Professional Documents

Culture Documents

Building Your Own CNC Milling Machine

Building Your Own CNC Milling Machine

Uploaded by

nasir akhtarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Building Your Own CNC Milling Machine

Building Your Own CNC Milling Machine

Uploaded by

nasir akhtarCopyright:

Available Formats

instructables

Building Your Own CNC Router/milling Machine

by Trochilidesign

Already when I was little I was thinking of making a year of my bachelor in Industrial Design, so I was

machine which could make things! A machine which confident enough to start a build. The real difference

would give me the opportunity to create products for between now and 5 years ago was, I learned to work

in and around the house. Years later I stumbled on with metal on manual milling machines and lathes

the words 'Computer Numerical Control' or more and above all I had the right tools to design a

specifically the CNC milling machine. After I found machine.

out people were able to build one themselves in their

own shed, I knew it! This Instructable will show you how I built my CNC

For three months I tried to find the proper parts (A milling machine. I know a lot of CNC dreamers do not

dremeltool, drawer slides, pieces of wood, etc.), but I have the knowledge or tools to build a full metal

didn't really know how to build a CNC. The idea fell machine. I still think and hope this Instructable

into oblivion. inspires you to make your own machine. I include all

of the necessary steps I went through in designing

In August 2013 the idea to build a CNC milling and building this CNC milling machine.

machine captivated me again. I just finished the first

Building Your Own CNC Router/milling Machine: Page 1

Step 1: The Design and CAD Model

It all started with a proper design, in my case a few machine.

sketches to get a good feeling for the dimensions and

shape. Quickly after the sketching phase came the Since I'm a lover of good designed tools, I tried to

CAD model. I created my model in SolidWorks. If you make maintenance and the possibility to adjust things

plan to design your own machine I recommend a on the machine as easy as possible. Bearings could

parametric CAD-modeling tool. Your machine will have been integrated in the machine, but I chose to

most likely have a lot of parts which have to fit place them in separate bearing blocks (in case it

together neatly, sometimes with some strange needs to be replaced in the future). Keeping your

dimensions (for example pre-ordered parts). After all machine clean is very important too, so guiderails are

the parts were modeled, technical drawings were all accessible (in case of the x-axis by detaching

made. I used these drawings to machine all of the some cover plates)

custom parts on the manual lathe and milling

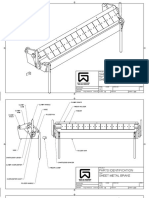

Step 2: The Frame

The frame provides the machine a rigid basis, not Since the frame sits beneath the worksurface dust

only to place it in your workshop but also for working could fall down on the guiderails (you want to keep

on. To the frame the gantry will be mounted on sliding them clean, more about that in step 5). To prevent

rails and later on a work surface. It also houses the this, dust covers were made and mounted around the

stepper motor and spindle for the x-axis. I constructed guiderails. A angular profile mounted with brass

my frame from 2 Maytec 40x80mm profiles, 2 milled t-nuts onto the may tech frame and 2mm

endplates (both 10 mm thick aluminium), 4 corner aluminium plates mounted in the milled pockets on

pieces and a square structural piece. the endplates.

All of the profiles are sawed right-angled and

afterward milled exactly square. With the corner On both endplates bearing blocks are mounted for the

pieces a heavy (well relatively lightweight; it's all spindle. They were hand milled and lathed to the right

aluminium) frame was bolted together. The square tolerances. On the front endplate mounting slots for

frame made from the smaller profiles were mounted the stepper motor were milled

with 4 milled blocks (aluminium) on the inside of the

Maytec profiles.

Building Your Own CNC Router/milling Machine: Page 2

6 3

4

5

3

2

1 2

1. Milled parts for dust covers 1. Dustcovers mounted

2. Linear guide rails; discussed in step 5 2. Linear guiderails with the runner blocks slided on

3. Maytech Aluminium 40x80mm extruded profile 3. The square structure assembled and mounted in the

4. 40x40mm aluminium profile for a rigid structure frame

5. 90degree angle pieces

6. Lots of T-slots for T-nuts. Mounting things to the frame is just peanuts

1. Dustcover

Building Your Own CNC Router/milling Machine: Page 3

Step 3: The Gantry

The gantry is the bridge between the x-axis guiderails Most of the work I planned to do with the CNC

and supports your milling motor above the workpiece. involved milling aluminium parts. An average vise for

The higher you make it, the thicker the workpiece can the machine would be 60 mm high. Since the thickest

be. There is however a disadvantage of high gantries. blocks of aluminium easily available for me would be

They work as levers on the guiderails and on the 60 mm high as well, I chose to space between the

other hand the side plates tend to bend more easily work surface and the piece of metal, which could hit

by making them longer. the workpiece first, to be 125 mm. This gave me a

starting point for the side plates. Since I wanted the formed out of an 5mm thick U-profile. It is mounted

center of an end mill hovering over the center of the between the side plate with the help of two simple

runnigblocks (from the machines side view), the side mounting blocks. On the inside the U-profile houses

plates had to be placed at an angle. Solidworks the y-axis spindle. Which is again supported by the

helped me to convert all of the measurements into the same bearing blocks used for the x-axis. They are

final parts. Because of all the complex dimensions I mounted on the outside of the side plates.

decided to mill these parts on an industrial CNC mill,

this also gave me the opportunity to round all of the Beneath the main frame a plate was mounted on the

corners (would have been very hard to mill on a underside of the gantry's side plates, giving a

manual mill). mounting point for the x-axis spindle nut.

The part which supports the y-axis guiderails is

1. Sideplates of the gantry; they were CNC milled on an industrial machine.

Building Your Own CNC Router/milling Machine: Page 4

Step 4: Last Movement

The last movement is what I call the end is floating behind the mounting plate for the

Stepermotorhousing for the z-axis (plus the z-axis milling motor. The spindle nut for the Z-axis was

itself of course). It is constructed out of a frontplate directly bolted on the mounting plate for the milling

mounted on the y-axis linear guiderails, 2 motor.

reinforcement plates, a motor mount and a backplate. The backplate provides a spot for the y-axis spindle

On the front plate 2 linear guiderails were mounted for nut to be mounted; it is mounted on the inside.

the z-axis onto which the Mountingplate for the milling

motor was placed with the runner blocks. All of the custom mechanics are now ready. The CNC

is assembled with the guiderails, spindles and a lot of

The motor mount has the bearing for the z-axis bolts ;-)

spindle fitted into it. So I didn't use a bearing block for

this spindle and is only supported on the top. he lower

Building Your Own CNC Router/milling Machine: Page 5

Step 5: Guide Rails

Since your endmills need to move in 3 directions, the support is recommended.

machine guides them with its guide rails. The guide I chose the most expensive option; profiled linear

rails provides the machine its rigidity in all directions guide rails with runner blocks. The are designed to

except the one it moves in. You want them to let the receive forces in all directions. In the third picture you

machine only move in the preferred direction. Any can see the looping bearing balls, they are positioned

backlash in other directions results in inaccuracies in on both sides of the profile. All with a tangent 45

your workpieces. degree relative to each other, giving it the ability to

On my machine I wanted to use guideways supported handle high loads.

on the full length of the rail, reducing the risk for

deflections on the longer axes. To get all guiderails perpendicular and parallel to

In my opinion some kitchen drawer slides are each other they were all aligned with a dial indicator

preferred above the hardened steel rods which are (with a maximum difference of 0,01 mm). If you spent

supported on the end (yes! they will deflect). Since your time on this part, the machine will perform very

you are constantly fighting the forces from the well in accuracy!

endmills against the material of the workpiece, a lot of

Building Your Own CNC Router/milling Machine: Page 6

Step 6: Spindles and Pulleys

The spindles translate the rotational movement from drivenut which reduce friction and are approach a

the stepper motors into a linear movement. When backlash free system. You can order the drive nuts

building your machine, you can choose between here: http://www.mixware.de/index.html\

three different version; leadscrews or ball screws,

either in metric or Imperial configuration. The main Both the ends of the x- and y-axis have to be turned

difference between leadscrews and ball screws is the to size to fit the bearings, pulleys and clamping nuts.

accuracy and friction. Leadscrews tend to have a lot Since the z-axis spindle is only supported on one and

more friction and are less precise than ball screws. If with a bearing, it is turned on only one side.

your looking for a very accurate machine without any

backlash, you should definitely consider ball screws. The pulleys are drilled to the turned shaft size (in my

However, they are relatively expensive! case 8 mm) and provided with a M4 setscrew

perpendicular to the shafthole.

I chose to use leadscrews with a special plastic

Building Your Own CNC Router/milling Machine: Page 7

Step 7: Worksurface

The work surface is the place you will clamp your surface! You could also use Mdf with anchor nuts and

pieces of material on. On a lot of professional bolts. Try to avoid screws and nails in Mdf, it doesn't

machine a T-slotted bed is used, giving you the grip them as good as a plywood board.

option the use T-nuts and bolts to clamp your

materials or vices. I chose to use a square piece of The work surface could be milled flat by the machine

18 mm birch-plywood on which a screw the materials itself after you've completed it. Your first project :-)

and replace it when needed. An affordable work

Building Your Own CNC Router/milling Machine: Page 8

Step 8: Electrical System

The main components in the electrical system are: You can of course also put together your own set.

Since I could not wait to sartup the machine I

-Stepper motors temporarily mounted all the drivers and power supply

on a open board. The enclosure is in the making.

-Stepper drivers

Since a few years it is also possible to connect a

-Powersupply (or 2) CNC very easily via USB. The UBS-breakout boards

on the market generally come with their own

-Breakoutboard software. I chose to use the parallel printer port found

on most older PC's. I do not intend to use a new

-Computer computer in a room full of dust, oil and aluminium

chips

-And last but not least: Safety first; a emergency stop

;-) Since I had a lot of difficulties in finding a proper

scheme with the needed components, I tried to make

I chose to buy a complete set on Ebay with 3 Nema everything clear in the infographic above (you can

23 stepper motors, 3 suitable drivers, a breakout also download the PDF and zoom in on the different

board and a 36 V power supply. I use a step down parts)

converter to convert the 36 volt DC into 5 Volt DC.

Download

http://www.instructables.com/ORIG/FHN/J01T/HVS1FHDO/FHNJ01THVS1FHDO.pdf

…

Step 9: The Milling Motor

Since we want to remove material from the piece we want to improve your machine, a reliable Hf spindle

clamp to the work surface, we need something that will please you. It all depents on the amount of money

drives the cutting bits; i.e. the endmills. The milling you can afford to spent on it.

motor will spin the cutters at low or high speeds.

From a simple Dremeltool to a High frequency Try to find something with the ability to use different

Spindle of several kWatts. For our machine size a sized collets.

Kress spindle is very convenient to start with. If you

Building Your Own CNC Router/milling Machine: Page 9

Step 10: CNC Software

In the topic CNC software I'll discuss not only the professional software offered by my University

program me that controls the machine, but also the

software which produces code the machine will The software that controls the machine is a Gcode

understand. interpreter. When you use a USB-hub, as discussed

in Electrical system), it will have it's own software. If

When we make a workpiece on our computer, either you use the parallel printer port on a older computer,

flat or a 3D CAD (Computer Aided Design) model, we you can choose your own. I chose to use Mach3

need to convert it into something the machine will since it it used by most hobbyists. You can find a lot

understand. With CAM (Computer Aided Machining) about it on forums and google. Since Mach3 has

we can read vectors and 3D models and create an many options and functions, I won't explain them.

output suitable (Gcode) for the software which Just play with it and you'll discover its secrets :-)

controls the machine. I'm allowed to use the

Building Your Own CNC Router/milling Machine: Page 10

Step 11: It's Alive!!!

Ones connected properly, hookup the power supply, to search for parts on Ebay etc., it took me half a

it just works!! Start with some pieces of wood or foam year. This keeps the costs down of course, I was able

and you'll get used to the speeds and properties of to build the machine for less then €1000,-

your machine. The work above shows some of the

pieces I'm working on in aluminium. As you can see I hope the story encourages you to build your own

the machine is able to work very intricately. CNC milling machine. Please feel free to contact me

or give a comment if you think something is missing.

Search for proper parts and take your time. I could

have build the machine in a month, but because I had

Building Your Own CNC Router/milling Machine: Page 11

I need more photos for the cnc project

can i have the cad file?

i need it because i want to finish my project

please send to my personal email jastimmanh@gmail.com

thank you

Guys is better to use steel and welding then aluminium?

From my point of view, welded steel is always harder to deal with on the tweaking and after

fabrication stages. i prefer using aluminium with screws so my final product will be more flexible to

work with like if i need to cut an oversized piece or anything else. so I vote for aluminium but you

can always use the method you prefer.

Moi également, d'autant que l'on trouve de bons profilés sur eBay qui font vraiment bien l'affaire.

Merci pour toutes vos précisions.

I agree with you :)

building isn't difficult..syncros and programming software is all together different.

Just depends on which aspects you're good at ;)

Bonsoir

Vraiment une très belle machine.

Qu'est t'il possible de monter niveau broche, est-ce qu'une KRESS pourrait faire le travat.

Building Your Own CNC Router/milling Machine: Page 12

Merci de votre réponse.

this is all open source and pretty simple

Çok iyi iş, Solidworks & pdf Dosyalarını paylaşabilir misin? erdag_Arif@hotmail.com

Hey grettings from Costa Rica! Nice job it looks very well made, i have a question;

If say you usa a nema 17 2A it will run the axis? or it needs more powerful motors? and also a

comment; if you change the plates to by made of 1/2 inch plywood it will take a lot of weight and

will get a similar estructure quality i guess. Any way thank you for sharing your work

This is a truly impressive project and what I needed for me to take the plunge in making my own!

I'm doing some "reverse engineering" based on your photos and drawing up my own plans. Could

you post more pics? Thanks! mickvaughan@roadrunner.com

mvaughan@archres.com

Hello, You got a great project and i gonna make this project on school to but i can't finde evry

pieces of the project its hard to find.and my question is can i get the full file sended to my

emailaddres. like the soldworksfile. and the full pdf files

email: andries.joris@gmail.com

already tanks and maybe soon you answer me :)

Hi, excellent job and plans!!

Can I have its CAD model?

Thanks

Really like the design. Not going to ask for your plans, but I will ask if there is a difference in those

stepper motors... Do they impact what you can achieve?

Good day

Great guide

Do you have cad drawings of the machine that you could share ?

Many thank you

Geordie

Your design is a standout!

You included a safety switch!

My employer has a Laser Shop with several machines the biggest of which is a 100W cutter. Our

problem is that the operators in our 24/7 shop get sloppy and try to bypass safety devices.

We use dual devices, now, the only challenge being to ensure they wear the goggles!

Building Your Own CNC Router/milling Machine: Page 13

Great post, shows that you are organised in your work.

Thank you so much for your very detailed instructions & taking the time to write/draw up the pdf's

for us to download. I've been looking to build one of these but the other instructables confused me

& I was about to give up (I'm not an idiot, just a noob when it comes to CNC).

I realise this is an old tutorial but it is still helping people.. Thanks again!

wonderful machine ! I am wondering ... what size of guide rails did you use ? mgn12 or something

else ? also i see u mounted only one plate on the rails ... did you notice any flexes ? Isn't it

necessary to use 2 plates on each rail to make it more steardy? Thx in advance for your answer

Step one is that you have to have a degree in mechanical design.

The only degree you needs to build one of these is the degree of comprehension it takes to follow

directions.l

If you can bake a cake, you can build one of these,

lol

And my step one is a degree in Industrial Design Engineering ;). I you have the drive to build one,

you can build one of these

Please let me know what is the hardness of the steel, machine parts

lol

all steel parts are from the mentioned manufacturers, I don't know why you would be

interested....but have a look on the websites.

Hi,

Firstly would just like to say your project is amazing, and the results are so good - that Aston Martin

badge. Wow!

Would you be able to share the 3D model?

Thanks

Of the CNC machine that is ;)

Dobry den. Lze vas kontaktovat? Dekuji. Staci sms na 773244112

Building Your Own CNC Router/milling Machine: Page 14

Hi, very nice!!!

Specially for a person like me who is too new to all this.

I want to contact you through email or whatever.

I am from India.

Plz atleast reply.

Are you able to machine metal parts (steel, iron, etc.) with your machine?

Probably but not much steel, im sure it can do a little aluminum, copper, and brass. Maybe small

cuts in mild steel. I have a cnc router parts pro 4824, I can cut aluminum but its not the greatest. I

have done steel sheets for computer cases but its brutal.

Drawer slides. Drawer slides. Why didn't I ever think of drawer slides. That machine looks

absolutely mean. Compared to flimsy looking three d printers your CNC machine could beat them

up all day. I'm probably going to incorporate your drawer slide design into my ultimate CNC

system. I've been cooking it up for a while and experimenting on little machines, I've decided to go

with over 2 foot of vertical axis so this would make it look so nice in my opinion. Last couple

months I've been sourcing ideas for the frame and I gotta say, the streamlined gantry design is

beautiful. A-plus material. Instruct on!

Good job mr. Thank you for share this. This will help me alot building my first cnc :) how do you

program it?

2 questions. no1 will this work for milling tracks, pads and holes on a circuit board, and will this

work with circuit wizard?

This instructable is very helpful, I would like to build my own cnc machine but I find it difficult to

understand everything about it, I just want to build a machine that can mill 1 inch thick plywood. I

have to order the electronics from ebay because they are very expensive in my country! what

electronics should I buy specifically? I hope to get your help :)

search for cnc kit nema. 2A is more than enough ffor you. it'll depend on speed you'll be working

too.

Hello, thanks for sharing your hard work. Please on what basis did you assume the inclination

angle of the gantry ?

Balance and posicioning.

This is a really clean and concise article. Nice build, and nice authoring. As a new hobbyist, I

would have really liked to learn more about the software side of running these machines. I have

googled much about it, but there seems to be a ton of different options. Regardless, nice work on

Building Your Own CNC Router/milling Machine: Page 15

this build.

Hi, Thanks for sharing the story of your great machine. I plan to buy a similar kit with 3x NEMA23

3.5A 3Nm steppers + drivers+ breakout board + 36V source; is this stepper powerful enough for

harder materials? not steel but aluminum or copper; especially for X axis , which is the carrier of

the other 2 axis + the tool head ... what speed do you use mostly ?( soft wood , hard wood, alu ?)

GREAT to hear that you managed to build it under 1000E. this is also my target . :D

i like this one. can you please tell me what is the accuracy?

Hey! your project looks pretty impressive :) Can I have its CAD model? Its really important :/

he already said he doesnt share :.(

Please upload your BOM and all 3d models as well as cad drawings. I want to build this

As mentioned earlier in the comment and in the article, I cannot share them

I do not recall seeing the thickness of the Gantry Plates in the Drawing or in the text of the article.

Did I miss it? If it was not in either spot, can you provide it?

Thanks,

Dean

They have a thickness of 15 mm :)

milled from 6082 aluminium

Building Your Own CNC Router/milling Machine: Page 16

You might also like

- DIY Bench Top Tubing BenderDocument17 pagesDIY Bench Top Tubing BenderMalcolm DiamondNo ratings yet

- DIY CNC RouterDocument67 pagesDIY CNC RouterKaled Rojas SantanaNo ratings yet

- Build Your Own CNC Milling Machine PDFDocument13 pagesBuild Your Own CNC Milling Machine PDFandres silvestreNo ratings yet

- Mini-Skat 6-Wheel Plans AssemblyDocument40 pagesMini-Skat 6-Wheel Plans AssemblyВладимир Батманов100% (3)

- How To Build A CNC Milling MachineDocument12 pagesHow To Build A CNC Milling MachineScott Campbell100% (3)

- Chapter 3 - Bending Forming ShapingDocument11 pagesChapter 3 - Bending Forming ShapingFrigeri FrigeriNo ratings yet

- How To Build A Fuel LineDocument15 pagesHow To Build A Fuel LineMech EngrNo ratings yet

- CNC DiyDocument15 pagesCNC DiyNimmala Ganesh0% (1)

- DIY Cheap and Sturdy Laser EngraverDocument28 pagesDIY Cheap and Sturdy Laser EngraverAnimatronic sonoroNo ratings yet

- CBH Vertical Tubing BenderDocument17 pagesCBH Vertical Tubing BenderRagos Segundo100% (1)

- Rigid Sportster Frame Assembly GuideDocument14 pagesRigid Sportster Frame Assembly GuideMalcolm DiamondNo ratings yet

- Soup To Nuts 2Document10 pagesSoup To Nuts 2mtang45No ratings yet

- Fundamentals of Fighter Aircraft DesignDocument291 pagesFundamentals of Fighter Aircraft DesignSoma Varga100% (2)

- Struck Dozers - CubCadetManDocument4 pagesStruck Dozers - CubCadetManNaveen BansalNo ratings yet

- Crossing the Line Baja 1000: What Secrets Starts as Fortune Might Cost Him His LifeFrom EverandCrossing the Line Baja 1000: What Secrets Starts as Fortune Might Cost Him His LifeNo ratings yet

- FGC-9 MkII GuideDocument174 pagesFGC-9 MkII GuideASAP CHAKINo ratings yet

- Medium Sized DIY CNC 20 X 30 Work AreaDocument21 pagesMedium Sized DIY CNC 20 X 30 Work AreaPatrick SawianNo ratings yet

- DIY Guide Rails Plans VSC ToolsDocument22 pagesDIY Guide Rails Plans VSC ToolsMiguel TravahoNo ratings yet

- Electric Go Kart in Retro Style For KidsDocument7 pagesElectric Go Kart in Retro Style For KidsPaul MerrickNo ratings yet

- Project Street Rod: The Step-by-step Restoration of a Popular Vintage CarFrom EverandProject Street Rod: The Step-by-step Restoration of a Popular Vintage CarNo ratings yet

- Three Trailers in One - Box, Car and Flat Top. The Box Top TrailerDocument10 pagesThree Trailers in One - Box, Car and Flat Top. The Box Top TrailerDavidNo ratings yet

- Ralph Patterson Speed Reducer 1Document31 pagesRalph Patterson Speed Reducer 1stilmix60100% (2)

- Free Plans Sheet Metal Brake WWW Gwellwood ComDocument20 pagesFree Plans Sheet Metal Brake WWW Gwellwood ComRomulo Barcos75% (4)

- Sheet Metal Bending PlansDocument11 pagesSheet Metal Bending PlansVivek_subzero100% (1)

- Low Cost DIY CNC RouterDocument18 pagesLow Cost DIY CNC Routerjlpicard100% (1)

- HTTP WWW - Cncroutersource.com Homemade-Cnc-RouterDocument53 pagesHTTP WWW - Cncroutersource.com Homemade-Cnc-Routerpremako100% (5)

- Maestro Editor PDFDocument498 pagesMaestro Editor PDFGaggx83% (6)

- Homemade Bandsaw Plans - YouTubeDocument3 pagesHomemade Bandsaw Plans - YouTubeStaroth Gonz Rodr100% (4)

- Youngsters T Bucket Frame Plans V1 0Document24 pagesYoungsters T Bucket Frame Plans V1 0weirdbennyNo ratings yet

- Mini CNC Milling Machine: InstructablesDocument26 pagesMini CNC Milling Machine: InstructablesMaxmore KarumamupiyoNo ratings yet

- Combined Troubleshooting Guide - 7.25.2022Document1 pageCombined Troubleshooting Guide - 7.25.2022Novan WP100% (1)

- WP - FDM - Metal Forming - 0420aDocument8 pagesWP - FDM - Metal Forming - 0420aBAF BafConsultingNo ratings yet

- AKT020 Rivet Jaws InstructionsDocument12 pagesAKT020 Rivet Jaws InstructionsDale WadeNo ratings yet

- Build Your Own 3d Printing Filament Factory Filame PDFDocument25 pagesBuild Your Own 3d Printing Filament Factory Filame PDFCesar AzcargortaNo ratings yet

- Rotary Table Bill of Materials A: TitleDocument12 pagesRotary Table Bill of Materials A: TitleComan Cristian MihailNo ratings yet

- Easy To Build CNC Mill Stepper Motor and Driver Ci - (Wazhua - Com)Document15 pagesEasy To Build CNC Mill Stepper Motor and Driver Ci - (Wazhua - Com)Kashif MirzaNo ratings yet

- Budget Chopper Bicycle Work in ProgressDocument21 pagesBudget Chopper Bicycle Work in ProgressMarius DanilaNo ratings yet

- Woodworking - Home Made Table Saw Box Joint JigDocument5 pagesWoodworking - Home Made Table Saw Box Joint Jigleehoin100% (2)

- CNC Plasma Torch ConstructionDocument2 pagesCNC Plasma Torch ConstructionMariane MottaNo ratings yet

- Mini Mill Assembly Drawings-2009Document5 pagesMini Mill Assembly Drawings-2009ModularCNCNo ratings yet

- Hybrid Electric AircraftDocument123 pagesHybrid Electric AircraftSoma Varga100% (1)

- Hot Wire Manchine - User Manual-ENDocument41 pagesHot Wire Manchine - User Manual-ENZoliNo ratings yet

- 34 Jigs and Fixtures For Machine ShopDocument12 pages34 Jigs and Fixtures For Machine ShopPRASAD326100% (8)

- CATIA V5-6R2015 Basics Part III: Assembly Design, Drafting, Sheetmetal Design, and Surface DesignFrom EverandCATIA V5-6R2015 Basics Part III: Assembly Design, Drafting, Sheetmetal Design, and Surface DesignRating: 5 out of 5 stars5/5 (2)

- Modular CNC Nema-23 For Acme Lead ScrewDocument1 pageModular CNC Nema-23 For Acme Lead ScrewModularCNCNo ratings yet

- Installing a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersFrom EverandInstalling a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersNo ratings yet

- Go KartDocument20 pagesGo KartVikas PuppalaNo ratings yet

- Modeling Aircraft Performance and Stability On X-PlaneDocument31 pagesModeling Aircraft Performance and Stability On X-PlaneSoma VargaNo ratings yet

- DIY CNC Router Build Fixed Gantry, Steel - Wade'O DesignDocument11 pagesDIY CNC Router Build Fixed Gantry, Steel - Wade'O DesignRed ErickNo ratings yet

- Ralph Patterson Diamond Tool HolderDocument12 pagesRalph Patterson Diamond Tool Holderian_newNo ratings yet

- E-Book - Cutting Tools For CNC RouterDocument11 pagesE-Book - Cutting Tools For CNC RouterVictor ParvanNo ratings yet

- Catalogo Apache Rtr180 PDF 2012Document48 pagesCatalogo Apache Rtr180 PDF 2012Edgar Sorto63% (8)

- 3D Printed Tooling, Jigs and Fixtures Standard RequirementsFrom Everand3D Printed Tooling, Jigs and Fixtures Standard RequirementsNo ratings yet

- SolidWorks 2015 Learn by doing-Part 2 (Surface Design, Mold Tools, and Weldments)From EverandSolidWorks 2015 Learn by doing-Part 2 (Surface Design, Mold Tools, and Weldments)Rating: 4.5 out of 5 stars4.5/5 (5)

- Rubber Belt ConveyorDocument4 pagesRubber Belt ConveyorMohamed ShehataNo ratings yet

- 01 40 eFJ 1 2020 v6 WEBFINAL PDFDocument40 pages01 40 eFJ 1 2020 v6 WEBFINAL PDFSoma Varga100% (1)

- CBTA PLAN AviationDocument11 pagesCBTA PLAN AviationRashdan AhmadNo ratings yet

- Configure and Verify A Site-To-Site IPsec VPN Using CLIDocument6 pagesConfigure and Verify A Site-To-Site IPsec VPN Using CLIMilošKovačevićNo ratings yet

- BS en Iso 01514-2016Document22 pagesBS en Iso 01514-2016Krishna Vacha50% (2)

- Centrifugal Pump TheoryDocument5 pagesCentrifugal Pump TheoryFungsam LimNo ratings yet

- CNCinst SherlineDocument72 pagesCNCinst SherlineDejan StalovicNo ratings yet

- Setting Up Blueprints in Dassault SolidworksDocument10 pagesSetting Up Blueprints in Dassault SolidworksrasgeetsinghNo ratings yet

- Carbine Receiver ExtensionsDocument2 pagesCarbine Receiver Extensionsjordanbowles2579No ratings yet

- Australian: Drill Bit Speed ChartDocument1 pageAustralian: Drill Bit Speed ChartDavid TuaineNo ratings yet

- Sheet Metal Bending PlansDocument17 pagesSheet Metal Bending Plansสกล ธีระกานตภิรัตน์100% (1)

- 2012 Logosol CatalogDocument60 pages2012 Logosol Catalogbogdanb1No ratings yet

- CNC Plan FinalDocument5 pagesCNC Plan FinalAlex HC100% (2)

- SmithFlyerBlueprints PDFDocument12 pagesSmithFlyerBlueprints PDFMark HogebackNo ratings yet

- CNC Touch Probe DrawingsDocument13 pagesCNC Touch Probe DrawingsmikcomiNo ratings yet

- F-16A Block 15 Falcon SAC - March 1984Document12 pagesF-16A Block 15 Falcon SAC - March 1984Soma VargaNo ratings yet

- Scaled and RAF Research Projects: MannedDocument48 pagesScaled and RAF Research Projects: MannedSoma VargaNo ratings yet

- Propulsive Efficiency of Boundary Layer Ingestion Propellers: November 2019Document12 pagesPropulsive Efficiency of Boundary Layer Ingestion Propellers: November 2019Soma VargaNo ratings yet

- A - Simplified - Flexible - Multibody - Dynamics - For - A - Main Landing GearDocument11 pagesA - Simplified - Flexible - Multibody - Dynamics - For - A - Main Landing GearSoma VargaNo ratings yet

- Design A Composite Materials Landing GearDocument12 pagesDesign A Composite Materials Landing GearSoma VargaNo ratings yet

- SC Vtol 01Document31 pagesSC Vtol 01Soma VargaNo ratings yet

- NASA Weight EstimationDocument91 pagesNASA Weight EstimationSoma VargaNo ratings yet

- Week 8 - Elon Musk Compares Building Artificial Intelligence To SummDocument9 pagesWeek 8 - Elon Musk Compares Building Artificial Intelligence To Summapi-241908362No ratings yet

- Sim300d Atc V2.00Document214 pagesSim300d Atc V2.00Marcos SantosNo ratings yet

- Section 4 - Sediment Transport - Final ReportDocument13 pagesSection 4 - Sediment Transport - Final ReportNazakat HussainNo ratings yet

- Customs Clearance Process For Import of Capital MachineryDocument43 pagesCustoms Clearance Process For Import of Capital Machinery2rmjNo ratings yet

- Jyoti Resin 1520F and Hardener 1758 - E Potting CompoundDocument5 pagesJyoti Resin 1520F and Hardener 1758 - E Potting CompoundBabyboy2010No ratings yet

- KrishDocument15 pagesKrishRamliana ThNo ratings yet

- How To Skip Files in Netbackup - Error 41Document5 pagesHow To Skip Files in Netbackup - Error 41amsreekuNo ratings yet

- Idirect HandbookDocument1 pageIdirect HandbookRudy's ChannelNo ratings yet

- Doppler EffectDocument47 pagesDoppler EffectLouies UngriaNo ratings yet

- AITS 2016 FT I JEEM JEEA/Advanced/PAPER-2/Questions/PAPER PDFDocument23 pagesAITS 2016 FT I JEEM JEEA/Advanced/PAPER-2/Questions/PAPER PDFAparNo ratings yet

- Direct Memory Access and DMA-controlled I/ODocument3 pagesDirect Memory Access and DMA-controlled I/ODeepak SinghNo ratings yet

- Kurukshetra University Bca Syllabus 3 SemDocument7 pagesKurukshetra University Bca Syllabus 3 SemAshutosh Sharma0% (1)

- E113Document11 pagesE113Anonymous dH1y9nyNjcNo ratings yet

- Emu8086 TutorialDocument19 pagesEmu8086 TutorialhlvhungNo ratings yet

- Exp 4equilibriumDocument4 pagesExp 4equilibriumSamantha IgoNo ratings yet

- Mca 101Document39 pagesMca 101Ankit GuptaNo ratings yet

- Rakesh Sharma Chandrayaan Satellite Information and Pic 1 Page EachDocument2 pagesRakesh Sharma Chandrayaan Satellite Information and Pic 1 Page EachJasvinder SinghNo ratings yet

- The Hidden Symmetry of The Coulomb Problem in Relativistic Quantum Mechanics - From Pauli To Dirac (2006)Document5 pagesThe Hidden Symmetry of The Coulomb Problem in Relativistic Quantum Mechanics - From Pauli To Dirac (2006)Rivera ValdezNo ratings yet

- Mechanical and Electrical System (BFC 32602) Sem I 2020/2021 Assignment: Answer All QuestionsDocument3 pagesMechanical and Electrical System (BFC 32602) Sem I 2020/2021 Assignment: Answer All Questionscxyung98No ratings yet

- Byk P9920Document2 pagesByk P9920Eugene PaiNo ratings yet

- Boite Satronic Page307 309Document3 pagesBoite Satronic Page307 309rhuircanNo ratings yet

- SALT Bath HardeningDocument1 pageSALT Bath HardeningmaheshNo ratings yet