Professional Documents

Culture Documents

Build Your Own CNC Milling Machine PDF

Uploaded by

andres silvestreOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Build Your Own CNC Milling Machine PDF

Uploaded by

andres silvestreCopyright:

Available Formats

instructables

Build Your Own CNC Milling Machine

by BonJiba

Now that I'm retired, I have time to create things that interest and passion to do so, as so many have done

I've always wanted to, like this CNC milling machine. I for me.

did a lot of research here on Instructables, which

provided me a lot of ideas of how I wanted mine to Again, I'm no expert, just a hobbyist as many of you

look and work. I have no experience in this area, so the are and have a lot to learn yet. The choices I made

project itself was fun and enjoyable to see if I could here may not be right for everyone, but worked for

actually do it! My goal was to make one that was me.

accurate, reliable, with a reasonable work area and

cheap as possible. Accurate, yes, it can retrace the Supplies:

same path over and over, consistently. Reliable, not

1/2" MDF

sure yet as I have only been using it for a month or so.

Work area 32.5" by 18.5". Cheap, perhaps, all in at $400

Supported Rails and Ball Screws

excluding laptop which I already had.

Arduino UNO, GRBL Shield

By the way I already have an ANET A6 3D printer

which I love. So I gured how hard can this be, LOL!

NEMA 17 Steppers

My main goal for submitting this instructable is not to

Dewalt 660 cutout tool

provide every single step (that's too complicated for

me), but to help inspire those out there with the

Build Your Own CNC Milling Machine: Page 1

Step 1: Tools

I decided to make mine out of 1/2" MDF since its little pieces like brackets, etc. Many of those could be

cheaper than extruded aluminum. Thus, I only needed made out of wood or metal brackets from the

conventional wood working tools. I used a table saw, hardware store.

miter saw, drill and bits and a drill block for

perpendicular holes, since I don't have a drill press. A soldering iron to solder all the wire.

3D Printer is optional; I designed and printed many

Build Your Own CNC Milling Machine: Page 2

Build Your Own CNC Milling Machine: Page 3

Step 2: The Mechanical Build

Because this is my own design I had no plans to follow the 2D drawing on a standard computer printer in

nor did I create any. The rails dictated what the size of actual size. I would then use a center punch to mark

the unit would be. The Y rails are 1000mm, X rails are the center of each hole and then use a hand drill to

600mm and the Z rails are 300mm. drill them out as seen in the 3rd and fourth picture

above.

I started with the base and built a torsion style box

which makes it very rigid and strong. I would cut a After it was all together, I took it all apart and put a

piece of 1/2" MDF and keep adding to the puzzle. couple coats of polyurethane on it, those are the

There are ribs or reinforcements anywhere its needed pieces in the seventh picture.

to keep the MDF from exing. There is no ex in the

entire machine An im po rt a nt no t e : I took a considerable amount

of time making sure everything was perfectly aligned

The base was easy...now to all the other tidbits... and square to each other, especially the rails. This way

there was absolutely no binding and everything

To get 25 holes drilled with some sort of accuracy I moved very smoothly.

would draw the board layout in Fusion 360 and print

Build Your Own CNC Milling Machine: Page 4

Build Your Own CNC Milling Machine: Page 5

Step 3: Electrical

Since the gantry, etc. slid with such ease I decided to prevent false triggers on the limit switches and Z-

try NEMA 17 motors (only 92 oz. holding torque). With probe as seen in the second picture. So all that, plus

those motors I can move any axis at 3200mm/min or an emergency switch and fan was packed into that

125 inches per minute and cut at 1600mm/min little box.

without the motors missing a step. I haven't tried to

cut any faster as that seems fast enough for me. I ran all the wires in cable drag chains, motor and limit

switches together thus the need for the opticoupler

I used an Arduino UNO, running GRBL and a CNC isolation.

GRBL Shield with 8825 drivers. I had no experience

with an Arduino (again, I'm old, LOL), but there are I used a 20V - 7A laptop type power supply for all the

may instructables here that will teach you! motors, etc. The actual draw is only about 2 Amps.

I did however design a board with 4 opticouplers to I used a Dewalt 660 cutout tool since its half the price

of a trim router, has the same capabilities and comes I made a slide out drawer and mounted a docking

with both 1/8" and 1/4" collets. I removed the nose station for the laptop. I use a wireless keyboard with

cone and designed and 3D printed the mount for the built track pad as a remote pendant.

tool.

Build Your Own CNC Milling Machine: Page 6

Build Your Own CNC Milling Machine: Page 7

Step 4: Software

I use Fusion 360 to design my models and use their Of course the CNC is out in the garage, so instead of

built-in CAM to set up the tool paths. I run CNCjs on waiting out there, I use remote desktop software to

the laptop which sends the g-code to the Arduino. see the desktop of the laptop from inside my house

CNCjs can use a USB connected camera to display the on my desktop PC. I can then see how much time is

picture right in its user interface. Again, I'm no expert left and see it actually milling too.

as these are the only programs I have ever used. They

seem to meet my needs.

Build Your Own CNC Milling Machine: Page 8

Step 5: Finishing Touches

I then realized I had no place to put the CNC machine a hinged cover that tilts back. Its much quieter and

and it weighs in at 120 pounds, so I had to build a there is no more dust outside of the box! Inside its a

rolling base. Then after working with it brie y, I mess, LOL. I also milled the removable fence, cam

realized it made way too much dust and noise. I clamps and hold-down clamps on this machine.

gured I could address both of those with a cover. I

bought art foam board at the dollar store and created

Build Your Own CNC Milling Machine: Page 9

Build Your Own CNC Milling Machine: Page 10

Step 6: Conclusion

I thought I would have to redesign and rebuild this Again, its almost impossible to provide every detail

several times to get it right, but luckily I haven't. It and plans since so many of the items depend on each

works just ne for me. I still have a lot to learn about other as you build it. But please let it be known that it

modeling, bits and tool paths. But in the mean time I can be done as so many others have made similar

have designed and created these projects. The rst ones.

two pictures are a laptop stand and the rest are some

plaques. The video is this machine milling some HDPE. Thanks for viewing and if I can answer any questions

I milled these ags and have it published in another please ask.

Instructables - Click Here

Build Your Own CNC Milling Machine: Page 11

https://youtu.be/LwBuTgBlDNs

This is fantastic! I am a highschool student (definitely not retired), but I may try to make a similar

machine. I wish I had the templates for all your parts, but going off the pictures, I hope I can get

similar results.

Great job with this!!!

Thanks, I wish I had templates too, LOL. Basically everything was designed in my head around

some components I had. So every part is customized to every other part. So, If anything in that

chain of parts changes it affects everything down the path. So I was very patient and progressed

forward slowly making sure it fit my overall plan. But feel free to hit me up with any questions in

your process. Thanks and good luck!

Love this project and have similar background but in digital areas of electronics. I have all the

electronics and steppers ready and like your base frame design. I used Arduino Mega and Marlin

software with Nema 23 steppers. Although I have a frame to use I think your sliding gantry is a

better design. Great project thanks, and keep up the good work!!

Sorry I posted my question on the wrong section. It’s a very neat project. Very inspirational .

Keep up the good work /G\

Build Your Own CNC Milling Machine: Page 12

One suggestion: print a vacuum shoe for the router, and connect your shop vac while milling, that

will greatly improve the dust collection Here's a bunch: https://www.thingiverse.com/tag:dust_shoe

Thanks...that will be next then!

GREAT JOB!....

Thanks...

Tanks for a really nice tutorial. I can't wait to get retired some day (most likely not until 30+ years:).

Can I ask what the total budget for the project was? Regards

My budget and what I spent were not quite the same, LOL. I was hoping to do it for about $300, but

I spent $400 dollars to make the CNC, including the router, electrical and all hardware, everything,

except the rolling cart and enclosure which was probably only another $40. Thanks

How do you keep it from drilling into the bed?

I have a replaceable spoil board on top of the platform. The spoil board has T-nuts inserted from

the bottom side that I can use with either the cam clamps or hold downs. The only time it can cut

down into the bed (spoil board), is If I'm cutting down through the stock. To get my spoil board to

last longer I usually use something very thin under the stock and I only cut down below the stock

about 0.2mm. I hope that answered you question

I absolutely LOVE this! Great job! I've been wanting to build one.

Thanks...

Thanks!

Really like the look of this! I'm also researching to make my own, once I get "the workshop"

finished.

Build Your Own CNC Milling Machine: Page 13

You might also like

- 3D Printed Tooling, Jigs and Fixtures Standard RequirementsFrom Everand3D Printed Tooling, Jigs and Fixtures Standard RequirementsNo ratings yet

- DIY CNC Router Plans HobbyCNCDocument73 pagesDIY CNC Router Plans HobbyCNCAnonymous QJ5j94luLm92% (12)

- DIY CNC Router Plans HobbyCNC PDFDocument73 pagesDIY CNC Router Plans HobbyCNC PDFAnonymous eoV4CVyW100% (1)

- Functional Composite Materials: Manufacturing Technology and Experimental ApplicationFrom EverandFunctional Composite Materials: Manufacturing Technology and Experimental ApplicationNo ratings yet

- Diy CNCDocument46 pagesDiy CNCSyamali SeeramNo ratings yet

- Medium Sized DIY CNC 20 X 30 Work AreaDocument21 pagesMedium Sized DIY CNC 20 X 30 Work AreaPatrick SawianNo ratings yet

- Building A CNC RouterDocument54 pagesBuilding A CNC RouterAntónio França100% (2)

- Building Your Own CNC Milling MachineDocument19 pagesBuilding Your Own CNC Milling MachineMarius DanilaNo ratings yet

- CNC Plasma TableDocument37 pagesCNC Plasma Tablenjsoffice100% (1)

- CNC Plasma Cutter Plans for a 4' x 4' TableDocument76 pagesCNC Plasma Cutter Plans for a 4' x 4' Tableuguraydemir100% (3)

- CNC DiyDocument15 pagesCNC DiyNimmala Ganesh0% (1)

- Without Detail Drawings: DIY CNC Router PlansDocument47 pagesWithout Detail Drawings: DIY CNC Router PlansLiteBox VentasNo ratings yet

- Building A CNC RouterDocument37 pagesBuilding A CNC RouterDavid Morris60% (5)

- Easy To Build CNC Mill Stepper Motor and Driver CircuitsDocument11 pagesEasy To Build CNC Mill Stepper Motor and Driver CircuitsAhida Butik100% (1)

- Make A CNC Hot Wire Foam Cutter - CNCDocument17 pagesMake A CNC Hot Wire Foam Cutter - CNCKem SorrellNo ratings yet

- CNC Machine DIY InstructionDocument65 pagesCNC Machine DIY Instructioncxin168100% (3)

- Building Your Own CNC Milling MachineDocument17 pagesBuilding Your Own CNC Milling MachineAlan AguilarNo ratings yet

- DIY CNC RouterDocument67 pagesDIY CNC RouterKaled Rojas SantanaNo ratings yet

- Build an Aluminum CNC Router in 4 StepsDocument7 pagesBuild an Aluminum CNC Router in 4 StepsMarius DanilaNo ratings yet

- Ultimate Guide to CNC RoutersDocument27 pagesUltimate Guide to CNC RoutersLeopoldoSantos100% (1)

- HTTP WWW - Cncroutersource.com Homemade-Cnc-RouterDocument53 pagesHTTP WWW - Cncroutersource.com Homemade-Cnc-Routerpremako100% (5)

- CNC PlanDocument1 pageCNC PlanKevin Blaner100% (1)

- E-Book - Cutting Tools For CNC RouterDocument11 pagesE-Book - Cutting Tools For CNC RouterVictor ParvanNo ratings yet

- Mini Bike LightDocument2 pagesMini Bike LightperacNo ratings yet

- Cnc-Build 2x4 CNC Plasma Free PlansDocument6 pagesCnc-Build 2x4 CNC Plasma Free PlansAxels_Man_Cave73% (11)

- Building Your Own CNC Router/milling Machine: InstructablesDocument16 pagesBuilding Your Own CNC Router/milling Machine: InstructablesSoma VargaNo ratings yet

- DIY CNC Router Build Fixed Gantry, Steel - Wade'O DesignDocument11 pagesDIY CNC Router Build Fixed Gantry, Steel - Wade'O DesignRed ErickNo ratings yet

- Very Interestin Table Saw PlansDocument4 pagesVery Interestin Table Saw PlansSonia CireaşăNo ratings yet

- Precision Plasma GantryDocument15 pagesPrecision Plasma GantryRay ZerNo ratings yet

- CNC Router ProjectDocument32 pagesCNC Router ProjectanouarNo ratings yet

- How To Build A CNC Milling MachineDocument12 pagesHow To Build A CNC Milling MachineScott Campbell100% (3)

- How-To - Build Your Own CNC Machine (Part 2) PDFDocument9 pagesHow-To - Build Your Own CNC Machine (Part 2) PDFCicero Milan100% (1)

- Sheet Metal Bending PlansDocument17 pagesSheet Metal Bending Plansสกล ธีระกานตภิรัตน์100% (1)

- Home Built CNCDocument110 pagesHome Built CNCBobby Chipping100% (4)

- DIY Guide Rails Plans VSC ToolsDocument22 pagesDIY Guide Rails Plans VSC ToolsMiguel TravahoNo ratings yet

- Build Your Own LatheDocument3 pagesBuild Your Own LatheNICOLASNo ratings yet

- Mini Mill Assembly Drawings-2009Document5 pagesMini Mill Assembly Drawings-2009ModularCNCNo ratings yet

- Low Cost DIY CNC RouterDocument18 pagesLow Cost DIY CNC Routerjlpicard100% (1)

- 93 Best Measuring ToolsDocument96 pages93 Best Measuring ToolsKeone SemanaNo ratings yet

- Modular CNC Mini Mill Assy-01Document1 pageModular CNC Mini Mill Assy-01ModularCNC100% (1)

- Raspberry Pi Mini Laser EngraverDocument30 pagesRaspberry Pi Mini Laser Engraverazir86No ratings yet

- How-To - Build Your Own Spot Welder - HackadayDocument17 pagesHow-To - Build Your Own Spot Welder - HackadayAndrew McLarenNo ratings yet

- CNC Plasma Torch ConstructionDocument2 pagesCNC Plasma Torch ConstructionMariane MottaNo ratings yet

- Mig Welding MasteryDocument32 pagesMig Welding MasteryRevankar B R ShetNo ratings yet

- Workshop Practice Series 35 - Milling A Complete CourseDocument71 pagesWorkshop Practice Series 35 - Milling A Complete CourseGOUTHAM RATHINAM100% (2)

- Lyman Mulier Filament Extruder v5 Manual r1Document64 pagesLyman Mulier Filament Extruder v5 Manual r1Pablo Valero Martínez100% (4)

- Build Your Own LatheDocument4 pagesBuild Your Own LatheThanadol Wilachan0% (1)

- Modular CNC Nema-23 For Acme Lead ScrewDocument1 pageModular CNC Nema-23 For Acme Lead ScrewModularCNCNo ratings yet

- Mill Keyways On LatheDocument1 pageMill Keyways On LatheJim100% (3)

- Basic TechDraw Tutorial FreeCADDocument7 pagesBasic TechDraw Tutorial FreeCADJorge Alberto Zorro Sanchez100% (1)

- ModularCNC 72x14x4 Large RouterDocument3 pagesModularCNC 72x14x4 Large RouterModularCNC100% (1)

- 3 in 1 MachineDocument5 pages3 in 1 Machinemarandan85100% (1)

- Go-Kart ProjetoDocument11 pagesGo-Kart Projetojulius1No ratings yet

- How To Build A MultimachineDocument80 pagesHow To Build A MultimachineTerrence LopezNo ratings yet

- Workshop Practice Series 02 Vertical Milling in The Home WorkshopDocument49 pagesWorkshop Practice Series 02 Vertical Milling in The Home WorkshopParaschiv DariusNo ratings yet

- Low Budget CNC: InstructablesDocument10 pagesLow Budget CNC: InstructablesXavier TorrasNo ratings yet

- Arduino Powered CNC Router: Step 1: Building The FrameDocument12 pagesArduino Powered CNC Router: Step 1: Building The Framemuhamad_377293548No ratings yet

- Modular DIY CNC V2Document45 pagesModular DIY CNC V2Arif RahmanNo ratings yet

- DIY Arduino Drawing MachineDocument19 pagesDIY Arduino Drawing MachineBeto53No ratings yet

- 3D Engine ModelingDocument16 pages3D Engine Modelingandres silvestreNo ratings yet

- Eaglet KK 24inDocument7 pagesEaglet KK 24inAnonymous J1sELDp7No ratings yet

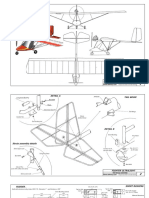

- Ultimate 3D Park Flyer Assembly GuideDocument20 pagesUltimate 3D Park Flyer Assembly GuideDario DominguezNo ratings yet

- Postal Contest Rules PDFDocument5 pagesPostal Contest Rules PDFandres silvestreNo ratings yet

- Cabinete 2Document4 pagesCabinete 2andres silvestreNo ratings yet

- 445 035149 1939 WakefieldDocument2 pages445 035149 1939 Wakefieldandres silvestreNo ratings yet

- Bob Angel Spark Ignition Trouble ShootingDocument3 pagesBob Angel Spark Ignition Trouble Shootingandres silvestreNo ratings yet

- f44572536 Sheet1Document25 pagesf44572536 Sheet1andres silvestreNo ratings yet

- JayBurkart Speed 400 Motor Replacement 26jul2022-1Document2 pagesJayBurkart Speed 400 Motor Replacement 26jul2022-1andres silvestreNo ratings yet

- Acro Four Star 60 ManualDocument26 pagesAcro Four Star 60 Manualandres silvestreNo ratings yet

- Rainbow 30 Article-1Document2 pagesRainbow 30 Article-1andres silvestreNo ratings yet

- Marvv Stern Mark IIIDocument1 pageMarvv Stern Mark IIIandres silvestreNo ratings yet

- Tandy Walker Laser Cut GasketsDocument4 pagesTandy Walker Laser Cut Gasketsandres silvestreNo ratings yet

- Model airplane fuse and wing construction materialsDocument63 pagesModel airplane fuse and wing construction materialsandres silvestreNo ratings yet

- Avion Katana Full Plano PDFDocument1 pageAvion Katana Full Plano PDFKEVIN FAJARDO100% (1)

- Wee - Bee Air World 02 48 - Oz5788 - VectorDocument1 pageWee - Bee Air World 02 48 - Oz5788 - Vectorandres silvestreNo ratings yet

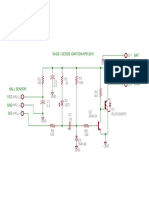

- SAGE / GEDDE IGNITION CIRCUIT DIAGRAMDocument1 pageSAGE / GEDDE IGNITION CIRCUIT DIAGRAMandres silvestreNo ratings yet

- Caja de Vuelo GoldbergDocument15 pagesCaja de Vuelo Goldbergandres silvestreNo ratings yet

- Puma IIIDocument3 pagesPuma IIIandres silvestreNo ratings yet

- Is Now Part ofDocument11 pagesIs Now Part ofandres silvestreNo ratings yet

- Fighter Ultralight: Osvaldo DuranaDocument24 pagesFighter Ultralight: Osvaldo Duranaandres silvestreNo ratings yet

- Fieseler FL156 StorchDocument1 pageFieseler FL156 Storchandres silvestreNo ratings yet

- PT 40 PlanDocument1 pagePT 40 Planandres silvestreNo ratings yet

- PT 19 Builders Guide PDFDocument20 pagesPT 19 Builders Guide PDFandres silvestreNo ratings yet

- Castaibert IV 1Document1 pageCastaibert IV 1andres silvestreNo ratings yet

- Sky Chief RC Oz8676Document1 pageSky Chief RC Oz8676andres silvestreNo ratings yet

- Two Stroke Tuning GuideDocument171 pagesTwo Stroke Tuning Guideavista123100% (1)

- Pilot QB 40S.Document3 pagesPilot QB 40S.andres silvestreNo ratings yet

- Strikemaster ArticleDocument4 pagesStrikemaster Articleandres silvestreNo ratings yet

- Cap 232 TiledDocument25 pagesCap 232 Tiledandres silvestreNo ratings yet

- Crane, Hoist and Lift Inspection ChecklistDocument1 pageCrane, Hoist and Lift Inspection ChecklistpakistaniNo ratings yet

- National High School's 4th Periodical Test in TLE 8Document3 pagesNational High School's 4th Periodical Test in TLE 8Vivian Salahid100% (1)

- Manual VX 500Document16 pagesManual VX 500Felipe oliveira guimarãesNo ratings yet

- AHU CHW Coil ConnectionDocument1 pageAHU CHW Coil ConnectionMULTIKARTHI07100% (1)

- Meridian FundamentalsDocument44 pagesMeridian Fundamentalsapi-3754378100% (3)

- Schneider Electric List Prices Sub-Collection 4 Large Buildings June 2022 V1 enDocument355 pagesSchneider Electric List Prices Sub-Collection 4 Large Buildings June 2022 V1 enSidali Hadj BenaliNo ratings yet

- Precautions Eltek Power SystemsDocument1 pagePrecautions Eltek Power SystemsIsac ClaroNo ratings yet

- Adjustable Rigging Wires - The Easy Way: Alan YendleDocument6 pagesAdjustable Rigging Wires - The Easy Way: Alan YendleCarmelo D ZNo ratings yet

- EcoBead Data SheetDocument2 pagesEcoBead Data SheetNordson Adhesive Dispensing SystemsNo ratings yet

- 04-02 Turning and Related Operations - ProblemsDocument56 pages04-02 Turning and Related Operations - ProblemsAaqib ArshadNo ratings yet

- ByStar Fiber Datasheet Eng Original 14278Document2 pagesByStar Fiber Datasheet Eng Original 14278Trần Ngọc ThànhNo ratings yet

- 17-Bfa-266 1911 22 1911 380 SR Om WebDocument23 pages17-Bfa-266 1911 22 1911 380 SR Om Webhutz5000No ratings yet

- Turbo Super TermDocument92 pagesTurbo Super TermBostiAndreiNo ratings yet

- General Work Permit - HSE-CTN-HPP-FMT-021Document3 pagesGeneral Work Permit - HSE-CTN-HPP-FMT-021Radha BuildtechNo ratings yet

- Etr345 Junghenrich TranspalletDocument13 pagesEtr345 Junghenrich TranspalletLuis ArcudiaNo ratings yet

- Quick start guide for Live Valve suspension calibrationDocument68 pagesQuick start guide for Live Valve suspension calibrationGabriel Silviu BadarauNo ratings yet

- Basorfil E-Bfr enDocument8 pagesBasorfil E-Bfr enZagoni-Szabo Jozsef-CsabaNo ratings yet

- Ultrasonic sensor data sheet with specs for Hyde Park SC956A4C0Document3 pagesUltrasonic sensor data sheet with specs for Hyde Park SC956A4C0Ricardo PinedaNo ratings yet

- K20 Engine Control Module X1 (LGX) Document ID# 4739079Document3 pagesK20 Engine Control Module X1 (LGX) Document ID# 4739079Data TécnicaNo ratings yet

- Jenbacher M6 Maintenance Oil Filter ReplacementDocument1 pageJenbacher M6 Maintenance Oil Filter ReplacementArîfNo ratings yet

- Chapteradf 5Document27 pagesChapteradf 5yikamnn100% (5)

- Manual 50 Dghe Spec C 961-0213bDocument77 pagesManual 50 Dghe Spec C 961-0213bRolando Angeles CastroNo ratings yet

- P&H Mining Equipment Offices: Back To IndexDocument4 pagesP&H Mining Equipment Offices: Back To Indexfernando chinchazoNo ratings yet

- Landing Gear Operating and Maintenance ProceduresDocument6 pagesLanding Gear Operating and Maintenance ProceduresTerminal TruckNo ratings yet

- 24v-Catalogue ASP 24v 17 e 012019 Ansicht ReduziertDocument116 pages24v-Catalogue ASP 24v 17 e 012019 Ansicht ReduzierturlatiNo ratings yet

- Fuse TypesDocument6 pagesFuse Typesphild2na2No ratings yet

- TempoDocument4 pagesTempoAbdul Majid ShabbirNo ratings yet

- AE Solar SpécificationsDocument2 pagesAE Solar SpécificationsBoudaouara Med ChafikNo ratings yet

- Brun-Latrige Model 1900 Pocket Pistol (Video)Document4 pagesBrun-Latrige Model 1900 Pocket Pistol (Video)Roddy PfeifferNo ratings yet

- Flotec FP4105 FP410515H FP4107Document29 pagesFlotec FP4105 FP410515H FP4107Jurgen GeeregatNo ratings yet

- Certified Solidworks Professional Advanced Weldments Exam PreparationFrom EverandCertified Solidworks Professional Advanced Weldments Exam PreparationRating: 5 out of 5 stars5/5 (1)

- FreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsFrom EverandFreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsRating: 5 out of 5 stars5/5 (1)

- Certified Solidworks Professional Advanced Surface Modeling Exam PreparationFrom EverandCertified Solidworks Professional Advanced Surface Modeling Exam PreparationRating: 5 out of 5 stars5/5 (1)

- From Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsFrom EverandFrom Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsNo ratings yet

- Autodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)From EverandAutodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Rating: 5 out of 5 stars5/5 (2)

- Mastering Autodesk Inventor 2014 and Autodesk Inventor LT 2014: Autodesk Official PressFrom EverandMastering Autodesk Inventor 2014 and Autodesk Inventor LT 2014: Autodesk Official PressRating: 5 out of 5 stars5/5 (1)

- SolidWorks 2015 Learn by doing-Part 2 (Surface Design, Mold Tools, and Weldments)From EverandSolidWorks 2015 Learn by doing-Part 2 (Surface Design, Mold Tools, and Weldments)Rating: 4.5 out of 5 stars4.5/5 (5)

- Autodesk Inventor | Step by Step: CAD Design and FEM Simulation with Autodesk Inventor for BeginnersFrom EverandAutodesk Inventor | Step by Step: CAD Design and FEM Simulation with Autodesk Inventor for BeginnersNo ratings yet

- Beginning AutoCAD® 2020 Exercise WorkbookFrom EverandBeginning AutoCAD® 2020 Exercise WorkbookRating: 2.5 out of 5 stars2.5/5 (3)

- Autodesk Inventor 2020: A Power Guide for Beginners and Intermediate UsersFrom EverandAutodesk Inventor 2020: A Power Guide for Beginners and Intermediate UsersNo ratings yet

- Fusion 360 | Step by Step: CAD Design, FEM Simulation & CAM for Beginners.From EverandFusion 360 | Step by Step: CAD Design, FEM Simulation & CAM for Beginners.No ratings yet

- The Geometrical Tolerancing Desk Reference: Creating and Interpreting ISO Standard Technical DrawingsFrom EverandThe Geometrical Tolerancing Desk Reference: Creating and Interpreting ISO Standard Technical DrawingsRating: 4.5 out of 5 stars4.5/5 (10)