Professional Documents

Culture Documents

Mobil DTE 800 Series: Product Description

Uploaded by

Raghavendra MurthyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mobil DTE 800 Series: Product Description

Uploaded by

Raghavendra MurthyCopyright:

Available Formats

Mobil DTE 800 Series

Superior Performance Turbine Oils

Product Description

Mobil DTE 832 and 846 are superior performance turbine oils designed for use in steam turbines, gas turbines and combined cycle gas

turbine (CCGT) applications under the most severe operating conditions. These progressive products are based on high quality

hydrotreated basestocks for exceptional thermal/oxidation resistance along with specially chosen additives engineered to provide the

deposit control and "keep-clean" performance required by severe duty gas turbines as well as excellent water separability needed for

steam turbine operation. The formulations also include a non-zinc antiwear system to meet the load carrying requirements of geared

turbines.

In addition to meeting the separate requirements of modern steam and gas turbine designs, Mobil DTE 800 Series are excellent

choices for combined cycle applications that require a single oil for a gas turbine and a steam turbine run in tandem. Simultaneously

meeting both deposit control and water separation requirements is the key performance highlight of this advanced lubricant technology.

The excellent thermal/oxidative resistance of Mobil DTE 832 and 846 ensures that they can be operated in the most severe turbine

environments.

The performance features of Mobil DTE 800 Series oils translate into excellent equipment protection, reliable operation, with reduced

down-time and extended oil charge life. These products also provide the ultimate flexibility to the operator because they can be used in

all turbine types: steam, gas and geared-turbines.

Features & Benefits

Mobil DTE brand mineral-based products have been the choice for turbine operators worldwide for more than one hundred years.

During that period our company's scientists have maintained the strongest ties with turbine equipment builders and operators to ensure

that the needs of new turbine designs are met or exceeded by our lubricants. This has required a continual upgrading of Mobil turbine

oils and the application of the most appropriate modern base oil and additive technology

For modern stationary gas turbines that operate at high power outputs, exceptional protection against thermal/oxidative degradation

and deposit control are key requirements. Severe operation causes thermal stressing of the lubricant that can result in filter plugging,

servo valve deposits or short oil life. For modern steam turbines, a high level of oxidation resistance is required as well as good water

separability in cases of steam leaks. For combined cycle operation, it is necessary for the lubricant to meet the needs of both turbine

types

DTE 800 Series oils offer the following features and potential benefits:

Features Advantages and Potential Benefits

Meets or exceeds both gas turbine and steam turbine Avoids lube misapplication and costly change-out

requirements of key builders

Reduces inventory costs

Excellent thermal/oxidation stability Reduced downtime, more reliable operation

Extended oil charge life; lower product costs

Excellent antiwear protection Excellent protection for geared turbines (gas- and steam-), lower

maintenance and replacement costs

ExxonMobil Lubricants & Specialties

All products may not be available locally. For more information, contact your local sales office or visit www.exxonmobil.com.

ExxonMobil is comprised of numerous affiliates and subsidiaries, many with names that include Esso, Mobil, or ExxonMobil. Nothing in this document is intended to override or

supersede the corporate separateness of local entities. Responsibility for local action and accountability remains with the local ExxonMobil-affiliate entities. Due to continual

product research and development, the information contained herein is subject to change without notification. Typical Properties may vary slightly.

© 2001 Exxon Mobil Corporation. All rights reserved.

Features Advantages and Potential Benefits

Extended equipment protection and reduced replacement costs

Excellent demulsibility Efficient system operation and reduced maintenance

Applications

Mobil DTE 832 and 846 are superior performance turbine oils designed for use in steam and gas turbine oil systems, direct- or gear-

coupled and turbine speed control mechanisms. Specific applications include:

• Combined cycle (CCGT) electric power generation applications including those with a common circulation system for the steam

turbine and gas turbine.

• Lubrication of steam turbine or gas turbine units used for electric power generation, natural gas pipeline transmission, process

operations and cogeneration plants.

Specifications & Approvals

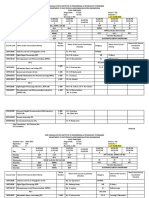

Mobil DTE 800 Series meets or exceeds the following industry specifications 832 846

JIS K2213 Type 2 X X

DIN 51515-1 L-TD X X

DIN 51515-2 L-TG X X

GE GEK 28143A X X

Solar ES 9-224, Class II X X

GE GEK 32568-E/F X

GE GEK 101941-A X

GE GEK 107395 X

Alstom Power Sweden 812108 X

Alstom Power Sweden 812109 X

Mobil DTE 800 Series has the following builder approvals: 832 846

Alstom Power HTGD 90 117 X X

Siemens TLV 9013 04 X X

Quality level GE GEK 32568-C X

Typical Properties

Mobil DTE 800 Series 832 846

ISO Viscosity Grade 32 46

Viscosity, ASTM D 445:

cSt @ 40º C 29.6 42.4

cSt @ 100º C 5.4 6.2

Viscosity Index, ASTM D 2270 110 106

Pour Point, ºC, ASTM D 97 -30 -30

Flash Point, ºC, ASTM D 92 224 244

Specific Gravity 15.6º C/15.6º C, ASTM D 4052 0.86 0.87

ExxonMobil Lubricants & Specialties

All products may not be available locally. For more information, contact your local sales office or visit www.exxonmobil.com.

ExxonMobil is comprised of numerous affiliates and subsidiaries, many with names that include Esso, Mobil, or ExxonMobil. Nothing in this document is intended to override or

supersede the corporate separateness of local entities. Responsibility for local action and accountability remains with the local ExxonMobil-affiliate entities. Due to continual

product research and development, the information contained herein is subject to change without notification. Typical Properties may vary slightly.

© 2001 Exxon Mobil Corporation. All rights reserved.

Mobil DTE 800 Series 832 846

TOST, ASTM D 943, Hours to 2 NN 10,000+ 10,000+

RBOT, ASTM D 2272, min. 1200 1100

FZG Scuffing, DIN 5182, A/8.3/90, Fail Stage 9 9

Rust Prevention, ASTM D 665:

Distilled Water Pass Pass

Sea Water Pass Pass

Water Seperability, ASTM D 1401, Min. to 0 ml emulsion @ 54º C 15 15

Copper Strip Corrosion, ASTM D 130, 3 hrs @ 100º C 1A 1A

Foam Test, ASTM D 892, Seq I, II & III Tendency/stability, ml/ml 20/0 20/0

Air Release, mins. 2 2

Health & Safety

Based on available information, this product is not expected to produce adverse effects on health when used for the intended

application and the recommendations provided in the Material Safety Data Sheet (MSDS) are followed. MSDS's are available upon

request through your sales contract office, or via the Internet. This product should not be used for purposes other than its intended use.

If disposing of used product, take care to protect the environment.

The Mobil logotype, the Pegasus design and Mobil DTE are trademarks of ExxonMobil Corporation, or one of its subsidiaries.

ExxonMobil Lubricants & Specialties

All products may not be available locally. For more information, contact your local sales office or visit www.exxonmobil.com.

ExxonMobil is comprised of numerous affiliates and subsidiaries, many with names that include Esso, Mobil, or ExxonMobil. Nothing in this document is intended to override or

supersede the corporate separateness of local entities. Responsibility for local action and accountability remains with the local ExxonMobil-affiliate entities. Due to continual

product research and development, the information contained herein is subject to change without notification. Typical Properties may vary slightly.

© 2001 Exxon Mobil Corporation. All rights reserved.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Control System InstrumentationDocument88 pagesControl System Instrumentationyeay_meNo ratings yet

- Python Tutorial For BeginnersDocument10 pagesPython Tutorial For BeginnerscidBookBee100% (2)

- Note How To File An AnswerDocument5 pagesNote How To File An AnswerAbc FghNo ratings yet

- Komatsu Hd785-7 Rigid Dump TrucksDocument20 pagesKomatsu Hd785-7 Rigid Dump Truckswahyu100510No ratings yet

- Flight Ops Eng PDFDocument6 pagesFlight Ops Eng PDFIrfan Azmi0% (2)

- Molykote 55 O Ring GreaseDocument7 pagesMolykote 55 O Ring GreaseRaghavendra MurthyNo ratings yet

- SG-630 SelcoDocument2 pagesSG-630 SelcoRaghavendra MurthyNo ratings yet

- SG920 Electrically Conductive GreaseDocument2 pagesSG920 Electrically Conductive GreaseRaghavendra MurthyNo ratings yet

- Orelube LubricantsDocument8 pagesOrelube LubricantsRaghavendra MurthyNo ratings yet

- APC Surge Protector 6 Outlets With Master/ Slave Control, Energy Saving and Noise FilterDocument2 pagesAPC Surge Protector 6 Outlets With Master/ Slave Control, Energy Saving and Noise FilterRaghavendra MurthyNo ratings yet

- Characteristics (Typical Figures) Agip Blasia S 150 220 320Document1 pageCharacteristics (Typical Figures) Agip Blasia S 150 220 320Raghavendra MurthyNo ratings yet

- Swaggers Catalouge - 2021Document10 pagesSwaggers Catalouge - 2021Raghavendra MurthyNo ratings yet

- Shell Cardium® Fluid EP: Premium Performance Open Gear and Wire Rope FluidDocument1 pageShell Cardium® Fluid EP: Premium Performance Open Gear and Wire Rope FluidRaghavendra MurthyNo ratings yet

- AGIP SX100 Gear OilDocument1 pageAGIP SX100 Gear OilRaghavendra MurthyNo ratings yet

- Mobil EAL Envosyn H Series Hydraulic OilsDocument3 pagesMobil EAL Envosyn H Series Hydraulic OilsRaghavendra MurthyNo ratings yet

- Mobil Delvac 1330, 1340, 1350: Heavy Duty Diesel Engine OilsDocument2 pagesMobil Delvac 1330, 1340, 1350: Heavy Duty Diesel Engine OilsRaghavendra MurthyNo ratings yet

- Mobil Grease SpecialDocument2 pagesMobil Grease SpecialRaghavendra MurthyNo ratings yet

- TF 15Document2 pagesTF 15Raghavendra MurthyNo ratings yet

- S-10 15Document2 pagesS-10 15Raghavendra MurthyNo ratings yet

- Habasit Tensile Force BlogDocument2 pagesHabasit Tensile Force BlogRaghavendra MurthyNo ratings yet

- S-18 20Document2 pagesS-18 20Raghavendra MurthyNo ratings yet

- Problem: While Printing On 12"x15" Single Paper Continuous Stationery The Paper Gets Stuck Near BlackDocument1 pageProblem: While Printing On 12"x15" Single Paper Continuous Stationery The Paper Gets Stuck Near BlackRaghavendra MurthyNo ratings yet

- Evaluation of Antimicrobial AgentsDocument8 pagesEvaluation of Antimicrobial AgentsSureshCoolNo ratings yet

- Credit Transactions Reviewer FinalDocument23 pagesCredit Transactions Reviewer Finalpit1xNo ratings yet

- De Thi Hoc Ky 2 Mon Tieng Anh Lop 10 Thi Diem So GD DT Binh PhuocDocument12 pagesDe Thi Hoc Ky 2 Mon Tieng Anh Lop 10 Thi Diem So GD DT Binh Phuoc17. Phạm Tuyết Nga 10HNo ratings yet

- K-Means in Python - SolutionDocument6 pagesK-Means in Python - SolutionRodrigo ViolanteNo ratings yet

- What Color Is Your ParachuteDocument3 pagesWhat Color Is Your Parachuteapi-374774533100% (1)

- Pelican StoresDocument6 pagesPelican StoresDavid EscurraNo ratings yet

- PNG 8 Directory Health Language v1 m56577569830506654Document28 pagesPNG 8 Directory Health Language v1 m56577569830506654Alex Efkarpidis100% (1)

- European J of Haematology - 2020 - Rasmussen - Unexpected Isolated Activated Partial Thromboplastin Time Prolongation ADocument7 pagesEuropean J of Haematology - 2020 - Rasmussen - Unexpected Isolated Activated Partial Thromboplastin Time Prolongation Akallolchakraborty779204No ratings yet

- Explanation LetterDocument1 pageExplanation LetterBebe KwahNo ratings yet

- Challenges of International BusinessDocument4 pagesChallenges of International BusinessRikesh SapkotaNo ratings yet

- Campus Security AwarenessDocument19 pagesCampus Security AwarenessMiyangNo ratings yet

- Material Safety Data Sheet: 1 Chemical Product and Company Identification FENOL LFR (6015-6020-6025-6035)Document5 pagesMaterial Safety Data Sheet: 1 Chemical Product and Company Identification FENOL LFR (6015-6020-6025-6035)Zirve PolimerNo ratings yet

- Analisis Proses Quality Control Pada Produksi Cylinder Comp Di PT.XDocument8 pagesAnalisis Proses Quality Control Pada Produksi Cylinder Comp Di PT.XAyu AnsyariNo ratings yet

- Solution Manual For Mis Cases Decision Making 4th Edition by MillerDocument8 pagesSolution Manual For Mis Cases Decision Making 4th Edition by MillerElizabethSteelefocgk100% (81)

- Chapter IV-Principles and Conditions of Learning and The CurriculumDocument9 pagesChapter IV-Principles and Conditions of Learning and The CurriculumJennifer PagatpatanNo ratings yet

- Sales DataDocument6 pagesSales DataSandeep Rao VenepalliNo ratings yet

- Thin Capitalization Rules Di Indonesia Studi KasusDocument19 pagesThin Capitalization Rules Di Indonesia Studi KasusafniNo ratings yet

- 1 s2.0 S0308521X23000616 MainDocument18 pages1 s2.0 S0308521X23000616 MainInpecta BalramNo ratings yet

- ATSMDE BrochureDocument2 pagesATSMDE Brochureswapnil100% (1)

- JD - PW HR Business Partner-1Document1 pageJD - PW HR Business Partner-1VidyaNo ratings yet

- Termina Details 5 21Document17 pagesTermina Details 5 21Harikesh YadavNo ratings yet

- Environment Position PaperDocument6 pagesEnvironment Position PaperJenlisa KimanobanNo ratings yet

- Biofuels Industry ReportDocument2 pagesBiofuels Industry ReportNiravNo ratings yet

- Sexual HarassmentDocument11 pagesSexual HarassmentKrip KNo ratings yet

- III B.Tech TT 2021-22Document5 pagesIII B.Tech TT 2021-22ravikumar rayalaNo ratings yet