Professional Documents

Culture Documents

GAR-WI-IMS-001 Water Removal Manitowoc 4100w (Signed)

Uploaded by

Hamza Nouman0 ratings0% found this document useful (0 votes)

18 views4 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views4 pagesGAR-WI-IMS-001 Water Removal Manitowoc 4100w (Signed)

Uploaded by

Hamza NoumanCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

oT WORK INSTRUCTION

OPEL crac

5 ad MAINTENANCE DEPARTMENT

INSTRUCTION TITLE: Rain Water Removal From Manitowoc Crane Gear Oil Sump

Hazard rating :

HIGHEST LOWEST

~~ LEVEL LEVEL 2 LEVEL 3 LEVEL 4

PREPARED BY: Hamza Nouman

APPROVED BY: Khurram Bin Atta

CHANGE RECORD:

Sf Rem ate | Pose | Chaprer Section No. Deseription of change

No. | No. No. | Ne.

1 | 00 [06-06-18 [ALL | ALL New Document Approved

2

3

a

5

6

7

8

9

10

ROUTE | Prepared By REVIEWED BY ‘APPROVED BY REFERENCE

Name ‘Abdul Hafeez

‘Arain HAMZA NOUMAN KHURRAM BIN ATTA ees

Bap Enay Workshb

[Pestadsion. [Sesto —— [ween

Date HP Le| sHou E- ay

DOCUMENT CODE

carnnisoe [REV

REV. DATE | 06-06-2018

PAGE | 2of4

TABLE OF CONTENTS:

TITLE: Rain Water Removal From Manitowoc Crane Gear Oil Sump

10 3

20 3

3.0 Safety Precautions / Hazards Identified. 3

40 Abbreviations / Terms & Definitions. 3

5.0 Responsibility / Role Statement. 3

60 3

7.0 Related Documents/ References 3

80 4

9.0 Distribution List. . 4

ROUTE REVIEWED BY ‘APPROVED BY REFERENCE

re HAMZA NOUMAN KHURRAM BIN ATTA ore

Date oFod] id : (3

Desig Sign. wordsobr gave on

Garage Enginoor

DOCUMENT CODE] GARWrIms-oo9 | Rev. # | 00 [REV. DATE [06-06-2018] PAGE | Jota |

1.0 PURPOSE:

14 Purpose of this document is to provide general & safety guidelines for Rain Water

Removal from Manitowoc Crane Gear Oil Sump.

2.0 SCOPE:

at This document applies to the Manitowoc 4100 W Crane being used in PFL site.

3.0 SAFETY PRECAUTIONS:

34 PPE's required: Steel-toe boots, Safety Goggles, Gloves.

3.2 Donot use adjustable wrenches as they may damage the bolts & may slip causing an

aan

4.0 ABBREVIATIONS AND DEFINITION:

44 FLT: Fork Lift Truck

42 PFL: Pakarab Fertilizers Limited

43 MC: Manitowoc Crane

44 PTW: Permit to Work

5.0 RESPONSIBILITY:

5.1 Concerned technician is responsible to carry out the job as per given guic

6.0 PROCEDURE:

6.1 Arrange (tool kit, Drain Hose, Empty Tray).

62 Get Cold Work Permit from Concerned Area as per procedure.

6.3 _ Install drain hose at gear oil pump & place empty tray underneath.

6.4 Then communicate Crane Operator to Start Crane.

65 Remove Purging Plug from Gear Oil pump.

66 Accelerate Engine Upto Half Throttle.

67 As soon engine is started & reached at Half Throttle then Oil will flow through Drain

Hose to empty Tray.

6.8 Allowto drain until water ingress completely end & pure oil start coming.

6.9 Switch Off Engine.

6.10 _ Install Purging Plug & remove Drain Hose & Tray dispose of properly,

6.11 Check Gear Oil level & Maintain.

6.12 Perform complete House Keeping of the area and remove any spill leaving no taces

of oil or contaminated water on/ under the MC.

6.13 Close the work pemmit as per procedure.

ROUTE Prepared By REVIEWED BY. ‘APPROVED BY REFERENCE

Name] AbaulHatee= | ezawouman | KnunRAMeINATTA | Geers

= wee Ty A Toe]

DesigiSign. aes th ims" 7H eaten

od

DOCUMENT CODE | GAR-W-IMS.009 | REV.# | 00 [REV. DATE | 06-06-2010] PAGE

sofa

7.0

@NOneoNaD

RELATED DOCUMENTS / REFERENCES:

74 NIL

RECORDS:

8.1 RelevantWork Permit Copy (for one Month)

DISTRIBUTION LIST:

Original: IMS Office

Copy # 1: UM Workshop/Garage

Copy # 2: UM Plant Urea

Copy #3: UM Plant Ammonia

Copy #4: UM Plant NP

Copy # 5: Workshop/Garage Engineer

Copy #6: Concerned Technician

Copy #7: UM HNO3

9. Copy #8:SH CAN

10. Copy #9: UM Maint (East)

11. Copy #10: UM Maint (West)

12. Copy #11: UM Machinery

ROUTE Prepared By REVIEWED BY APPROVED BY

REF

Name “Abdul Hate: ERENCE

‘Arain HAMZA NOUMAN KHURRAM BIN ATTA OMs:7.5

HSE:7.5

= CAPE We ;

Desig /Sign. | Se Sub per Workshdp ls = te

aoe ys Garage Engineer teri 7\o\l!

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CV Hamza wORKSHOP eNGINEERDocument3 pagesCV Hamza wORKSHOP eNGINEERHamza NoumanNo ratings yet

- Replacing An Engine Drive BeltDocument5 pagesReplacing An Engine Drive BeltHamza NoumanNo ratings yet

- Direction On How To Replace A Fuel Filter.Document5 pagesDirection On How To Replace A Fuel Filter.Hamza NoumanNo ratings yet

- List of Workshop Machines, 2011 RevisedDocument3 pagesList of Workshop Machines, 2011 RevisedHamza Nouman100% (1)

- Quality Plan For WorkshopDocument1 pageQuality Plan For WorkshopHamza NoumanNo ratings yet

- List of Documetns, Rev-2, 29-09-2012Document4 pagesList of Documetns, Rev-2, 29-09-2012Hamza NoumanNo ratings yet

- Guidelines For Access ScaffoldingDocument28 pagesGuidelines For Access ScaffoldingHamza Nouman100% (1)

- Scaffold 2Document2 pagesScaffold 2Hamza NoumanNo ratings yet

- Scaffolding: "It's Big, It's Ugly, It's There,"Document2 pagesScaffolding: "It's Big, It's Ugly, It's There,"Hamza NoumanNo ratings yet

- Muhammad Rehan Khan Maintenance EngineerDocument13 pagesMuhammad Rehan Khan Maintenance EngineerHamza NoumanNo ratings yet

- ER-Format (Version 1)Document1 pageER-Format (Version 1)Hamza NoumanNo ratings yet

- GRG-WP-IMS-005 Derating of Cranes Dump Truck (Updated)Document5 pagesGRG-WP-IMS-005 Derating of Cranes Dump Truck (Updated)Hamza NoumanNo ratings yet

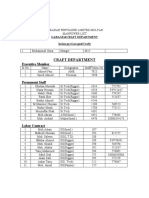

- Craft Department: Executive MemberDocument2 pagesCraft Department: Executive MemberHamza NoumanNo ratings yet