings yet

- Content Sheet HaynesPro WorkshopData Truck 20190212Document2 pagesContent Sheet HaynesPro WorkshopData Truck 20190212Francisco Arroyo100% (1)

- ENCODER General-Installation-Wiring-GuideDocument16 pagesENCODER General-Installation-Wiring-GuideNirav PatelNo ratings yet

- Siemens NC-Z 01-1143-02Document119 pagesSiemens NC-Z 01-1143-02mrtansNo ratings yet

- 0595 vsb6 Section D Rear AxlesDocument9 pages0595 vsb6 Section D Rear AxlesJustin Trevor NyathiNo ratings yet

- Daimler MB Prospekt Programm09 en 090716Document16 pagesDaimler MB Prospekt Programm09 en 090716DzmitryNo ratings yet

- Melucci Catalogo CPC Guide Miniaturizzate ENG LowDocument62 pagesMelucci Catalogo CPC Guide Miniaturizzate ENG LowZoran SpiroskiNo ratings yet

- D450 Shaft Alignment: Vibration MeasurementDocument6 pagesD450 Shaft Alignment: Vibration MeasurementJegan PrasadNo ratings yet

- AMC-servo Drive Overview PDFDocument28 pagesAMC-servo Drive Overview PDFMehdi Houari ZaidNo ratings yet

- Mdsksbs 040 53 Servo Motor Lenze ManualDocument42 pagesMdsksbs 040 53 Servo Motor Lenze Manualcatur skakNo ratings yet

- VV SiemensDocument60 pagesVV SiemensNicole FelicianoNo ratings yet

- Crankshaft Tester & Dial IndicatorsDocument2 pagesCrankshaft Tester & Dial Indicatorsahme_eng_1500No ratings yet

- Servomotor MOOGDocument63 pagesServomotor MOOGEmilio TovarNo ratings yet

- Haskel H DriveDocument4 pagesHaskel H DriveShreyasNo ratings yet

- HS E10102 0 02 15 - HydraulikzylinderundSysteme PDFDocument8 pagesHS E10102 0 02 15 - HydraulikzylinderundSysteme PDFĐỗ HuyNo ratings yet

- Bus Sandwich PDFDocument31 pagesBus Sandwich PDFManishPandyaNo ratings yet

- ShaftDesigner by IMT (English)Document2 pagesShaftDesigner by IMT (English)Monglen Z. Casiño100% (1)

- PTL 011-05-2021 BOP Handling Systems CatalogDocument13 pagesPTL 011-05-2021 BOP Handling Systems CatalogCamilo Andres Gonzalez RojasNo ratings yet

- Our Know-How. Your Peace of Mind.: Innovative Sealing and Gasket SolutionsDocument14 pagesOur Know-How. Your Peace of Mind.: Innovative Sealing and Gasket SolutionsShiv ChevliNo ratings yet

- WEB - 72DPI - Gen-Set Controller Catalogue 2019 PDFDocument13 pagesWEB - 72DPI - Gen-Set Controller Catalogue 2019 PDFsabarNo ratings yet

- Unimotor FMDocument24 pagesUnimotor FMmperez3774No ratings yet

- Motor Nema 34Document9 pagesMotor Nema 34jose calleNo ratings yet

- SFT Company Profile USDocument8 pagesSFT Company Profile USSALES HOANG HANo ratings yet

- Kollmorgen KBM Series 2011 CatalogDocument80 pagesKollmorgen KBM Series 2011 CatalogElectromateNo ratings yet

- Abb Acs550 Catalog en 3afe64792857Document24 pagesAbb Acs550 Catalog en 3afe64792857Prakash UmaleNo ratings yet

- DemagDocument20 pagesDemagPajserchinaNo ratings yet

- CSK One Way Bearing Clutches: Altra Industrial MotionDocument8 pagesCSK One Way Bearing Clutches: Altra Industrial MotionvenothNo ratings yet

- OX - Solutions Profile 2023Document25 pagesOX - Solutions Profile 2023dove4suppliesNo ratings yet

- Unimotor FM: AC Brushless Servo MotorDocument28 pagesUnimotor FM: AC Brushless Servo Motoryonan RodriguezNo ratings yet

- ACS850 Drive Modules Technical CatalogueDocument20 pagesACS850 Drive Modules Technical CatalogueANOOP KRISHNANNo ratings yet

- Midas Release NoteDocument12 pagesMidas Release NoteLoka GaneshanNo ratings yet

- Twin Disc HP610SDocument2 pagesTwin Disc HP610Sxinpu shanNo ratings yet

- Demag Spare Part Sets: The Future Starts HereDocument4 pagesDemag Spare Part Sets: The Future Starts HereJESUSCALVILLONo ratings yet

- Technifor Dot Peend and Scribing Solutions Technifor 3 29 18Document16 pagesTechnifor Dot Peend and Scribing Solutions Technifor 3 29 18api-581452247No ratings yet

- Fluid Controls RailwaysDocument42 pagesFluid Controls RailwaysjayendrapatilNo ratings yet

- Resolver CatalogDocument85 pagesResolver CatalogAlex StanNo ratings yet

- Demag Katalog PDFDocument392 pagesDemag Katalog PDFgogo995No ratings yet

- Weatlock 2007Document7 pagesWeatlock 2007Javier DengraNo ratings yet

- 2013 - 14 HydraulicsDocument122 pages2013 - 14 HydraulicspradeepalokrajNo ratings yet

- Helical Worm: Quick Selection GuideDocument24 pagesHelical Worm: Quick Selection GuideMohammad Ali TaghdiriNo ratings yet

- MDSKSRS030 33 Servo Motor Lenze Manual PDFDocument44 pagesMDSKSRS030 33 Servo Motor Lenze Manual PDFSantiago GallingerNo ratings yet

- Walker 4020Document2 pagesWalker 4020Khanh DoanNo ratings yet

- Advanced and Appropriate Solutions in Automation: Servo Drives Servo Motor Heater Controller Embedded ControlDocument9 pagesAdvanced and Appropriate Solutions in Automation: Servo Drives Servo Motor Heater Controller Embedded ControlAnuragNo ratings yet

- Upload FileDocument8 pagesUpload FileahadabbasadiNo ratings yet

- Auto Diaphragm: Introduction ToDocument17 pagesAuto Diaphragm: Introduction ToPoshan DhunganaNo ratings yet

- Couplings and Mechanical Soft Starts: CatalogDocument52 pagesCouplings and Mechanical Soft Starts: Catalogashumishra007No ratings yet

- WWW Online Iso Calculator Com Online Bolt Torque CalculatorDocument6 pagesWWW Online Iso Calculator Com Online Bolt Torque CalculatormashudiNo ratings yet

- Fujifilm PS Experience-Interventional-Pulmonology-Brochure E Dez2016 21Document1 pageFujifilm PS Experience-Interventional-Pulmonology-Brochure E Dez2016 21Wesam Fh WfhNo ratings yet

- Video Rhino-Laryngo Endoscope: - High Quality Images - Larger and Brighter Images - Support of Accurate ProceduresDocument2 pagesVideo Rhino-Laryngo Endoscope: - High Quality Images - Larger and Brighter Images - Support of Accurate ProceduresWesam Fh WfhNo ratings yet

- 47088749Document34 pages47088749Wesam Fh WfhNo ratings yet

- Exceptional Performance - Delivering A High-Resolution Image in A Slim 4.8 MM DiameterDocument2 pagesExceptional Performance - Delivering A High-Resolution Image in A Slim 4.8 MM DiameterWesam Fh WfhNo ratings yet

- Panduan Sitasi Bibliografis IEEE StyleDocument4 pagesPanduan Sitasi Bibliografis IEEE StyleNova KristantoNo ratings yet

- SD-006 Capacitor Box - Deionizaiton Assy - SW UpdateDocument3 pagesSD-006 Capacitor Box - Deionizaiton Assy - SW UpdateErico RodrguesNo ratings yet

- CRI A380 F-36 Ed 2 Closed (Use of Object Oriented Techniques at Design or Source Code Level) )Document6 pagesCRI A380 F-36 Ed 2 Closed (Use of Object Oriented Techniques at Design or Source Code Level) )juan HECTORNo ratings yet

- MST UNIT I r20 IotDocument40 pagesMST UNIT I r20 IotYadavilli Vinay100% (1)

- Flight Control System Modeling With SysML To SuppoDocument7 pagesFlight Control System Modeling With SysML To Suppo2654720877No ratings yet

- Sec-Erb Engineering Standards: Eastern Region Branch Saudi Electricity CompanyDocument55 pagesSec-Erb Engineering Standards: Eastern Region Branch Saudi Electricity Companyexa academyNo ratings yet

- HC SoundstimDocument2 pagesHC SoundstimTahir YousafNo ratings yet

- MSP Series: Magnetic Speed PickupsDocument2 pagesMSP Series: Magnetic Speed PickupsAmit KumarNo ratings yet

- 09 NPV ImplementationDocument21 pages09 NPV ImplementationSanjeev PatilNo ratings yet

- Service Manual: Digital HD Video Camera RecorderDocument86 pagesService Manual: Digital HD Video Camera RecorderDanNo ratings yet

- A Survey On Segment Anything Model (Sam)Document20 pagesA Survey On Segment Anything Model (Sam)1286313960No ratings yet

- Data Flow Diagram Example ThesisDocument6 pagesData Flow Diagram Example Thesislauriegunlickssiouxfalls100% (2)

- Video Game Development and User Experience: Graham Mcallister and Gareth R. WhiteDocument11 pagesVideo Game Development and User Experience: Graham Mcallister and Gareth R. WhiteParamaresthi WindriyaniNo ratings yet

- GO16WDCH06GRADER6FAS - Publicity Rights 12 InstructionsDocument2 pagesGO16WDCH06GRADER6FAS - Publicity Rights 12 InstructionsSATNAM SINGHNo ratings yet

- Revo Uninstaller Pro HelpDocument76 pagesRevo Uninstaller Pro HelpEric TizonNo ratings yet

- 300+ (UPDATED) CISSP MCQs and Answers (PDF)Document25 pages300+ (UPDATED) CISSP MCQs and Answers (PDF)Pierre-Marie Diambra0% (1)

- 10 Mobile-Only Banks Who Do It All From The AppDocument9 pages10 Mobile-Only Banks Who Do It All From The AppRobin KusmantoNo ratings yet

- Spare Parts: Cooling Unit Model No.: SK 3269.100Document1 pageSpare Parts: Cooling Unit Model No.: SK 3269.100Albert Renart LanauNo ratings yet

- Setting SunliteDocument15 pagesSetting SunliteTopi MiringNo ratings yet

- Equity in Technology EAPP AssignmentDocument3 pagesEquity in Technology EAPP AssignmentJamaela BulajaoNo ratings yet

- Accuvix V20 - User ManualDocument400 pagesAccuvix V20 - User ManualHồng Đức NguyễnNo ratings yet

- Social Media RegulationDocument12 pagesSocial Media RegulationBhashkar MehtaNo ratings yet

- Enroll. No. - : Marwadi UniversityDocument3 pagesEnroll. No. - : Marwadi Universityjefin0290No ratings yet

- EvtGenGuide PDFDocument126 pagesEvtGenGuide PDFSusskinoNo ratings yet

- JEE Main 2023 Answer Key 25 Jan Shift 1Document35 pagesJEE Main 2023 Answer Key 25 Jan Shift 1Anne BrokeNo ratings yet

- Dock Worker Cover LetterDocument9 pagesDock Worker Cover Lettervyp0wosyb1m3100% (2)

- v4 Empowering MFG With Private Lte-5gDocument14 pagesv4 Empowering MFG With Private Lte-5gSantosh NathanNo ratings yet

- CSAA Whizcard Revised 19 07 2021Document119 pagesCSAA Whizcard Revised 19 07 2021CC DreamerNo ratings yet

- 2014 02 Beacon-Cat VitDocument12 pages2014 02 Beacon-Cat VitAyouvNo ratings yet

- Advanced Auditing - MCQ Full SyallabusDocument21 pagesAdvanced Auditing - MCQ Full Syallabussonali ghatvilkarNo ratings yet